Study on Microstructure and Fatigue Properties of 6005 Aluminum Alloy Lap Joint

-

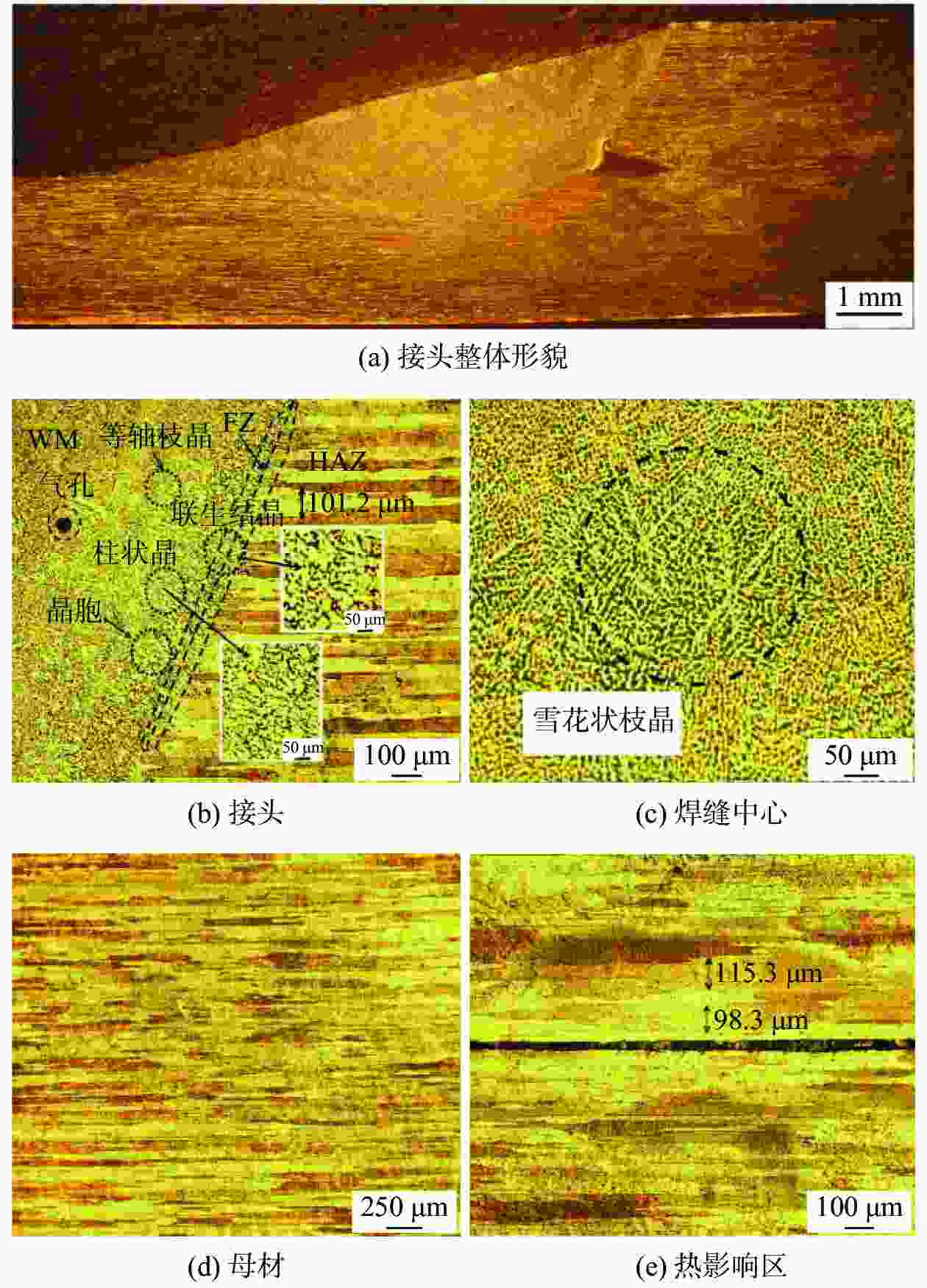

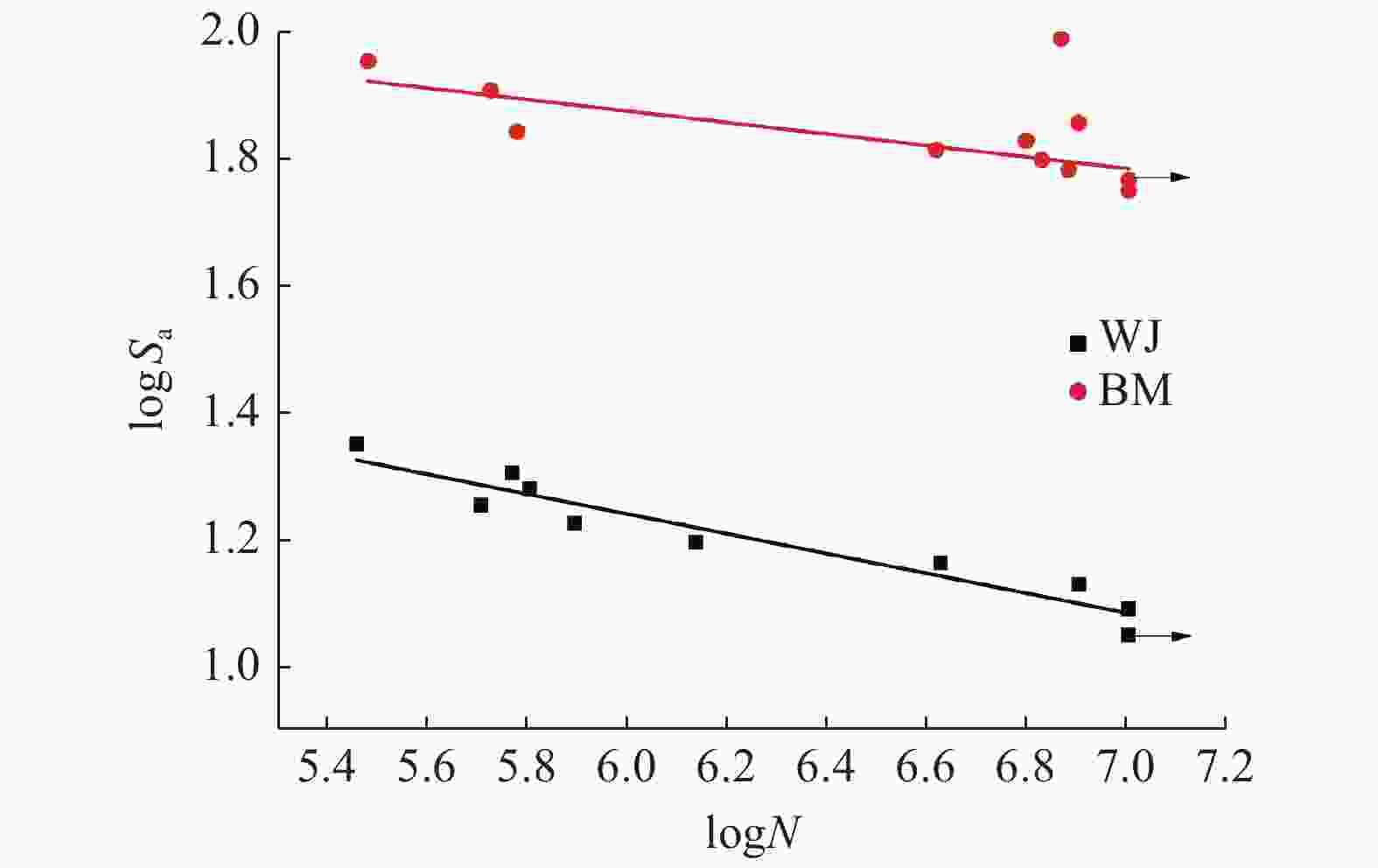

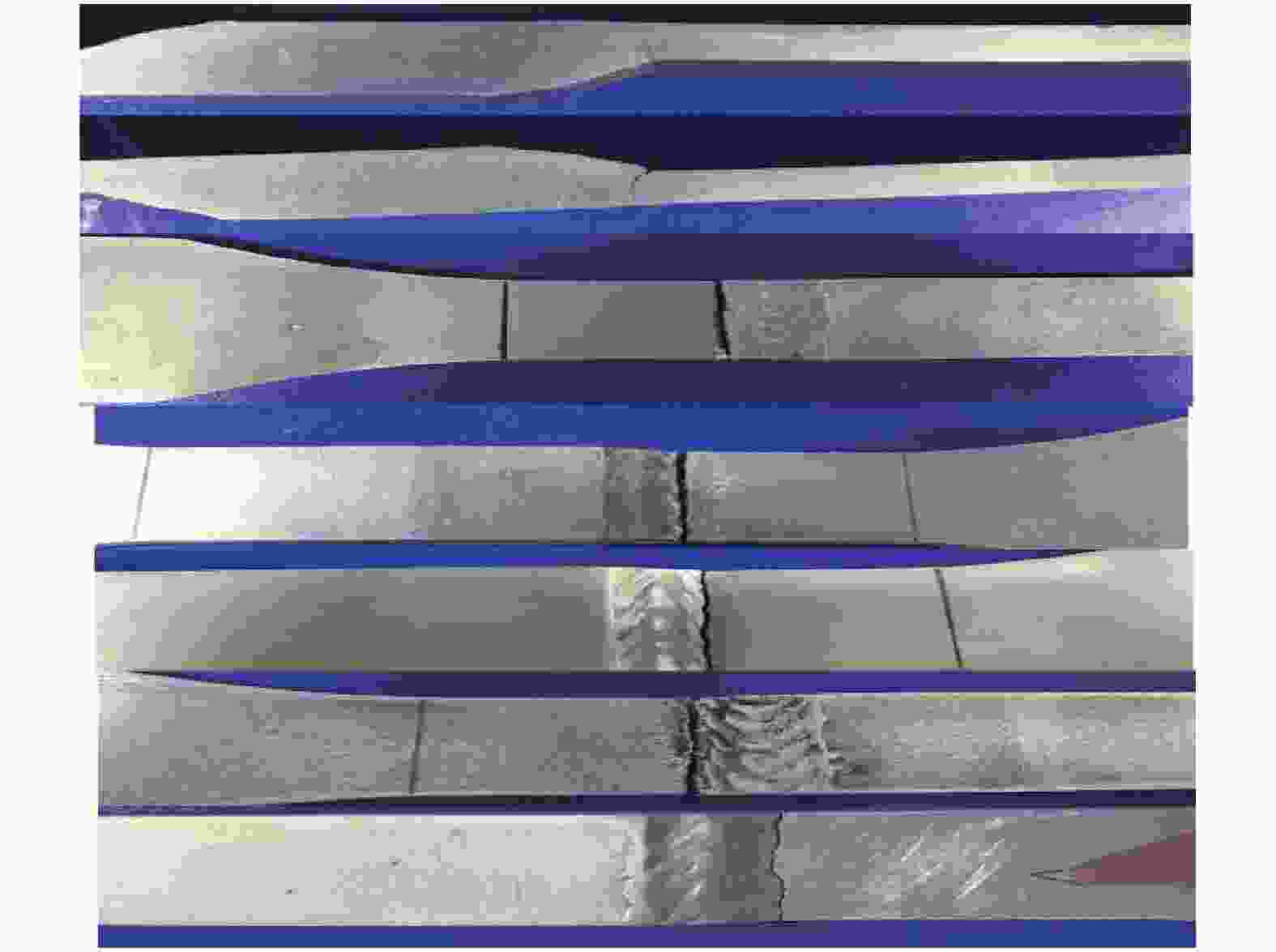

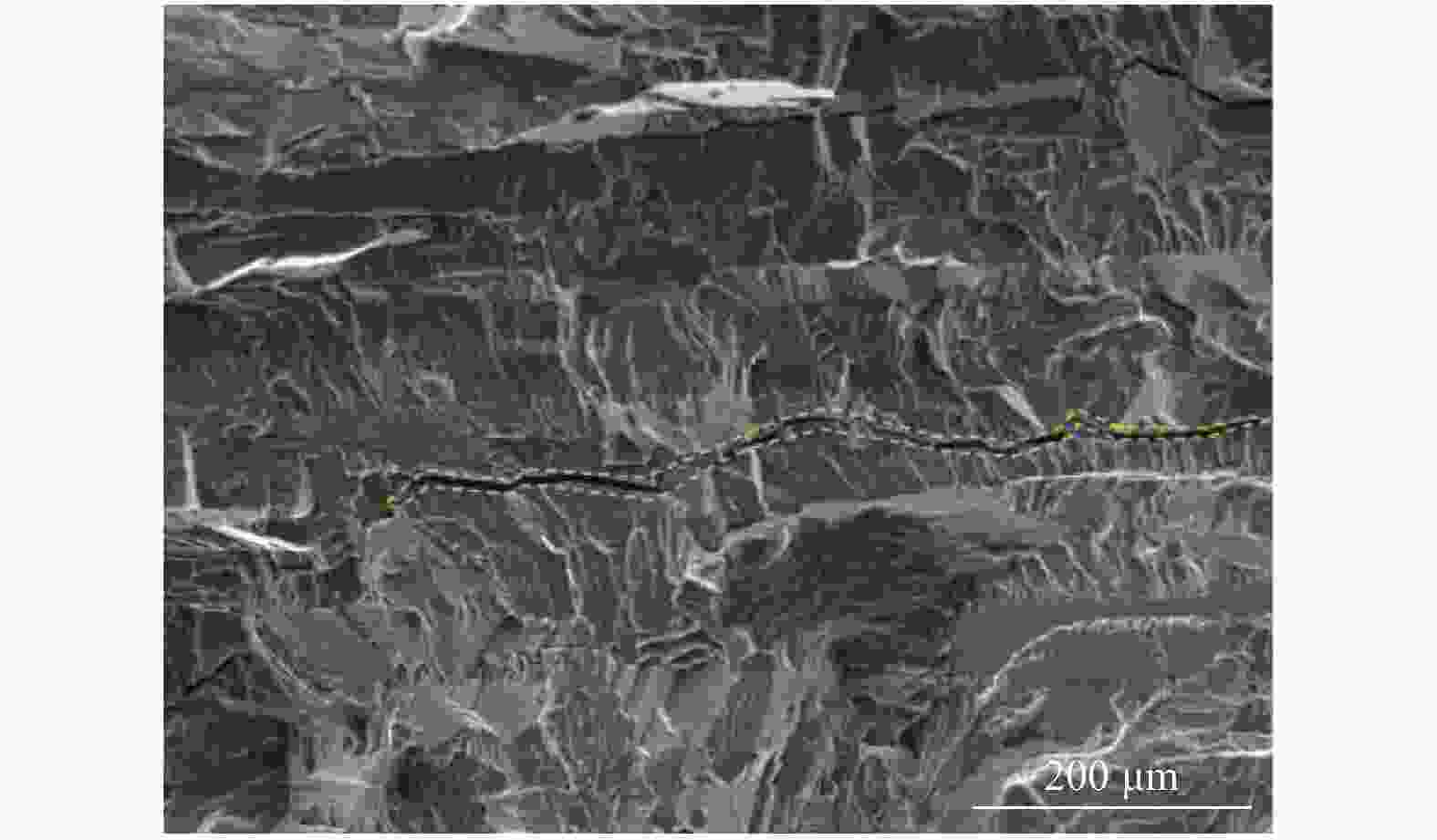

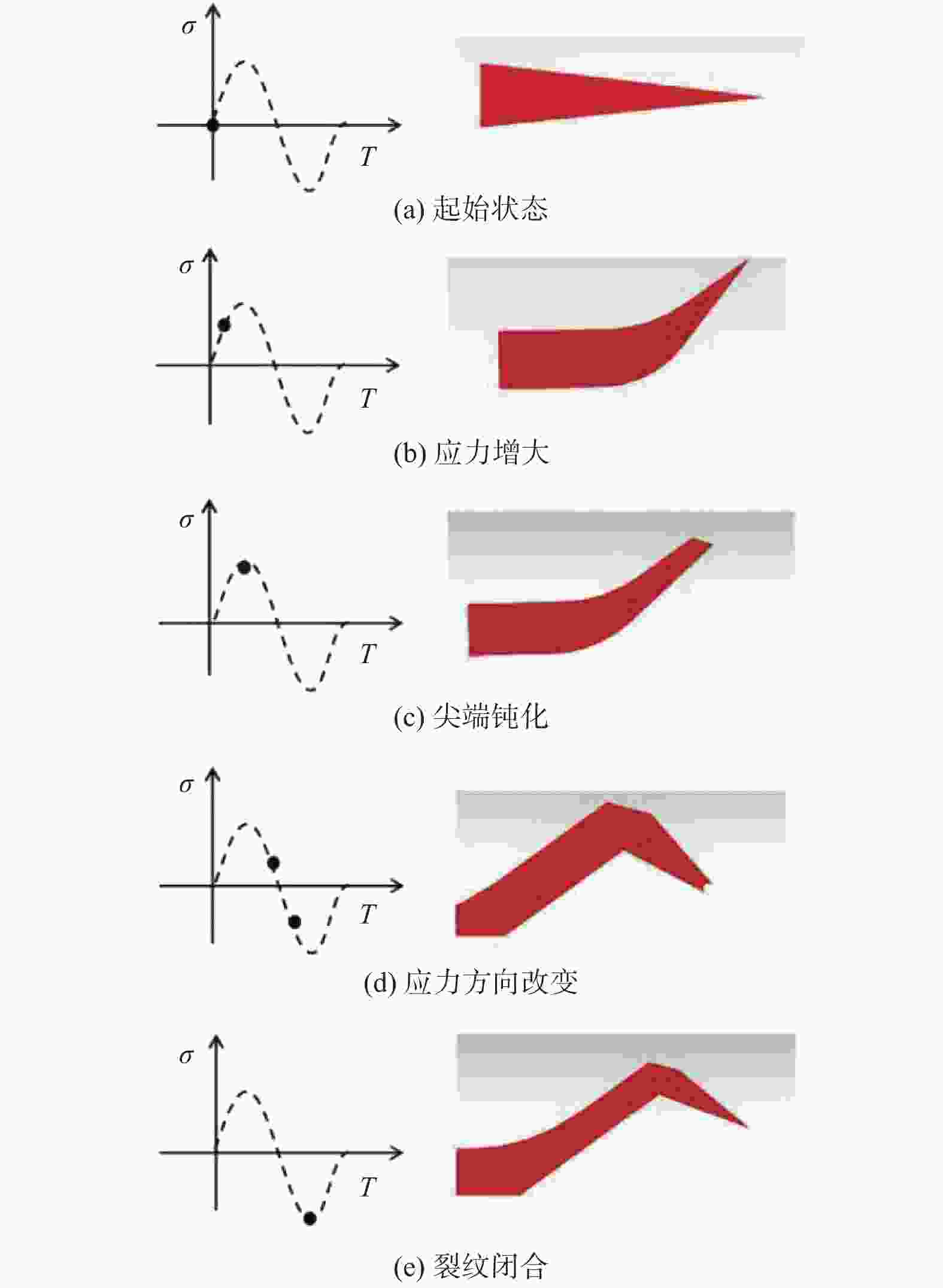

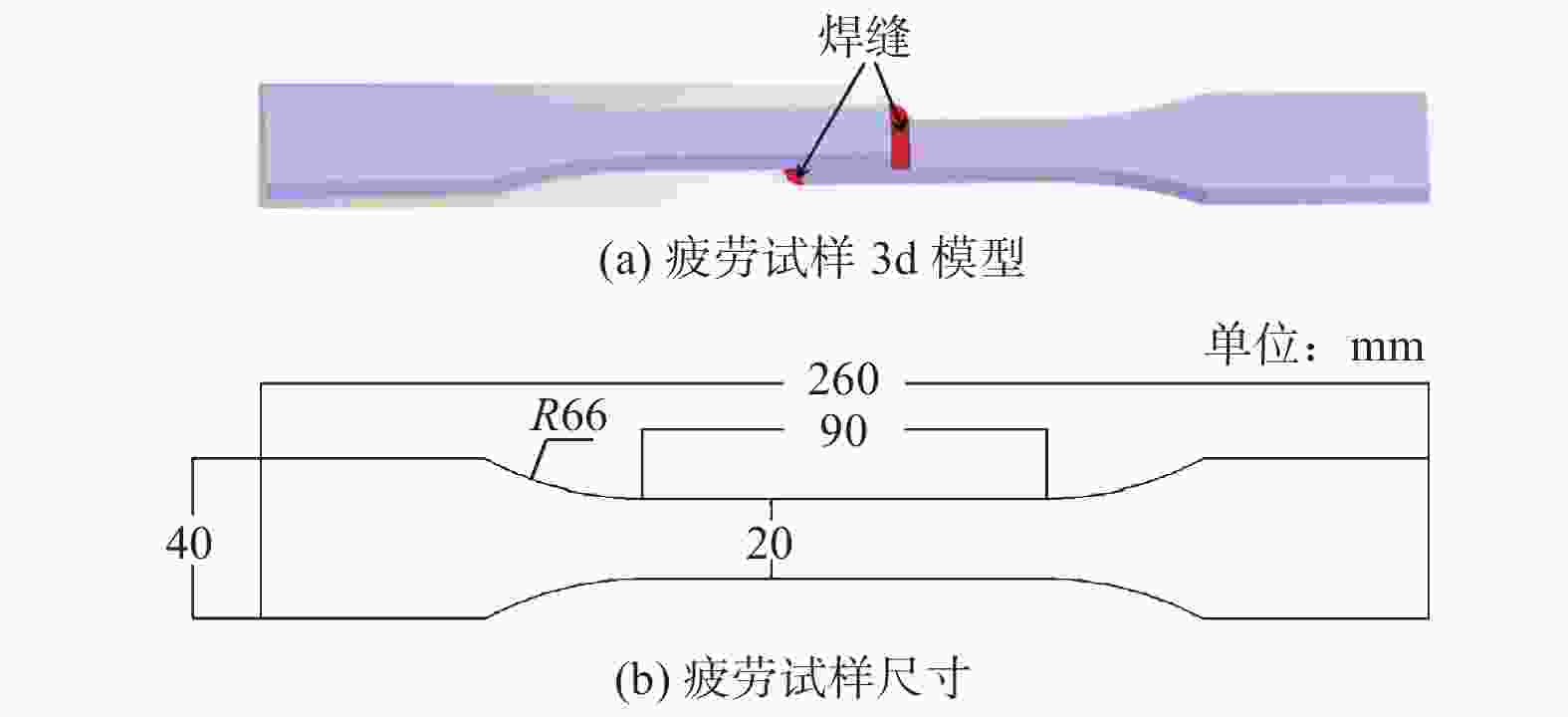

摘要: 采用熔化极惰性气体保护(MIG)焊对6005铝合金进行搭接焊接试验. 对焊接接头进行微观组织观察和显微硬度测试,结果显示,熔合区出现联生结晶特点,焊缝中心以等轴晶为主,热影响区(HAZ)晶粒发生严重粗化,焊缝区的维氏硬度(HV)为64.5,母材区为89.6,接头出现明显软化区. 在疲劳性能测试中焊接接头疲劳强度只有母材的21.41%,焊接接头疲劳断口呈韧性断裂和解理断裂的混合性断裂. 分析疲劳裂纹扩展机理得出,在裂纹尖端钝化和加载应力循环下,裂纹沿45°方向呈“Z”字型扩展.Abstract: Metal inert-gas (MIG) welding was used to conduct lap welding experiments on 6005 aluminum alloy. The microstructure and microhardness of the welded joint were observed. The results show that the intergrowth crystal appears in the fusion zone, the equiaxed crystal is dominant in the weld center, and the grain coarsening has occurred in the heat affected zone (HAZ). The Vickers hardness (HV) of the weld zone is 64.5, and that of the base metal zone is 89.6, and the joint appears obvious softening zone. The fatigue strength of the welded joint is only 21.41% of the base material in the fatigue performance test, and the fatigue fracture of the welded joint is a mixed fracture of ductile fracture and dissociative fracture. By analyzing the mechanism of fatigue crack propagation, it is concluded that the crack propagates in a “Z” shape along the 45° direction under the condition of crack tip passivation and loading stress cycle.

-

Key words:

- 6005 aluminum alloy /

- microstructure /

- fatigue properties /

- crack growth

-

表 1 6005铝合金和ER5356焊丝的化学成分

Table 1. Chemical composition of 6005 aluminum alloy and ER5356 welding wire

% 材料 Fe Cu Si Mn Mg Cr Zn Ti Al 6005 0.35 0.30 0.60 0.50 0.40 0.30 0.20 0.10 余量 ER5356 0.40 0.10 0.25 0.35 4.80 0.15 0.10 0.13 余量 表 2 焊接工艺参数

Table 2. Welding process parameters

焊接电流 / A 焊接电压 / V 焊接速度 / (mm·s−1) 气体流速 / (L·min−1) 160 21 5.0 20 -

[1] NIE J C, LI S C, ZHONG H L, et al. Microstructure and mechanical properties of laser welded 6061-T6 aluminum alloy under high strain rates[J] . Metals-Open Access Metallurgy Journal,2020,10(9):1145. [2] YANG W C, JI S X, HUANG L P, et al. Initial precipitation and hardening mechanism during non-isothermal aging in an Al–Mg–Si–Cu 6005A alloy[J] . Materials Characterization,2014,94:170 − 177. doi: 10.1016/j.matchar.2014.05.007 [3] ABDULSTAAR M A, AL-FADHALAH K J, WAGNER L. Microstructural variation through weld thickness and mechanical properties of peened friction stir welded 6061 aluminumalloy joints[J] . Materials Characterization,2017,126:64 − 73. doi: 10.1016/j.matchar.2017.02.011 [4] ZHANG L, ZHONG H L, LI S C, et al. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy[J] . International Journal of Fatigue,2020,135:105556. doi: 10.1016/j.ijfatigue.2020.105556 [5] MENG X A, YANG S L, HUANG Y B, et al. Microstructure characterization and mechanism of fatigue crack propagation of 6082 aluminum alloy joints[J] . Materials Chemistry and Physics,2021,257:123734. doi: 10.1016/j.matchemphys.2020.123734 [6] DUAN C F, YANG S L, LIU H B, et al. Formation and fatigue property of MIG welded high-speed train 6005A-T6 aluminum alloy[J] . Materials Research Express,2019,6(5):532 − 542. [7] JI S D, MENG X C, LIU J G, et al. Formation and mechanical properties of stationary shoulder friction stir welded 6005A-T6 aluminum alloy[J] . Materials and Design,2014,62:113 − 117. doi: 10.1016/j.matdes.2014.05.016 [8] XIE C J, YANG S L, LIU H B, et al. Microstructure and mechanical properties of robot cold metal transfer Al5.5Zn2.5Mg2.2Cu aluminium alloy joints[J] . Journal of Materials Processing Technology,2018,255:507 − 515. doi: 10.1016/j.jmatprotec.2017.12.045 [9] ZHAN X H, ZHANG D, WEI Y H, et al. Research on the microstructure and properties of laser-MIG hybrid welded joint of Invar alloy[J] . Optics and Laser Technology,2017,97:124 − 136. doi: 10.1016/j.optlastec.2017.06.014 [10] GU J X, YANG S L, DUAN C F, et al. Microstructure and mechanical properties of laser welded Al–Mg–Si alloy joints[J] . Materials Transactions,2019,60(2):230 − 236. doi: 10.2320/matertrans.M2018333 [11] XU X D, YANG X Q, ZHOU G, et al. Microstructures and fatigue properties of friction stir lap welds in aluminum alloy AA6061-T6[J] . Materials and Design,2012,35:175 − 183. doi: 10.1016/j.matdes.2011.09.064 [12] CHEN J Q, LI S C, CONG H L, et al. Microstructure and mechanical behavior of friction stir-welded Sc-modified Al-Zn-Mg alloys made using different base metal tempers[J] . Journal of Materials Engineering and Performance,2019,28(2):916 − 925. doi: 10.1007/s11665-019-3877-1 -

下载:

下载: