Research progress on detection technology of large-size aircraft parts

-

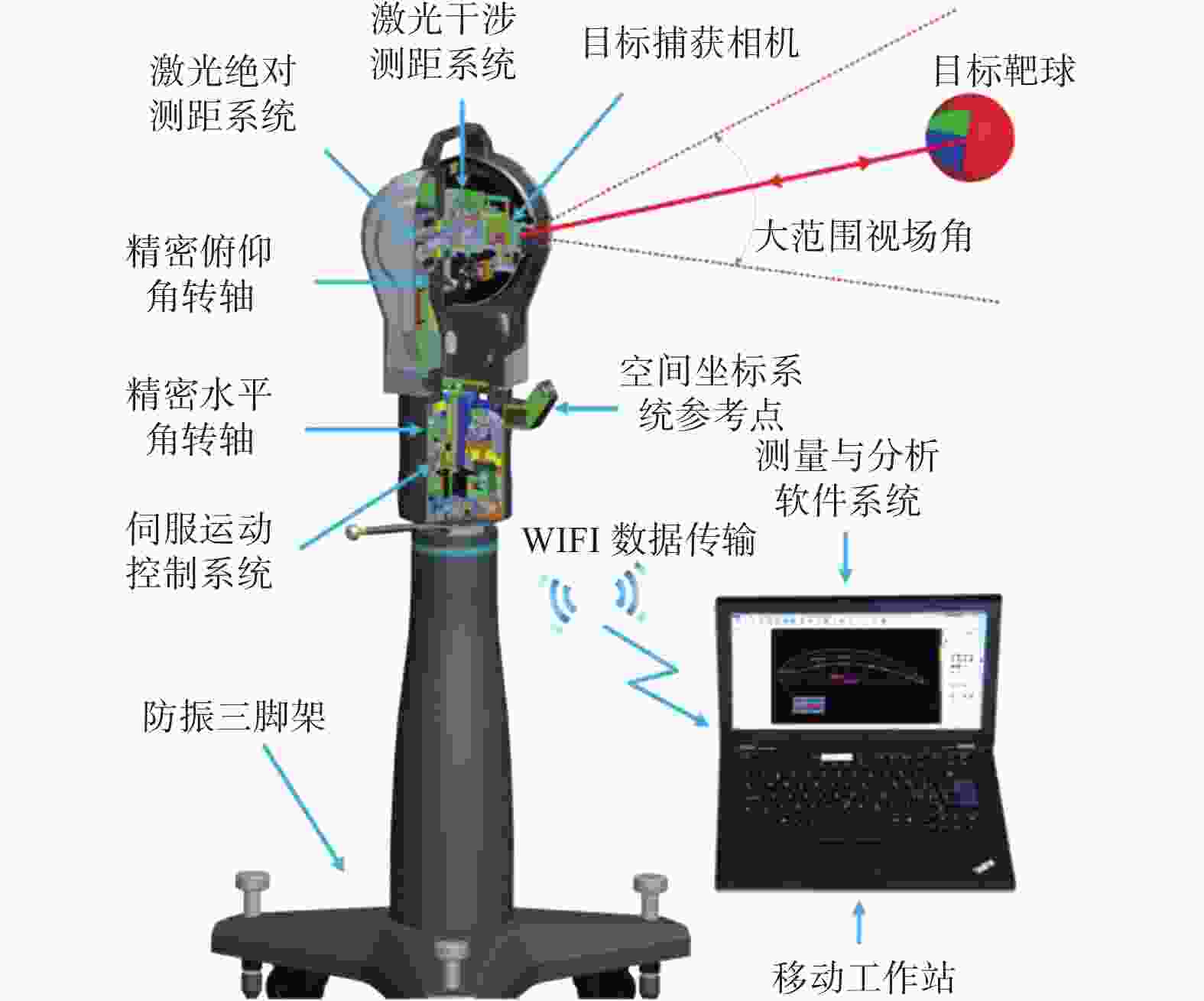

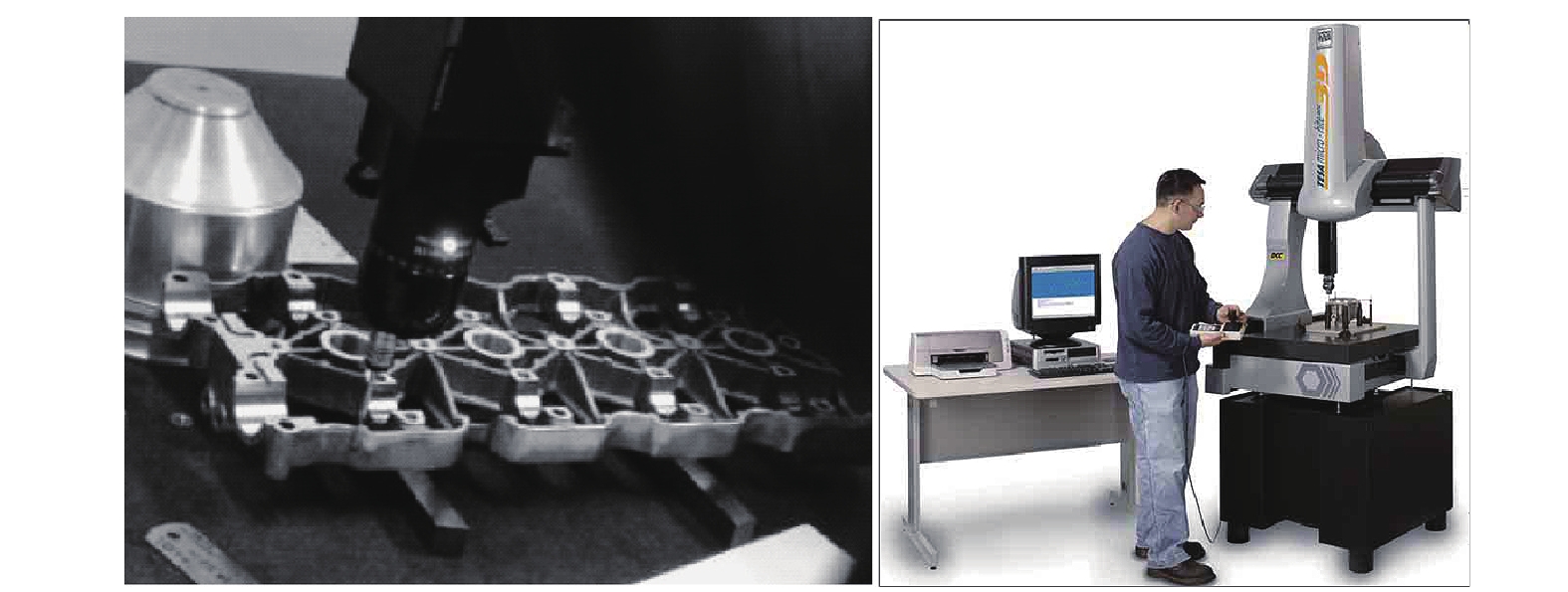

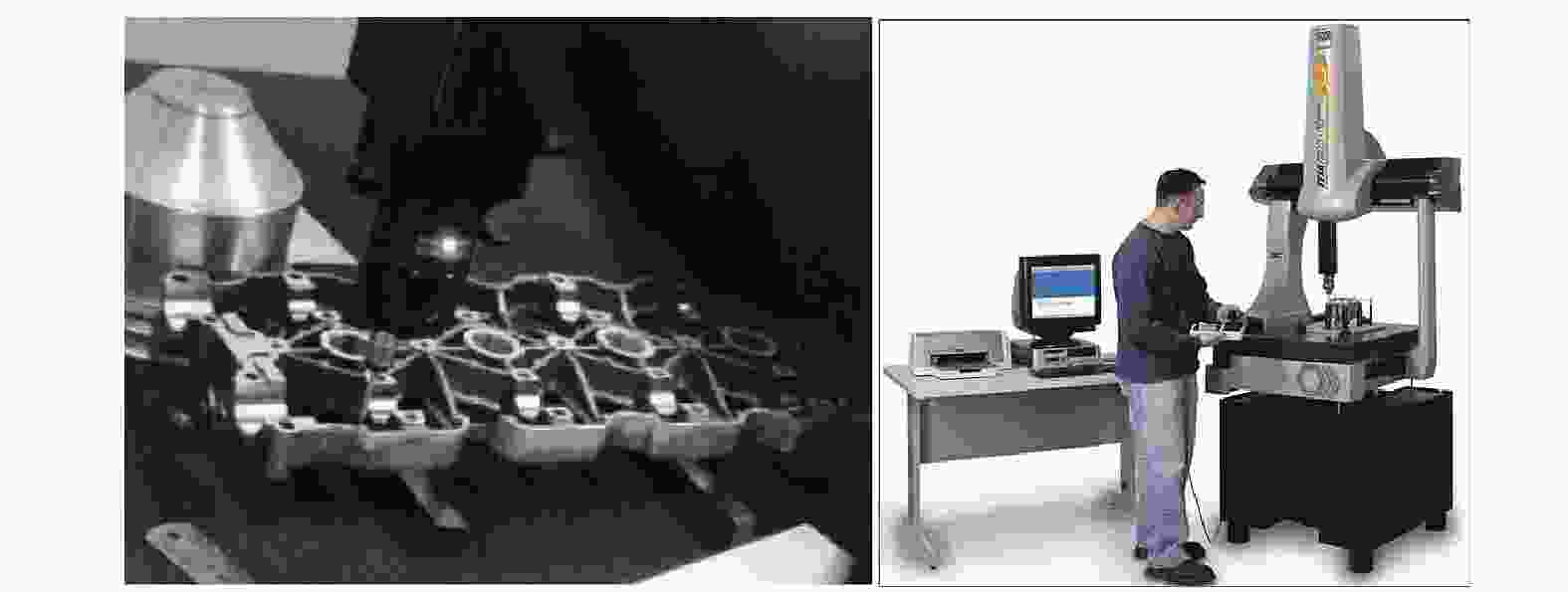

摘要: 大尺寸飞机零部件具有结构复杂、外形尺寸大等特点. 针对飞机制造过程中大尺寸测量技术的研究,探讨5种大尺寸部件的检测技术方法:三坐标测量法、激光雷达测量法、室内GPS测量法、激光跟踪仪测量法以及机器视觉测量法,分析5种检测方法的适用领域以及各自的优势和不足. 视觉测量具有非接触、高精度、高效率的特点,能够实现实时测量,在航空测量领域前景良好. 最后指出视觉测量技术是大尺寸测量领域的研究方向,未来在理论模型建立、检测参数优化及实时反馈等一系列问题有待进一步深入研究.Abstract: Large-size aircraft parts have complex structure and huge external dimension characteristics. In view of the research of large-size measurement technology in the aircraft manufacturing process, five kinds of detection technology methods for large-size parts, like three-coordinate measurement method, LIDAR measurement method, indoor GPS measurement method, laser tracker measurement method and machine vision measurement method were proposed. The applicable fields and respective advantages and short-comings of five detection methods were analyzed. The visual measurement which can achieve real-time measurement has non-contact, high precision and efficiency characteristics. It has a great prospect in the field of aviation measurement. It was pointed out that vision measurement technology is research direction in large-size measurement. A series of issues such as the theoretical models establishment, detection parameters optimization and real-time feedback need to be further studied in the future.

-

Key words:

- large-size measurement /

- machine vision /

- laser radar /

- laser tracking /

- indoor GPS

-

表 1 各测量方法优缺点及其适用场合

Table 1. Advantages and disadvantages of measurement methods and their applicable occasions

测量方法 优点 缺点 适用场合 三坐标测量 测量精度和自动化程度较高 测量效率低,对环境有较高要求,如恒温条件,探头可能划伤零件表面 一般用于测量叶轮等复杂曲面 激光雷达测量 测量精度和分辨率较高 因波束极窄易受环境影响,测量效率低 一般用于外形尺寸大、形状复杂表面的测量 室内GPS测量 测量范围大,效率高 精度不高,设备多,容易受到环境震动影响 一般与其他方法协同测量 激光跟踪仪测量 可实现动态测量和快速测量 成本较高,需要较大空间,否则难以测量全貌 可通过单站多站位对大型零部件进行测量 视觉测量 非接触,精度与效率较高 需要进一步提高实时性 光线条件较好时,测量效果更佳 -

[1] 杨帆. 面向大型航空构件测量的大视场相机标定技术研究[D]. 大连: 大连理工大学, 2017. [2] 金涨军. 飞机装配中大尺寸测量场的建立与优化技术[D]. 杭州: 浙江大学, 2016. [3] 史建华, 刘新宇. 基于三坐标测量机的大型扭转叶片型面测量方法研究[J] . 计测技术,2016,36(S1):23 − 25. [4] 高继昆, 闫峰, 李季. 三坐标测量机在整体叶盘叶片型面检测中的应用[J] . 航空制造技术,2015(22):94 − 97. [5] 张现东, 卜昆, 董一巍. 航空发动机叶片三坐标测量优化采样方法[J] . 航空动力学报,2019(1):168 − 176. [6] 欧阳婷婷, 刘延平, 彭江涛, 等. 基于三坐标测量机的曲面轮廓度坐标测量技术[J] . 航天制造技术,2020(2):4 − 8. doi: 10.3969/j.issn.1674-5108.2020.02.002 [7] 戚明轩, 刘震磊, 兆尔波, 等. 某型航空发动机叶片逆向工程方法研究[J] . 航空精密制造技术,2021,57(1):13 − 16. [8] STOJADINOVIC S M, MAJSTOROVIC V D, DURAKBASA N M. An approach to development of the digital inspection twin based on CMM[J] . Measurement: Sensors,2021,18:100300. doi: 10.1016/j.measen.2021.100300 [9] FORBES A. Approximate models of CMM behaviour and point cloud uncertainties[J] . Measurement: Sensors,2021,18:100304. doi: 10.1016/j.measen.2021.100304 [10] 亢甲杰, 张福民, 曲兴华. 激光雷达坐标测量系统的测角误差分析[J] . 激光技术,2016,40(6):834 − 839. doi: 10.7510/jgjs.issn.1001-3806.2016.06.013 [11] 崔深山, 万爽, 张涛. 大型结构高次曲面外形精密测量技术研究与应用[J] . 宇航计测技术,2017,37(6):1 − 5, 15. doi: 10.12060/j.issn.1000−7202.2017.06.01 [12] 刘玉松, 王志海, 刘琦, 等. 基于Metrascan与激光雷达融合的飞机外形数字化测量方法研究[J] . 现代制造工程,2019(2):36 − 40,47. [13] 潘鑫, 张俐, 何凯. 激光雷达复材型面测量精度分析方法[J] . 北京航空航天大学学报,2020,46(7):1398 − 1404. [14] 张欣婷, 亢磊, 安志勇. 三维形貌测量激光雷达光学系统设计[J] . 应用光学,2015,36(3):337 − 342. [15] YANG X Y, HAO L T, WANG Y Q. Adjustable higher SNR and long-range 3D-imaging cluster lidar based on a coded full-waveform technique[J] . Applied Optics,2019,58(17):4671 − 4677. doi: 10.1364/AO.58.004671 [16] 赵子越, 甘晓川, 马骊群. 激光跟踪仪与室内GPS的协同测量组网方法[J] . 测控技术,2019,38(7):79 − 83,88. [17] 范斌, 季青松, 李明飞, 等. iGPS测量系统与激光跟踪仪在某飞机大部件数字化装配中的对比应用[J] . 航空制造技术,2019,62(5):57 − 62. [18] 范景韬, 黄翔, 曾琪, 等. 基于免疫优化算法的iGPS发射器布局优化方法[J] . 激光与光电子学进展,2021,58(11):238 − 246. [19] 陈良杰, 孙占磊, 景喜双, 等. 基于iGPS的飞机部件对接技术研究[J] . 航空制造技术,2017(11):34 − 39,51. [20] 栗辉. 基于iGPS和激光雷达的飞机水平测量设计与实现[D]. 成都: 电子科技大学, 2019. [21] ZHOU N, AN Z Y, LI L J, et al. iGPS measurement network multi-station arrangement design[J] . Applied Mechanics and Materials,2014,443:223 − 227. [22] SCHMITT R, KIMMELMANN W, QUINDERS S, et al. Investigation of the applicability of an iGPS metrology system to automate the assembly in motion of a truck cabin[J] . Applied Mechanics and Materials,2016,840:58 − 65. [23] 王子辰, 张爱梅. 面向特大齿轮的激光跟踪测量精度提升方法研究[J] . 红外与激光工程,2021,50(11):20210030. [24] 乔贵方, 孙大林, 温秀兰, 等. 面向机器人标定的单激光跟踪仪顺序多站式测量系统建模与分析[J] . 计量学报,2020,41(11):1313 − 1320. doi: 10.3969/j.issn.1000-1158.2020.11.01 [25] 朱绪胜, 刘蕾, 陈雪梅. 基于蒙特卡洛仿真的车间现场激光跟踪仪测量站位优化[J] . 计算机集成制造系统,2020,26(11):3001 − 3010. [26] 汪昭义, 何晓业, 王巍, 等. 激光跟踪仪的高精度预准直方法和精度分析[J] . 武汉大学学报(信息科学版),2021,46(4):555 − 560. [27] GAI Y H, ZHANG J, GUO J, et al. Construction and uncertainty evaluation of large-scale measurement system of laser trackers in aircraft assembly[J] . Measurement,2020,165:108144. doi: 10.1016/j.measurement.2020.108144 [28] AGUADO S, PEREZ P, ALBAJEZ J A, et al. Configuration optimisation of laser tracker location on verification process[J] . Materials,2020,13(2):331. doi: 10.3390/ma13020331 [29] ZHOU G F, LI X X, LI D S, et al. Large-scale compact range on-site alignment based on laser tracker measurement network[J] . Measurement,2015,68:143 − 154. doi: 10.1016/j.measurement.2015.02.036 [30] WANG J D, GUO J J. Research on volumetric error compensation for NC machine tool based on laser tracker measurement[J] . Science China Technological Sciences,2012,55(11):3000 − 3009. doi: 10.1007/s11431-012-4959-6 [31] 冯西, 吴静静, 安伟. 基于机器视觉的大尺寸工件自动测量系统[J] . 传感器与微系统,2019,38(4):104 − 107. [32] 吴庆华, 陈慧, 朱思斯, 等. 一种多相机阵列大尺寸测量系统快速标定方法[J] . 光学学报,2018,38(12):214 − 220. [33] 杨帆, 刘巍, 张洋, 等. 结合四角共线约束的大视场双目相机标定方法[J] . 光学学报,2016,36(7):186 − 195. [34] 熊峰, 王桂棠, 陈永彬, 等. 大尺寸复杂精冲零件智能测量系统的研究[J] . 计算机测量与控制,2018,26(1):55 − 58,63. [35] 刘之远, 张丽艳. 基于双目视觉的钣金件边缘检测技术研究与系统开发[J] . 航空制造技术,2020,63(7):30 − 39. [36] HAO F, ZHU S Q, GAO H T. Gray image composition method for measurement based on multi-software cooperation[C]//Advanced Materials Research. Switzerland: Trans Tech Publications Ltd, 2014, 889: 1052−1056. [37] HE B X, ZHANG Z S, DAI M, et al. A novel method of machine vision measurement based on sequential partial images[C]//Proceedings of the International Conference on Mechanical Engineering and Mechanics. Wuxi: Jiangsu Province Industrial Design Association, Nanjing University of Science and Technology, 2007, 889/890: 561−566. -

下载:

下载: