Application of glass and glass-ceramics in solid oxide fuel cell

-

摘要: 描述玻璃和微晶玻璃作为固体氧化物燃料电池(Solid Oxide Fuel Cell,SOFC)密封材料的使用要求. 尝试基于SOFC所用的玻璃和微晶玻璃进行分类,介绍基于不同体系的SOFC用密封玻璃(硅酸盐密封、硼硅酸密封、铝硅酸盐密封和硼铝硅酸盐密封),并对玻璃和微晶玻璃在SOFC中的发展趋势进行展望.Abstract: The application requirements of glass and glass-ceramics as solid oxide fuel cell (SOFC) sealing materials were described. An attempt was made to classify the glass and glass-ceramics used in SOFC, and the sealing glasses for SOFC based on different systems (silicate sealing, borosilicate sealing, aluminosilicate sealing and boroalumino-silicate sealing) were introduced. The development trend of glass and glass-ceramics in SOFC was prospected.

-

Key words:

- solid oxide fuel cell (SOFC) /

- glass /

- glass-ceramics /

- sealing /

- thermochemical stability

-

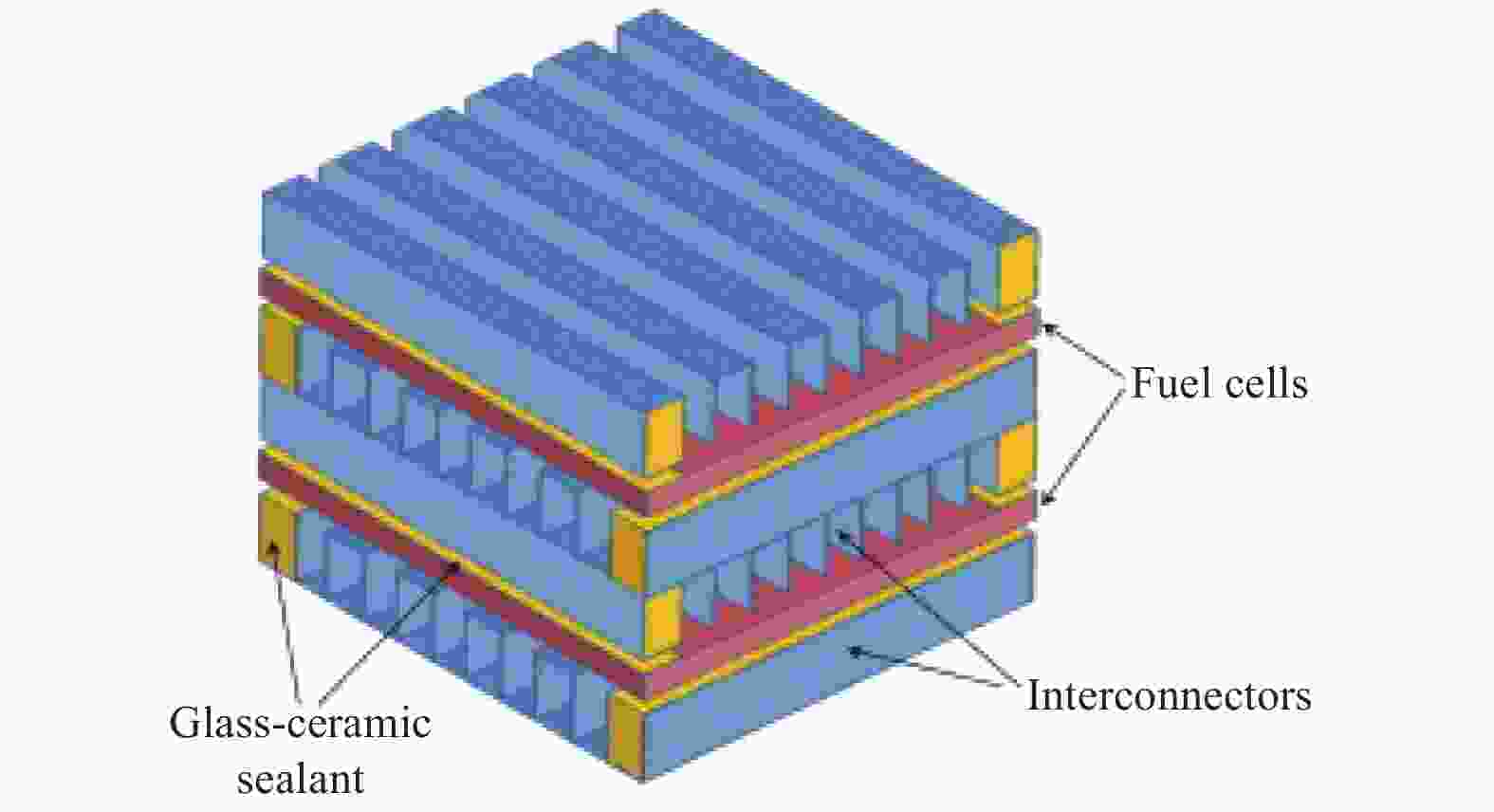

图 1 典型的平板型SOFC密封结构[8]

Figure 1. Typical sealing configurations in planar SOFC

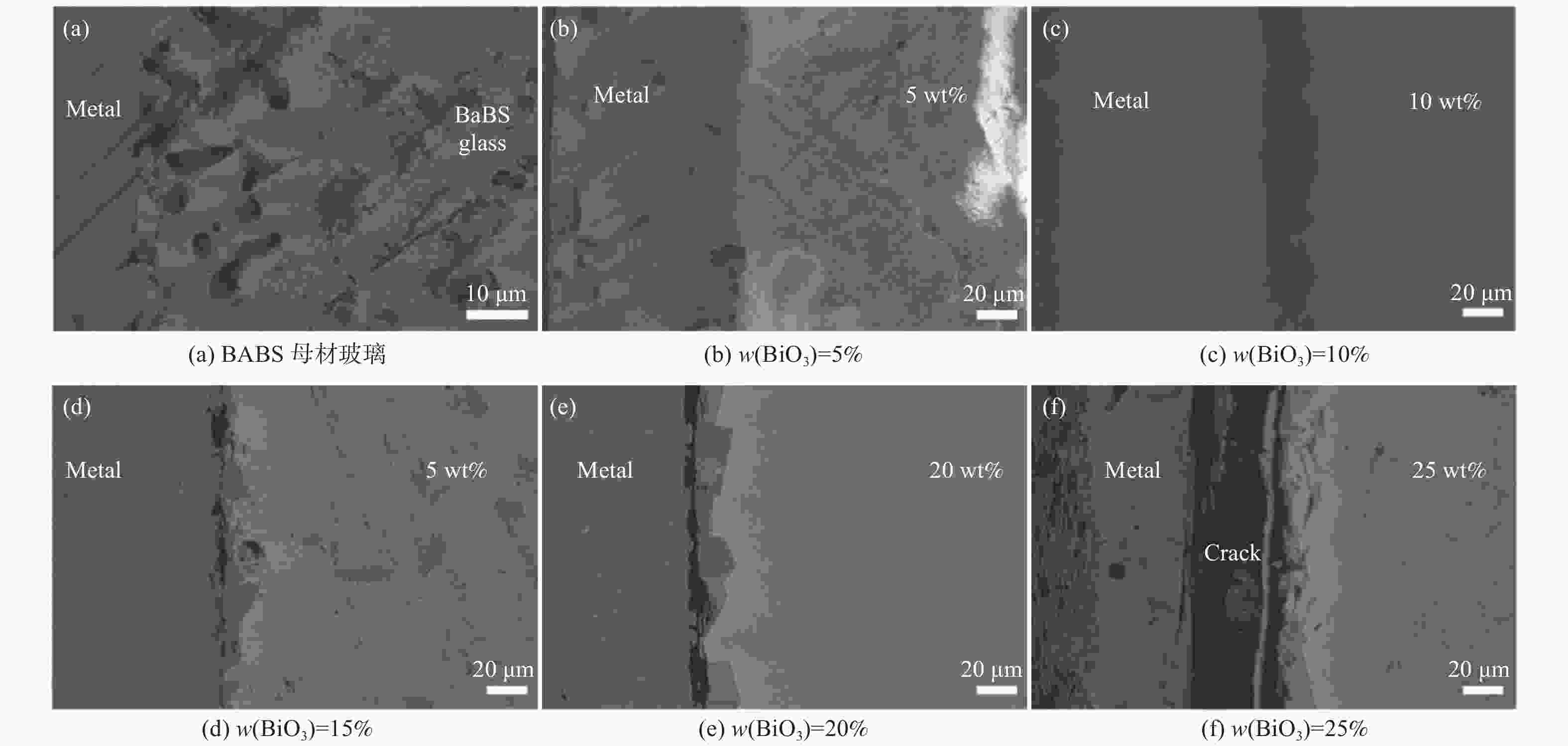

图 2 BABS密封剂与Crofer22APU在800 ℃下保温30 h后的橫截面的SEM[30]

Figure 2. Back scattered electron micrographs of cross-section interfaces between glass-ceramic sealants and SDC electrolyte after crystallization at 800 ℃ for 30 h

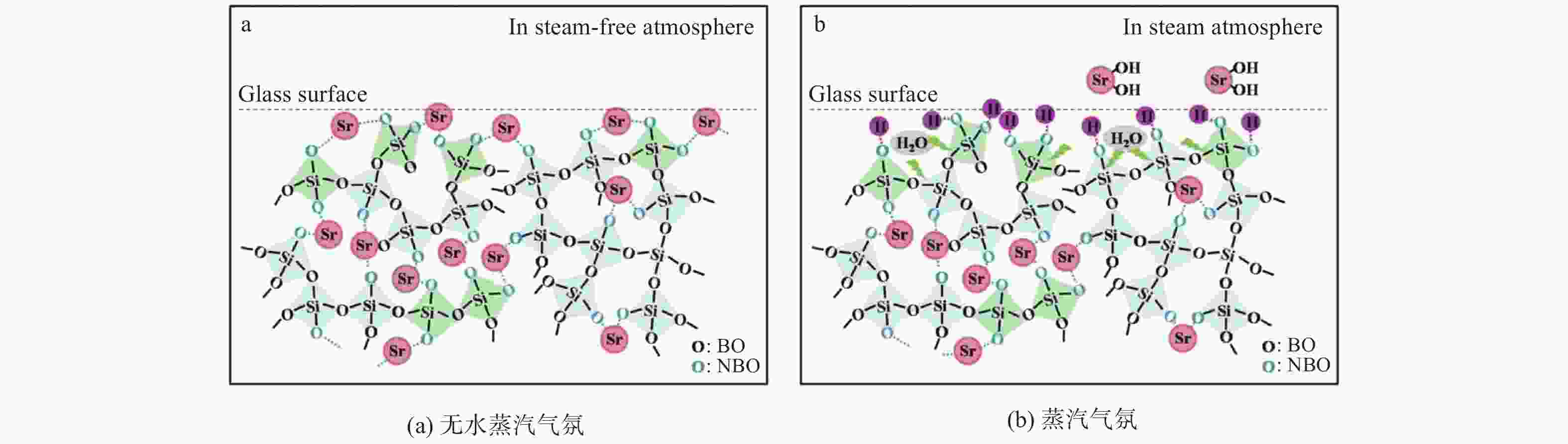

图 3 不同气氛下玻璃网络结构的示意图[33]

Figure 3. Schematic network structure of glasses

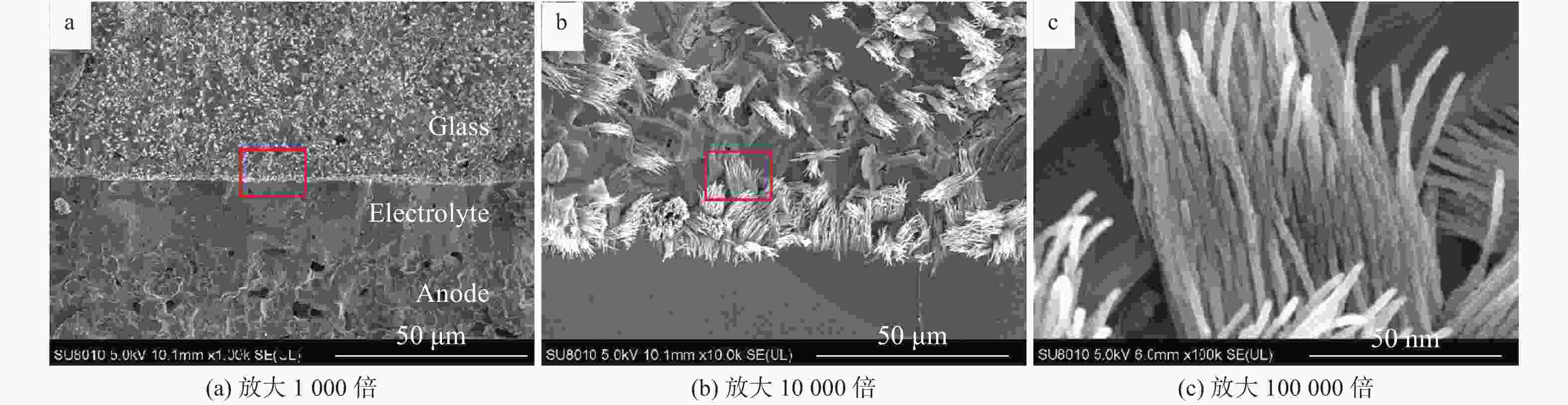

图 4 在800 ℃下密封并在600 ℃下保温100 h后,BCABS玻璃与电解质界面的横截面SEM图像 [34]

Figure 4. Cross-sectional SEM images of interface between BCABS glass and electrolyte after sealing at 800 ℃ and keeping warm at 600 ℃ for 100 h

-

[1] MANDEEP S, DARIO Z, ELISABETTA C. Solid oxide fuel cell: Decade of progress, future perspectives and challenges[J] . International Journal of Hydrogen Energy,2021,46(54):27643 − 27674. [2] HADI N H, SOMALU M R, SAMAT A A, et al. A review on the preparation of anode materials and anode films for solid oxide fuel cell applications[J] . International Journal of Energy Research,2021,45(10):14357 − 14388. doi: 10.1002/er.6763 [3] ZHANG X B, JIN Y M, LI D, et al. A review on recent advances in micro-tubular solid oxide fuel cells[J] . Journal of Power Sources,2021,506:230135. [4] YU F Y, HAN T T, WANG Z G, et al. Recent progress in direct carbon solid oxide fuel cell: Advanced anode catalysts, diversified carbon fuels, and heat management[J] . International Journal of Hydrogen Energy,2021,46(5):4283 − 4300. doi: 10.1016/j.ijhydene.2020.10.259 [5] SU H R, HU Y H. Progress in low-temperature solid oxide fuel cells with hydrocarbon fuels[J] . Chemical Engineering Journal,2020,402:126235. doi: 10.1016/j.cej.2020.126235 [6] JULIA S, GRAEME W W. Computational modelling of solid oxide fuel cells[J] . Current Opinion in Electrochemistry,2020,21:14 − 21. doi: 10.1016/j.coelec.2019.12.007 [7] MAHMUD L S, MUCHTAR A, SOMALUA M R. Challenges in fabricating planar solid oxide fuel cells: A review[J] . Renewable and Sustainable Energy,2017,72:105 − 116. doi: 10.1016/j.rser.2017.01.019 [8] DILSHAT U, TULYAGANOV, ALLU A R, et al. Aluminosilicate-based sealants for SOFCs and other electrochemical applications: A brief review[J] . Journal of Power Sources,2013,242:486 − 502. doi: 10.1016/j.jpowsour.2013.05.099 [9] WANG S F, LU H C, LIU Y X, et al. Characteristics of glass sealants forintermediate-temperature solid oxide fuel cell applications[J] . Ceramics International,2017,43(1):S613 − S620. [10] YUTO W, YUYA T, HIRONORI N, et al. Visualization and mechanical strength of glass seal in planar type solid oxide fuel cells[J] . International Journal of Hydrogen Energy,2020,45(41):21754 − 21766. doi: 10.1016/j.ijhydene.2020.05.153 [11] LUO L H, LIN Y C, HUANG Z Z, et al. Application of BaO-CaO-Al2O3-B2O3-SiO2 glass-ceramic seals in large size planar IT-SOFC[J] . Ceramics International,2015,41(8):9239 − 9243. doi: 10.1016/j.ceramint.2015.01.091 [12] MAHAPATRA M K, LU K. Glass-based seals for solid oxide fuel and electrolyzer cells: A review[J] . Materials Science and Engineering R,2009,67(5-6):65 − 85. [13] HEYDARI F, MAGHSOUDIPOUR A, HAMNABARD Z, et al. Evaluation on properties of CaO-BaO-B2O3-Al2O3-SiO2 glassceramic sealants for intermediate temperature solid oxide fuel cells[J] . Journal of Materials Science and Technology,2013,29(1):49 − 54. doi: 10.1016/j.jmst.2012.11.011 [14] GARAI M, SINGH S P, KARMAKAR B. Mica (KMg3AlSi3O10F2) based glass-ceramic composite sealant with thermal stability for SOFC application[J] . International Journal of Hydrogen Energy,2021,46(45):23480 − 23488. doi: 10.1016/j.ijhydene.2020.10.252 [15] YEONG-SHYUNG C, STEVENSON J W. Long-term thermal cycling of Phlogopite mica-based compressive seals for solid oxide fuel cells[J] . Journal of Power Sources,2005,140(2):340 − 345. doi: 10.1016/j.jpowsour.2004.08.030 [16] WANG X C, ZHANG W, LI R Z, et al. Development of a novel compressive h-BN based seal for planar intermediate temperature SOFC[J] . Ceramics International,2018,44(6):6272 − 6277. doi: 10.1016/j.ceramint.2018.01.015 [17] SUN Z, ZHANG L X, LI X, et al. Reactive air brazing of the YSZ/AISI 310s couples using a novel Ag-Nb2O5 sealant[J] . Ceramics International,2020,46(4):5168 − 5174. doi: 10.1016/j.ceramint.2019.10.262 [18] WANG Z Q, LI C, SI X Q, et al. Brazing YSZ ceramics by a novel SiO2 nanoparticles modified Ag filler[J] . Ceramics International,2020,46(10):16493 − 16501. doi: 10.1016/j.ceramint.2020.03.214 [19] BORHAN A I, GROMADA M, NEDELCU G G, et al. Influence of (CoO, CaO, B2O3) additives on thermal and dielectric properties of BaO-Al2O3-SiO2 glass-ceramic sealant for OTM applications[J] . Ceramics International,2016,42(8):10459 − 10468. doi: 10.1016/j.ceramint.2016.03.199 [20] ELSAYED H, JAVED H, SABATO A G, et al. Novel glass-ceramic SOFC sealants from glass powders and a reactive silicone binder[J] . Journal of the European Ceramic Society,2018,38(12):4245 − 4251. doi: 10.1016/j.jeurceramsoc.2018.05.024 [21] LUO Z, LEI W, LIANG H, et al. Improving sealing properties of CaO-SrO-Al2O3-SiO2 glass and glass-ceramics for solid oxide fuel cells: Effect of La2O3 addition[J] . Ceramics International,2020,46(11):17698 − 17706. doi: 10.1016/j.ceramint.2020.04.074 [22] YEONG S C, STEVENSON J W, SINGH P. Thermal cycle stability of a novel glass-mica composite seal for solid oxide fuel cells: Effect of glass volume fraction and stresses[J] . Journal of Power Sources,2005,152:168 − 174. doi: 10.1016/j.jpowsour.2005.03.213 [23] GARAI M, KARMAKAR B. Zr+4-controlled nucleation and microstructure in Si-Mg-Al-K-B-F glass-ceramic sealant (solid oxide fuel cell)[J] . Materialstoday Energy,2020,18:100535. [24] LI R Z, LIANG X P, WANG X C, et al. Improvement of sealing performance for Al2O3 fiber-reinforced compressive seals for intermediate temperature solid oxide fuel cell[J] . Ceramics International,2019,45(17):21953 − 21959. doi: 10.1016/j.ceramint.2019.07.209 [25] WU Z, HU R, ZHANG T B, et al. Moisture induced environmental embrittlement of a high Nb containing TiAl alloy[J] . Materials Science and Engineering:A,2017,701:214 − 220. doi: 10.1016/j.msea.2017.06.064 [26] PASCUAL M J, GUILLET A, DURÁN A. Optimization of glass-ceramic sealant compositions in the system MgO–BaO–SiO2 for solid oxide fuel cells (SOFC)[J] . Journal of Power Sources,2007,169(1):40 − 46. doi: 10.1016/j.jpowsour.2007.01.040 [27] CHRISTIAN T, CHRISTIAN R. High thermal expansion of crystallized glasses in the system BaO-ZnO-NiO-SiO2[J] . Ceramics International,2015,41(10):13310 − 13319. doi: 10.1016/j.ceramint.2015.07.114 [28] RODRÍGUEZ-LÓPEZ S, HAANAPPEL V A C, DURÁN A, et al. Glass-ceramic seals in the system MgO-BaO-B2O3-SiO2 operating under simulated SOFC conditions[J] . International Journal of Hydrogen Energy,2016,41(34):15335 − 15345. doi: 10.1016/j.ijhydene.2016.07.051 [29] SILVA L D, RODRIGUES A M, RODRIGUES A C M, et al. Sintering and crystallization of SrO-CaO-B2O3-SiO2 glass-ceramics with different TiO2 contents[J] . Journal of Non-Crystalline Solids,2017,473:33 − 40. doi: 10.1016/j.jnoncrysol.2017.07.021 [30] AYAWANNA J, KINGNOIA N, LAORODPHAN N. Effect of bismuth oxide on crystallization and sealing behavior of barium borosilicate glass sealant for SOFCs[J] . Journal of Non-Crystalline Solids,2019,509:48 − 53. doi: 10.1016/j.jnoncrysol.2019.01.028 [31] SASWATI G A, SHARMA D, KUNDU P, et al. Development and characterizations of BaO-CaO-Al2O3-SiO2 glass-ceramic sealants for intermediate temperature solid oxide fuel cell application[J] . Journal of Non-Crystalline Solids,2008,354(34):4081 − 4088. doi: 10.1016/j.jnoncrysol.2008.05.036 [32] KRAINOVA D A, SAETOVAA N S, KUZMINA A V, et al. Non-crystallising glass sealants for SOFC: Effect of Y2O3 addition[J] . Ceramics International,2020,46(4):5193 − 5200. doi: 10.1016/j.ceramint.2019.10.266 [33] WANG X L, OU D R, ZHAO Z, et al. Stability of SrO-La2O3-Al2O3-SiO2 glass sealants in high-temperature air and steam[J] . Ceramics International,2016,42(6):7514 − 7523. doi: 10.1016/j.ceramint.2016.01.158 [34] LIU L G, LUO L H, QIN Y, et al. Study on non-isothermal crystallization kinetics of the BaO-CaO-Al2O3-B2O3-SiO2 glass for IT-SOFCs sealing[J] . Ceramics International,2018,44(17):21277 − 21283. doi: 10.1016/j.ceramint.2018.08.176 [35] KUMAR V, KAUR G, LU K, et al. Interfacial compatibility of alumino-borosilicate glass sealants with AISI 441 and YSZ for different atmospheres[J] . International Journal of Hydrogen Energy,2015,40(2):1195 − 1202. doi: 10.1016/j.ijhydene.2014.11.037 [36] REN M Y, YANG P, XU J, et al. Effect of nickel doping on structure and suppressing boron volatility of borosilicate glass sealants in solid oxide fuel cells[J] . Journal of the European Ceramic Society,2019,39(6):2179 − 2185. doi: 10.1016/j.jeurceramsoc.2019.01.034 -

下载:

下载: