Research status of dissimilar welding-brazing of aluminum to copper

-

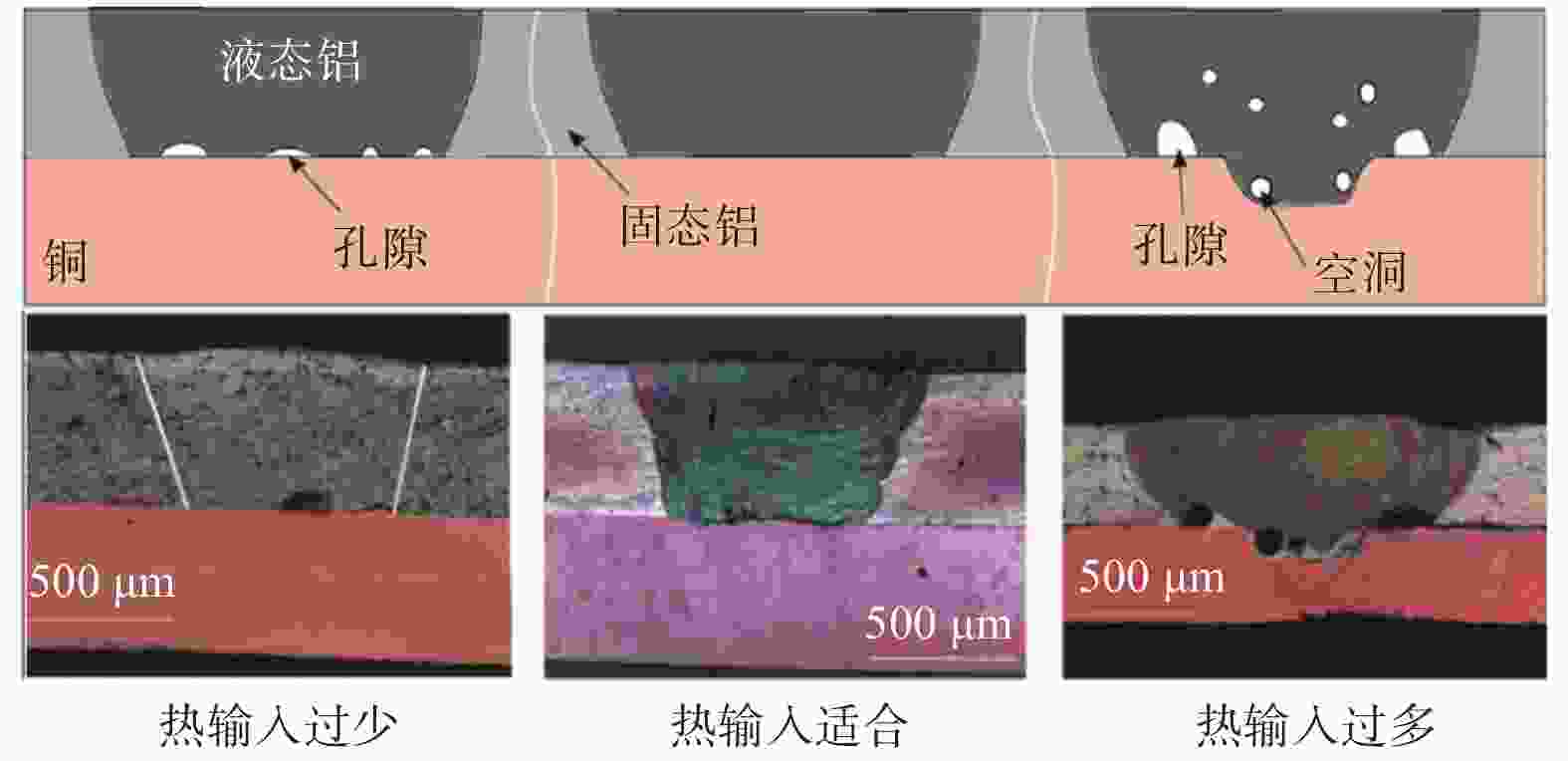

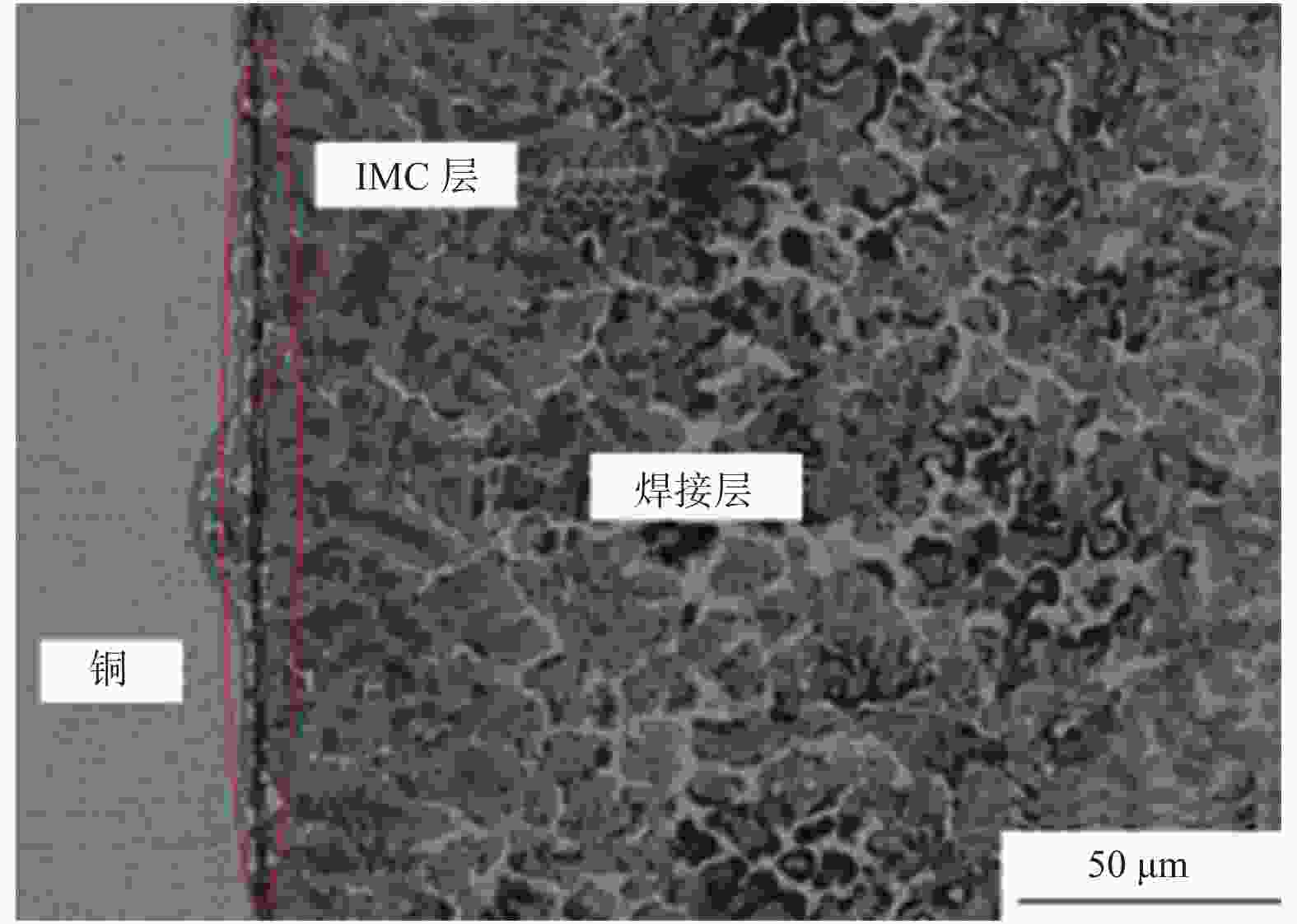

摘要: 由于铝合金和铜异种金属之间的物化性能差异较大,铝合金具有强氧化性等因素,铝/铜异种金属连接是焊接领域的研究难点. 综述近年来铝/铜异种金属熔钎焊的研究现状,介绍了铝合金和铜异种金属的焊接性,评述了铝/铜异种金属电弧和激光熔钎焊的研究进展,讨论了铝/铜异种金属熔钎焊仍然存在的共性问题;通过采用合适的焊接工艺配合合金元素调控是解决铝/钢异种金属熔钎焊问题的关键,并对该领域的研究发展进行展望和评述.Abstract: Due to the great difference in physical and chemical properties between aluminum alloy and copper dissimilar metals, the strong oxidation property of aluminum alloy and other factors, it has become a difficult point in the welding field of dissimilar metals joining. The research status of aluminum/copper dissimilar metal welding-brazing in recent years and weldability of aluminum and copper dissimilar metal were reviewed, common problems of the aluminum/copper dissimilar metal welding-brazing were discussed. Appropriate welding process with adjustment of alloy elements is the key to solve the problem of aluminum/steel dissimilar metal welding and brazing, and the research and development in this field are prospected and reviewed.

-

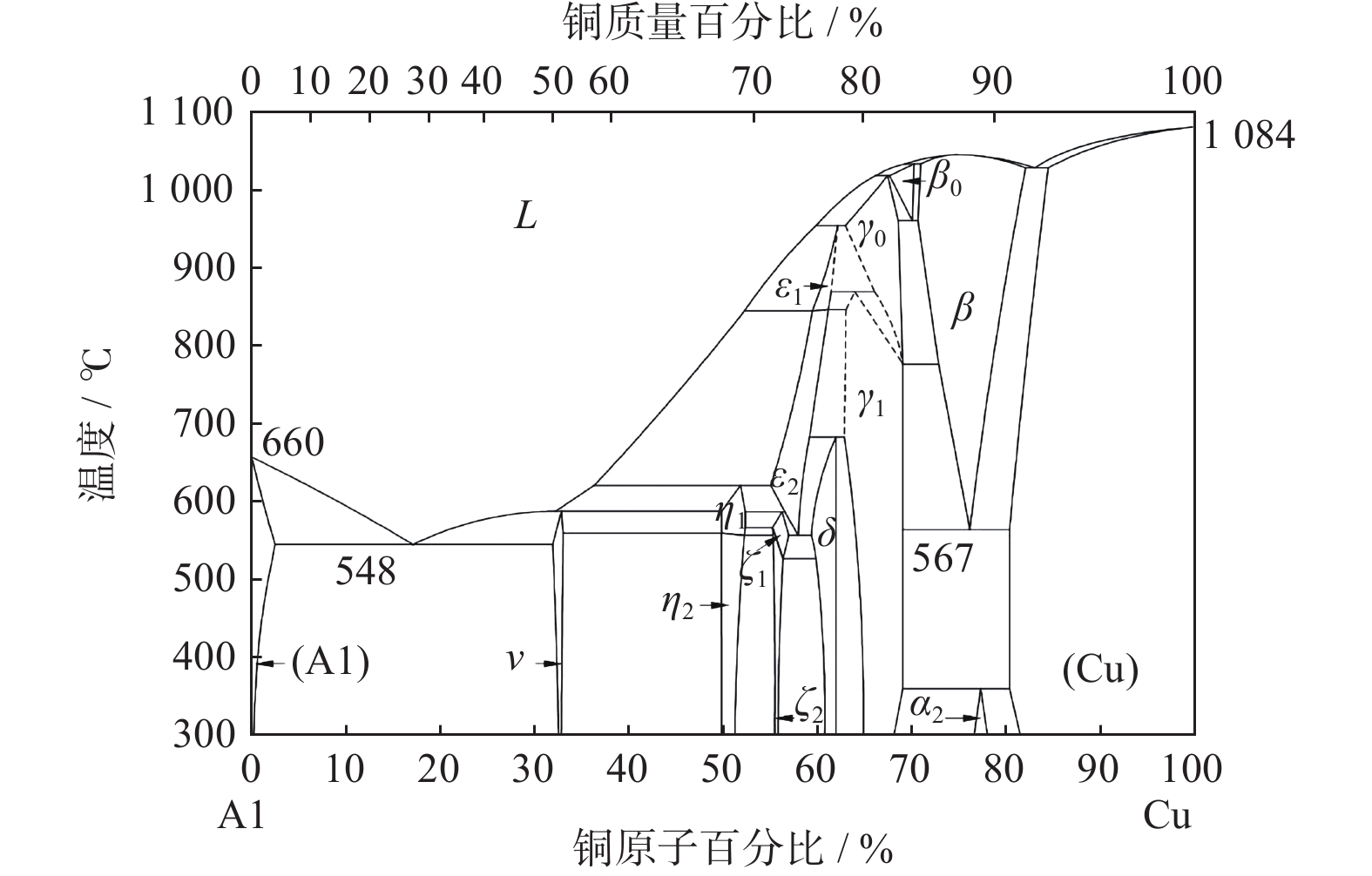

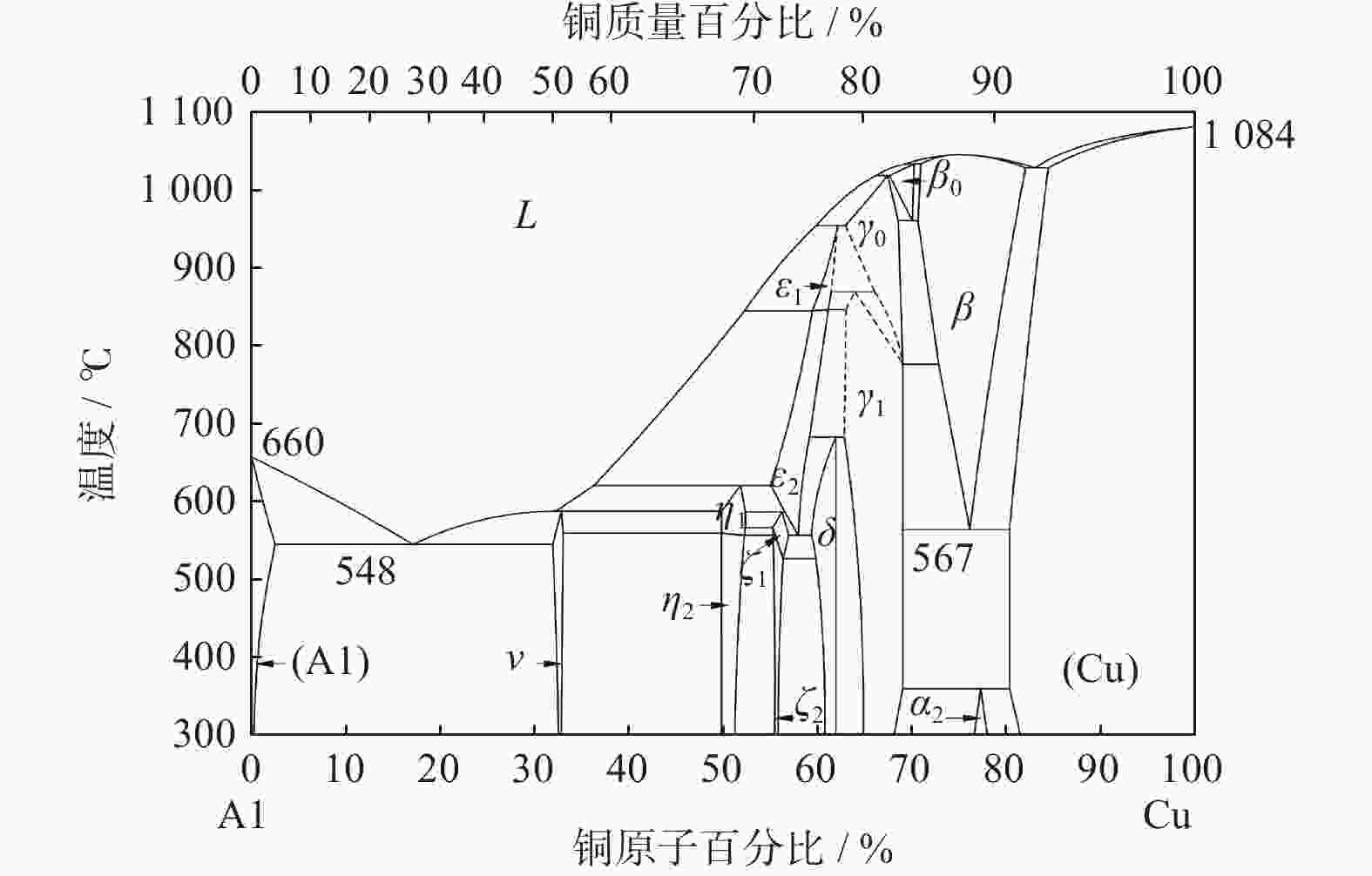

材料 铝 铜 点阵类型 面心立方 面心立方 熔点Tm/ ℃ 660 1084 密度ρ / (g·cm−3) 2.70 8.96 比热容c / (W·m−1·K−1) 917 386 热导率λ / (W·m−1·K−1) 238 397 热膨胀系数q / K−1 2.38×10−6 1.20 电阻率ρ / (Ω·m) 2.65×10−8 1.68 表 2 铝/铜异种金属熔钎焊研究(铝硅焊丝)

Table 2. Study on welding-brazing of aluminum and copper dissimilar metals (Al-Si filler metal)

母材 厚度/mm 焊接工艺 填充金属 焊接参数 接头性能 参考文献 5052铝合金

H62黄铜铜:1 mm

铝:2 mmTIG搭接

(铝上)1.6 mm Al-12%Si

药芯焊丝焊接电流:90~130 A

焊接速度:120 mm / min

送丝速度:80 mm / minIMCs层:CuAl2,Cu9Al4,CuZn

硬度(HV):<100

拉剪强度:0.920 kN

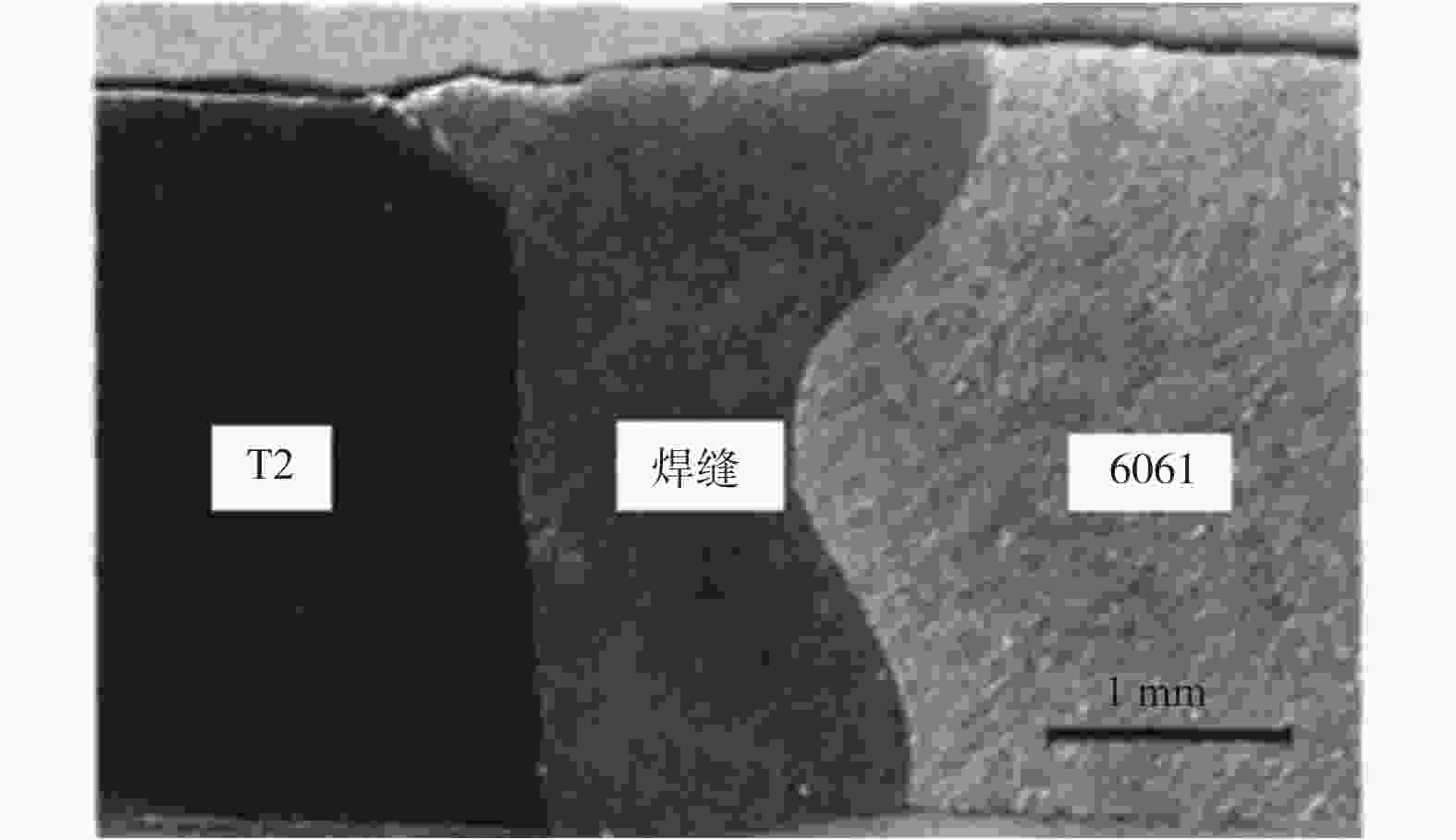

断裂形式:解理断裂[48] 6061铝合金

T2紫铜铜:1 mm

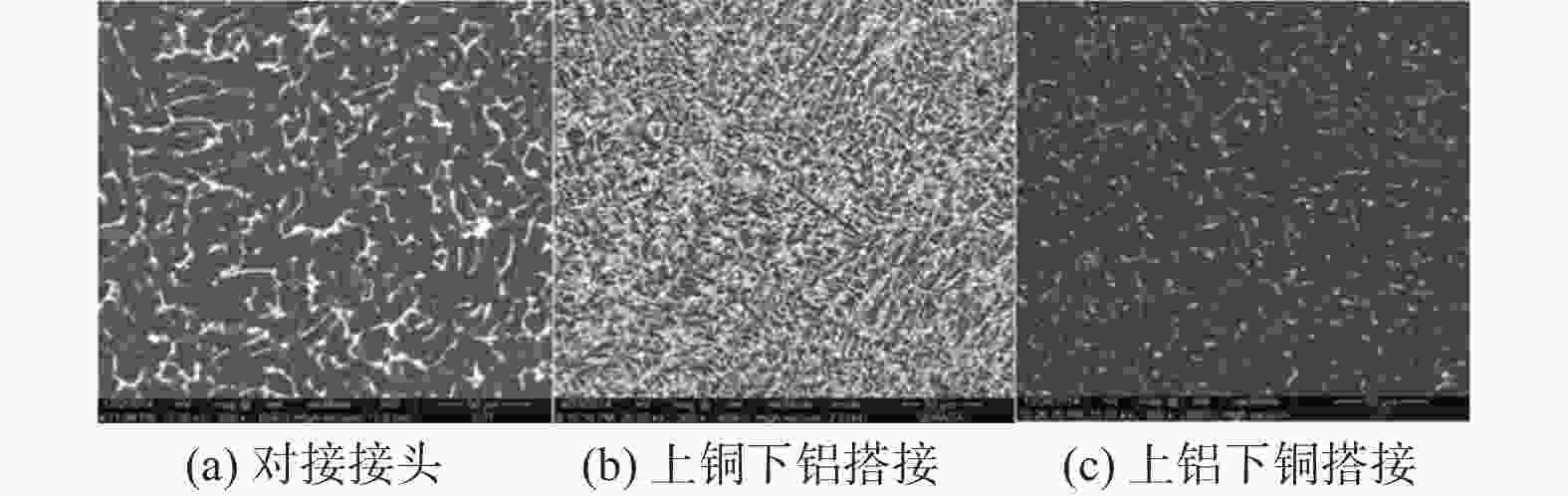

铝:1 mmCMT对接/搭接

(铝上、铜上)1.2 mm ER4043焊丝 焊接速度:6 mm / min

送丝速度:520~590 mm / min(对接)

650~740 mm / min(铜上)

480~600 mm / min(铝上)IMCs层:CuAl,CuAl2,α-Al

拉剪强度:0.88 kN (对接)

154 N / mm (铜上)

195 N / mm(铝上)

断裂形式:解理断裂[52] 1060铝合金

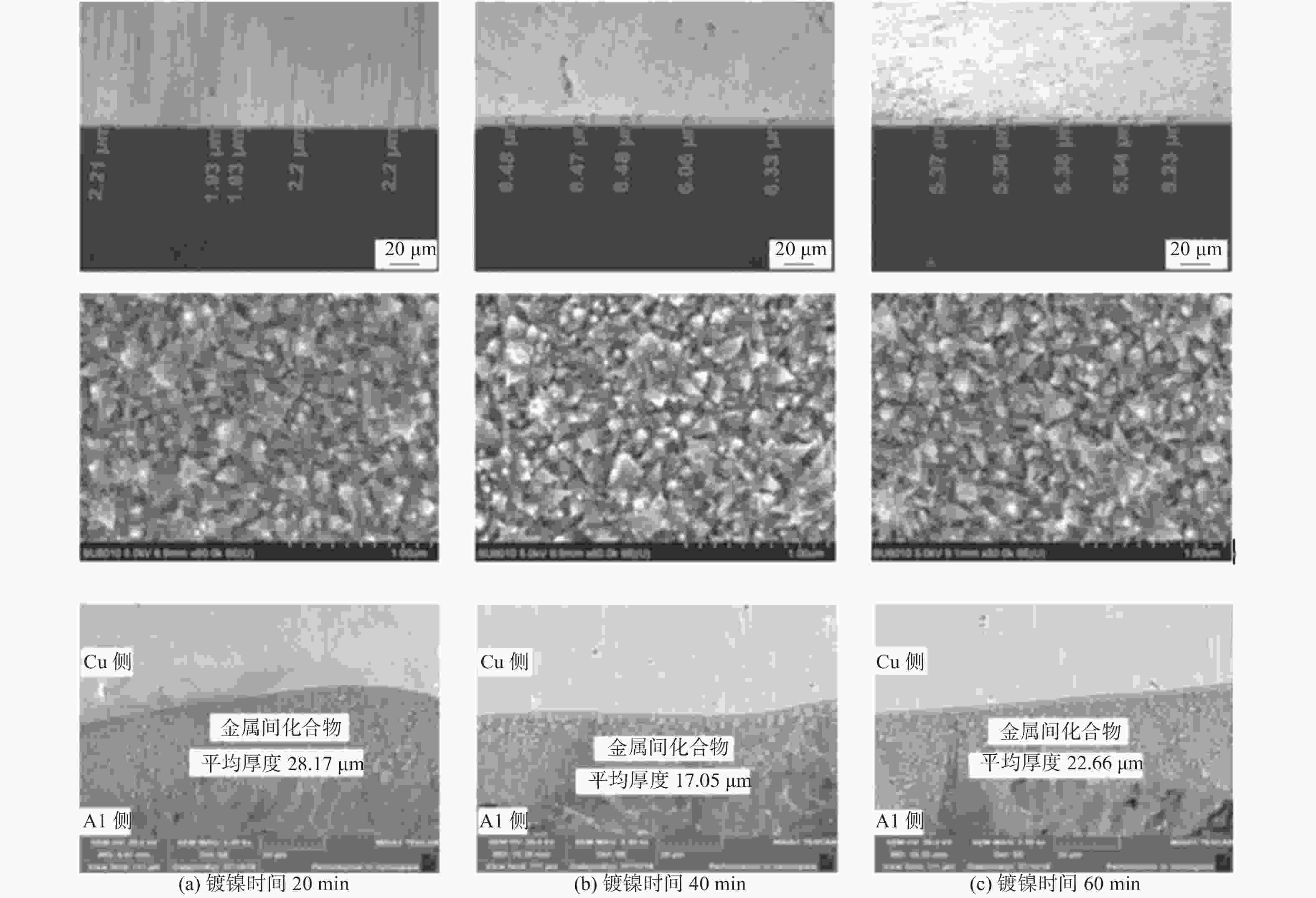

镀镍T2紫铜铜:2 mm

铝:2 mmCMT搭接

(铝上)1.2 mm ER4043焊丝 焊接电流:110 A

焊接电压:13.5 V

焊接速度:750 mm / minIMCs层:Cu3.8Ni,Al3Ni2

拉剪强度:70.77 MPa

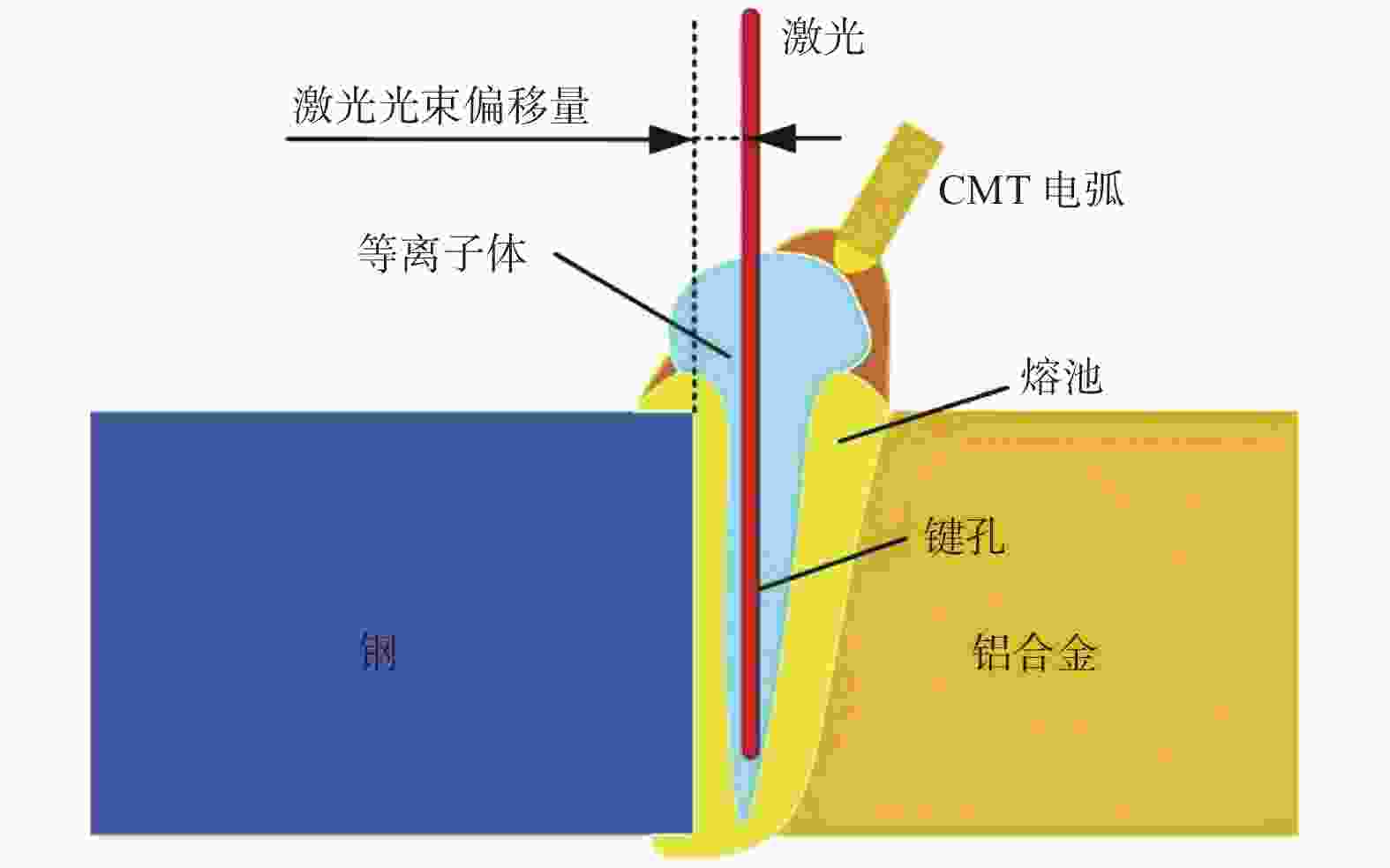

断裂形式:解理断裂[53] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmCMT搭接

(铝上)1.2 mm ER4043焊丝

1.2 mm ER4047焊丝焊接电流:110 A

焊接速度:750 mm / min

纯氩保护气流量:20 L / min

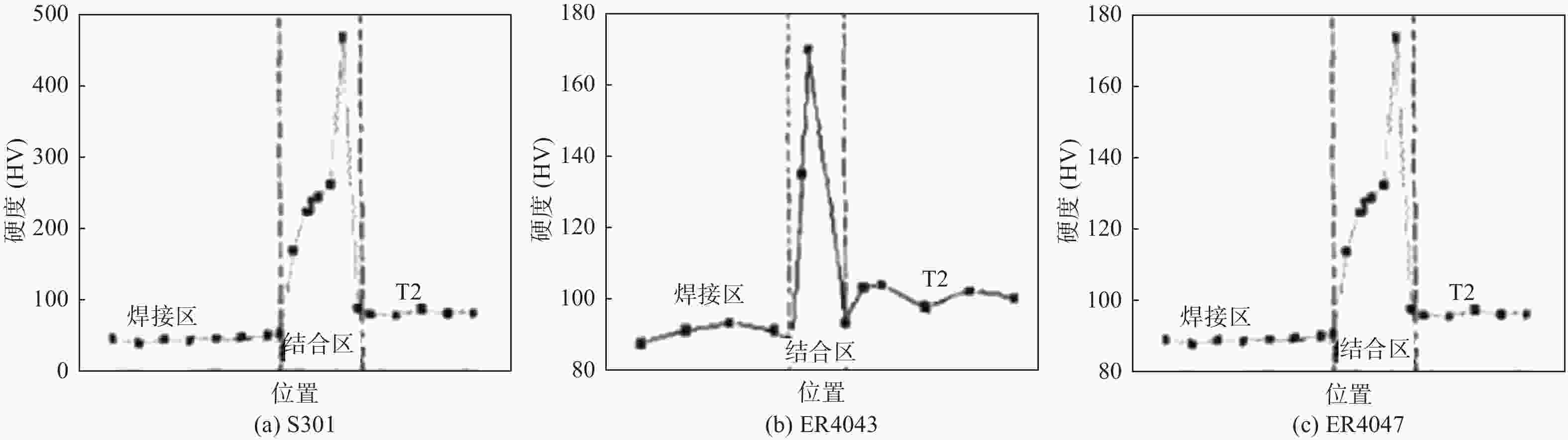

焊枪倾角:45°IMCs层:α-Al,CuAl2

硬度(HV):470 (ER4043)

170~180 (ER4047)[54] 5A06铝合金

T2紫铜铜:1.5 mm

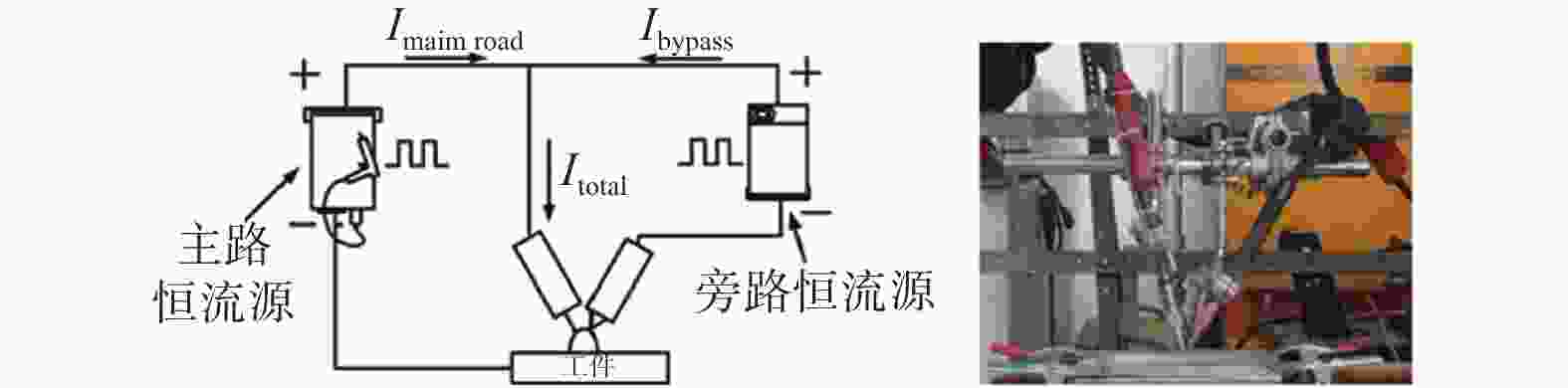

铝:1.5 mmDE-MPAW搭接

(铝上)1.2 mm ER4047焊丝 焊接电流:45 A

旁路电流:0 A

焊接速度:90 mm / min

送丝速度:32 mm / min

离子气流量:0.6 L / minIMCs层:CuAl,CuAl2,Cu9Al4

硬度(HV):436

拉剪强度:0.69 kN

断裂形式:脆性断裂[56] 5052铝合金

T2紫铜铜:2 mm

铝:1 mmDE-GMAW 搭接

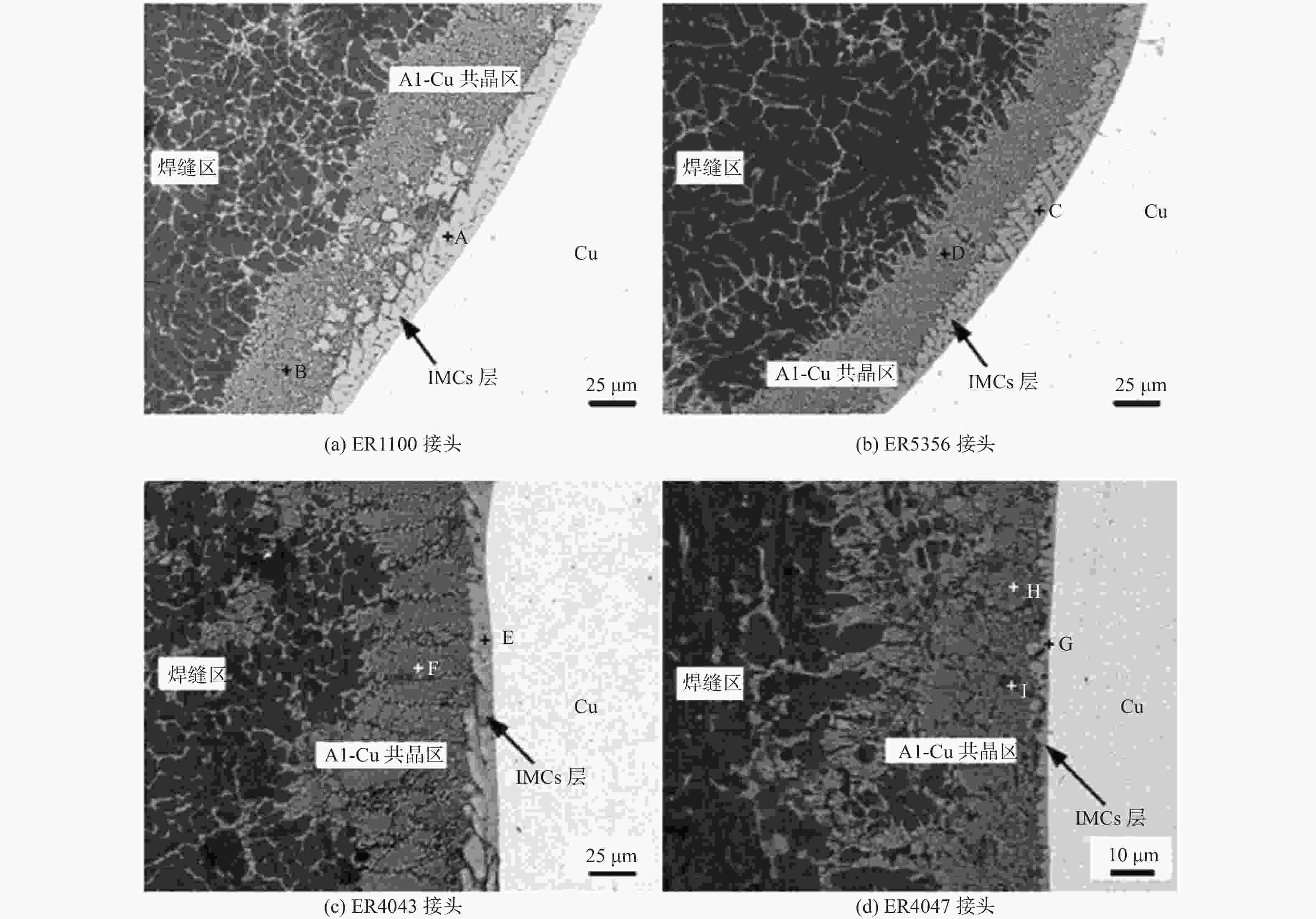

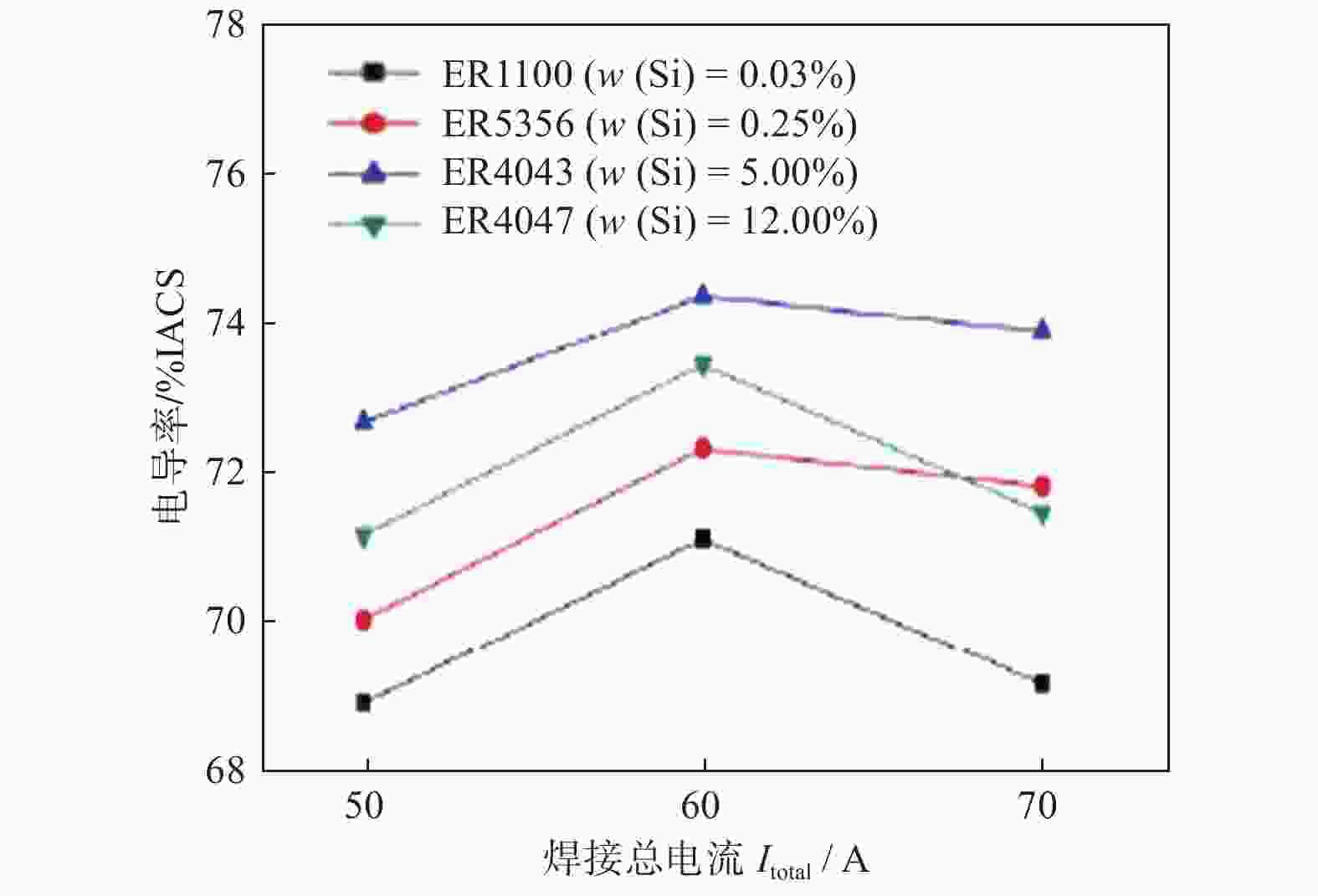

(铝上)1.2 mm ER4047焊丝 焊接电流:15~65 A

旁路电流:25 A

脉冲频率:80 Hz

焊接速度:30 mm / minIIMCs层:CuAl2,α-Al

拉剪强度:168 MPa

断裂形式:解理断裂[57] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmDE-GMAW 搭接

(铝上)1.2 mm ER4043焊丝

1.2 mm ER4047焊丝焊接电流:35 A

旁路电流:25 A

脉冲频率:80 Hz

焊接速度:30 mm / minIMCs层:CuAl2,α-Al,Si相

拉剪强度:

158 MPa (ER4043)

161 MPa (ER4047)

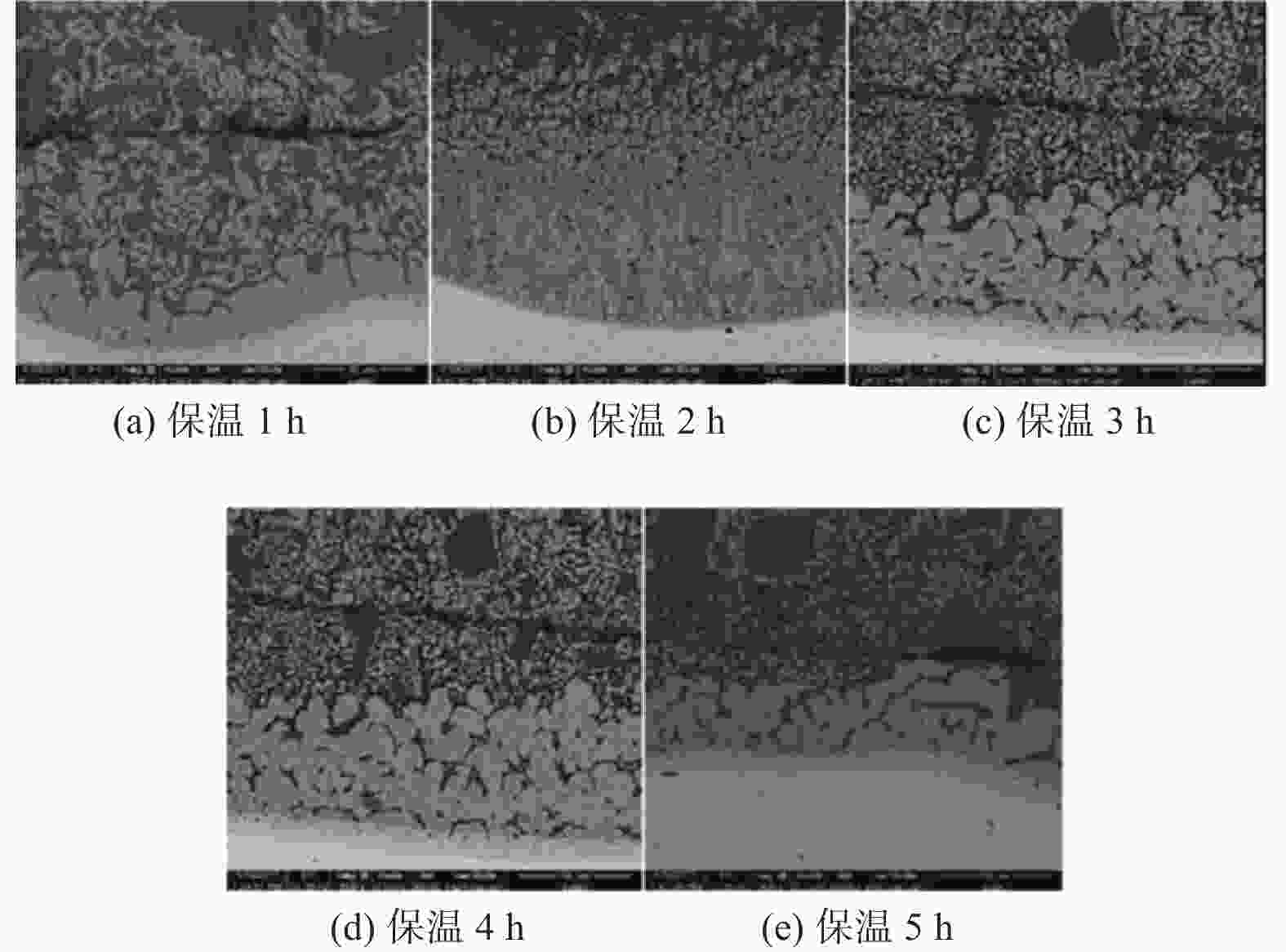

硬度(HV):444[58-60] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmDE-GMAW 搭接

(铝上)1.2 mm ER4043焊丝

1.2 mm ER4047焊丝焊接电流:35 A

旁路电流:25 A

脉冲频率:80 Hz

焊接速度:30 mm / min

IMCs

层:CuAl, Cu4Al3, CuAl2,

Cu3Al2,Cu9Al4[61] 表 3 铝/铜异种金属熔钎焊研究(锌铝焊丝)

Table 3. Study on welding-brazing of aluminum and copper dissimilar metals (Zn-Al filler metal)

母材 厚度/mm 焊接工艺 填充金属 焊接参数 接头性能 参考文献 5052铝合金

H62黄铜铜:1 mm

铝:2 mmTIG搭接

(铝上)1.6 mm Zn-2%Al

药芯焊丝焊接电流:90~130 A

焊接速度:120 mm / min

送丝速度:80 mm / minIMCs层: CuAl2,CuAl,Cu9Al4,CuZn

硬度(HV):270

拉剪强度:1.917 kN

断裂形式:解理断裂[47-48] 纯铜

纯铝铜:2 mm

铝:2 mmTIG搭接

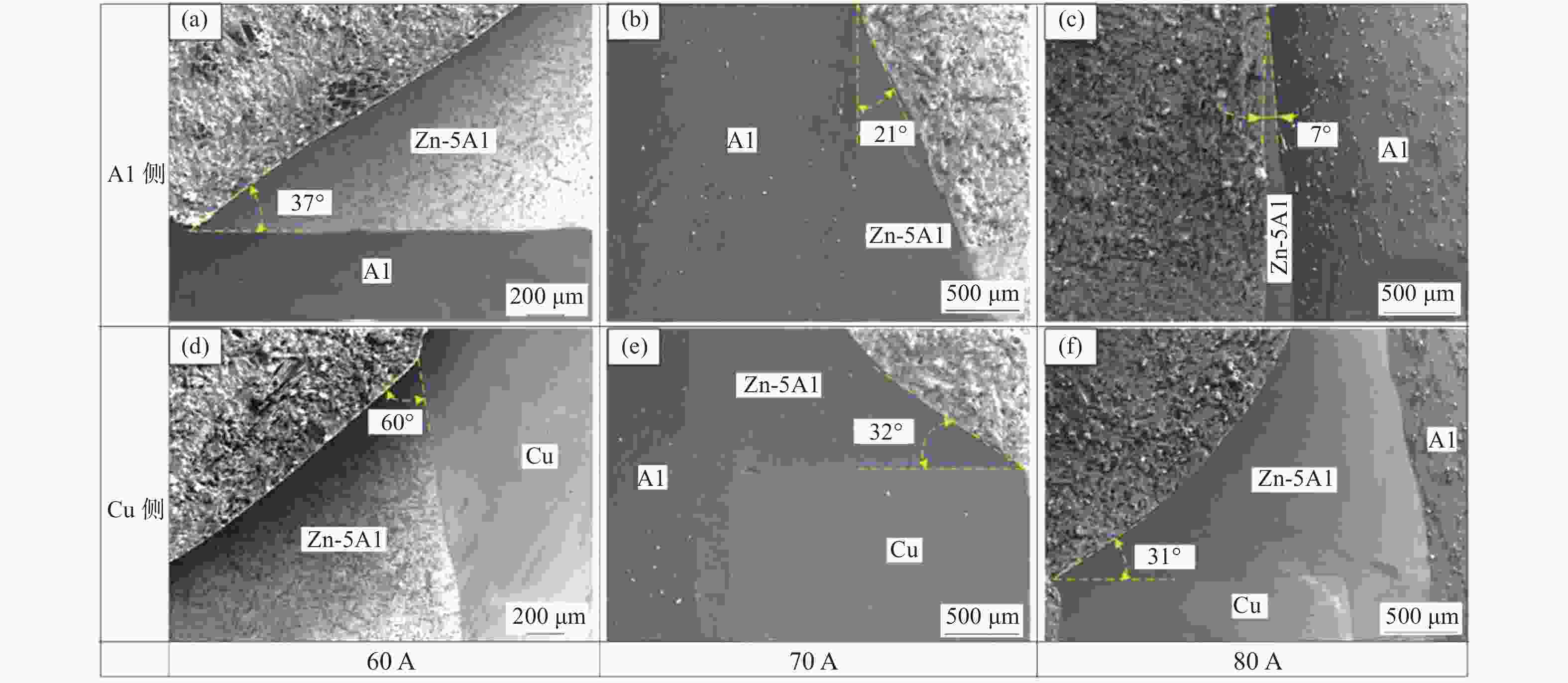

(铝上)2 mm Zn-5%Al

药芯焊丝焊接电流:60~80 A

焊接电压:30 V

焊接速度:150 mm / min

送丝速度:240 mm / minIMCs层:CuAl2

拉剪强度:90 MPa

断裂形式:解理断裂[49] 2A16铝合金

T2紫铜铜:1 mm

铝:1 mmTIG搭接

(铝上)2 mm Zn-5%Al

药芯焊丝焊接电流:60~105 A

焊接速度:35,62,85 mm / minIMCs层:CuZn4,Zn基固溶体,Al基固溶体

拉剪强度:240 MPa

断裂形式:解理断裂[51] LY16铝合金

T2紫铜铜:2 mm

铝:2 mm激光对接 2 mm Zn-5%Al

药芯焊丝激光功率:1800~2600 W

焊接速度:500~1300 mm / minIMCs层:CuAl,CuZn4, α-Al,β-Zn

拉剪强度:274 MPa

断裂形式:解理断裂[66] 表 4 铝/铜异种金属熔钎焊研究(其他填充金属)

Table 4. Study on welding-brazing of aluminum and copper dissimilar metals (other filler metal)

母材 厚度/mm 焊接工艺 填充金属 焊接参数 接头性能 参考文献 1060铝合金

T2紫铜铜:3 mm

铝:3 mm激光搭接

(铝上)无 激光功率:3500 W

焊接速度:2000 mm / min

光斑向铝侧偏移0.4 mmIMCs层: CuAl2,Cu3Al2

拉剪强度:101 MPa

断裂形式:解理断裂[62] 1050A铝合金

SF-Cu紫铜铜:200 μm

铝:210 μm激光搭接

(铝上)无 激光功率:400 W

焊接速度:3 mm / min

焦点直径:31 μm

波长:1070 nm

脉冲时间:32 μs

扫描频率:500 HzIMCs层:CuAl2,Cu9Al4

拉剪强度:121 MPa[63-65] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmDE-GMAW 搭接

(铝上)1.2 mm ER1100焊丝

1.2 mm ER5356焊丝焊接电流:35 A

旁路电流:25 A

脉冲频率:80 Hz

焊接速度:30 mm / min

纯氩保护气流量:20 L / min

旁路纯氩保护气流量:5 L / min

焊枪倾角:45°IMCs层:CuAl2,α-Al

拉剪强度:112 MPa (ER5356)

硬度(HV):444[59-60] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmDE-GMAW 搭接

(铝上)1.2 mm ER1100焊丝 焊接电流:35 A

旁路电流:25 A

脉冲频率:80 Hz

焊接速度:30 mm / min

纯氩保护气流量:20 L / min

旁路纯氩保护气流量:5 L / min

焊枪倾角:45°IMCs层:CuAl,Cu4Al3,

CuAl2,Cu3Al2,Cu9Al4[61] 1060铝合金

T2紫铜铜:1 mm

铝:1 mmCMT搭接(铝上) 1.2 mm ER2319焊丝

1.2 mm AlCu5焊丝焊接电流:80~102 A

焊接速度:900-1500 mm / min

纯氩保护气流量:15 L / min

焊枪倾角:90°IMCs层:α-Al,CuAl,CuAl2,

Cu3Al2,Cu9Al4[55] 1060铝合金

T2紫铜铜:2 mm

铝:2 mmCMT搭接(铝上) 1.2 mm S301焊丝 焊接电流:110 A

焊接速度:750 mm / min

纯氩保护气流量:20 L / min

焊枪倾角:45°IMCs层:α-Al,CuAl2

硬度(HV):470[54] 纯铜

纯铝铜:1 mm

铝:1 mm激光对接 1.6 mm CuSi3焊丝 纯氩保护气流量:5 L / min

波长:1064 nm硬度(HV):800 (0.5 N )

弯曲变形:0.28±0.06 mm[67] 3003铝合金

110紫铜铜:0.54 mm

铝:0.49 mm激光搭接

(铝上)100 μm Sn–Ag–Ti 激光功率:500 W

焦点直径:10 μm

焦距:100 mmIMCs层:CuAl,Cu9Al4,CuAl2

拉剪强度:0.78 kN

断裂形式:解理断裂[68] -

[1] 李冬梅. 大力发展“以铝代铜”[N]. 中国电力报, 2015-03-12(5). [2] 张义. 异种金属焊接技术[M]. 北京: 机械工业出版社, 2016: 261 − 262. [3] MOHANRAJ M, JAYARAJ S, MURALEEDHARAN C. Environment friendly alternatives to halogenated refrigerants: A review[J] . International Journal of Greenhouse Gas Control,2009,3(1):108 − 119. doi: 10.1016/j.ijggc.2008.07.003 [4] 丁全利. 理性看待铜铝替代问题[N]. 中国国土资源报, 2016-03-31(6). [5] 佚名. “以铝代铜”不宜过度推广[J] . 特种铸造及有色合金,2016,36(4):348. [6] 潘龙威. 铝/铜旋转摩擦焊接头界面组织与性能不均匀性研究[D]. 大连: 大连理工大学, 2018. [7] 李亚江. 异种难焊材料的焊接及工程应用[M]. 北京: 化学工业出版社, 2004: 179 − 182. [8] 唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙: 中南大学出版社, 2009: 51. [9] LEE T H, LEE Y J, PARK K T, et al. Controlling Al/Cu composite diffusion layer during hydrostatic extrusion by using colloidal Ag[J] . Journal of Materials Processing Technology,2013,213(3):487 − 494. doi: 10.1016/j.jmatprotec.2012.10.001 [10] 万於辉. 铜/铝搅拌摩擦焊工艺研究[D]. 南昌: 南昌航空大学, 2014. [11] 杨文威. 电缆导体连接的新技术[J] . 高电压技术,2001, 27(S1):16, 18. [12] GANATRA R H, MCKOON T L. Reliability of connections: a comparison of aluminum alloy stranded conductors and electrically equivalent copper conductors[J] . Wire journal international,1998,31(7):112 − 123. [13] KUMAR S, KUMAR S. Multi-response optimization of process parameters for friction stir welding of joining dissimilar Al alloys by gray relation analysis and Taguchi method[J] . Journal of the Brazilian Society of Mechanical Sciences and Engineering,2015,37(2):665 − 674. doi: 10.1007/s40430-014-0195-2 [14] CARVALHO G, GALVÃO I, MENDES R, et al. Friction stir welding and explosive welding of aluminum/copper: Process analysis[J] . Materials and Manufacturing Processes,2019,34(11):1243 − 1250. doi: 10.1080/10426914.2019.1644452 [15] 徐荣正, 张德良, 李慧, 等. 铝/铜异种金属搅拌摩擦焊研究[J] . 热加工工艺,2018,47(11):7 − 10, 16. [16] 陶娟. 铝/铜异种金属搅拌摩擦焊接机理和工艺研究[D]. 南京: 南京理工大学. 2015. [17] 张满. 铝/铜异种材料焊接的研究现状[J] . 热加工工艺,2009,38(9):116 − 119, 122. doi: 10.3969/j.issn.1001-3814.2009.09.037 [18] RZAEV R, CHULARIS A, SMIRNOV V, et al. The influence of the friction stir welding parameters on the formation of welded joint of aluminum and copper alloys[J] . Materials Today: Proceedings,2019,11:534 − 542. doi: 10.1016/j.matpr.2019.01.025 [19] 匡彬彬. 铝/铜异种金属搅拌摩擦钎焊搭接工艺及组织性能[D]. 南京: 南京航空航天大学, 2015. [20] MEHTA K P, BADHEKA V J. A review on dissimilar friction stir welding of copper to aluminum: Process, properties, and variants[J] . Materials and Manufacturing Processes,2016,31(3):233 − 254. doi: 10.1080/10426914.2015.1025971 [21] 庞嘉尧, 杨宏, 程伟, 等. 铜−铝合金搅拌摩擦焊研究进展[J] . 金属加工(热加工),2021(2):53 − 59. [22] 魏艳妮, 李辉, 肖鹏, 等. 铜/铝搅拌摩擦焊工艺及组织研究进展[J] . 热加工工艺,2020,49(1):1 − 5. [23] ARGESI F B, SHAMSIPUR A, MIRSALEHI S E. Dissimilar joining of pure copper to aluminum alloy via friction stir welding[J] . Acta Metallurgica Sinica (English Letters),2018,31(11):1183 − 1196. doi: 10.1007/s40195-018-0741-5 [24] LI G, ZHOU L, ZHOU W, et al. Influence of dwell time on microstructure evolution and mechanical properties of dissimilar friction stir spot welded aluminum-copper metals[J] . Journal of Materials Research and Technology,2019,8(3):2613 − 2624. doi: 10.1016/j.jmrt.2019.02.015 [25] REGENSBURG A, PETZOLDT F, BENSS T, et al. Liquid interlayer formation during friction stir spot welding of aluminum/copper[J] . Welding in the World,2019,63(1):117 − 125. doi: 10.1007/s40194-018-0620-8 [26] 顾子豪. 中间层对铝/铜搅拌摩擦焊接头显微组织与力学性能的影响[D]. 镇江: 江苏科技大学, 2019. [27] 李慧, 张德良, 侯艳喜, 等. 锌夹层对铝–铜搅拌摩擦搭接焊接头的影响[J] . 特种铸造及有色合金,2018,38(5):543 − 547. [28] ANBUKKARASI R, KAILAS S V. Influences of shape of the new interfaces and morphology of the intermetallics on mechanical properties of aluminum AA2024-pure copper joints by friction stir welding[J] . The International Journal of Advanced Manufacturing Technology,2020,106(11):5071 − 5083. [29] 张威. 铝/铜异种金属齿形对接型式的搅拌摩擦焊研究[D]. 南京: 南京航空航天大学, 2018. [30] 雷振, 于宁, 游爱清, 等. 5A02/Q235钢Nd: YAG 激光–脉冲MIG复合热源熔–钎连接[J] . 焊接学报,2008, 29(6):21 − 24, 28. [31] LIU J, JIANG S, SHI Y, et al. Laser fusion-brazing of aluminum alloy to galvanized steel with pure Al filler powder[J] . Optics & Laser Technology,2015,66:1 − 8. [32] CHEN S, LI S, LI Y, et al. Butt welding-brazing of steel to aluminum by hybrid laser-CMT[J] . Journal of Materials Processing Technology,2019,272:163 − 169. doi: 10.1016/j.jmatprotec.2019.05.018 [33] DHARMENDRA C, RAO K P, WILDEN J, et al. Study on laser welding-brazing of zinc coated steel to aluminum alloy with a zinc based filler[J] . Materials Science and Engineering: A,2011,528(3):1497 − 1503. doi: 10.1016/j.msea.2010.10.050 [34] ZHAO X, TAN C, XIAO L, et al. Effect of the Ni coating thickness on laser welding-brazing of Mg/steel[J] . Journal of Alloys and Compounds,2018,769:1042 − 1058. doi: 10.1016/j.jallcom.2018.08.080 [35] CAO R, CHANG J H, HUANG Q, et al. Behaviors and effects of Zn coating on welding-brazing process of Al-Steel and Mg-steel dissimilar metals[J] . Journal of Manufacturing Processes,2018,31:674 − 688. doi: 10.1016/j.jmapro.2018.01.001 [36] TAN C, SONG X, MENG S, et al. Laser welding-brazing of Mg to stainless steel: Joining characteristics, interfacial microstructure, and mechanical properties[J] . The International Journal of Advanced Manufacturing Technology,2016,86(1):203 − 213. [37] ZHAN X, BU H, GAO Q, et al. Temperature field simulation and grain morphology on laser welding-brazing between Ti-6Al-4V and 1050 aluminum alloy[J] . Materials Research Express,2019,6(5):056551. doi: 10.1088/2053-1591/ab061a [38] CHEN S, LI L, CHEN Y, et al. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process[J] . Journal of Alloys and Compounds,2011,509(3):891 − 898. doi: 10.1016/j.jallcom.2010.09.125 [39] XU C. The influence of Al content from filler metals on tungsten inert gas welding-brazing of Mg-Ti[J] . Materials Research Express,2019,6(11):116567. doi: 10.1088/2053-1591/ab4a68 [40] TAN C W, GONG X T, LI L Q, et al. Laser welding-brazing characteristics of dissimilar metals Mg/Ti with Al interlayers[J] . Chinese Journal of Lasers,2015,42(1):0103002 − 0103001. doi: 10.3788/CJL201542.0103002 [41] TAN C, YANG J, ZHAO X, et al. Influence of Ni coating on interfacial reactions and mechanical properties in laser welding-brazing of Mg/Ti butt joint[J] . Journal of Alloys and Compounds,2018,764:186 − 201. doi: 10.1016/j.jallcom.2018.06.039 [42] DONG H, HU W, DUAN Y, et al. Dissimilar metal joining of aluminum alloy to galvanized steel with Al-Si, Al-Cu, Al-Si-Cu and Zn-Al filler wires[J] . Journal of Materials Processing Technology,2012,212(2):458 − 464. doi: 10.1016/j.jmatprotec.2011.10.009 [43] SU Y, HUA X, WU Y. Influence of alloy elements on microstructure and mechanical property of aluminum-steel lap joint made by gas metal arc welding[J] . Journal of Materials Processing Technology,2014,214(4):750 − 755. doi: 10.1016/j.jmatprotec.2013.11.022 [44] SINGH J, ARORA K S, SHUKLA D K. Lap weld-brazing of aluminium to steel using novel cold metal transfer process [J]. Journal of Materials Processing Technology, 2020, 283: 271-284. [45] POURANVARI M, ABBASI M. Dissimilar gas tungsten arc weld-brazing of Al/steel using Al-Si filler metal: Microstructure and strengthening mechanisms[J] . Journal of Alloys and Compounds,2018,749:121 − 127. doi: 10.1016/j.jallcom.2018.03.224 [46] SHI Y, LI J, ZHANG G, et al. Corrosion behavior of aluminum-steel weld-brazing joint[J] . Journal of Materials Engineering and Performance,2016,25(5):1916 − 1923. doi: 10.1007/s11665-016-2020-9 [47] 周利, 李志勇, 赵洪运, 等. 铝/黄铜异种金属TIG熔钎焊接头显微组织与力学性能[J] . 中国有色金属学报,2015(9):2389 − 2395. [48] 谢宇. 铝/铜异种金属TIG熔钎焊工艺及机理研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. [49] 孙建新, 孙震, 徐文凯, 等. TIG钎焊铜–铝异种金属接头的组织和力学性能[J] . 热加工工艺,2018,47(21):66 − 70. [50] 戴常青, 胡德安, 程东海, 等. Zn-Al钎料在紫铜板上的润湿性行为及界面研究[J] . 稀有金属,2020,44(9):905 − 911. [51] 彭迟, 程东海, 陈益平, 等. 铝/铜异种材料填丝钨极氩弧焊对接接头的组织和性能[J] . 中国有色金属学报,2015,25(4):975 − 981. [52] 艾兵权. 铝/铜异种金属冷金属过渡技术焊接性分析[D]. 兰州: 兰州理工大学, 2015. [53] 张璐瑶, 武小娟, 孙焕焕, 等. 镀镍层对铜铝金属间化合物的影响[J] . 沈阳理工大学学报,2019,38(1):20 − 23. [54] 孟凡玲, 吕曜晨, 武小娟, 等. 铝硅焊丝成分对铜铝异种金属CMT焊接接头特征的影响[J] . 材料热处理学报,2016,37(6):95 − 100. [55] FENG J, LIU Y, SUN Q, et al. Microstructures and properties of aluminum-copper lap-welded joints by cold metal transfer technology[J] . Advanced Engineering Materials,2015,17(10):1480 − 1485. doi: 10.1002/adem.201400573 [56] 王梓懿. 铝/铜熔钎焊工艺及其界面机理研究[D]. 兰州: 兰州理工大学, 2018. [57] SHI Y, LIU X, ZHANG Y, et al. Analysis of metal transfer and correlated influences in dual-bypass GMAW of aluminum[J] . Welding Journal,2008,87(9):229 − 236. [58] 石玗, 周相龙, 朱明, 等. 铝/铜异种金属脉冲旁路耦合电弧MIG熔钎焊接头的组织与力学性能[J] . 中国有色金属学报,2017,27(9):1816 − 1822. [59] 周相龙. 铝/铜异种金属连接工艺及性能研究[D]. 兰州: 兰州理工大学, 2017. [60] 许瑾. 铝-铜异种金属熔钎焊工艺及接头性能研究[D]. 兰州: 兰州理工大学, 2015. [61] 马敏敏. 铝−铜异种金属连接接头的组织及导电性研究[D]. 兰州: 兰州理工大学, 2017. [62] 董鹏, 陈凯华, 肖荣诗. 铝−铜异种金属激光深熔钎焊接头力学性能[J] . 中国激光,2011,38(6):129 − 133. [63] SOLCHENBACH T, PLAPPER P. Mechanical characteristics of laser braze-welded aluminium-copper connections[J] . Optics & Laser Technology,2013,54:249 − 256. [64] SOLCHENBACH T, PLAPPER P, CAI W. Electrical performance of laser braze-welded aluminum-copper interconnects[J] . Journal of Manufacturing Processes,2014,16(2):183 − 189. doi: 10.1016/j.jmapro.2013.12.002 [65] SCHMIDT P A, SCHWEIER M, ZAEH M F. Joining of lithium-ion batteries using laser beam welding: Electrical losses of welded aluminum and copper joints[C]//International Congress on Applications of Lasers & Electro-Optics. Orlando: Laser Institute of America, 2012: 915−923. [66] 万秀莲, 王龙, 姚志文, 等. 铝/铜异种金属激光填丝熔钎焊工艺研究[J] . 稀有金属,2019,43(5):494 − 499. [67] WEIGL M, ALBERT F, SCHMIDT M. Enhancing the ductility of laser-welded copper-aluminum connections by using adapted filler materials[J] . Physics Procedia,2011,12:332 − 338. doi: 10.1016/j.phpro.2011.03.141 [68] HAILAT M M, MIAN A, CHAUDHURY Z A, et al. Laser micro-welding of aluminum and copper with and without tin foil alloy[J] . Microsystem Technologies,2012,18(1):103 − 112. doi: 10.1007/s00542-011-1378-8 [69] RIBIC B, PALMER T A, DEBROY T. Problems and issues in laser-arc hybrid welding[J] . International Materials Reviews,2009,54(4):223 − 244. doi: 10.1179/174328009X411163 [70] 耿相英, 何艳玲, 李世春. 固相扩散Cu/Al界面研究[J] . 中国石油大学学报(自然科学版),2006,30(2):78 − 80, 84. -

下载:

下载: