Fracture analysis of ductile fracture of AA6063 aluminum alloy

-

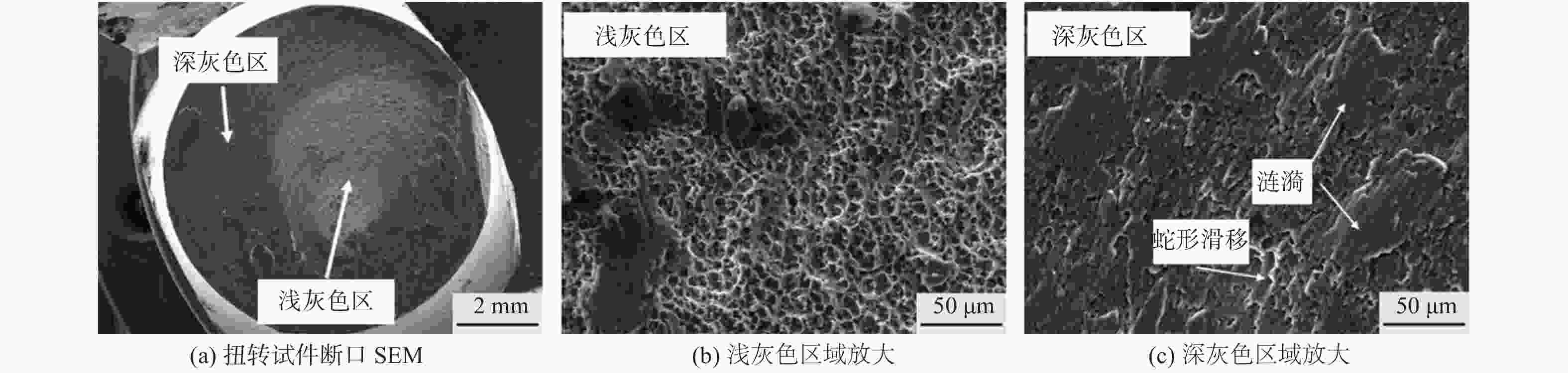

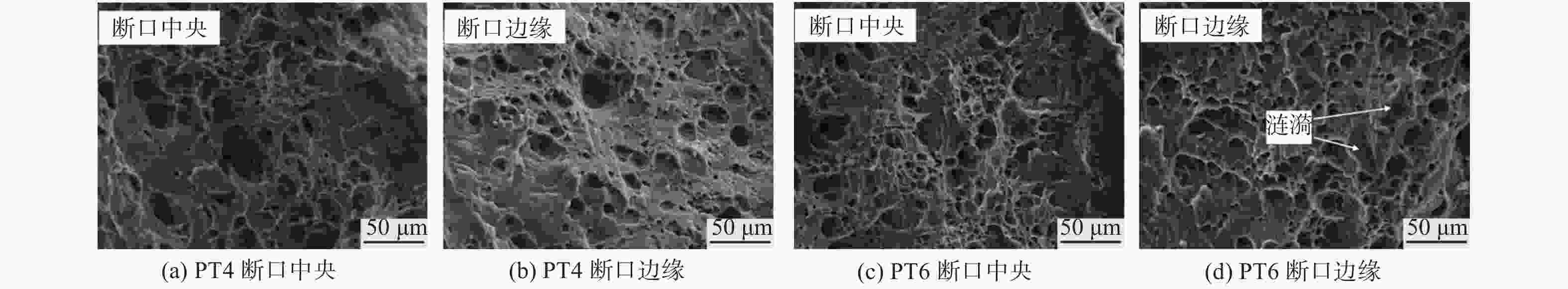

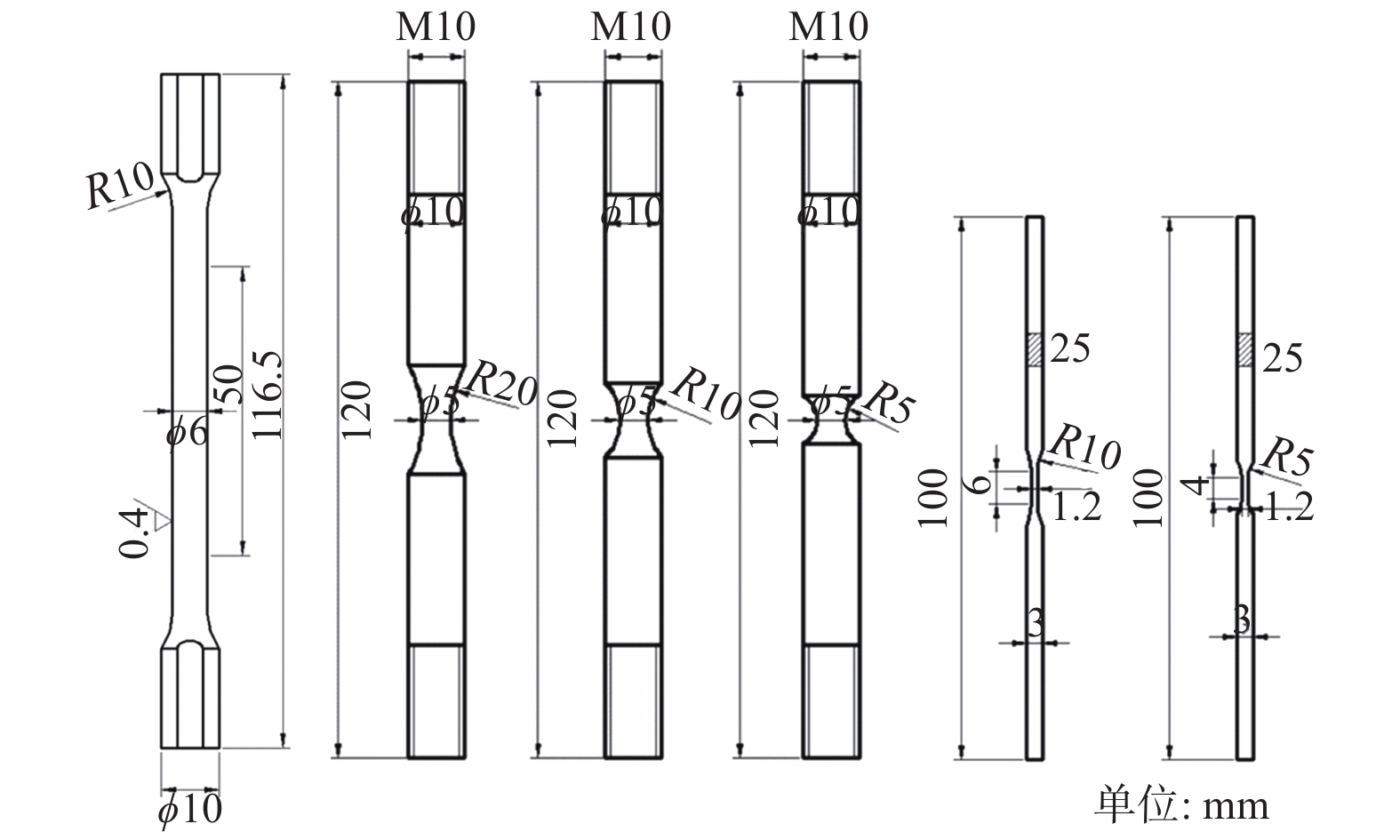

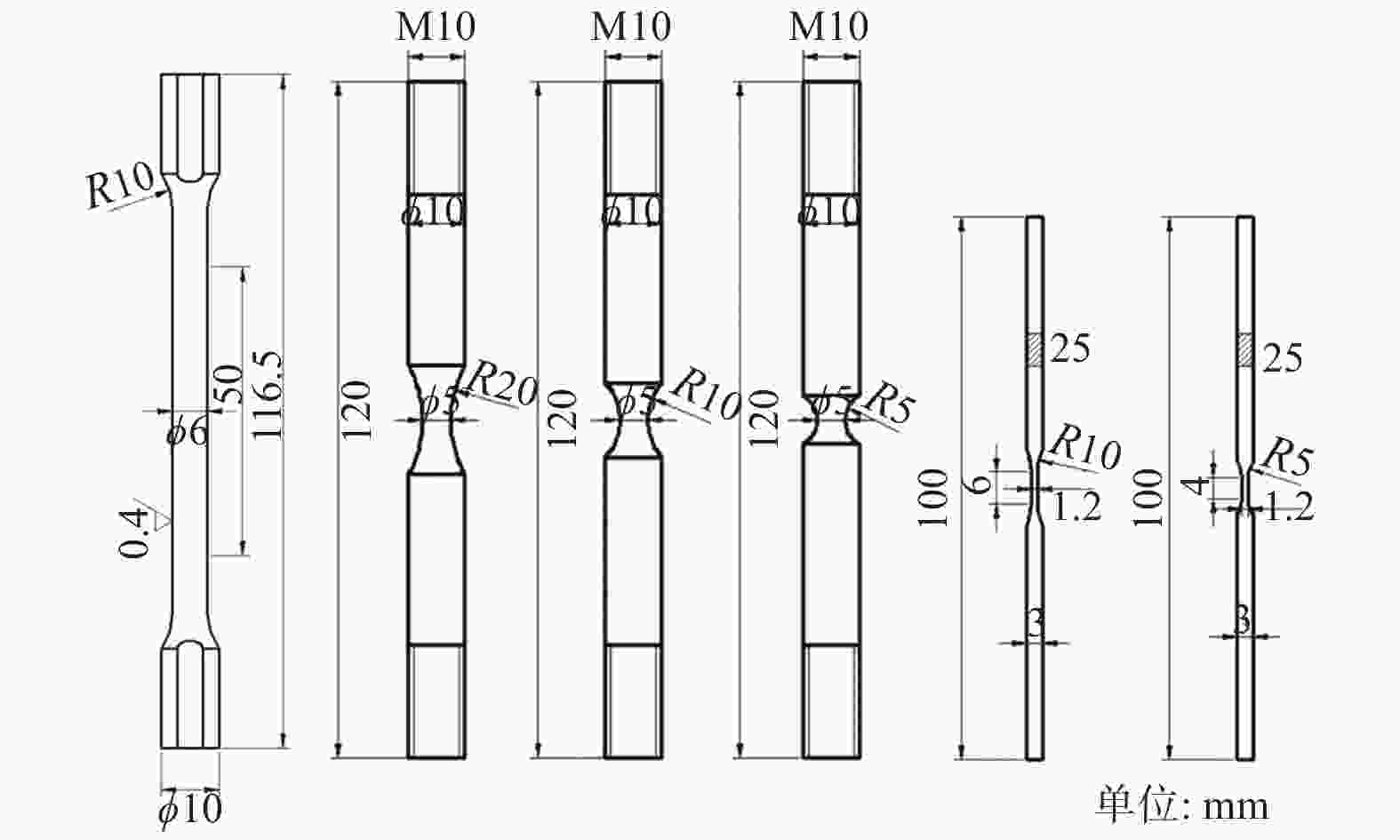

摘要: 为探究6063铝合金的韧性断裂机制, 通过一系列韧性断裂试验观察6063铝合金不同应力三轴度试件的韧性断口形貌. 结果表明:应力三轴度越高,孔洞的形核、长大、汇聚越快,孔洞更大更深. 不同应力三轴度下主导试件韧性断裂的方式也有所不同:缺口圆柱拉伸试件断裂由韧窝断裂主导;凹槽板拉伸试件断裂由韧窝断裂与剪切断裂共同主导;圆柱扭转试验断裂主要由剪切断裂主导,并且试件表面存在部分韧窝断裂特征.Abstract: In order to explore the ductile fracture mechanism of AA6063 aluminum alloy, a series of ductile fracture tests were carried out, and the ductile fracture morphology of AA6063 aluminum alloy specimens under different stress triaxiality was observed. The results show that the higher the stress triaxiality, the faster the nucleation, growth, and convergence of the holes, and the larger and deeper the holes. The mode of dominant ductile fracture of specimens under different stress triaxiality is also different. The fracture of notched cylindrical tensile specimens is dominated by dimple fracture, and the fracture of grooved plate tensile specimens is co-dominant by dimple fracture and shear fracture. The cylindrical torsion test fracture is mainly dominated by shear fracture and there are some dimple fracture characteristics on the surface of the specimens.

-

Key words:

- 6063 aluminum alloy /

- ductile fracture /

- stress triaxiality

-

表 1 初始应力三轴度计算公式

Table 1. Calculation formula of initial stress triaxiality

测试/试件 初始应力三轴度 缺口圆柱拉伸(NR) $\dfrac{ {\rm{1} } }{ {\rm{3} } }{\rm{ + ln} }\left( { {\rm{1 + } }\dfrac{ { {a_0} } }{ {2{R_0} } } } \right)$ 光滑圆柱扭转 0 凹槽平板拉伸试件(PT) $\dfrac{ {\rm{1} } }{ {\sqrt 3 } }\left[ {1 + 2{\rm{ln} }\left( { {\rm{1 + } }\dfrac{ { {t_0} } }{ {4{R_0} } } } \right)} \right]$ 表 2 不同试件的初始应力三轴度

Table 2. Initial stress triaxiality of different specimens

扭转试件 NR20 NR10 NR5 PT6 PT4 0 0.451 0.556 0.738 0.611 0.739 -

[1] 苑世剑, 刘伟, 徐永超. 板材液压成形技术与装备新进展[J] . 机械工程学报,2015,51(8):20 − 28. [2] 魏玉. 时效时间对汽车用6063铝合金组织与力学性能的影响[J] . 热加工工艺,2020,49(14):134 − 136. [3] 汪学阳, 黄志垣, 陈国恩, 等. 低成本的铝合金油底壳压铸工艺开发及应用[J] . 特种铸造及有色合金,2018,38(9):971 − 973. [4] 丁发俊. 铝合金在光伏支架上的应用[J] . 轻合金加工技术,2019,47(10):11 − 13. [5] 庞彦国, 王祝堂. 铝及铝合金在高新兵器中的应用[J] . 轻合金加工技术,2018,46(6):1 − 7. [6] 刘俊言, 蒋日鹏, 李晓谦. 7A09铝合金液压缸的开裂失效分析[J] . 热加工工艺,2019,48(13):164 − 167. [7] 任发才, 梁骁, 吴兴华. 铝合金自动扶梯梯级断裂失效分析[J] . 金属热处理,2019(S1):286 − 289. [8] 叶拓, 王冠, 姚再起, 等. 汽车用6xxx系铝合金薄壁件的韧性断裂行为[J] . 中国有色金属学报,2014,24(4):878 − 887. [9] TAYLOR K L, SHERRY A H. The characterization and interpretation of ductile fracture mechanisms in Al2024-T351 using X-ray and focused ion beam tomography[J] . Acta Materialia,2012,60(3):1300 − 1310. doi: 10.1016/j.actamat.2011.11.031 [10] 姜薇, 李亚智, 苏杰, 等. 2024–T3铝合金拉伸及剪切断裂行为[J] . 固体火箭技术,2015,38(3):426 − 432, 450. [11] 高建烨, 何涛, 霍元明, 等. 基于Bai-Wierzbicki准则的ECAP塑性损伤研究[J] . 塑性工程学报,2021,28(2):52 − 62. doi: 10.3969/j.issn.1007-2012.2021.02.008 [12] 朱浩, 朱亮, 陈剑虹, 等. 不同应力状态下铝合金变形及损伤机理的研究[J] . 稀有金属材料与工程,2007,36(4):597 − 601. doi: 10.3321/j.issn:1002-185X.2007.04.008 [13] LOU Y S, YOON J W, HUH H, et al. Correlation of the maximum shear stress with micro-mechanisms of ductile fracture for metals with high strength-to-weight ratio[J] . International Journal of Mechanical Sciences,2018,146-147:583 − 601. doi: 10.1016/j.ijmecsci.2018.03.025 [14] SHANG X Q, ZHANG H M, CUI Z S, et al. A multiscale investigation into the effect of grain size on void evolution and ductile fracture: Experiments and crystal plasticity modeling[J] . International Journal of Plasticity,2020,125:133 − 149. doi: 10.1016/j.ijplas.2019.09.009 [15] 范梦婷, 罗欣然, 房庆生, 等. 热处理对挤压铸造6063铝合金组织与性能的影响[J] . 特种铸造及有色合金,2020,40(8):915 − 920. [16] 王俊杰, 王伟. 考虑罗德角参数的钢材薄板延性断裂标定方法[J] . 工程力学,2019,36(5):37 − 42. -

下载:

下载: