Warpage optimization of automobile connector based on response surface method

-

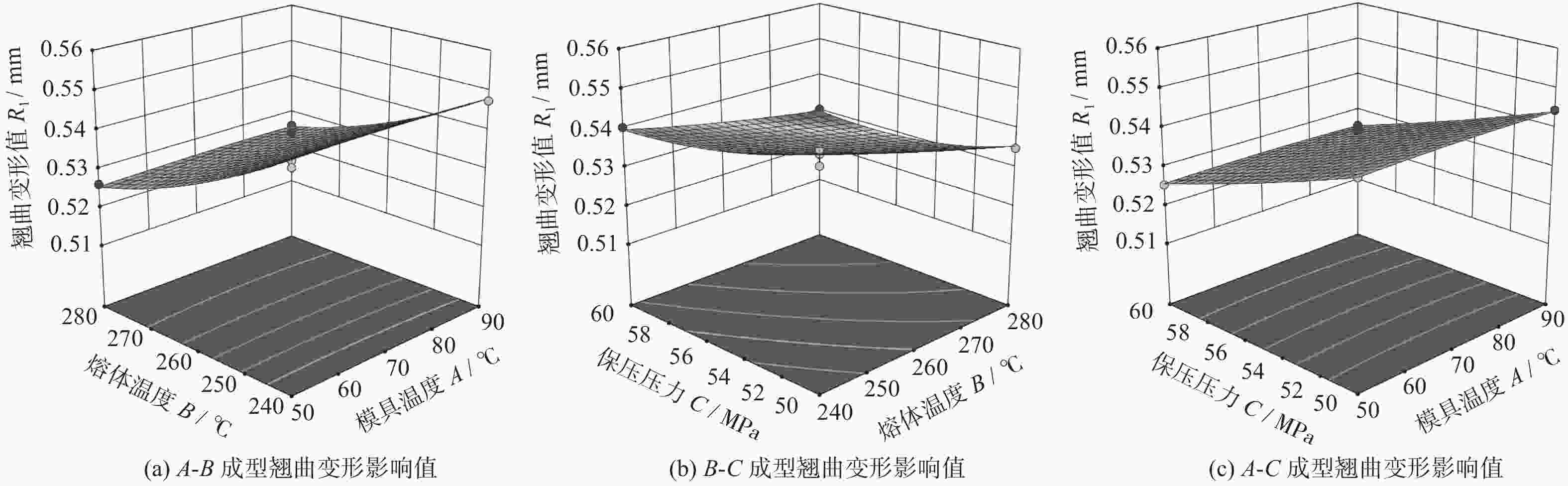

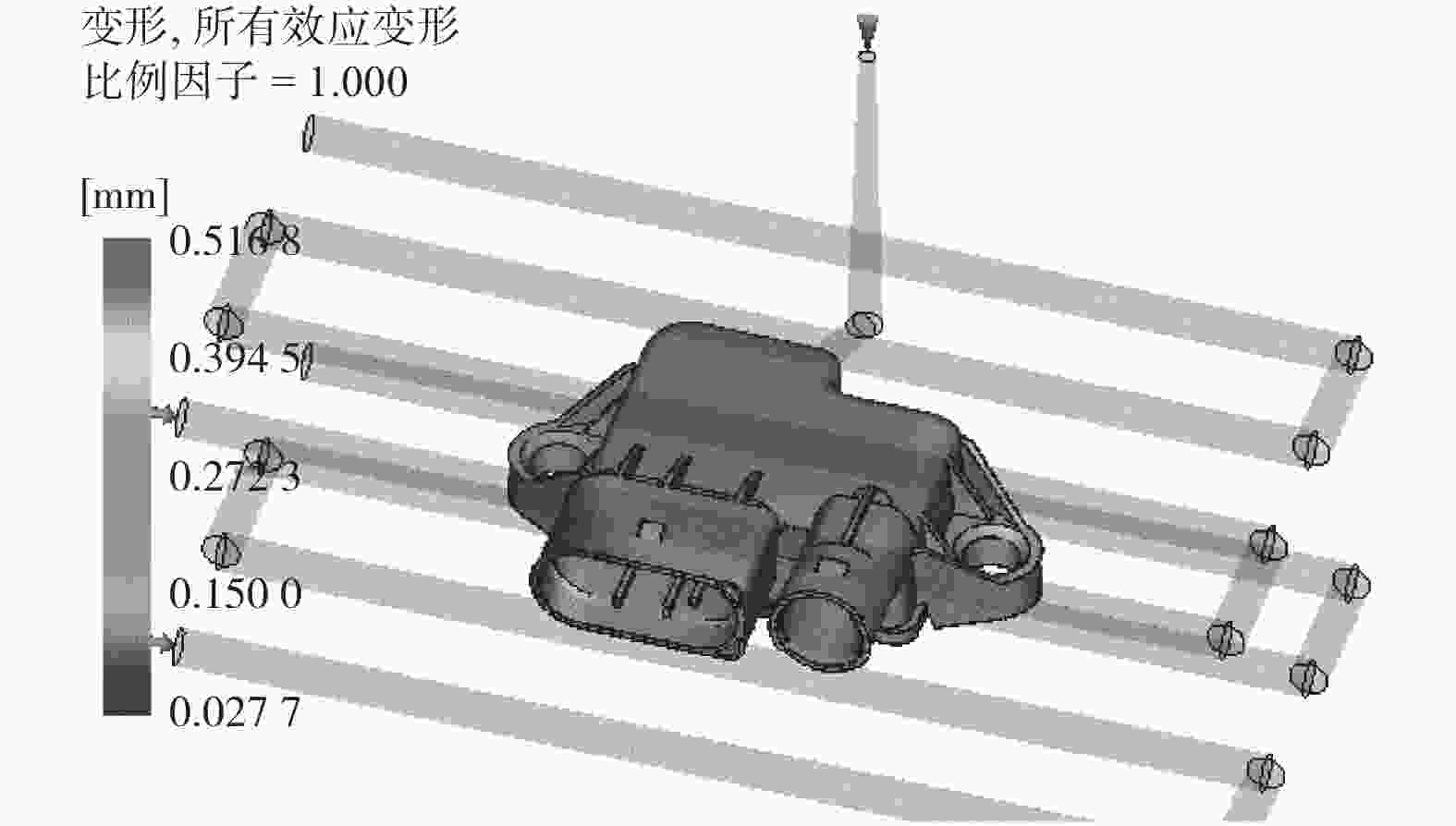

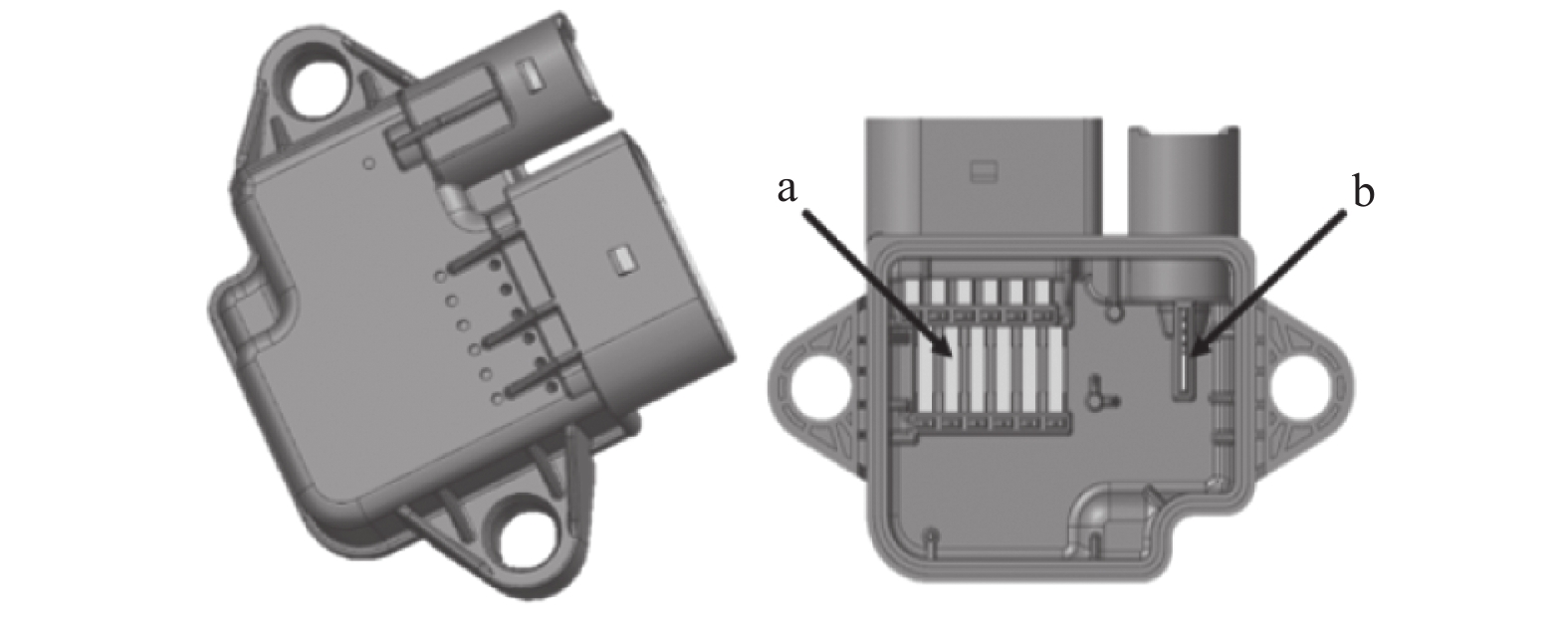

摘要: 为减少汽车接插件在注塑成型过程中出现翘曲变形问题,以某汽车接插件为研究对象,选取模具温度、熔体温度和保压压力为响应面影响因素,以塑件的翘曲变形值为响应目标,运用响应面法Box-Behnken设计试验方案. 利用Design-Expert软件分析试验结果,建立响应面响因素与响应值之间的二阶响应面模型,获得最佳工艺参数组合为:模具温度为50 ℃、熔体温度为280 ℃、保压压力为60 MPa. 试验结果表明,采用该工艺组合生产的注塑件翘曲变形值下降21.26%,符合预期要求.Abstract: In order to reduce the warp deformation problem in injection molding process of car plug-in, a car plug-in was used as the research object, the mold temperature, solute temperature and pressure-keeping pressure were selected as the response surface influence factors, the warping deformation value of the plastic part was used as the response target, experiment scheme was designed by using the response surface method Box-Behnken. Taking advantage of Design-Expert software, the test results were analyzed, the second-order response surface model between the response surface sound factor and the response value was established, and the best combination of process parameters obtained as follow: mold temperature of 50℃, melt temperature of 280℃, pressure of 60 MPa. The experimental verification results show that the warped deformation value of injection molding parts produced by the process combination decreases by 21.26%, which can meet the expected requirements.

-

Key words:

- response surface method /

- warpage deformation /

- automobile connector /

- Moldflow software

-

表 1 材料性能参数

Table 1. Material performance parameters

材料 PBT/ASA-GF20 模具温度/℃ 70 熔体温度/℃ 260 推荐模具温度范围/℃ 50~90 推荐熔体温度范围/℃ 240~280 最大剪切应力/MPa 0.4 最大剪切速率/s−1 50000 表 2 注塑水平因素表

Table 2. Factors of injection level

水平 模具温度A/℃ 熔体温度B/℃ 保压压力C/MPa 1 50 240 50 2 90 280 60 表 3 试验目标及其响应目标

Table 3. Experimental objectives and response objectives

序号 模具温度A/℃ 溶体温度B/℃ 保压压力C/MPa 翘曲变形值R1/mm 1 70 260 55 0.5347 2 50 260 50 0.5444 3 70 260 55 0.5305 4 90 280 55 0.5263 5 50 280 55 0.5261 6 70 280 60 0.5174 7 70 240 50 0.5596 8 50 240 55 0.5487 9 70 240 60 0.5404 10 90 260 60 0.5256 11 70 260 55 0.5395 12 50 260 60 0.5255 13 70 280 50 0.5351 14 90 260 50 0.5446 15 90 240 55 0.5475 表 4 回归模型方差分析

Table 4. Analysis of variance of regression model

因素 偏差平方和 自由度 方差 F值 P值 显著性 模型 1.770E−03 9 1.968E−04 23.090 0.0015 显著 A 6.125E−08 1 6.125E−08 7.188E−03 0.9357 B 1.042E−03 1 1.042E−03 122.270 0.0001 C 6.994E−04 1 6.994E−04 82.070 0.0003 AB 4.900E−07 1 4.900E−07 0.058 0.820 0 AC 2.500E−09 1 2.500E−09 2.934E−04 0.987 0 BC 5.625E−07 1 5.625E−07 0.066 0.8075 A2 6.669E−07 1 6.669E−07 0.078 0.7909 B2 2.642E−05 1 2.642E−05 3.100 0.1386 C2 1.117E−06 1 1.117E−06 0.130 0.7321 残差 4.261E−05 5 8.522E−06 失拟项 2.047E−06 3 6.825E−07 0.034 0.9895 不显著 纯误差 4.056E−05 2 2.025E−05 总误差 1.814E−03 14 相关系数${R^2}$=0.9765 校正系数${R^2}$=0.9342 模型信噪比r=17.422 表 5 非线性算法优化条件

Table 5. Optimization conditions of nonlinear algorithm

控制范围 A/℃ B/℃ C/MPa R1/mm 上限 50 240 50 0.5174 下限 90 280 60 0.5596 表 6 最优设计变量取值

Table 6. Values of the optimal design variables

模具温度A/℃ 熔体温度B/℃ 保压压力C/MPa 翘曲变形值R1/mm 50 280 60 0.5170 表 7 验证方案工艺参数及响应值

Table 7. Process parameters and response values of validation scheme

模具温度A/℃ 熔体温度B/℃ 保压压力C/MPa 翘曲变形值R1/mm 50 280 60 0.5168 -

[1] 姚建冲, 廖秋慧, 祝璐琨, 等. 汽车接插件注塑生产在线质量检测系统设计[J] . 轻工机械,2020(2):69 − 73. doi: 10.3969/j.issn.1005-2895.2020.02.012 [2] 王博, 蔡安江, 孟广慧, 等. 采用组合算法的注塑制品翘曲变形预测[J] . 西安交通大学学报,2020(8):84 − 90. [3] 付燕. 注塑件翘曲变形分析及其解决途径[J] . 机电工程技术,2006(5):33 − 34, 82. doi: 10.3969/j.issn.1009-9492.2006.05.011 [4] 齐雪, 廖秋慧, 祝璐琨, 等. 基于响应面法的汽车接插件注塑工艺优化[J] . 塑料科技,2018(10):95 − 99. [5] 蔡厚道. 基于数值模拟和响应面法的支架注塑工艺优化[J] . 塑料工业,2015(11):56 − 60. doi: 10.3969/j.issn.1005-5770.2015.11.014 [6] 屈华昌, 张俊. 塑料成型工艺与模具设计[M]. 3版. 北京: 机械工业出版社, 2014. [7] 郑赣, 刘淑梅, 汪东升, 等. 基于响应面法的平衡轴成形工艺参数优化[J] . 锻压技术,2019(10):14 − 19. [8] 唐春华, 夏琴香, 张斌. 基于响应面模型的仪器外壳注塑成型工艺混合优化[J] . 塑料工业,2018(6):37 − 40. doi: 10.3969/j.issn.1005-5770.2018.06.009 -

下载:

下载: