Formation and microstructure of aluminum alloy CMT joint assisted by mechanical vibration

-

摘要:

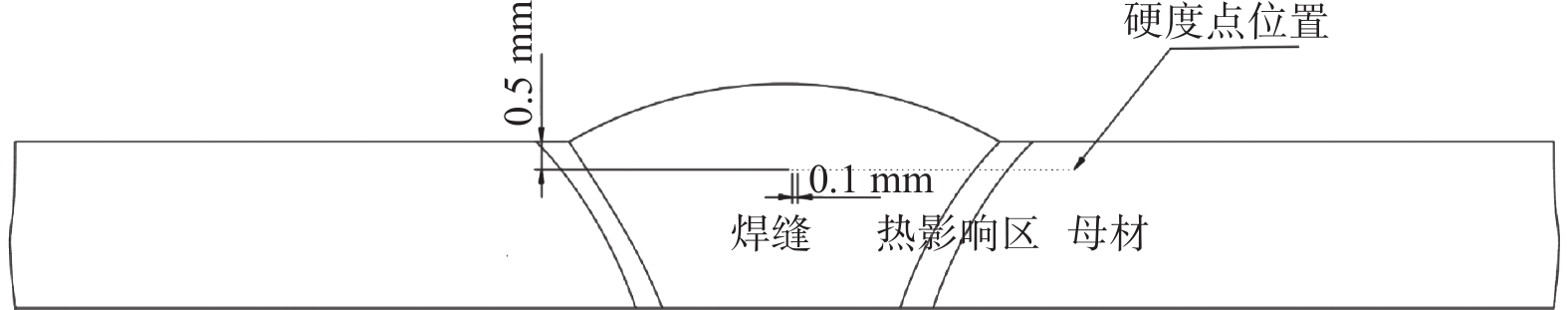

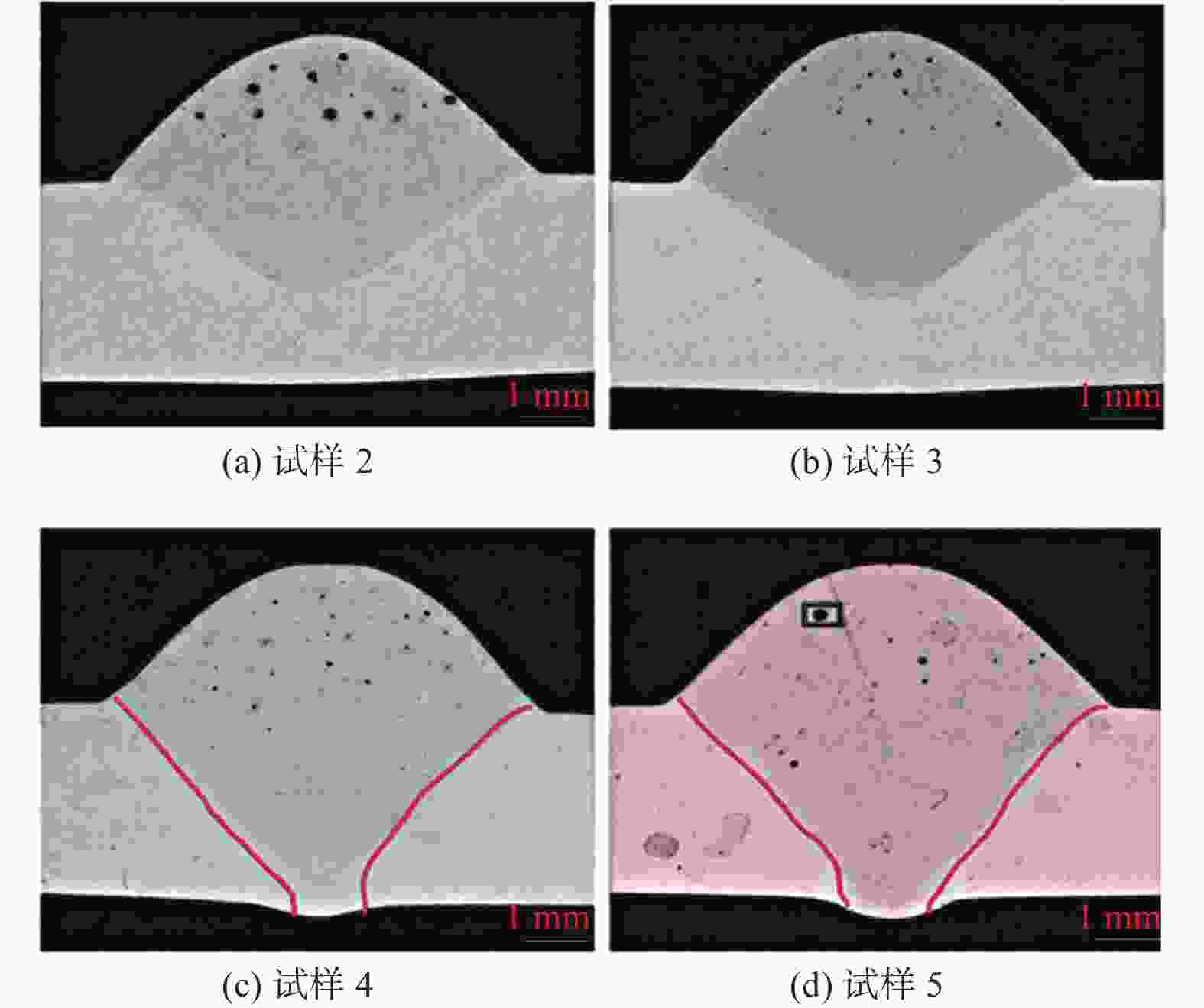

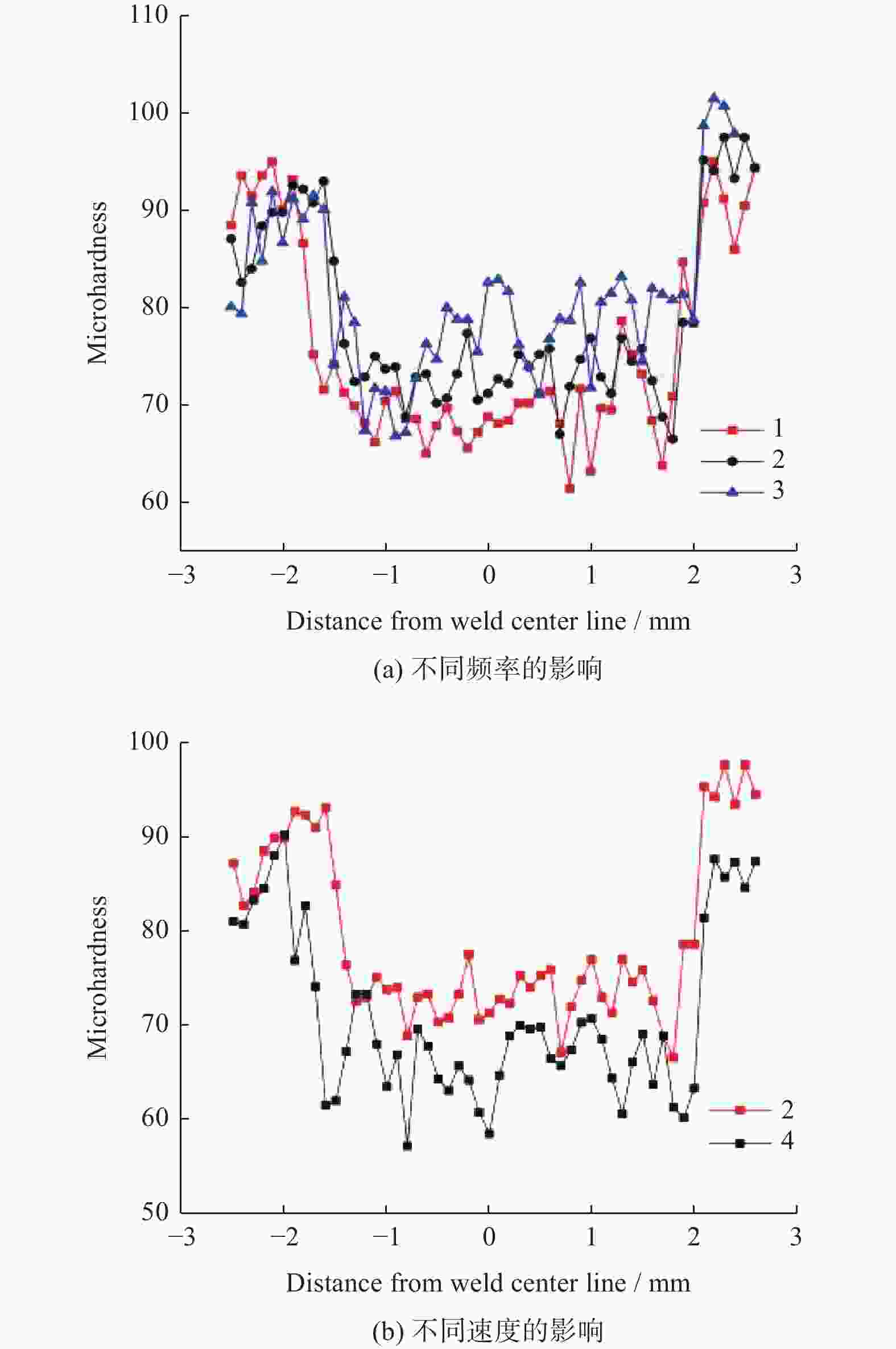

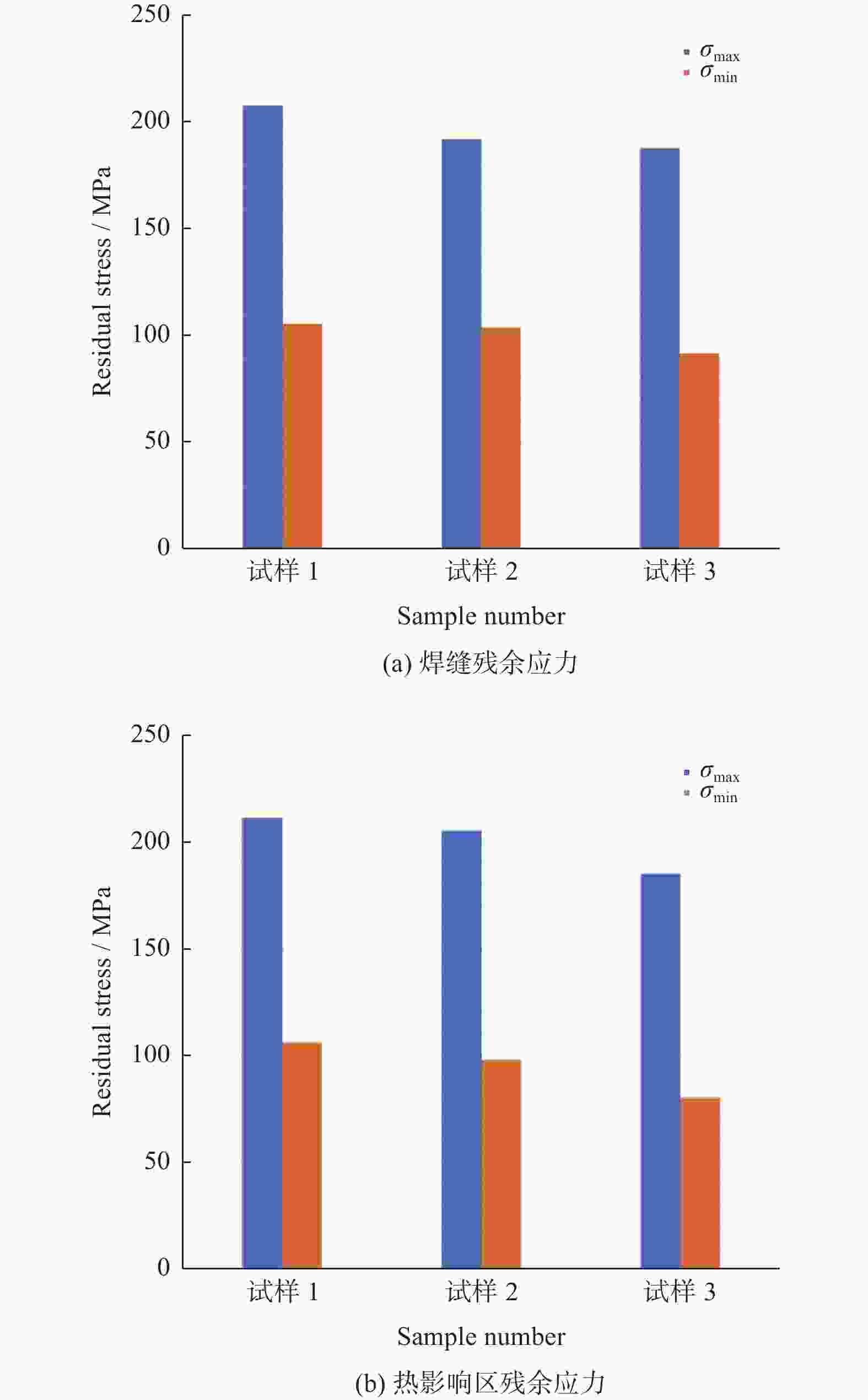

基于高频微振平台,进行6082铝合金机械振动辅助冷金属过渡焊接(CMT)试验,探究高频微振CMT工艺对焊接接头组织性能的影响. 结果表明:施加振动后,焊缝余高略有增加,熔宽减小,熔深增大. 当振动频率为1 119 Hz时,余高和熔深分别增加4.5%和23%. 振动使热影响区宽度变窄,熔合线附近晶粒尺寸从原先的20 µm减小到15 µm. 施加振动后,气泡逸出速度加快,柱状晶的生长趋势被抑制,晶粒细化,焊接接头软化区的硬度提高,接头硬度分布更加均匀. 当振动频率为1 119 Hz时,焊缝软化区维氏硬度值达到最高为77 . 施加振动可以有效降低接头焊缝和热影响区残余应力. 当振动频率为1 119 Hz时,焊接接头和热影响区最大残余应力平均值分别减小9.6%和6.3%,焊接接头力学性能得到提升.

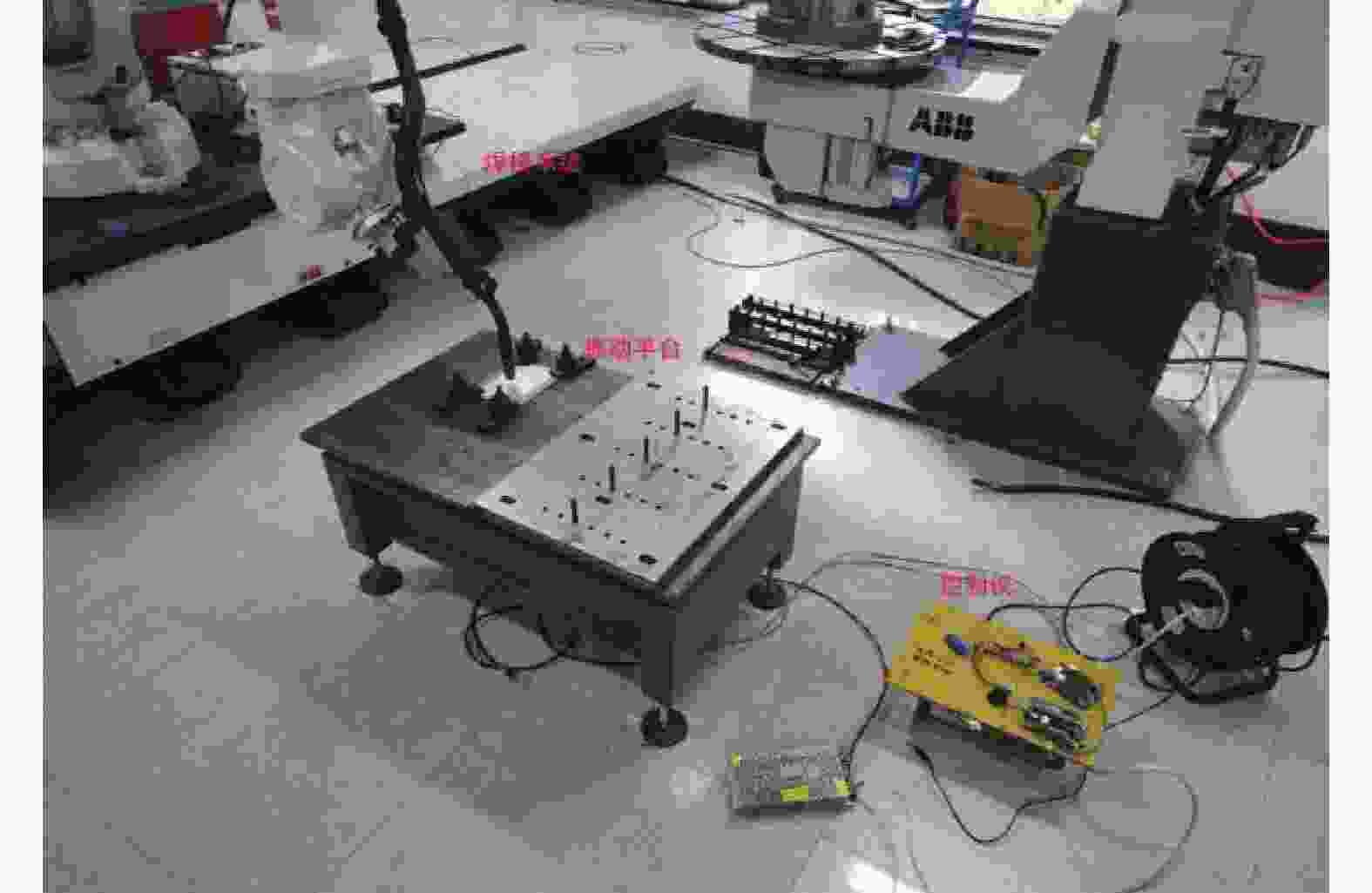

Abstract:Based on the high-frequency micro-vibration platform, the mechanical vibration-assisted cold metal transfer welding (CMT) test of 6082 aluminum alloy was carried out to explore the influence of high-frequency micro-vibration CMT process on the microstructure and properties of joints. The results show that after applying vibration, the weld reinforcement increased slightly, the weld width decreased, and the penetration depth increased. When the vibration frequency was 1 119 Hz, the weld reinforcement and penetration depth increased by 4.5% and 23% respectively. The vibration narrowed the width of the heat-affected zone, and the grain size near the fusion line had reduced from the original 20 µm to 15 µm. After vibration was applied, the bubble escape speed was accelerated, the growth trend of columnar crystals was suppressed, the crystal grains were refined, the hardness of the joint softening zone was improved, and the hardness distribution of the welded joint was more uniform. When the vibration frequency was 1 119 Hz, the Vickers hardness of the weld softening zone reached the highest value of 77. Vibration can effectively reduce the residual stress of the welded joint and the heat-affected zone. When the vibration frequency was 1119 Hz, the average value of the maximum residual stress of the welded joint and the heat-affected zone had reduced by 9.6% and 6.3% respectively, and the mechanical properties of the welded joint were improved.

-

表 1 焊接工艺参数

Table 1. Welding process parameters

样本 电流/A 电压/V 焊丝给进速度/(m∙min−1) 焊接速度/(mm∙s−1) 振动频率/Hz 振动加速度/(m∙s−2) 1 113 13.6 5.5 15 0 0 2 113 13.6 5.5 15 537 43 3 113 13.6 5.5 15 1119 28 4 113 13.6 5.5 11 537 43 5 113 13.6 5.5 11 1222 27.2 表 2 焊缝接头熔宽、熔深和余高

Table 2. Weld joint width, penetration and reinforcement

试样 熔宽/mm 熔深/mm 余高/mm 1 4.2 1.3 2.2 2 4.1 1.4 2.3 3 4.1 1.6 2.3 4 4.5 熔穿 2.3 5 4.5 熔穿 2.4 -

[1] 汪军. 汽车用铝合金冲压成型性能研究[J] . 热加工工艺,2015,44(17):123 − 125. [2] 刘茜. 满足汽车发展要求的零部件材料:塑料、铝和钢的应用状况[J] . 天津汽车,1997(3):29 − 33,44. [3] 李妍, 刘宁, 黄健康, 等. 提高铝钢焊接接头力学性能的研究现状[J] . 电焊机,2017,47(2):102 − 106. [4] LI X P, WANG X, LIANG Z M, et al. Influence of FSW Repairing Process on the Microstructures and Mechanical Properties of Friction Stir-Welded 6082Al Alloy[J] . Journal of Materials Engineering and Performance,2019,28(9):5299 − 5306. doi: 10.1007/s11665-019-04271-0 [5] 董春林, 董继红, 赵华夏, 等. 6082铝合金双轴肩FSW接头组织及腐蚀性能[J] . 焊接学报,2012,33(10):5 − 9. [6] PICKIN C G, YOUNG K. Evaluation of cold metal transfer (CMT) process for welding aluminum alloy[J] . Science and Technology of Welding and Joining,2006,11(5):583 − 585. doi: 10.1179/174329306X120886 [7] 刘强, 张亚雄, 张南南. 送丝速度对6061铝合金CMT焊接接头性能的影响[J] . 热加工工艺,2016,45(17):222 − 224. [8] 郭斌, 张李超. Cold Metal Transfer(CMT)与CMT Advanced的异同研究[J] . 精密成形工程,2016,8(2):50 − 54. doi: 10.3969/j.issn.1674-6457.2016.02.011 [9] RAMASWAMY A, MALARVIZHI S, BALASUBRAMANIAN V. Influence of post weld heat treatment on tensile properties of cold metal transfer (CMT) arc welded AA6061-T6 aluminium alloy joints[J] . Journal of the Mechanical Behavior of Materials,2019,28(1):135 − 145. doi: 10.1515/jmbm-2019-0015 [10] GU J L, DING J L, WILLIAMS S W, et al. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys[J] . Journal of Materials Processing Technology,2016,230:26 − 34. doi: 10.1016/j.jmatprotec.2015.11.006 [11] YUVARAJ K P, ASHOKA V P, DARSHAN R. Retraction note to: Effect of material position and ultrasonic vibration on mechanical behaviour and microstructure of friction stir-welded AA7075-T651 and AA6061 dissimilar joint[J] . Transactions of the Indian Institute of Metals,2020,73(1):1. doi: 10.1007/s12666-019-01821-x [12] DEGTYAREV V A. Estimation of the effect of vibration treatment on the life of low-carbon steel welded joints[J] . Strength of Materials,1999,31(2):185 − 190. doi: 10.1007/BF02511108 [13] BAGHERI B, ABBASI M, DADAEI M. Effect of water cooling and vibration on the performances of friction-stir-welded AA5083 aluminum joints[J] . Metallography Microstructure and Analysis,2020,9(1):33 − 46. doi: 10.1007/s13632-019-00606-4 [14] MOSTAFAPOUR A, GHOLIZADEH V. Experimental investigation of the effect of vibration on mechanical properties of 304 stainless steel welded parts[J] . International Journal of Advanced Manufacturing Technology,2014,70(5-8):1113 − 1124. doi: 10.1007/s00170-013-5350-x [15] TIAN Y, SHEN J, HU S, et al. Effects of ultrasonic vibration in the CMT process on welded joints of Al alloy[J] . Journal of Materials Processing Technology,2018,259:282 − 291. doi: 10.1016/j.jmatprotec.2018.05.004 [16] 陈轩, 卢庆华, 张静, 等. 高频微振条件下激光焊接组织研究[J] . 机械工程学报,2016,52(20):60 − 65. [17] 王红霞, 张国平, 许春香, 等. 机械振动对纯Al晶粒细化及凝固收缩的影响[J] . 铸造设备研究,2007(1):28 − 31. [18] 魏保立, 罗坤, 付伟, 等. 机械振动对2A14铝合金TIG焊接接头组织与性能的影响[J] . 轻合金加工技术,2021,49(4):68 − 73. -

下载:

下载: