Multi-objective optimization of process parameters of 45 steel laser cladding Ni60 alloy powder

-

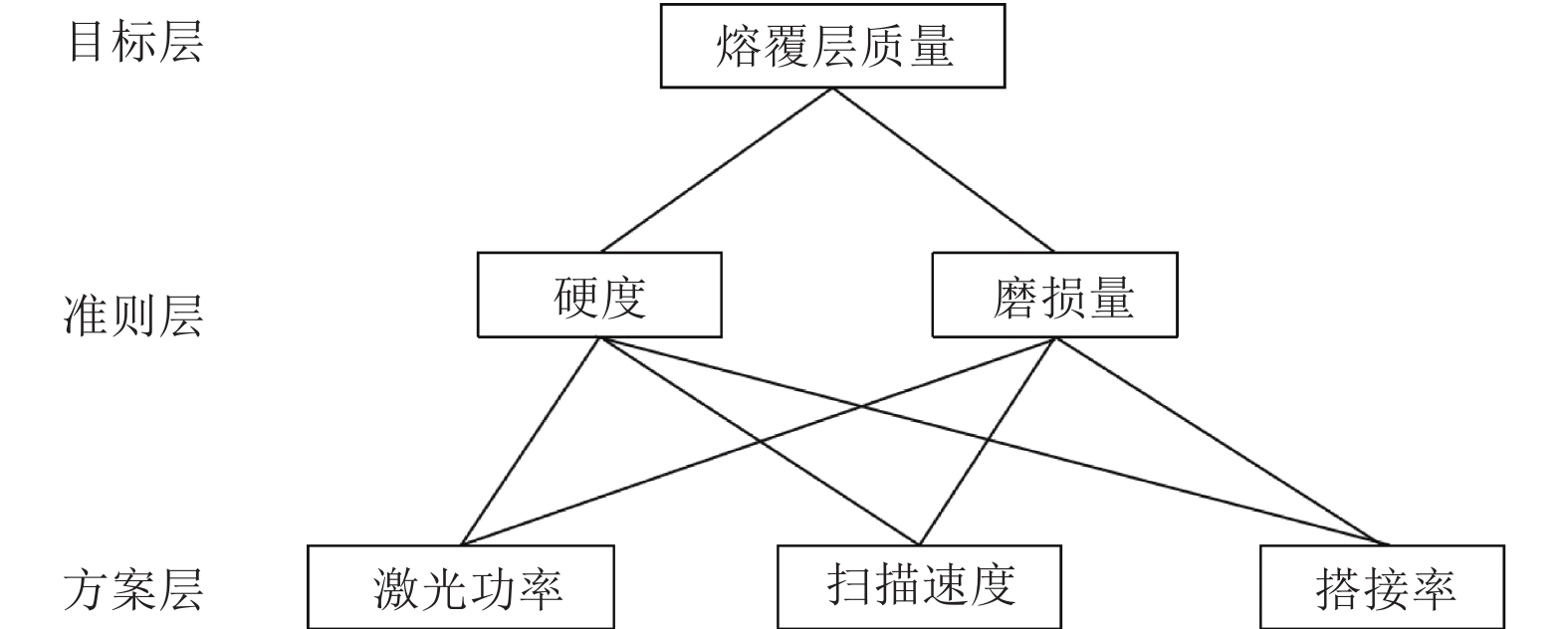

摘要: 为延长零件使用寿命,降低生产成本,在45钢表面激光熔覆Ni60熔覆层可以达到生产要求,避免资源浪费,实现绿色制造. 通过层次分析法确定权重,建立三水平三因素的正交试验,分析熔覆层的宏观和微观形貌、摩擦磨损特性、显微硬度. 结果表明:优化后的工艺参数为激光功率3 kW,扫描速度12 mm/s,搭接率45%. 合适的工艺参数可以使组织晶粒得到细化,避免裂纹和气孔的产生. 优化工艺参数得到的涂层耐磨性更好,摩擦因数比基体低,磨损失重比基体少,磨损机制为磨粒磨损,硬度为基体的3倍.Abstract: In order to extend the service life of the parts and reduce the production costs, the laser cladding of the Ni60 molten coating layer on the 45 steel surface can meet the production requirements, avoid the waste of resources and achieve green manufacturing. The weights were determined by analytic hierarchy process and a three-level, three-factor orthogonal test was established to analyze the macro and micro morphologies, friction wear characteristics and micro hardness of the molten coating layer. The results show that the optimized process parameters are laser power of 3 kW, a scanning speed of 12 mm/s and overlap rate of 45%. The suitable process parameters can refine the tissue grain and avoid the generation of cracks and pores. The coating obtained by optimizing the process parameters has better wear resistance, lower friction coefficient, less wear weight loss than the base, the wear mechanism is abrasive wear and the hardness is three times that of the base.

-

表 1 矩阵标度含义

Table 1. Matrix scale meaning

标度 含义 1 两个因素相比,具有同样重要性 3 两个因素相比,一个因素比另一个因素稍微重要 5 两个因素相比,一个因素比另一个因素明显重要 7 两个因素相比,一个因素比另一个因素强烈重要 9 两个因素相比,一个因素比另一个因素极端重要 2,4,6,8 上述两相邻判断的中值 倒数 因素i与j比较的判断,则因素j与i比较的判断aji=1/aij 表 2 随机一致性指标

${\rm{RI}}$ Table 2. Random consistency index

${\rm{RI}}$ n 1 2 3 4 5 6 7 8 9 10 11 ${\rm{RI}}$ 0 0 0.58 0.90 1.12 1.24 1.32 1.41 1.45 1.49 1.51 表 3 Ni60合金粉末主要化学成分

Table 3. Main chemical composition of Ni60 alloy powder

% C Cr Si B Fe Ni 0.5~1.0 14.0~19.0 3.5~5.0 3.0~4.5 <8.0 余量 表 4 激光熔覆试验工艺参数

Table 4. Process parameters of laser cladding test

试验序号 A1/kW A2/(mm·s−1) A3/% 1 1.5 6 15 2 1.5 9 30 3 1.5 12 45 4 3.0 6 30 5 3.0 9 45 6 3.0 12 15 7 4.5 6 15 8 4.5 9 45 9 4.5 12 30 表 5 正交试验结果

Table 5. Orthogonal test results

试验序号 B1 B2/(10−4×g) 1 538.0 190 2 677.4 194 3 791.4 172 4 774.3 169 5 876.3 179 6 764.4 173 7 441.1 186 8 530.1 179 9 589.0 178 表 6 显微硬度极差分析

Table 6. Range analysis of microhardness range

参数 A1/kW A2/(mm·s−1) A3 均值1 668.933 584.467 604.833 均值2 799.000 694.600 680.233 均值3 520.067 708.933 702.933 极差 278.933 124.466 98.100 表 7 磨损量极差分析

Table 7. Range analysis of wear range

参数 A1/kW A2/(mm·s−1) A3 均值1 185.333 181.667 180.667 均值2 173.667 184.000 180.333 均值3 181.000 174.333 179.000 极差 11.666 9.667 1.667 -

[1] HAZEN B T, BOONE C A, WANG Y C, et al. Perceived quality of remanufactured products: construct and measure development[J] . Journal of Cleaner Production,2017,142:716 − 726. doi: 10.1016/j.jclepro.2016.05.099 [2] 赵凯, 梁旭东, 王炜, 等. 基于NSGA−Ⅱ算法的同轴送粉激光熔覆工艺多目标优化[J] . 中国激光,2020,47(1):96 − 105. [3] 许向川, 温海骏, 王俊元, 等. 基于响应面的装备零件再制造激光熔覆工艺参数优化[J] . 真空科学与技术学报,2018,38(7):615 − 620. [4] 袁修饶. 基于GRNN和NSGA−Ⅱ的激光熔覆工艺参数多目标优化研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. [5] 赵丹丹, 焦锋. 基于灰色关联分析的35CrMoV钢活塞杆激光熔覆工艺参数优化[J] . 兵工学报,2018,39(10):2073 − 2080. doi: 10.3969/j.issn.1000-1093.2018.10.022 [6] 于天彪, 宋博学, 郗文超, 等. 激光熔覆工艺参数对熔覆层形貌的影响及优化[J] . 东北大学学报(自然科学版),2019,40(4):537 − 542. doi: 10.12068/j.issn.1005-3026.2019.04.016 [7] 张军锋, 史耀耀, 蔺小军, 等. 基于灰色关联分析的叶片砂带抛光参数优化[J] . 计算机集成制造系统,2017,23(4):806 − 814. [8] 陆海峰, 潘晨阳, 覃恩伟, 等. 45钢表面激光熔覆WC/Ni基合金复合覆层的组织和性能[J] . 金属热处理,2019,44(12):19 − 25. -

下载:

下载: