Research on Microstructure and Properties of TaC/FeCoCrNiTiMo Cladding Layer Prepared by Laser Cladding

-

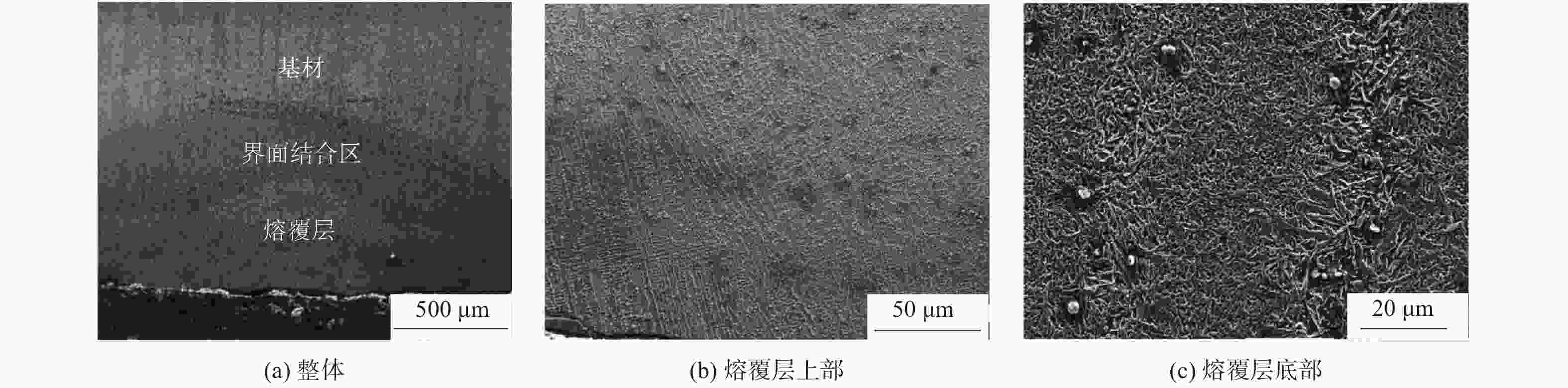

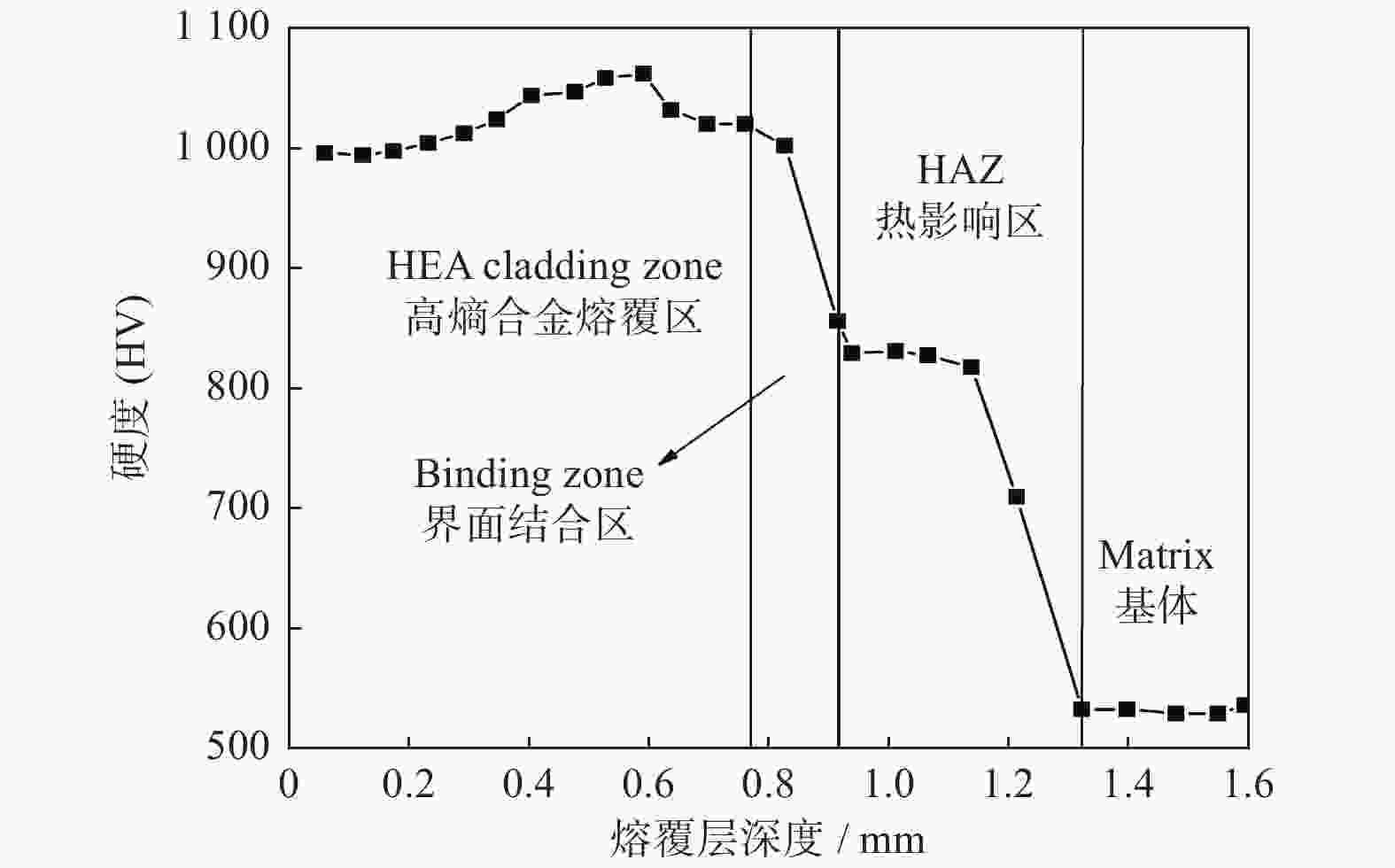

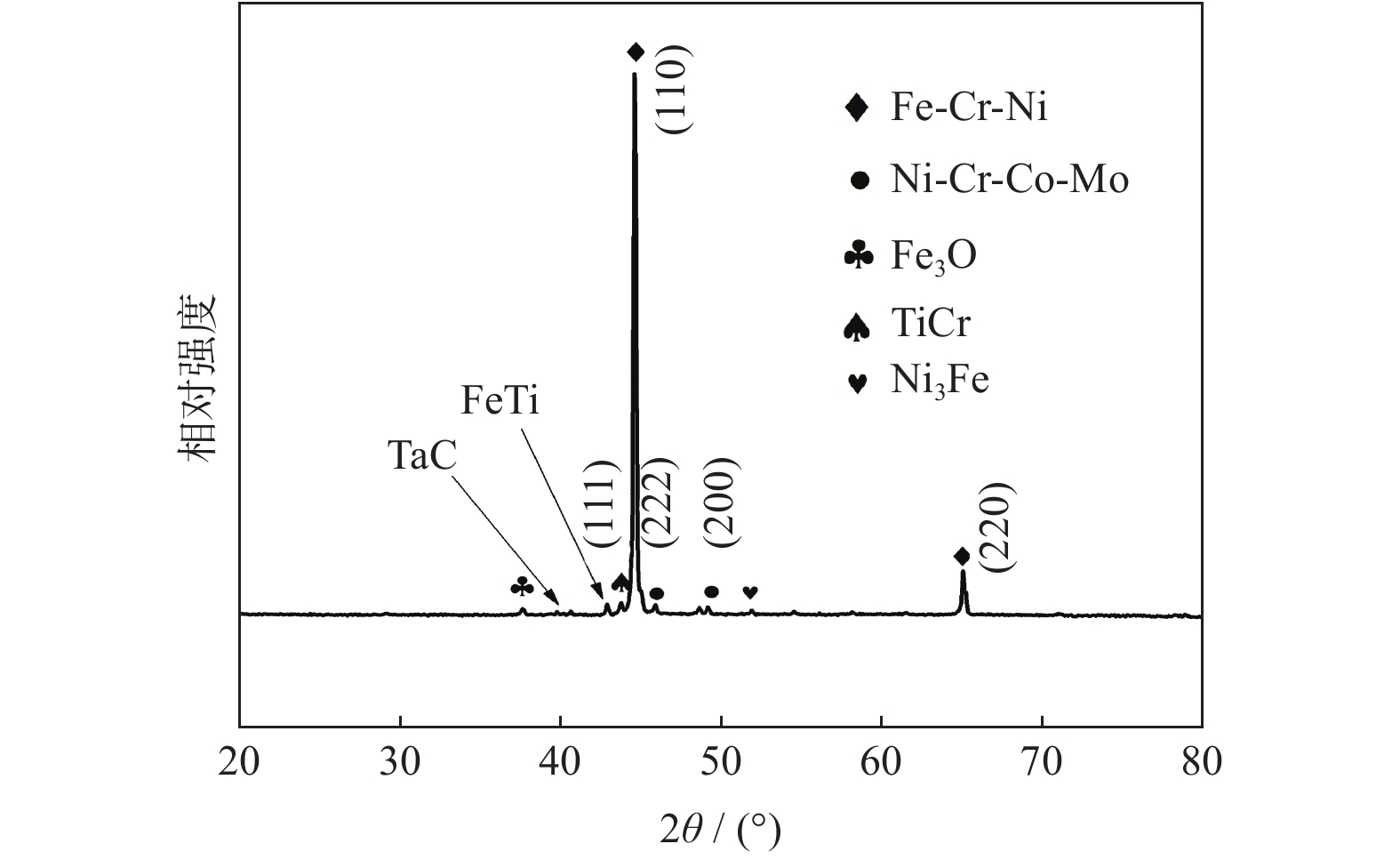

摘要: 采用激光熔覆技术在45#钢表面制备添加碳化钽(TaC)纳米颗粒的FeCoCrNiTiMo高熵合金熔覆层,利用X线衍射(XRD)、扫描电镜(SEM)、能谱仪(EDS)及显微硬度计分析测试熔覆层相结构、组织形貌及截面硬度. 研究表明,在FeCoCrNiTiMo高熵合金熔覆层中添加TaC纳米颗粒后,其相结构以体心立方结构的FeCrNi固溶体和面心立方结构的NiCrCoMo固溶体为主,并含有极少量的金属间化合物,熔覆层维氏硬度(HV)达到1058.89 ,是基材硬度的两倍.Abstract: The cladding layer of FeCoCrNiTiMo high entropy alloy with TaC nanoparticle was prepared on the surface of 45# steel by laser cladding. The phase composition, microstructure and the cross-section hardness of the cladding layer were analyzed and tested by X-ray diffraction (XRD), scanning electron microscope (SEM), energy dispersive spectrometer (EDS) and microhardness tester. Studies show that by adding TaC nanoparticles to FeCoCrNiTiMo high entropy alloy cladding layer, the phase structure of the alloy is mainly composed of body-centered cubic FeCrNi solid solution and face-centered cubic NiCrCoMo solid solution, and contains a very small amount of intermetallic compounds. The Vickers hardness (HV) of cladding layer reaches 1058.89, which is twice the hardness of the base material.

-

表 1 45#钢化学成分含量

Table 1. Chemical composition of 45# steel

% C Si Mn P S Fe 0.45 0.18 0.37 ≤0.02 ≤0.02 其余 -

[1] MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts[J] . Acta Materialia,2017,122:448 − 511. doi: 10.1016/j.actamat.2016.08.081 [2] CAI Z B, WANG Y D, CUI X F, et al. Design and microstructure characterization of FeCoNiAlCu high-entropy alloy coating by plasma cladding: In comparison with thermodynamic calculation[J] . Surface and Coatings Technology,2017,330:163 − 169. doi: 10.1016/j.surfcoat.2017.09.083 [3] CHENG Y Q, MA E. Atomic-level structure and structure-property relationship in metallic glasses[J] . Progress in Materials Science,2011,56(4):379 − 473. doi: 10.1016/j.pmatsci.2010.12.002 [4] HE J Y, WANG H, HUANG H L, et al. A precipitation-hardened high-entropy alloy with outstanding tensile properties[J] . Acta Materialia,2016,102:187 − 196. doi: 10.1016/j.actamat.2015.08.076 [5] TSAI K Y, TSAI M H, YEH J W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys[J] . Acta Materialia,2013,61(13):4887 − 4897. doi: 10.1016/j.actamat.2013.04.058 [6] 黄灿, 杜翠薇, 代春朵, 等. 高熵合金涂层的研究进展[J] . 表面技术,2019,48(11):15 − 22, 35. [7] DONG Y, LU Y P. Effects of tungsten addition on the microstructure and mechanical properties of near-eutectic AlCoCrFeNi2 high-entropy alloy[J] . Journal of Materials Engineering and Performance,2018,27(1):109 − 115. doi: 10.1007/s11665-017-3096-6 [8] SHA C H, ZHOU Z F, XIE Z H, et al. FeMnNiCoCr-based high entropy alloy coatings: Effect of nitrogen additions on microstructural development, mechanical properties and tribological performance[J] . Applied Surface Science,2020,507:145101. doi: 10.1016/j.apsusc.2019.145101 [9] 王根, 李新梅, 王松臣. 各类高熵合金的研究进展[J] . 功能材料,2019,50(12):12035 − 12040. [10] XIAO M H, SHEN X J, LIU X, et al. Study on properties of 45 carbon steel Ni-P electroless plating reinforced by Si3N4-Al2O3 particle based on response surface method[J] . Journal of Nanoscience and Nanotechnology,2020,20(8):4761 − 4772. doi: 10.1166/jnn.2020.17525 [11] 马明亮, 王青云, 张文军, 等. 添加碳化钽对SPS制备钨块力学性能的影响[J] . 硬质合金,2019,36(3):228 − 234. -

下载:

下载: