Numerical simulation and test analysis of magnetic field in 500 kA aluminum electrolyzer

-

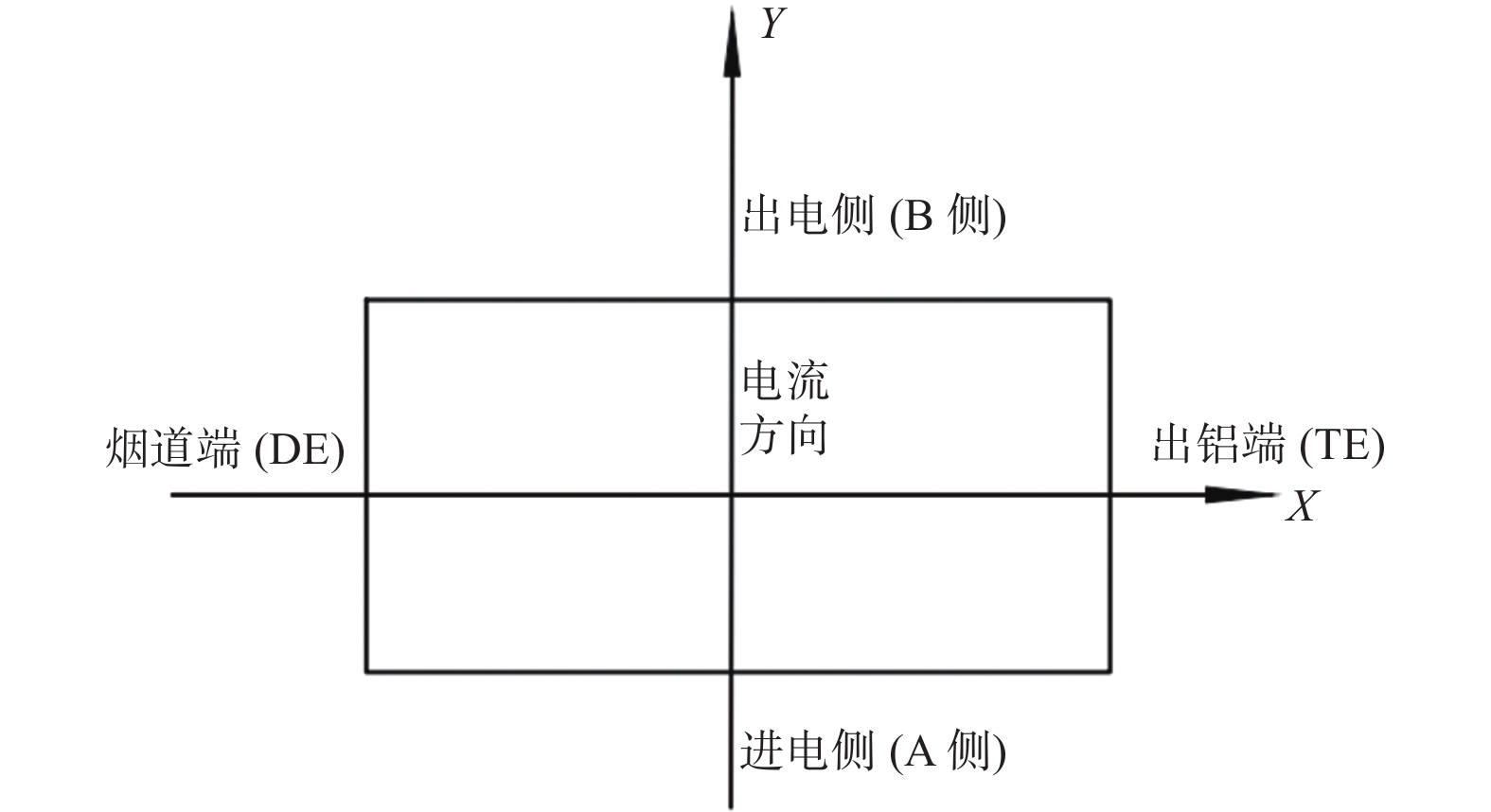

摘要: 利用 SolidWorks 三维建模及 COMSOL三维仿真模拟软件,对500 kA铝电解槽进行数值模拟. 对某厂家500 kA铝电解槽进行磁场测试,测试结果与模拟结果吻合较好. 得出500 kA铝电解槽的磁度分布,并对500 kA铝电解槽进行磁场优化,通过增加立柱母线和槽周母线到铝电解槽的距离降低立柱母线与槽周母线对铝液层的影响. 优化使得铝液层在Z轴方向上磁场分布趋于均匀稳定. 为改善生产工艺技术条件提供了技术支持.Abstract: Using 3D modeling of SolidWorks and 3D simulation software of COMSOL, the numerical simulation of 500 kA aluminum electrolyzer was carried out. A magnetic field test on 500 kA aluminum electrolyzer of a manufacturer is carried, and the test results are in good agreement with the simulation results. The magnetic field distribution of 500 kA aluminum electrolyzer was obtained and optimized, the influences of the column bus bar and groove bus bar on the molten aluminum layer are reduced by increasing the distance between the column bus bar and aluminum electrolyzer as well as the distance between the groove bus bar and aluminum electrolyzer. After the optimization, the magnetic field distribution of the molten aluminum layer tends to be uniform and stable along the Z-axis direction. The simulation and test provide technical support for improving the technical conditions of production process.

-

表 1 500 kA铝电解槽参数表

Table 1. Parameters of 500 kA aluminum electrolyzer

序号 项目名称 单位 参数 1 电流强度 kA 500 2 电解质水平 mm 360 3 铝液水平 mm 170 4 阳极炭块尺寸 mm×mm×mm 1750×740×370 5 阳极炭块数 块 48 6 阳极钢爪数 个 48 7 阴极炭块尺寸 mm×mm×mm 3810×740×510 8 阴极炭块数 块 48 9 阴极钢棒尺寸 mm×mm×mm 2030×105×225 表 2 磁场测试与模拟结果

Table 2. Magnetic field test and simulation results

Gs 项目 测点 Bx实测 Bx模拟 By实测 By模拟 Bz实测 Bz模拟 进电侧(A侧) α1 17 16 40 38 −123 −90 α2 19 17 46 43 −84 −79 α3 40 20 25 30 −50 −61 α4 −45 −28 −48 45 −120 −92 α5 −10 −11 −33 36 −110 −89 α6 −30 −28 −44 42 −70 −68 α7 15 17 38 37 −50 −50 α8 9 11 −48 48 20 10 出电侧(B侧) β1 13 12 −38 36 36 33 β2 26 23 −41 40 30 31 β3 12 13 −44 42 40 45 β4 14 15 −52 50 39 28 β5 13 12.6 −60 62 16 11 β6 15 15 −54 50 46 45 β7 −20 −19 −44 42 43 40 β8 −15 −14 −28 30 39 26 端部测点 A1侧 14 13 −36 33 −28 −25 B1侧 10 11 −30 28 −35 32 A48侧 9 13 −26 25 −40 −38 B48侧 −15 −13.9 28 31 −60 62 -

[1] KACPRZAK D, GUSTAFSSON M J, TAYLOR M P. A finite element analysis of busbars and magnetic field of an aluminum reduction cell[J] . IEEE Transactions on Magnetics,2006,42(10):3192 − 3194. doi: 10.1109/TMAG.2006.880102 [2] GRJOTHEM B, WELCH B J. Aluminium smelter technology[M]. Dusseldoff: Aluminium-Verlag, 1980. [3] 王旋, 刘伟, 李广彬, 等. 350 kA系列铝电解槽磁场模拟计算及优化[J] . 金属材料与冶金工程,2015,43(6):30 − 34. [4] 张含博, 陈端, 王旋, 等. 500 kA铝电解车间空间磁场的研究[J] . 轻金属,2019(7):25 − 28. [5] 张大庆, 段中波, 曹亚兵. 500 kA铝电解槽的磁场分布与电流效率[J] . 甘肃冶金,2019,41(1):39 − 41. doi: 10.3969/j.issn.1672-4461.2019.01.011 [6] 黄永忠, 王化章, 王平甫, 等. 铝电解生产 [ M] . 长沙: 中南工业大学出版社, 1994. [7] 邱竹贤. 铝电解[ M] . 2版. 北京: 冶金工业出版社, 1995. [8] 毛宇, 毛继红, 班允刚, 等. 一种7点进电500 kA铝电解槽母线设计及应用[J] . 世界有色金属,2019(4):238 − 239. doi: 10.3969/j.issn.1002-5065.2019.04.136 [9] 陈端, 王旋, 刘伟. SY500铝电解槽流动场的数值模拟与测试研究[J] . 有色冶金节能,2019,35(5):24 − 28. [10] 毛宇, 毛继红, 班允刚, 等. 集约型600 kA铝电解系列母线装置设计及应用[J] . 中国金属通报,2019(3):103, 105. [11] 闫照文, 汪友生, 苏东林, 等. 大型铝电解槽三维电磁场的数值模拟[J] . 电工技术学报,2003,18(5):23 − 26. doi: 10.3321/j.issn:1000-6753.2003.05.005 [12] 姜昌伟, 周乃君, 梅炽, 等. 154 kA预焙铝电解槽三维磁场的双标量磁位法计算[J] . 有色金属,2003,55(3):76 − 80. -

下载:

下载: