Configuration design and workspace solution of six degrees of freedom walking machining robot

-

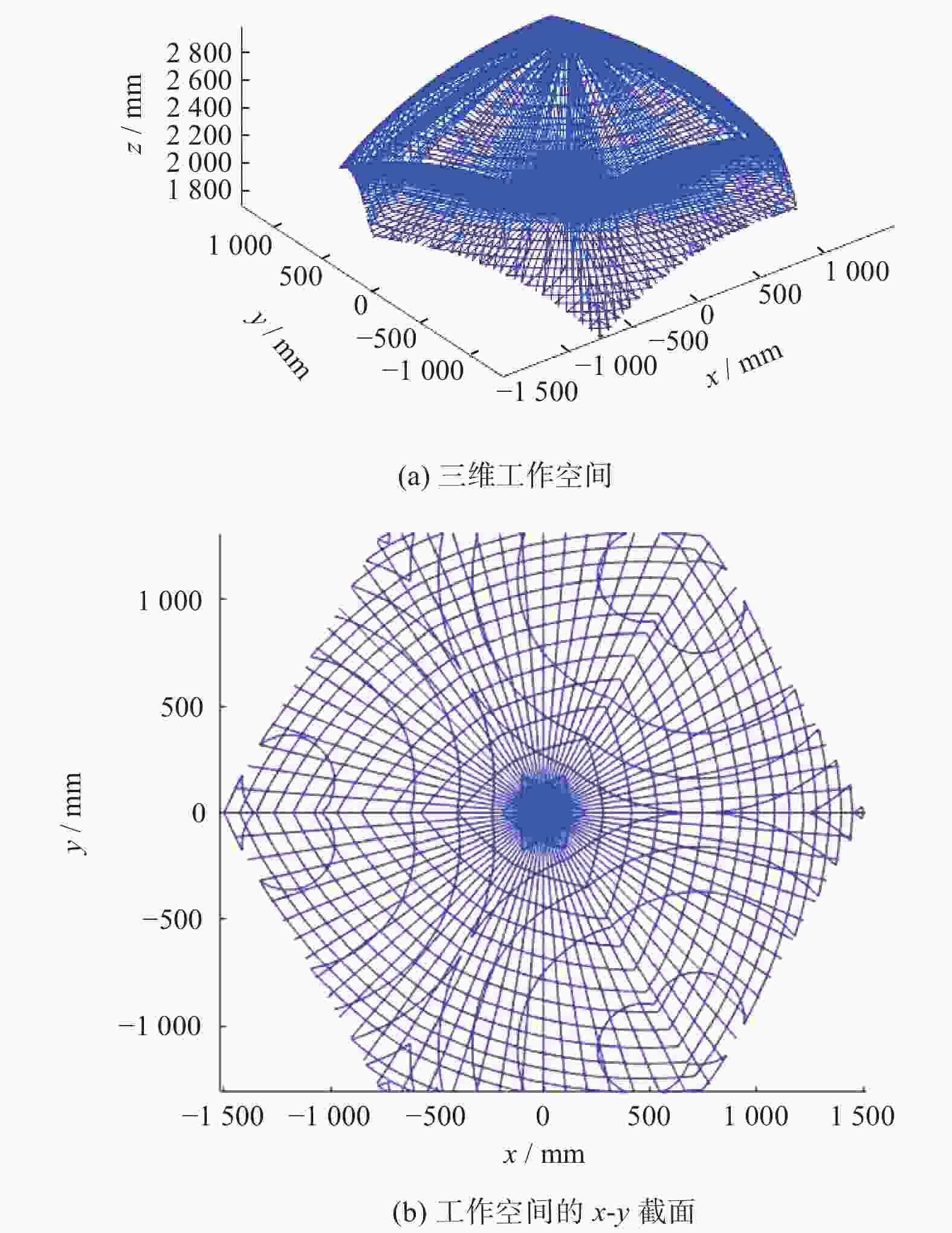

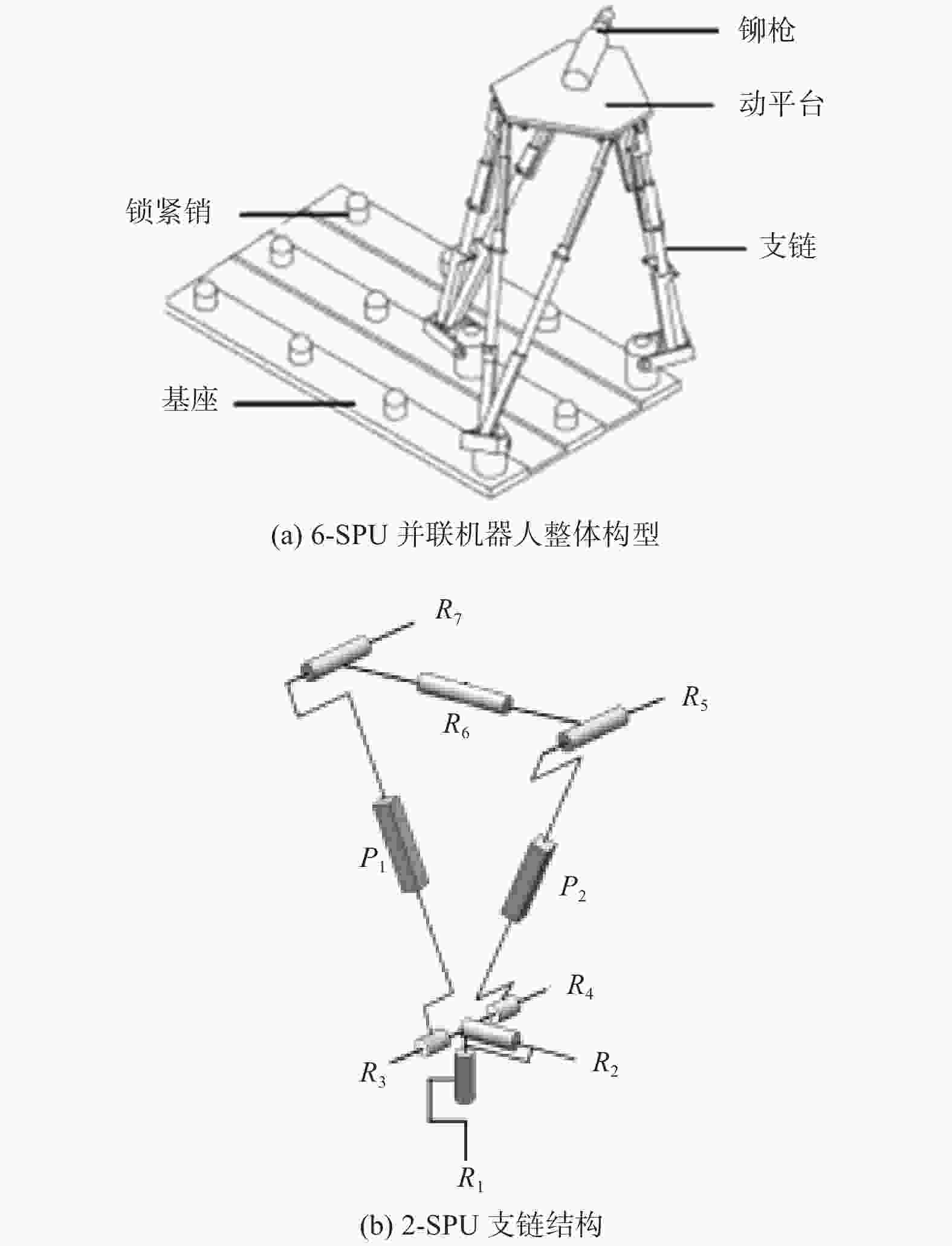

摘要: 提出一种6-SPU步行式加工机器人,依照结构紧凑、刚度大、易于安装等原则,对机器人机构支链及整体构型进行设计. 基于螺旋理论得出机器人具有6个自由度,通过姿态变换矩阵得出机器人位置逆解. 通过几何法得到机器人的工作空间,采用蒙特卡洛法对求解的工作空间的正确性进行验证.Abstract: A 6-SPU walking machining robot was proposed. According to the principle of compact structure, large stiffness and easy installation, the branch chain and overall configuration of robot mechanism were designed. Based on the screw theory, it was obtained that the robot had 6 degrees of freedom, and the inverse solution of robot position was obtained by the attitude transformation matrix. The workspace of the robot was obtained by geometric method, and the correctness of the workspace was verified by Montecarlo method.

-

Key words:

- configuration design /

- degrees of freedom /

- workspace /

- Montecarlo method

-

表 1 铆接工件点坐标

Table 1. Coordinates of riveting workpiece point

序号 铆接孔坐标/mm 1 ( 300.000, 350.000, 636.142 ) 2 ( 324.000, 374.000, 683.444 ) 3 ( 348.000, 398.000, 730.761 ) 4 ( 372.000, 422.000, 778.090 ) 5 ( 396.000, 446.000, 825.429 ) 6 ( 420.000, 470.000, 872.776 ) 表 2 机构参数

Table 2. Mechanism parameters

尺度参数符号 机构参数 定平台直径D /mm 4242.6 动平台直径d /mm 2121.3 驱动杆最小杆长lmin /mm 1909.2 驱动杆最大伸长量Δl /mm 424.3 动平台长边所对圆心角θ /rad 1.9 -

[1] 韩锋, 田威, 廖文和, 等. 基于并联机构的轻型自主爬行钻铆系统法向调姿算法[J] . 航空学报,2015(6):2083 − 2090. [2] 吴彦星. 基于并联机构的搅拌摩擦焊机床柔顺控制研究[D]. 秦皇岛: 燕山大学, 2017. [3] 孔垂麟, 姜秀梅, 岳永铭, 等. 四足仿生机器人斜面行走的运动研究[J] . 机械与电子,2019,37(7):58 − 63. doi: 10.3969/j.issn.1001-2257.2019.07.012 [4] LI Y Z, YAO Y A, HE Y Y. Design and analysis of a multi-mode mobile robot based on a parallel mechanism with branch variation[J] . Mechanism and Machine Theory,2018,130:276 − 300. [5] 王晓磊, 金振林, 李晓丹, 等. 串并混联四足仿生机器人动力学建模与分析[J] . 农业机械学报,2019,50(4):401 − 412. [6] PAN Y, GAO F. Position model computational complexity of walking robot with different parallel leg mechanism topology patterns[J] . Mechanism and Machine Theory,2017,107:324 − 337. doi: 10.1016/j.mechmachtheory.2016.09.016 [7] SUGAHARA Y, HOSOBATA T, MIKURIYA Y,et al. Realization of dynamic human-carrying walking by a biped locomotor[C]//IEEE International Conference on Robotics and Automation, New Orleans, 2004. [8] CARBONE G, SUGAHARA Y, LIM H O, et al. Stiffness performances estimation for biped locomotor WL-15[C]//Proceedings 2003 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM 2003), Kobe, 2003. [9] FUJII F. The largest two-legged walking robot in Kansai in hazardous locations[J] . Robot Laboratory,2005(19):7 − 12. [10] HE J, GAO F. Type Synthesis for Bionic Quadruped Walking Robots[J] . Journal of Bionic Engineering,2015,12(4):527 − 538. doi: 10.1016/S1672-6529(14)60143-8 [11] 潘阳. P-P结构六足机器人性能设计与控制实验研究[D]. 上海: 上海交通大学, 2014. [12] 荣誉, 金振林, 崔冰艳. 六足农业机器人并联腿构型分析与结构参数设计[J] . 农业工程学报,2012(15):9 − 14. [13] 王洪波, 齐政彦, 胡正伟,等. 并联腿机构在四足/两足可重组步行机器人中的应用[J] . 机械工程学报,2009(8):24 − 30. [14] 金振林, 何小静. 一种新型3-UPS并联机构及其工作空间分析[J] . 燕山大学学报,2011(3):203 − 207,227. doi: 10.3969/j.issn.1007-791X.2011.03.003 [15] 刘志忠, 柳洪义, 罗忠, 等. 机器人工作空间求解的蒙特卡洛法改进[J] . 农业机械学报,2013(1):230 − 235. doi: 10.6041/j.issn.1000-1298.2013.01.043 [16] 段学超, 仇原鹰, 段宝岩. 大射电望远镜精调Stewart平台工作空间研究[J] . 电子机械工程,2004(5):55 − 58. doi: 10.3969/j.issn.1008-5300.2004.05.016 [17] 黄真, 孔令富, 方跃法. 并联机器人机构学理论及控制[M]. 北京: 机械工业出版社, 1997. -

下载:

下载: