Study on relaxation rule of over temperature creep stress in superheater tube of ultra-supercritical boiler

-

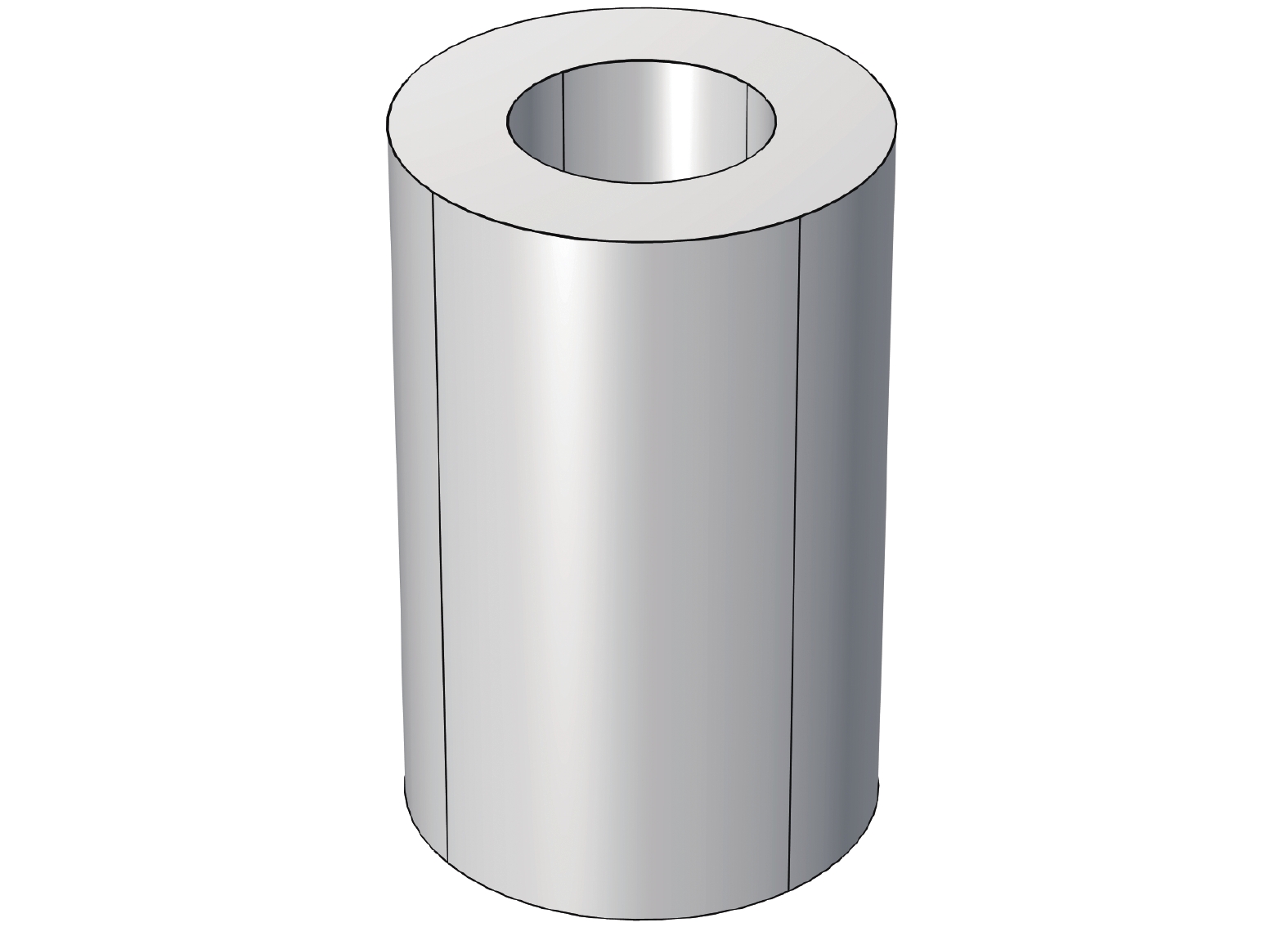

摘要: 超超临界锅炉高温过热器集箱出口区域的过热器管易处于超温运行的环境,产生蠕变应力松弛导致材料失效. 基于Norton蠕变模型,以烟气温度750℃、蒸汽温度600℃、蒸汽压力26 MPa的运行工况,模拟T91过热器管壁在长时间热诱导中产生的应力松弛行为及蠕变分布. 模拟结果显示,过热管应力松弛现象首先发生在管内壁面,随着时间累计沿着径向方向扩散;10000 h后内壁面出现应力松弛且松弛加速;同时管壁面在应力松弛的过程中发生高温蠕变行为,且蠕变行为首先出现在内壁面并沿着径向扩散,内壁面蠕变程度高于外壁面;10000 h后管壁面厚度开始减薄. 研究结果表明:超超临界锅炉过热器管超温运行10000 h是蠕变应力松弛到蠕变损伤的时间拐点.Abstract: The superheater tube in the outlet area of the high-temperature superheater box of ultra-supercritical boiler is easy to be exposed to overtemperature environment, resulting in creep stress relaxation and material failure. Based on Norton creep model, the stress relaxation behavior and creep distribution of T91 superheater tube wall during long-term thermal induction were simulated under the operating conditions of flue gas temperature of 750℃, steam temperature of 600℃ and steam pressure of 26 MPa. The simulation results show that stress relaxation phenomenon of the heat pipe firstly occurs on the inner wall and spreads along the radial direction with time accumulation. After 10000 h, the inner wall surface appears stress relaxation and relaxation accelerates. At the same time, high temperature creep behavior also occurs on the tube wall during the stress relaxation process, and the creep behavior firstly appears on the inner wall and spreads along the radial direction, and the creep degree of the inner wall is higher than that of the outer wall. After 10000 h, the thickness of pipe wall begins to decrease. The results show that the overtemperature operation of superheater tube of ultra-supercritical boiler for 10000 h is the time point from creep stress relaxation to creep damage.

-

Key words:

- ultra-supercritical boiler /

- superheater tube /

- creep /

- stress relaxation /

- time point

-

表 1 T91物性参数

Table 1. Physical parameters of T91

参数 温度/℃ 500 600 700 导热系数/(W·m−1·K−1) 29 29 29 线膨胀系数/K−1 1.21×10−5 1.24×10−5 1.26×10−5 比热容/

(J·kg−1·K−1)630 800 860 密度/(kg·m−3) 7770 7770 7770 弹性模量/GPa 181 168 165 泊松比 0.3 0.3 0.3 屈服强度/MPa 410 326 158 表 2 烟气与蒸汽物理参数

Table 2. Physical parameters of flue gas and steam

蒸汽压力/

MPa蒸汽温度/

℃烟气温度/

℃蒸汽换热系数/

(W·m−2·℃−1)烟气换热系数/

(W·m−2·℃−1)26 600 750 2053.65 123.51 表 3 网格统计

Table 3. Grid statistics

最小尺

寸/mm平均尺

寸/mm四面体

数量/个三角形

数量/个顶点数

量/个边单元

数量/个网格顶点

数量/个0.1953 0.6586 101952 10172 16 496 19563 表 4 T91钢蠕变参数

Table 4. Creep parameters of T91 steel

参数 温度/℃ 600 620 625 n 16.36 14.25 7.70 B 1.259×10−40 7.409×10−35 3.786×10−19 表 5 T91过热器管壁面不同径向位置仿真与试验等效应力

Table 5. Simulation and experimental equivalent stress of T91 superheater tube wall at different radial positions

过热器管壁径向位置/mm 10.1 14.5 19.0 10 h后应力仿真结果/MPa 62.3 30.1 18.2 10 h后应力试验值/MPa 63.5 30.9 19.0 104 h后应力仿真结果/MPa 58.7 31.2 18.2 104 h后应力试验值/MPa 57.4 30.5 17.8 105 h后应力仿真结果/MPa 51.0 32.1 18.7 105 h后应力试验值/MPa 52.3 34.7 20.9 表 6 T91过热器管壁面厚度仿真与试验测量值

Table 6. Simulation and experimental measurements of tube wall thickness of T91 superheater

参数 仿真值 试验测量值 壁面厚度/mm 8.996 8.994 -

[1] 何晓梅, 罗昌福, 刘漫博. 超超临界火电机组的选材及国产化进程[J] . 热加工工艺,2012,41(22):116 − 119. [2] 喻聪, 司风琪, 李敏, 等. 基于燃烧与水动力耦合模型的锅炉蒸汽管超温特性研究[J] . 热能动力工程,2021(8):92 − 98. [3] NGUYEN V P, IBUPOTO F A, LI Q P, et al. Creep lifetime prediction of 9Cr-1Mo (grade T91) steel via small punch creep tests and hierarchical multiscale analysis[J] . Materials at High Temperatures,2020,37(6):462 − 477. doi: 10.1080/09603409.2020.1824852 [4] LOK V, LE T G, YU J M, et al. Changes in creep property and precipitates due to aging of T91 steel after long-term service[J] . Journal of Mechanical Science and Technology,2020,34(8):3283 − 3293. doi: 10.1007/s12206-020-0720-4 [5] XUE F, CHENG T L, CARNEY C S, et al. Oxide scale exfoliation analysis of type T91 SS boiler tubes[J] . Materials Performance,2020,59(12):40 − 44. [6] 曹宇, 刘川槐, 潘卫国, 等. T91/TP347H异种钢焊接接头蠕变行为分析及寿命预测[J] . 动力工程学报,2021,41(8):707 − 712. [7] 张力文, 张小文, 宋继萍. 金属蠕变疲劳寿命预估模型研究进展[J] . 工业加热,2021,50(2):36 − 40. doi: 10.3969/j.issn.1002-1639.2021.02.010 [8] 涂善东, 轩福贞, 王卫泽. 高温蠕变与断裂评价的若干关键问题[J] . 金属学报,2009,45(7):781 − 787. doi: 10.3321/j.issn:0412-1961.2009.07.002 [9] HYDE T H, BECKER A A, SUN W, et al. Determination of creep properties for P91 weldment materials at 625 ℃[C]//Processing International Conference on Mechanics and Materials in Design, Chapter IV, Welds at High Temperature(WELDON)in Design. 2006: A0402. 0405. [10] HYDE T H, SUN W. Effect of bending load on the creep failure behavior of a pressurised thick walled CrMoV pipe weldment[J] . International Journal of Pressure Vessels and Piping,2002,79(5):331 − 339. doi: 10.1016/S0308-0161(02)00027-3 [11] HYDE T H, SUN W, BECKER A A, et al. Life prediction of repaired welds in a pressurised CrMoV pipe with incorporation of initial damage[J] . International Journal of Pressure Vessels and Piping,2004,81(1):1 − 12. doi: 10.1016/j.ijpvp.2003.12.015 [12] HYDE T H, BECKER A A, SUN W, et al. Finite-element creep damage analyses of P91 pipes[J] . International Journal of Pressure Vessels and Piping,2007,83(11-12):853 − 863. [13] 王进峰, 邢迪雄, 王洪洲, 等. P91钢高温蠕变数值模拟与实验研究[J] . 中国工程机械学报,2020,18(4):283 − 287. [14] 韩笑, 余海洋, 周帼彦, 等. 基于固支直杆弯曲小试样的P91/P92钢蠕变性能对比评价研究[J] . 压力容器,2021,38(4):1 − 10. doi: 10.3969/j.issn.1001-4837.2021.04.001 [15] 刘长军, 闫阿晨, 谈建平, 等. 全循环周期和保载时间对P91钢蠕变−疲劳裂纹扩展行为的影响[J] . 动力工程学报,2019,39(11):947 − 952. [16] 任海云, 陈辉, 王风涛, 等. 压力容器不连续区的有限元分析及优化设计[J] . 机械工程师,2011(7):104 − 105. doi: 10.3969/j.issn.1002-2333.2011.07.051 [17] SAWADA K, SEKIDO K, KIMURA K, et al. Effect of Init ial Microstructure on Creep Strength of ASME Grade T91 Steel[J] . ISIJ International,2020,60(2):382 − 391. doi: 10.2355/isijinternational.ISIJINT-2019-358 [18] GB/T 5310-2017, 高压锅炉用无缝钢管[S]. [19] 潘成飞. 基于不同方法的9Cr-1Mo钢高温蠕变寿命预测研究[D]. 西安: 西北大学, 2017. [20] PAN J P, TU S H, SUN G L, et al. High-temperature creep properties and life predictions for T91 and T92 steels[J] . IOP Conference Series:Materials Science and Engineering,2018,292(1):012098. -

下载:

下载: