Design and analysis of electromagnetic driver control system based on micro nano positioning

-

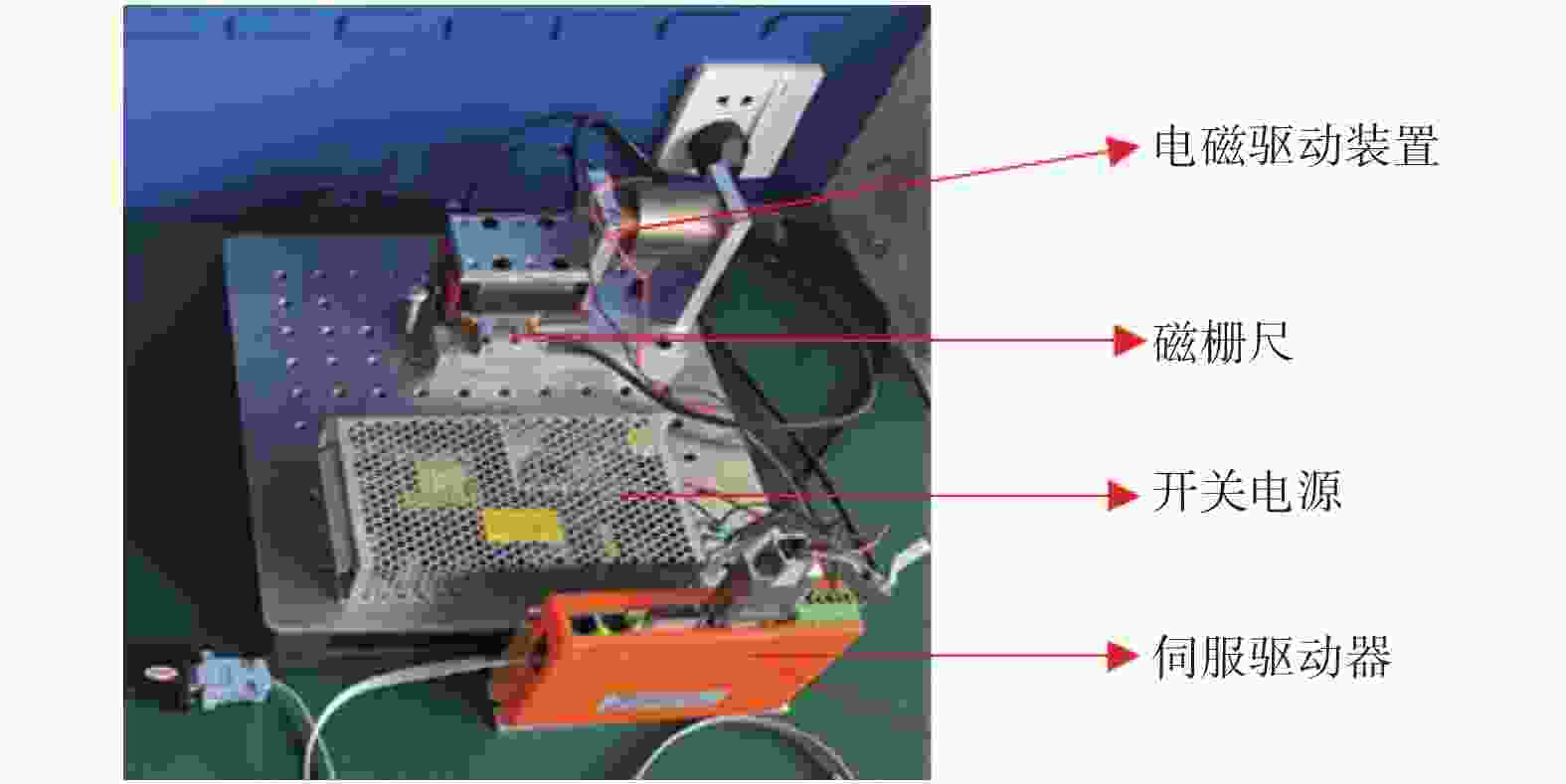

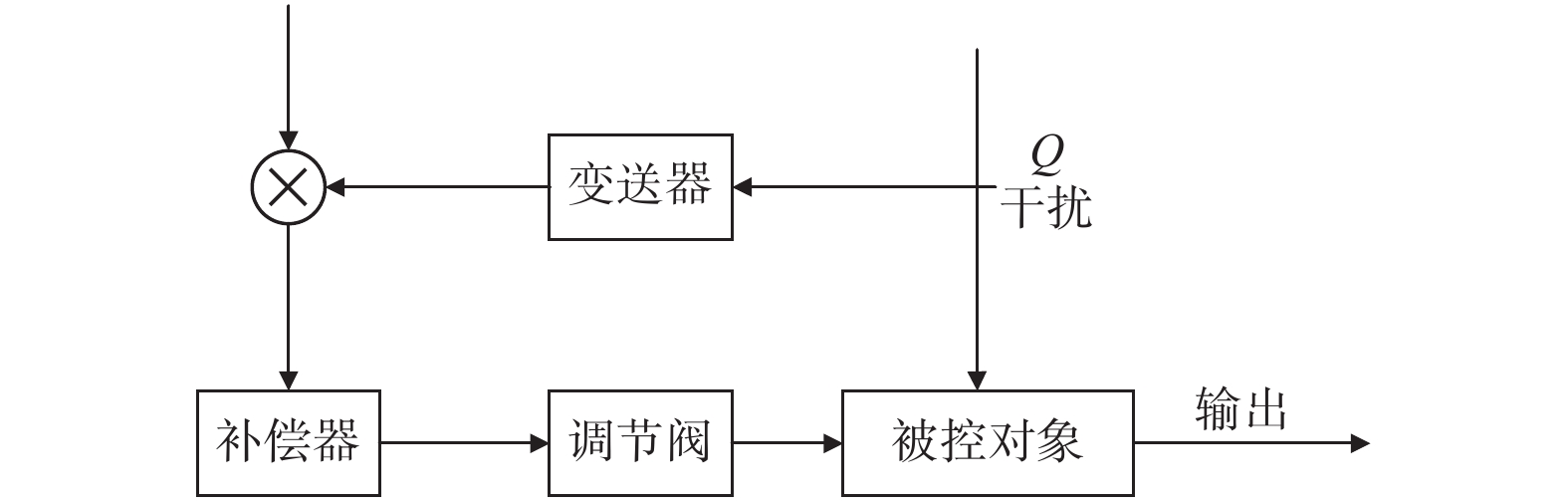

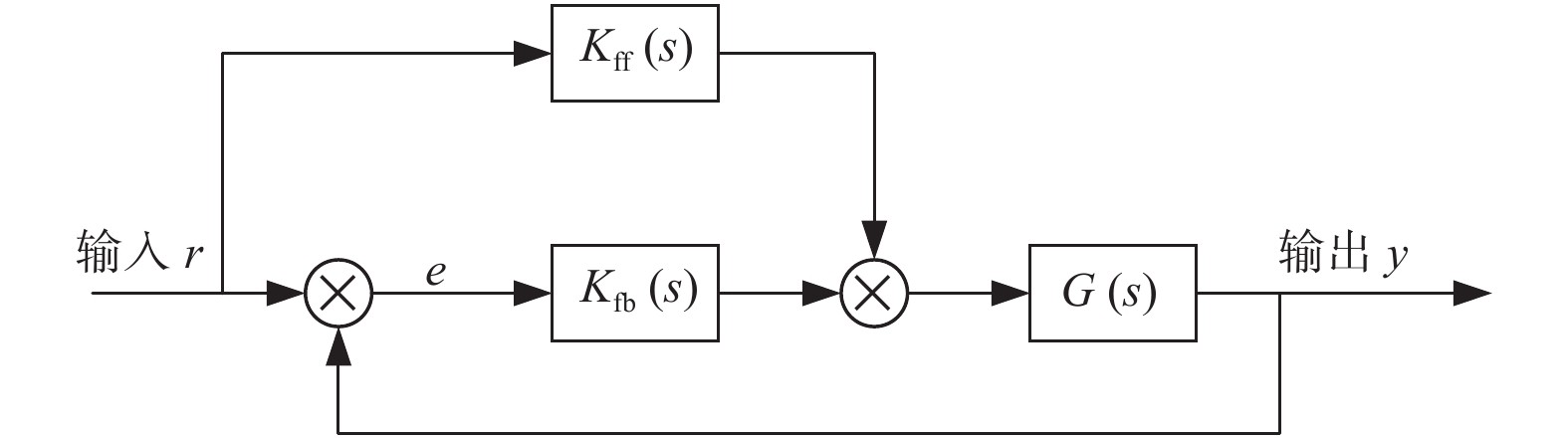

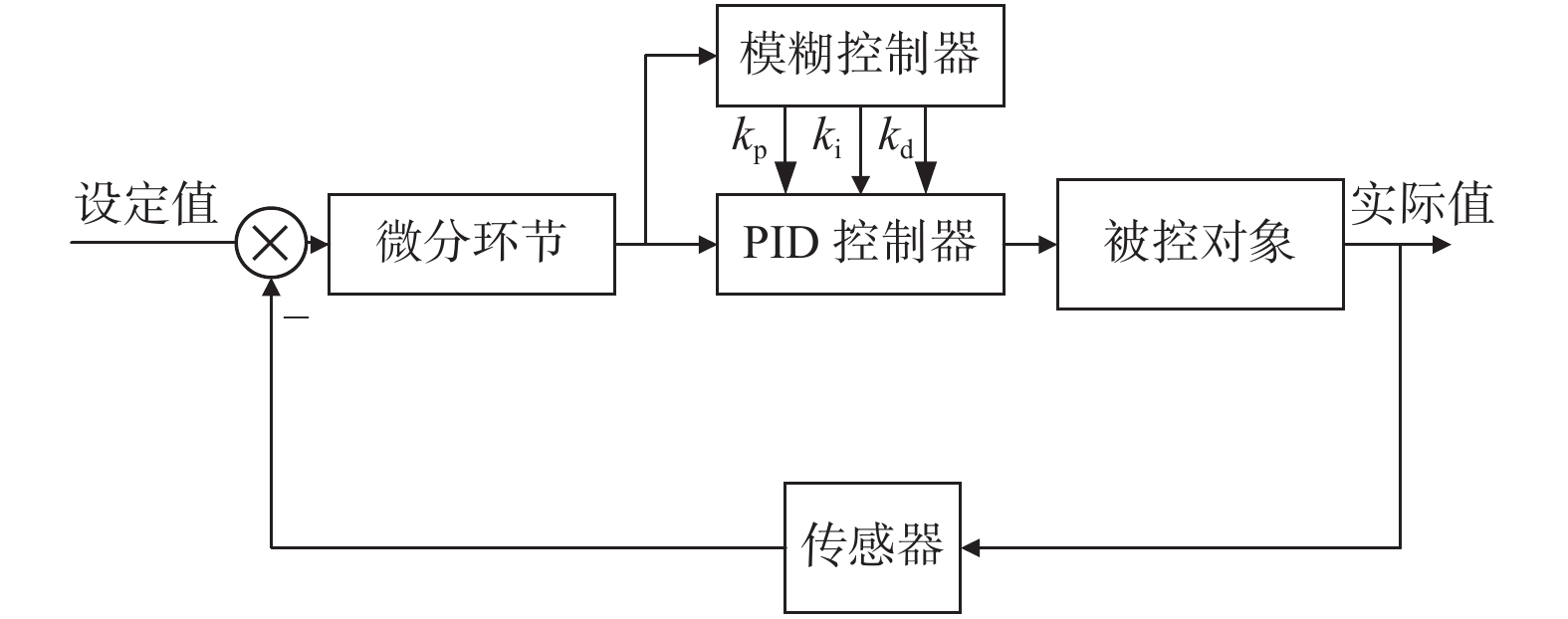

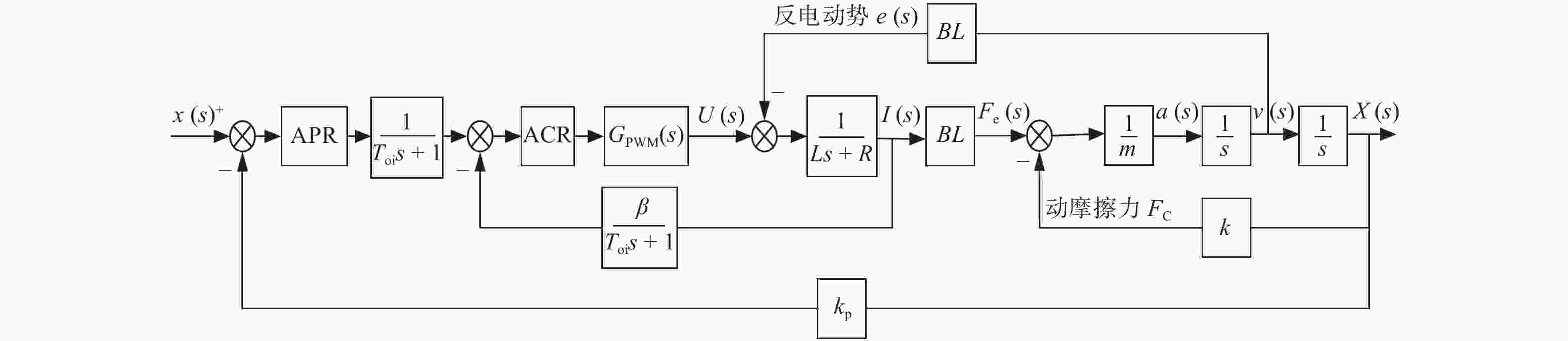

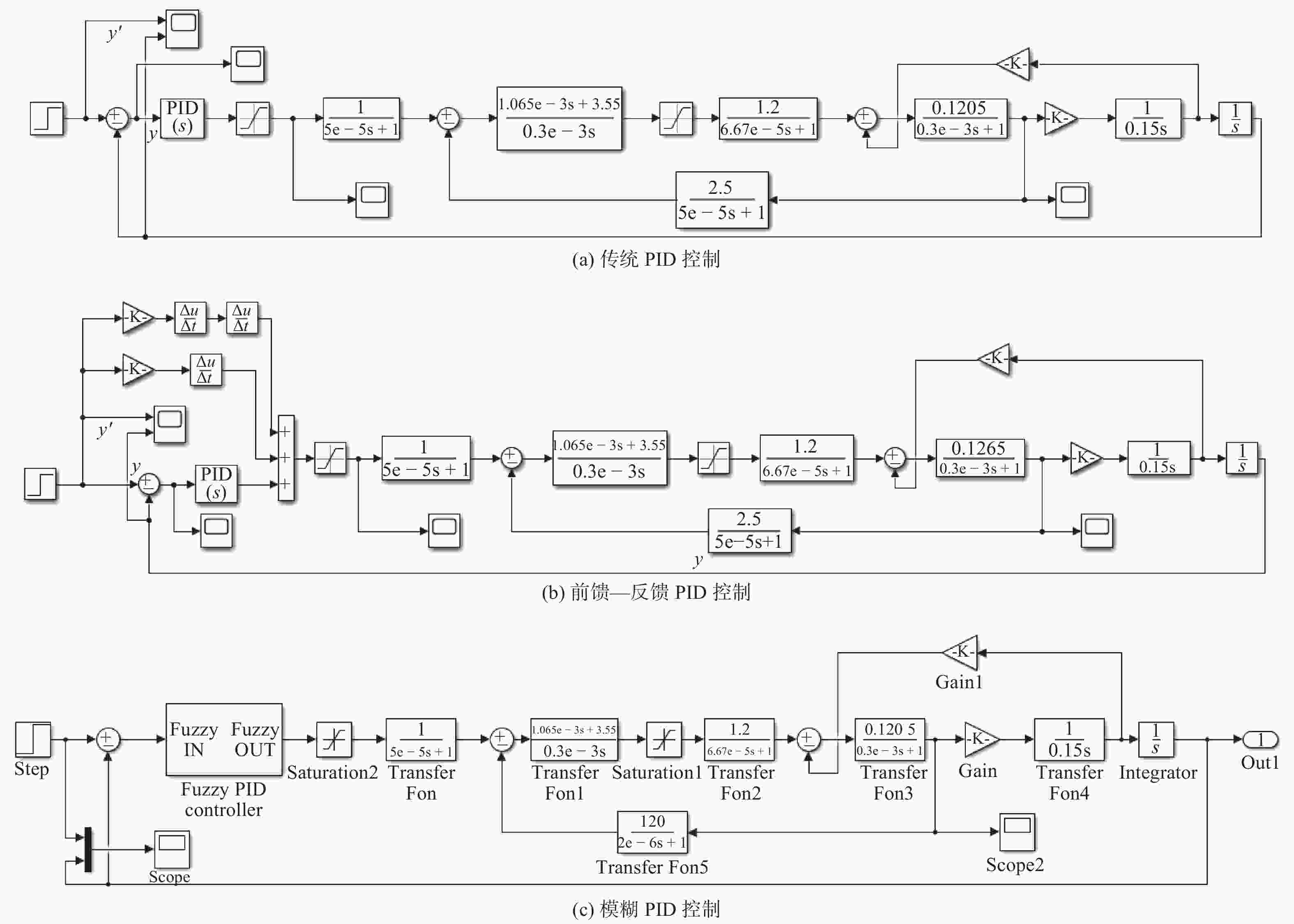

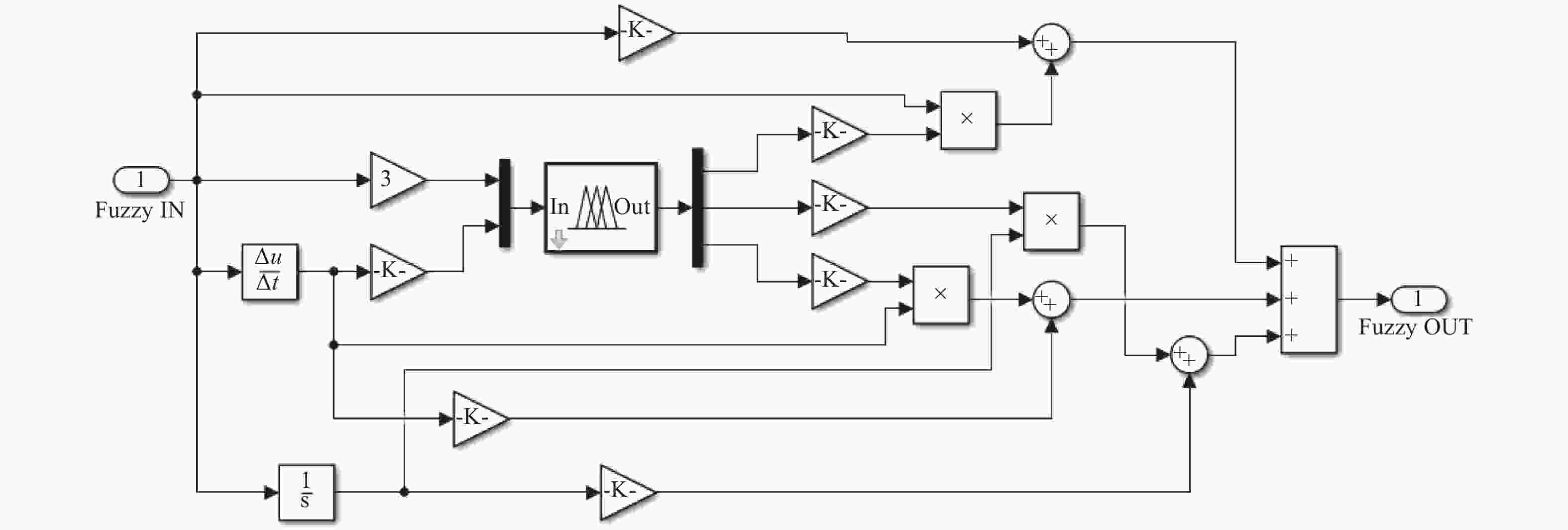

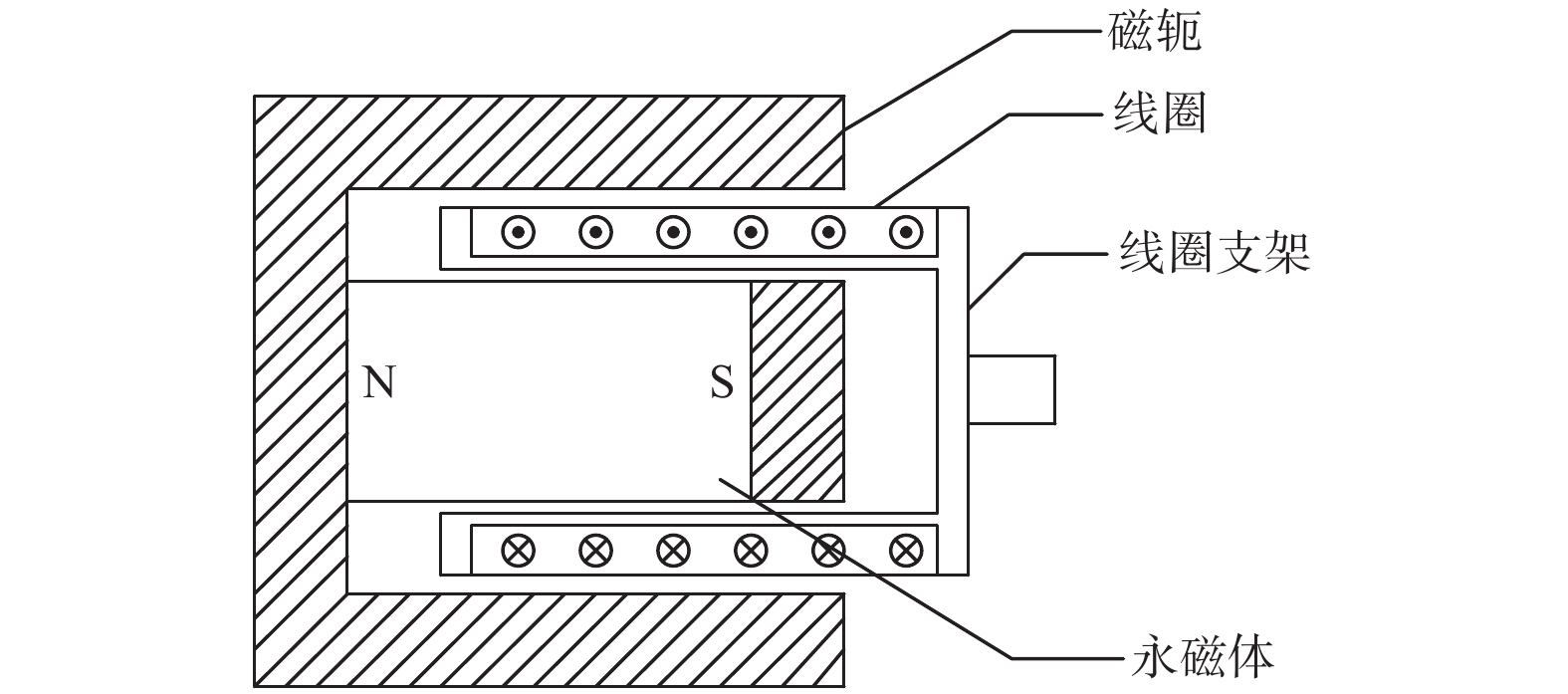

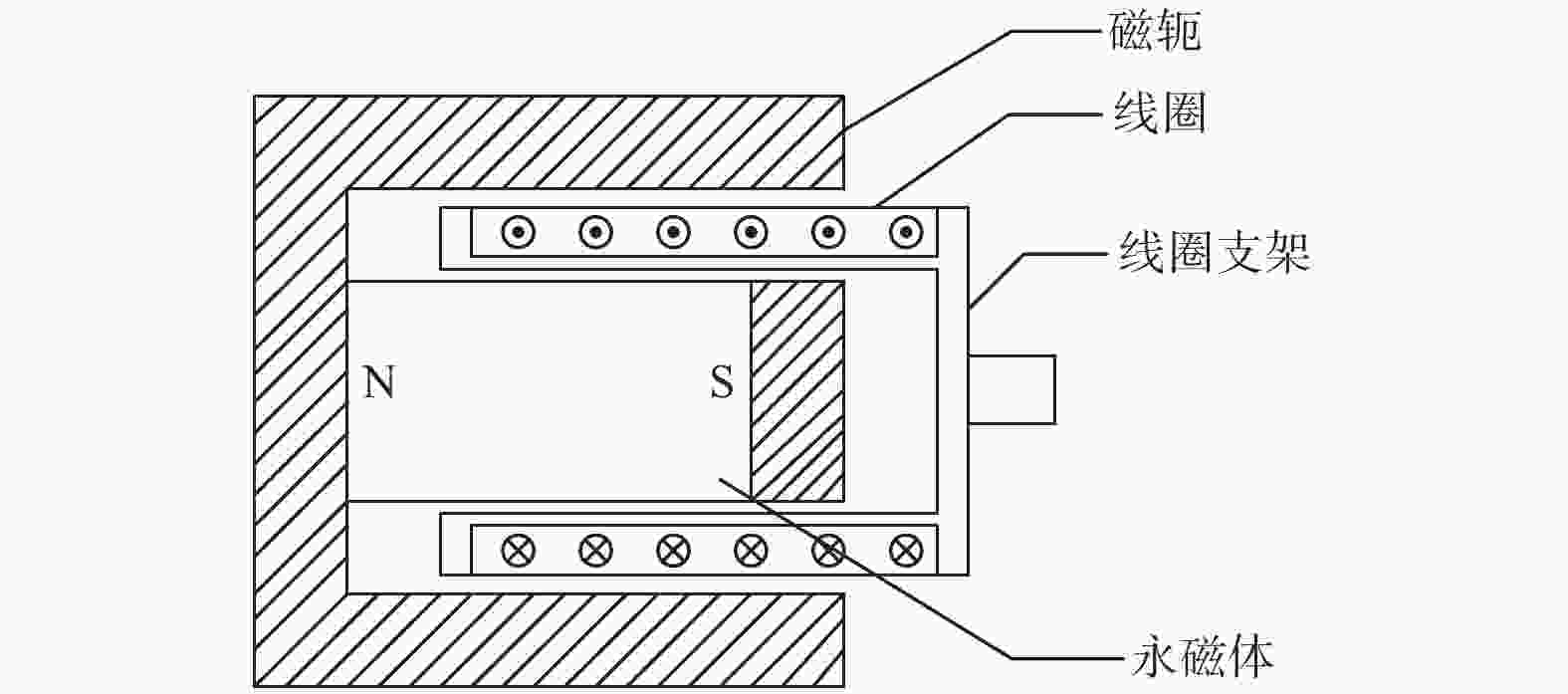

摘要: 针对大行程电磁驱动微纳米定位技术控制精度较低的问题,根据电磁驱动装置的工作原理,提出优化PID的控制方案,并在Matlab软件中搭建控制系统的Simulink模型. 相较传统PID控制,对前馈PID和模糊PID算法的改进效果进行研究,得出前馈PID拥有较好的动、静态控制性能,模糊PID鲁棒性较佳的结论.Abstract: Aiming at the problem of low control precision of large stroke electromagnetic drive micro-nano positioning technology, an optimized PID control scheme was proposed. According to the working principle of the electromagnetic drive device, the Simulink model of control system was established and built in Matlab software. Comparing with traditional PID control, the improvement effects of feedforward PID and fuzzy PID algorithm were studied. It is concluded that feedforward PID has better dynamic and static control performance, and fuzzy PID has better robustness.

-

Key words:

- electromagnetic drive /

- nano positioning /

- feedforward control /

- fuzzy control

-

表 1 模糊PID控制规则表

Table 1. Fuzzy PID control rules

ec e NB NM NS ZO PS PM PB NB PB / NB / PS PB / NB / NS PM / NM / NB PM / NM / NB PS / NS / NB Z / Z / NM Z / Z / PS NM PB / NB / PS PB / NB / NS PM / NM / NB PS / NS / NM PS / NS / NM Z / Z / NS NS / Z / Z NS PM / NB / Z PM / NM / NS PM / NS / NM PS / NS / NM Z / Z / NB NS / PS / NS NS / PS / Z ZO PM / NM / Z PM / NM / NS PS / NS / NS Z / Z / NS NS / PS / NS NM / PM / NS NM / PM / Z PS PS / NM / Z PS / NS / Z Z / Z / Z NS / PS / Z NM / PM / Z NM / PM / Z NM / PB / Z PM PS / Z / PB Z / Z / PS NS / PS / PS NM / PS / PS NM / PM / PS NM / PB / PS NB / PB / PB PB Z / Z / PB Z / Z / PM NS / PM / PM NM / PM / PM NM / PM / PS NM / PB / PS NB / PB / PB 表 2 电磁驱动装置主要性能参数

Table 2. Main performance parameters of electromagnetic drive device

参数 数值 线圈电阻R / Ω 8.3 线圈电感La / mH 2.5 驱动器动子质量m / kg 0.15 阻尼系数K /(N•s•m−1) 12.6 驱动装置力常数KS 14.1 电磁时间常数Tl / ms 0.3 机电时间常数tm / ms 6.26 -

[1] GARCIA R, KNOLL A W, RIEDO E. Advanced scanning probe lithography[J] . Nature Nanotechnology,2014,9(8):577 − 587. doi: 10.1038/nnano.2014.157 [2] ZHANG L, DONG J. High-rate tunable ultrasonic force regulated nanomachining lithography with an atomic force microscope[J] . Nanotechnology,2012,23(8):085303. doi: 10.1088/0957-4484/23/8/085303 [3] ZHANG Y, TAN K K, HUANG S. Vision-Servo System for Automated Cell Injection[J] . IEEE Transactions on Industrial Electronics,2009,56(1):231 − 238. doi: 10.1109/TIE.2008.925771 [4] RUSSELL R, HALL D. Manufacturing the future: Federal priorities for manufacturing research and development[R]. [S.l.]: Committee on Technology. National Science & Technology Council, 2008. [5] HUANG H B, SUN D, MILLS J K, et al. Robotic cell injection system with position and force control: Toward automatic batch biomanipulation[J] . IEEE Transactions on Robotics,2009,25(3):727 − 737. doi: 10.1109/TRO.2009.2017109 [6] HUANG W Q, SUN M X. Design, analysis, and experiment on a novel stick-slip piezoelectric actuator with a lever mechanism[J] . Micromachines,2019,10(12):863. doi: 10.3390/mi10120863 [7] JUUTI J, KORDÁS K, LONNAKKO R, et al. Mechanically amplified large displacement piezoelectric actuators[J] . Sensors and Actuators. A: Physical,2005,120(1):225 − 231. doi: 10.1016/j.sna.2004.11.016 [8] 李鸿, 周云飞. 预测前馈补偿在0.1 um光刻机硅片台长行程电机控制中的应用[J] . 长沙电力学院学报(自然科学版),2003,18(3):19 − 22. [9] 李鸣鸣. 大行程纳米定位系统若干关键技术研究[M]. 上海: 上海大学出版社, 2011. [10] SHINNO H, HASHIZUME H. Nanometer positioning of a linear motor-driven ultraprecision aerostatic table system with electrorheological fluid dampers[J] . CIRP Annals-Manufacturing Technology,1999,48(1):289 − 292. doi: 10.1016/S0007-8506(07)63186-2 [11] 卢礼华, 郭永丰, 大刀川博之, 等. 高增益PID控制器实现纳米定位[J] . 光学精密工程,2007,15(1):63. doi: 10.3321/j.issn:1004-924X.2007.01.011 [12] 师佳楠, 夏娇, 李宇帅, 等. 基于 Matlab 的PID控制算法仿真[J] . 电子质量,2020(7):4 − 12, 16. [13] 王树青, 戴连奎, 于玲. 过程控制工程[M]. 2版. 北京: 化学工业出版社, 2008: 60−65. [14] 王飞. 运动控制系统自校正前馈控制器研究与设计[D]. 杭州: 浙江理工大学, 2019. [15] 刘豹, 唐万生. 现代控制理论[M]. 北京: 机械工业出版社, 2011: 2−3. [16] 郭阳宽, 王正林. 过程控制工程及仿真: 基于MATLAB/Simulink[M]. 北京: 电子工业出版, 2009. -

下载:

下载: