Study on Preparation and Properties of Graphene/Carbon Fiber Waterborne Electrothermal Coatings

-

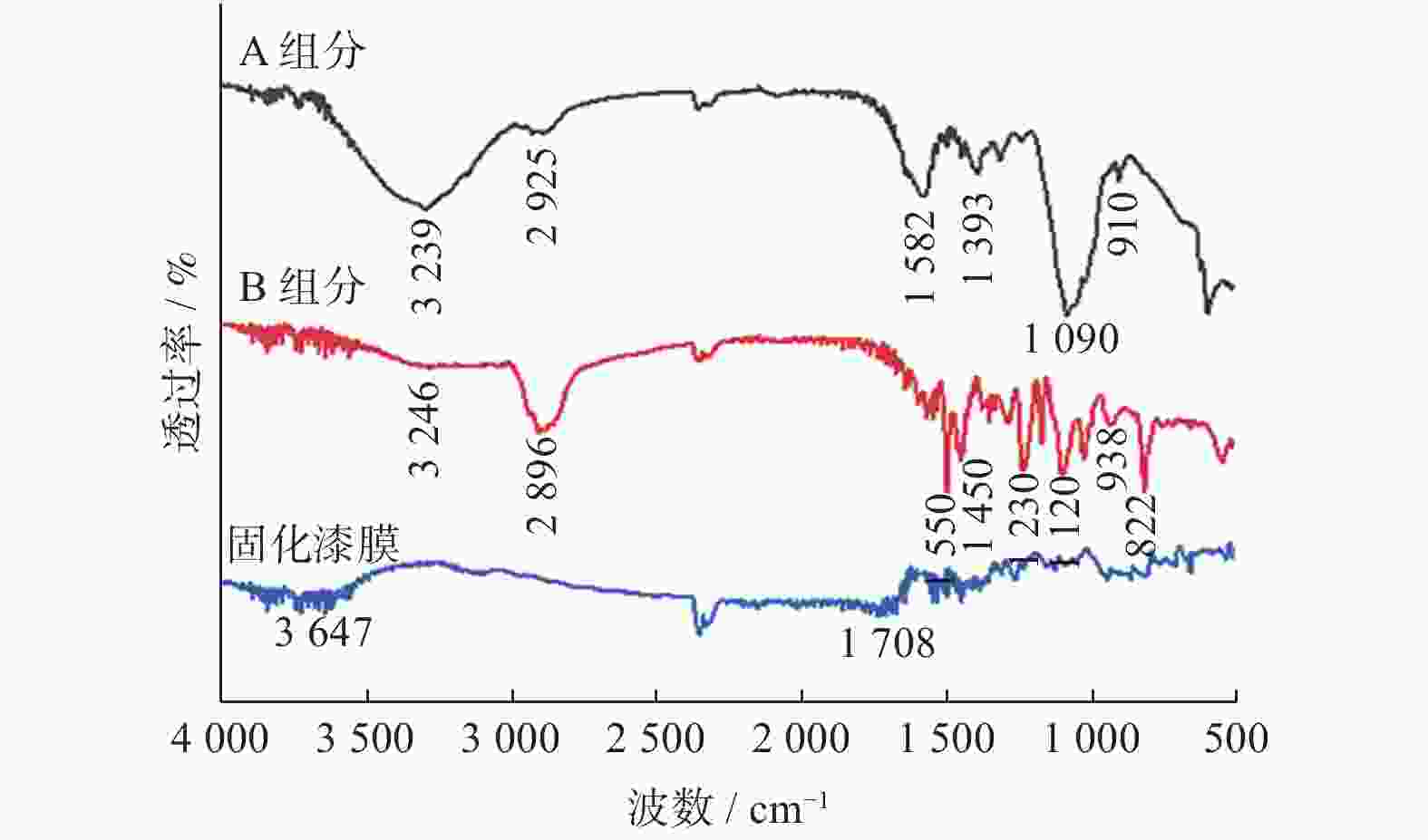

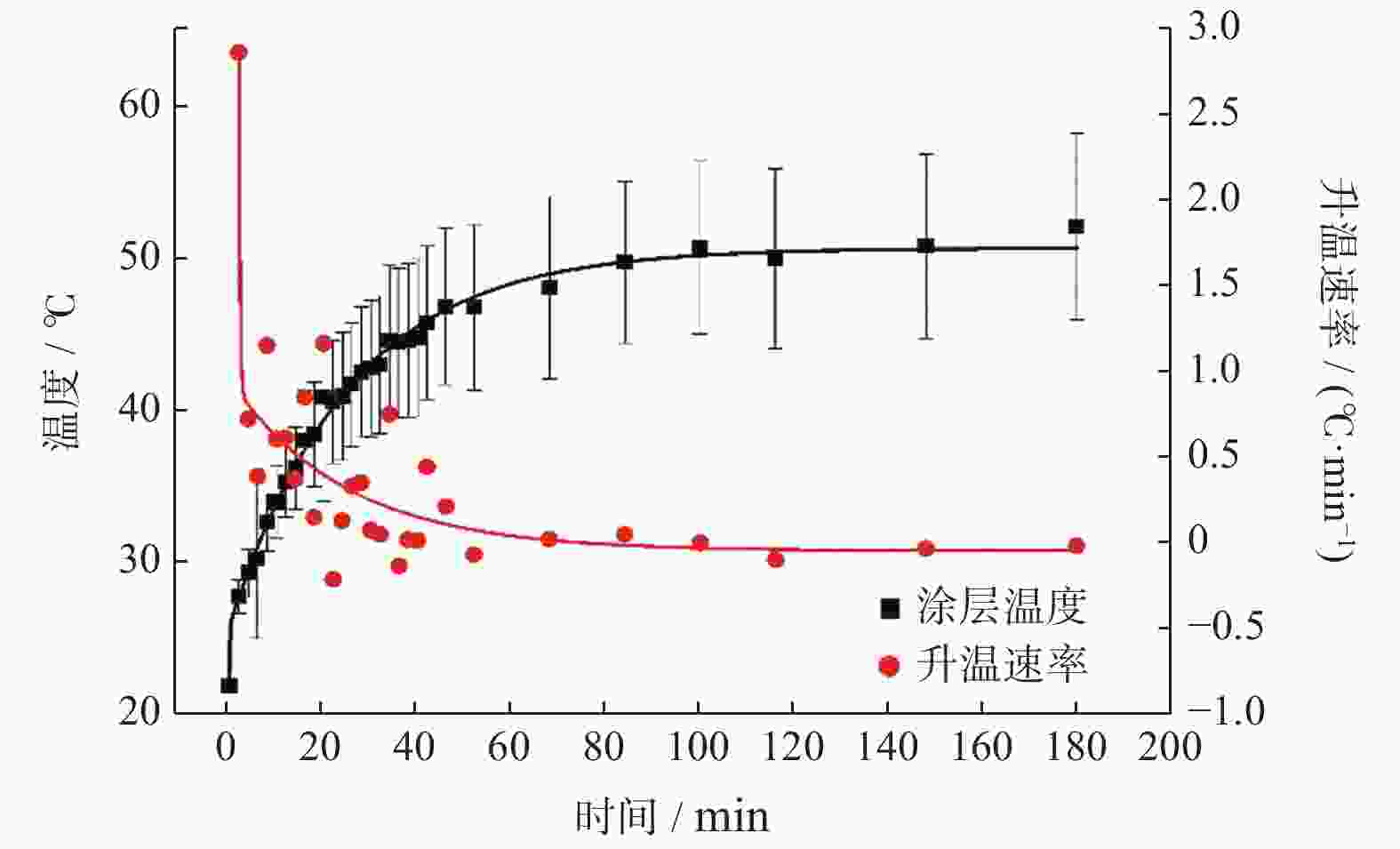

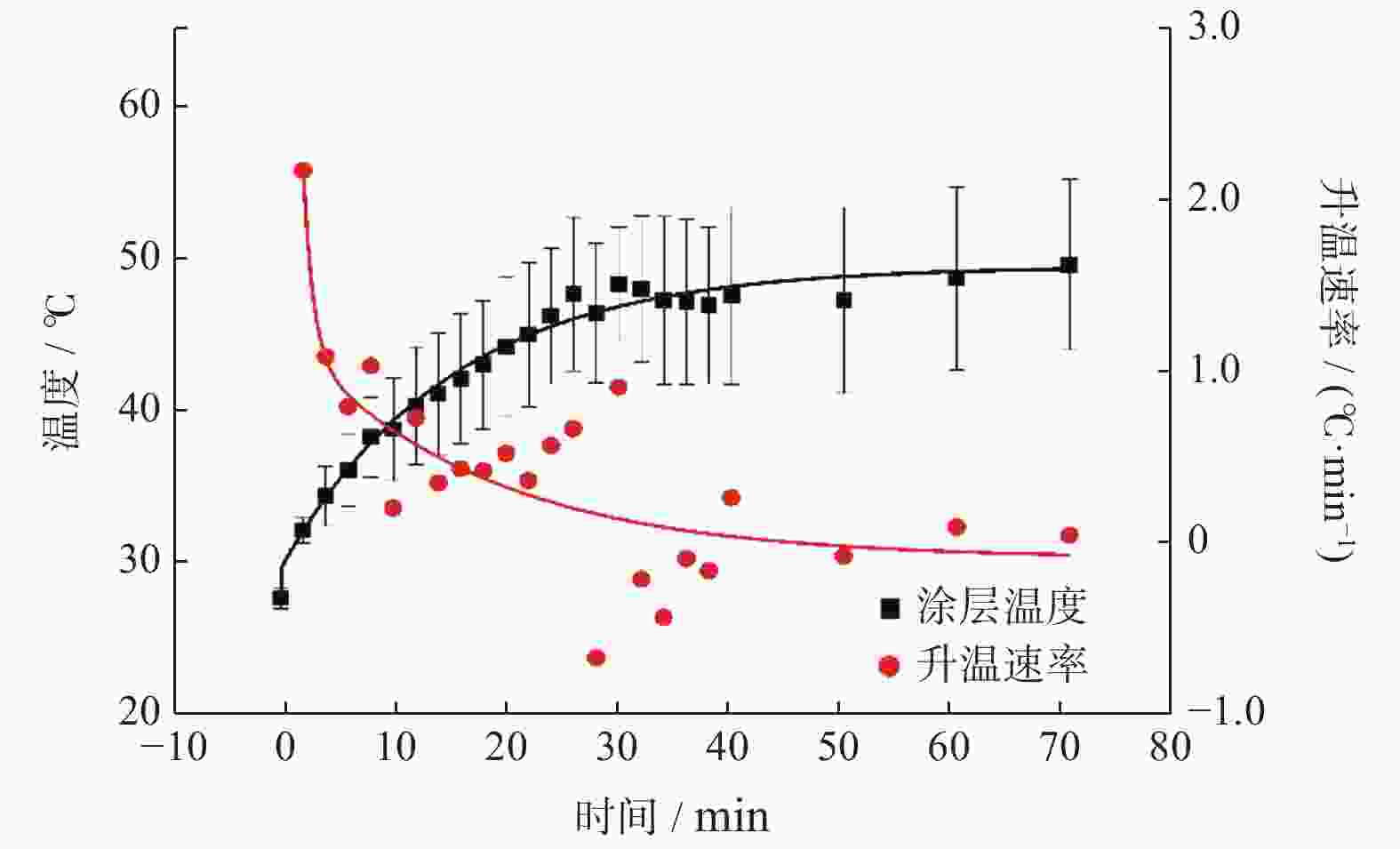

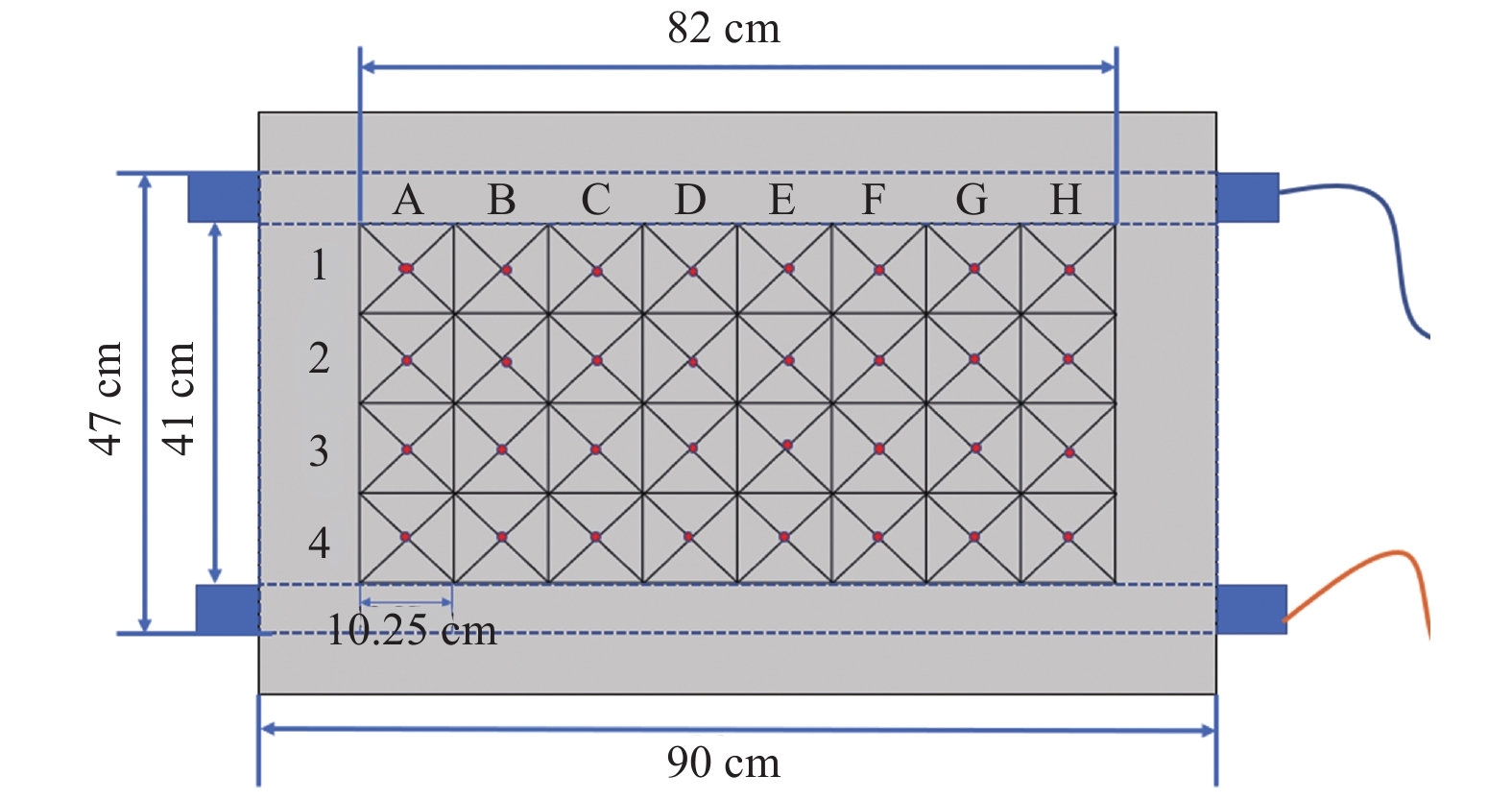

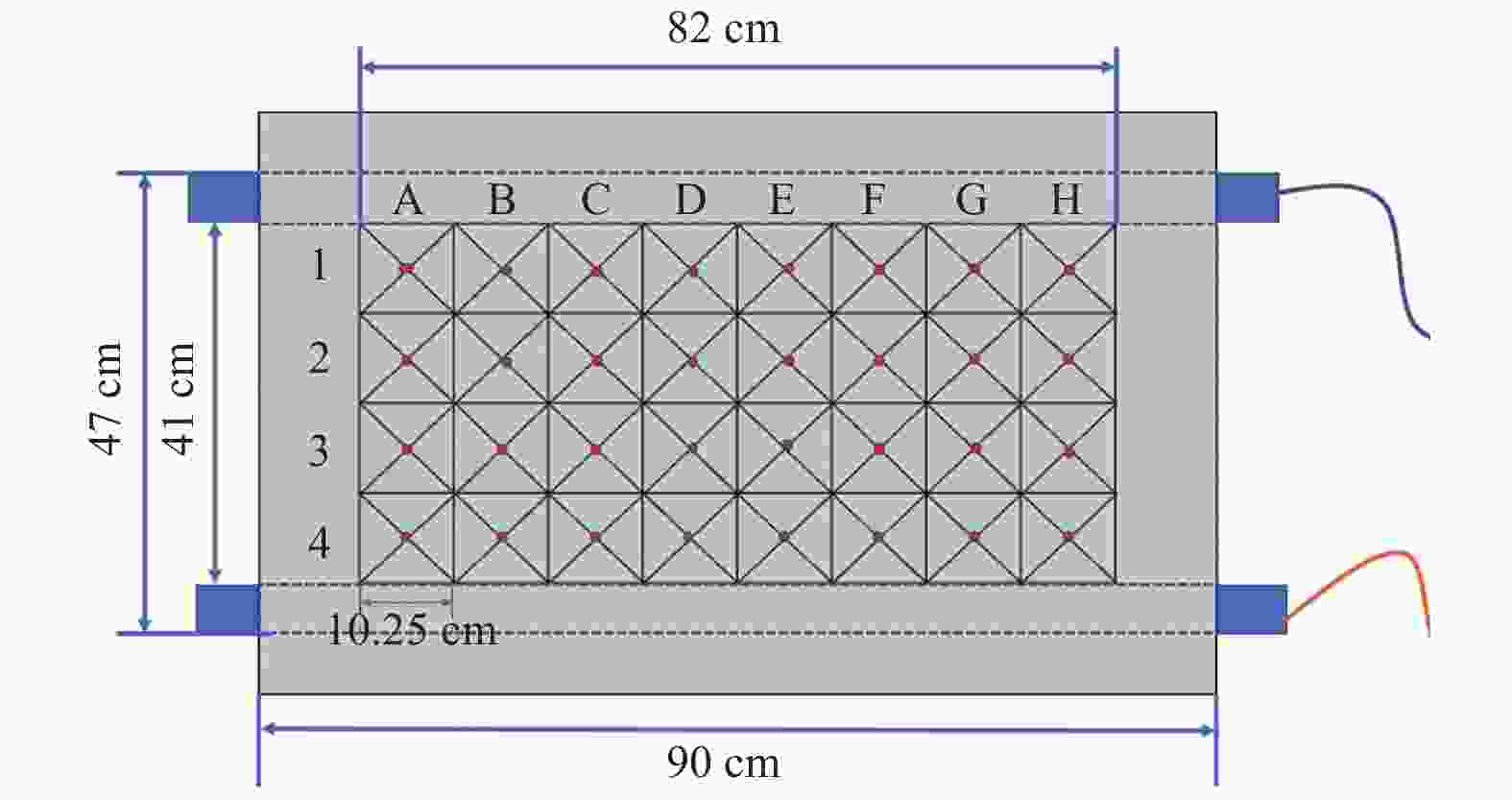

摘要: 电热涂料是在导电涂料的基础上开发出的一种直接将电能转化为热能或辐射能的功能性涂料. 研究一种以改性碳纤维和石墨烯为导电填料的水性环氧双组分发热涂料体系. 利用扫描电子显微镜(SEM)对涂层表面和断面进行表征,发现碳纤维在涂层中分布均匀,形成良好的导电传热网络. 导热测试结果显示涂层的导热系数为0.40 W /(m·K);涂层的温升曲线分3个阶段规律增长,升温在15~28 min达到峰值,理论热效能高达63.02%;涂层的安全电压为24 V,并具有良好的绝缘性能,能够保障使用安全.Abstract: Electrothermal coating is a kind of functional coating which can directly convert electric energy into heat or radiation energy on the basis of conductive coating. A waterborne epoxy two-component thermal coating system with modified carbon fiber and graphene as conductive filler was studied. Scanning electron microscopy (SEM) was used to characterize the surface and section of the coating. It was found that the carbon fibers were evenly distributed in the coating, forming a good conductive and heat transfer network.The thermal conductivity test results show that the thermal conductivity coefficient of the coating is 0.40 W / (m·K). The temperature rise curve of the coating increased regularly in three stages, and reached the peak value in 15~28 min, and the theoretical thermal efficiency reached 63.02%. The safe voltage of the coating is 24 V, and it has good insulation performance, which can guarantee the use safety.

-

Key words:

- electrothermal coatings /

- carbon fiber /

- graphene /

- waterborne coatings /

- safety performance

-

表 1 导电发热涂层基本性能

Table 1. Basic properties of electrothermal coatings

颜色 光泽度(60°) / (°) 硬度 反射率 / (°) 附着力(百格法) 黑色 0.7 5H 2.2 0 级 表 2 涂层导热系数

Table 2. Thermal conductivity of coating

样品名称 样品厚度 / mm 样品面积 / mm2 热流量 / W 样品热阻 / (cm2·K·W−1) 导热系数 / (W·(m·K)−1) EC-321G 1.00 706.86 3.57 29.49 0.40 空白 1.00 706.86 2.30 91.54 0.24 -

[1] 耿家钰. 碳系电热涂料的制备工艺及性能研究[D]. 哈尔滨: 哈尔滨工程大学, 2017. [2] 樊宝珠, 刘暄. 碳系导电填料在导电涂料中的应用专利综述[J] . 河南科技,2018(9):57 − 58. [3] JUNG S, CHO D. Effect of fiber feeding route upon extrusion process on the electromagnetic, mechanical, and thermal properties of nickel-coated carbon fiber/polypropylene composites[J] . Composites Part B: Engineering,2020,187:107861. doi: 10.1016/j.compositesb.2020.107861 [4] 刘暐昌. ZnO基薄膜和器件的制备及性能研究[D]. 杭州: 浙江大学, 2008. [5] 吕思琪. 新型网球球拍用碳纤维复合材料的制备与性能研究[J] . 合成材料老化与应用,2020,49(2):74 − 76; 11. [6] HONG G K, HEE J S, GWANG-CHEOL K, et al. Electromagnetic interference shielding characteristics for orientation angle and number of plies of carbon fiber reinforced plastic[J] . Carbon Letters,2014,15(4):268 − 276. doi: 10.5714/CL.2014.15.4.268 [7] 龙巍, 郑学林, 臧建彬. 基于碳纤维复合材料热性能的研究进展综述[J] . 应用化工,2019,48(9):2251 − 2255. [8] 张猛, 富秀荣. 碳纤维发热织物的电热性能研究[J] . 合成纤维,2015,44(11):25 − 27; 57. [9] 何文龙. 基于石墨烯的水性电热涂料的制备与性能研究[J] . 上海涂料,2019,57(3):11 − 14. [10] 杨小平, 荣浩鸣, 沈曾民. 碳纤维面状发热材料的性能研究[J] . 高科技纤维与应用,2000(3):39 − 42; 48. [11] MA C, SÁNCHEZ-RODRÍGUEZ D, KAMO T. Influence of thermal treatment on the properties of carbon fiber reinforced plastics under various conditions[J] . Polymer Degradation and Stability,2020,178:109199. doi: 10.1016/j.polymdegradstab.2020.109199 [12] ABERGEL D S L, APALKOV V, BERASHEVICH J, et al. Properties of graphene: A theoretical perspective[J] . Advances In Physics,2010,59(4):261 − 482. doi: 10.1080/00018732.2010.487978 [13] ZHU Y W, MURALI S, CAI W W, et al. Graphene and graphene oxide: Synthesis, properties, and applications[J] . Advanced Materials,2010,22(35):3906 − 3924. doi: 10.1002/adma.201001068 [14] 曲颖. 从VOC减排看我国涂料工业绿色发展[J] . 化学工业,2019,37(3):1 − 10. [15] 孟令巧, 史星照, 周志平, 等. 环保型水性涂料研究进展及发展趋势[J] . 中国胶粘剂,2019,28(1):55 − 60. [16] 赵海霞, 夏金童, 王双, 等. 水性炭系电热涂料的制备及性能研究[J] . 电镀与涂饰,2015,34(14):777 − 780. [17] 张朋, 刘舒, 魏志凯, 等. 纳米碳材料水性电热涂料的制备与性能研究[J] . 涂料工业,2017,47(4):23 − 28. [18] XIONG Y, HU J, NIE X, et al. One-step firing of carbon fiber and ceramic precursors for high performance electro-thermal composite: Influence of graphene coating[J] . Materials and Design,2020,191:108633. doi: 10.1016/j.matdes.2020.108633 [19] 黄坤, 曾宪光, 裴嵩峰, 等. 低压高效石墨烯复合涂料的电热性能研究[J] . 涂料工业,2016,46(4):13 − 17. [20] 陈小刚, 麻宁. 一种石墨烯发热涂料及其制备方法: CN111303703A[P]. 2020-06-19. [21] 希尔艾力·赛迪麦麦提. 一种碳纤维发热涂料及其制备方法: CN111187540A[P]. 2020-05-22. [22] 李洪锋, 李贺. 一种石墨烯低压发热涂料及其制备方法: CN106752878A[P]. 2017-05-31. [23] 田艳红, 乔伟静, 张学军, 等. 聚丙烯腈基高模量碳纤维导热性能的影响因素[J] . 材料导报,2018,32(10):1668 − 1671; 1682. [24] 陈坤, 李俊, 唐强, 等. 酚醛基碳纤维制备方法研究进展[J] . 应用化工,2017,46(8):1624 − 1626; 1634. [25] 闫明洋, 杨敏, 李红, 等. 原位生长的气相生长碳纤维增强C/C复合材料的制备及其弯曲性能[J] . 无机材料学报,2018,33(11):1161 − 1166. [26] 任蕊, 皇甫慧君, 曹晨茜, 等. 沥青基碳纤维的制备方法及其产业化研究[J] . 应用化工,2018,47(10):2254 − 2259. -

下载:

下载: