Parameter optimization of laser keyhole spot welding of Al/steel based on orthogonal experiment design

-

摘要:

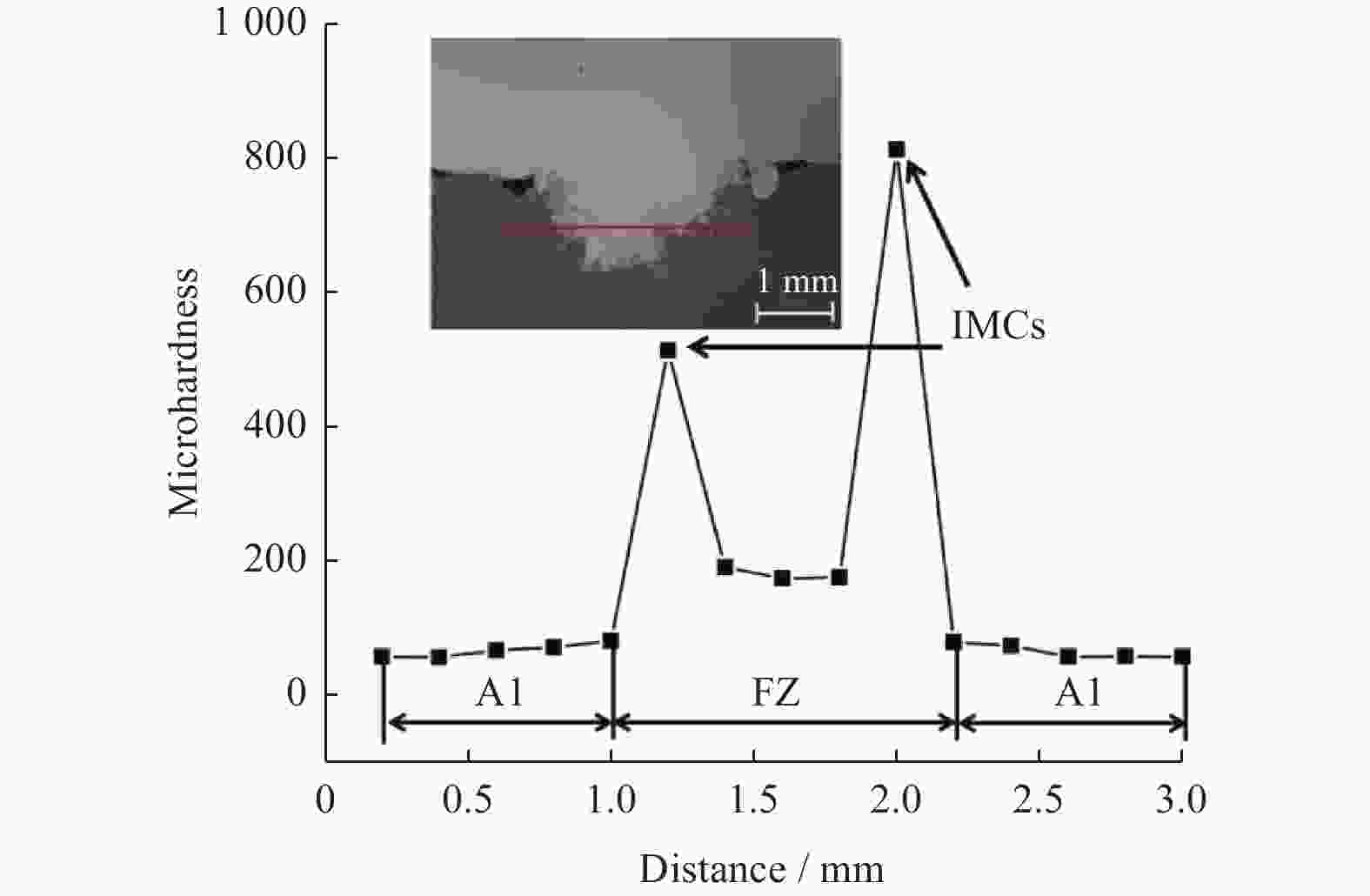

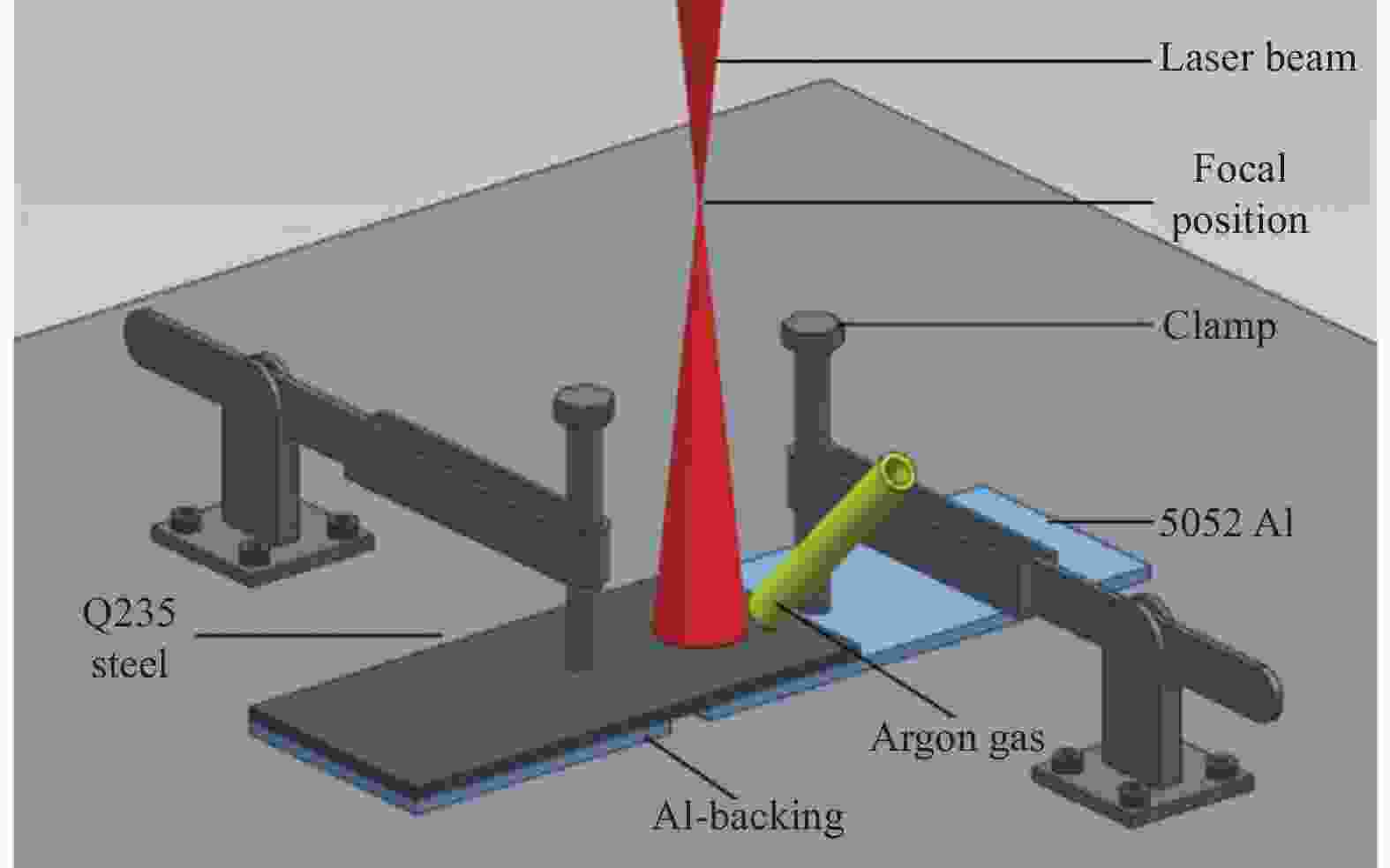

通过激光匙孔点焊技术实现铝与钢的焊接. 通过正交试验方法对铝/钢进行激光匙孔点焊试验,研究时间、功率和离焦量对接头力学性能的影响程度. 结果表明,激光功率对铝/钢激光匙孔点焊接头的力学性能影响最大,离焦量次之,焊接时间影响最少,最优参数为激光功率2.85 kW、离焦量22 mm、持续时间3 s,拉伸载荷达到1470 N. 焊缝处生成锥形熔化区,界面处无裂纹,生成包含Fe3Al、FeAl和FeAl2等金属间化合物(IMCs),最大显微硬度(HV)达到810.

Abstract:Aluminum and steel were welded by laser keyhole spot welding technology. The laser keyhole spot welding of Al/steel was tested by orthogonal experiment, influences of time, laser power and defocusing amount on mechanical properties of the joint were studied. The results show that the influence of laser power on the mechanical properties of Al/steel laser keyhole spot welding joints is the greatest, then defocusing amount, welding time affect the minimum. The optimal parameters are laser power 2.85 kW, defocusing amount 22 mm, duration 3 s, and tensile load is 1470 N. The cone-like fusion zone was formed at the weld seam and there was no crack, intermetallic compounds (IMCs) containing Fe3Al, FeAl and FeAl2 were formed at the interface. The maximum microhardness (HV) of the joint is 810.

-

表 1 母材的化学成分

Table 1. Chemical compositions of base materials

% 材料 Cu Mg Mn Fe Si Zn Cr Al C Ni Q235 钢 — — 0.147 Bal. 0.350 — 0.044 — 0.200 — AA5052铝 0.100 2.200~2.800 0.100 0.400 0.250 0.100 0.200 Bal. — — 表 2 试验因素和水平参数表

Table 2. Table of test factors and horizontal parameters

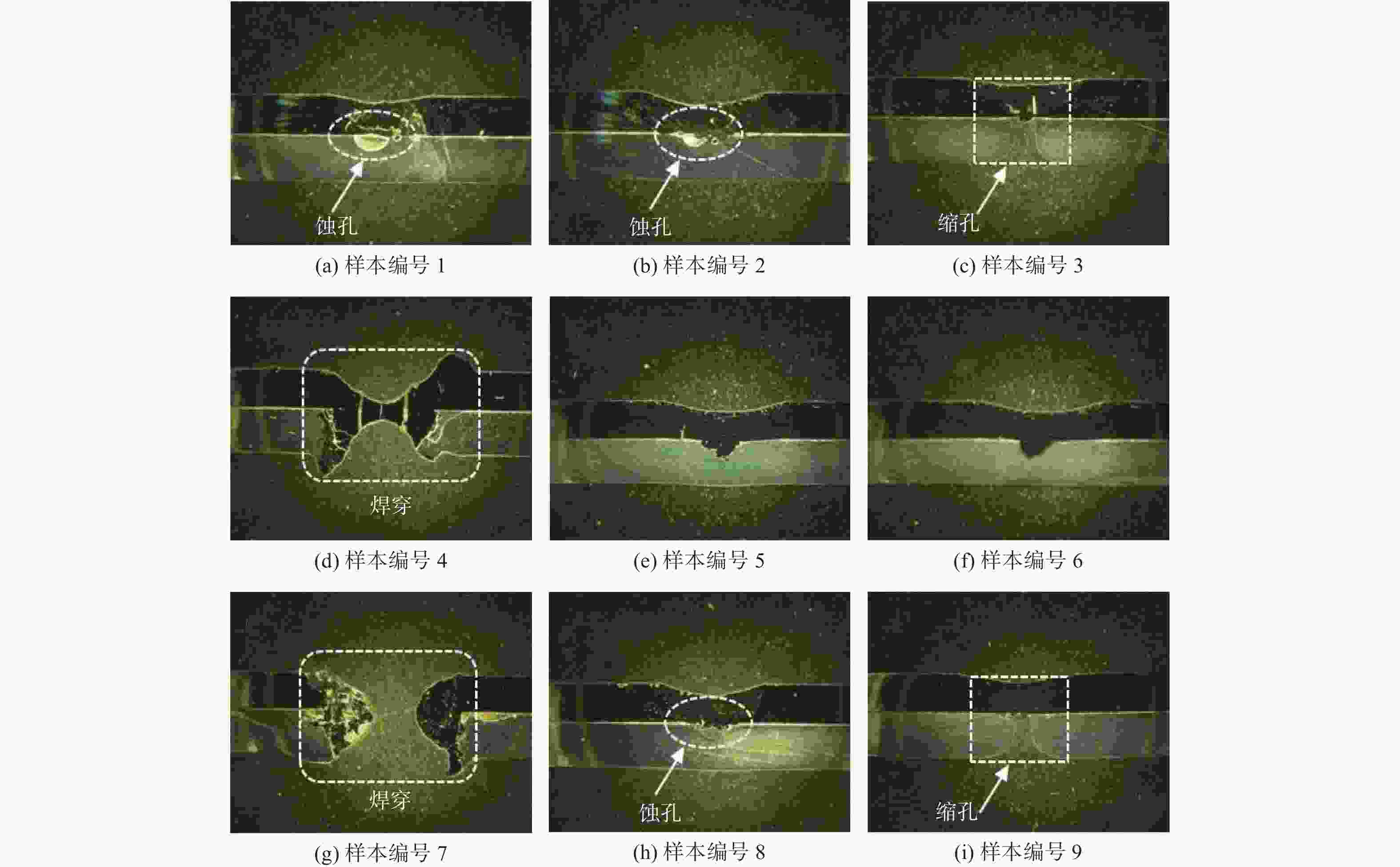

激光功率A/kW 离焦量B/mm 时间C/s A1=2.70 B1=20 C1=3 A2=2.85 B2=22 C2=4 A3=3.00 B3=24 C3=5 表 3 L9(34)正交试验参数和试验结果

Table 3. L9(34) orthogonal experimental parameters and experimental results

试验样本编号 试验因子 功率

/kW离焦量

/mm时间

/s试验方案 拉伸载荷

/N1 1 1 1 A1B1C1 519.00 2 1 2 2 A1B2C2 444.97 3 1 3 3 A1B3C3 446.54 4 2 1 2 A2B1C2 1037.51 5 2 2 3 A2B2C3 942.94 6 2 3 1 A2B3C1 872.40 7 3 1 3 A3B1C3 701.77 8 3 2 1 A3B2C1 896.97 9 3 3 2 A3B3C2 641.84 表 4 L9(34)正交试验数据处理结果

Table 4. Data processing results of L9(34) orthogonal experiment

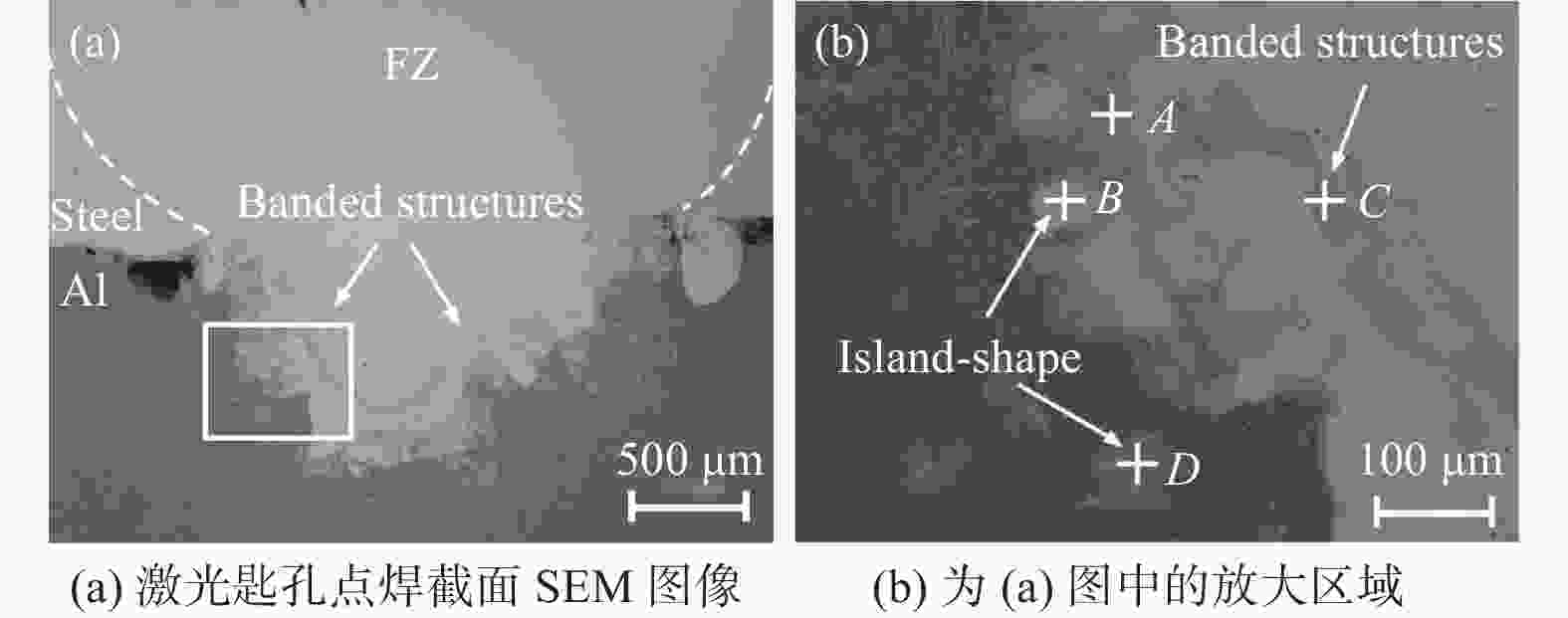

编号 激光功率A/kW 离焦量B/mm 时间C/s K1 1410.51 2258.28 2288.37 K2 2852.85 2284.88 2124.32 K3 2240.58 1960.78 2091.25 ${\overline {K}}_1 $ 470.17 809.64 762.79 $\overline {K}_2 $ 950.95 761.63 708.11 $\overline {K}_3 $ 746.86 653.59 697.08 Rj 480.78 156.04 65.71 表 5 图3所示点的EDS分析结果

Table 5. EDS analysis at points highlighted in Fig.3

% Points Fe Al Mg Possible phases A

B

C

D52.64

53.11

31.20

15.6745.97

45.68

65.11

80.741.27

1.21

3.69

3.59FeAl3

FeAl

FeAl2

FeAl3 -

[1] XIAO R, YANG J, TAN C W, et al. Fabrication of high strength and lightweight dissimilar material joints by laser: A review[C]// Proceedings of Advanced Laser Processing and Manufacturing III. [S.l.: s. n.], 2019. [2] SU J H, YANG J, LI Y L, et al. Microstructure and mechanical properties of laser fusion welded Al/steel joints using a Zn-based filler wire[J] . Optics & Laser Technology,2020,122:105882. doi: 10.1016/j.optlastec.2019.105882 [3] 韩锐波, 王红阳, 杨帆, 等. 铝合金与高强钢激光-电弧焊铆复合连接机制研究[J] . 机械工程学报,2020,56(6):57 − 64. [4] OLIVEIRA J, PONDER K, BRIZES E, et al. Combining resistance spot welding and friction element welding for dissimilar joining of aluminum to high strength steels[J] . Journal of Materials Processing Technology,2019,273:116192. doi: 10.1016/j.jmatprotec.2019.04.018 [5] 杜宜乐. 铝合金A6061与低碳钢Q235的电阻点焊研究[D]. 洛阳: 河南科技大学, 2012. [6] MIRZA F A, MACWAN A, BHOLE S D, et al. Effect of welding energy on microstructure and strength of ultrasonic spot welded dissimilar joints of aluminum to steel sheets[J] . Materials Science & Engineering: A,2016,668:73 − 85. [7] YANG J, SU J H, YU Z S, et al. Influence of Ni interlayer width on interfacial reactions and mechanical properties in laser welding/brazing of Al/Mg lap joint[J] . Science & Technology of Welding & Joining,2020,25(1):37 − 44. [8] PARDAL G, MECO S, GANGULY S, et al. Dissimilar metal laser spot joining of steel to aluminum in conduction mode[J] . International Journal of Advanced Manufacturing Technology,2014,73(1/2/3/4):365 − 373. doi: 10.1007/s00170-014-5802-y [9] PARDAL G, MECO S, DUNN A, et al. Laser spot welding of laser textured steel to aluminum[J] . Journal of Materials Processing Technology,2017,241:24 − 35. doi: 10.1016/j.jmatprotec.2016.10.025 [10] CHEN S H, HUANG J H, MA K, et al. Microstructures and mechanical properties of laser penetration welding joint with/without Ni-foil in an overlap steel-on-aluminum configuration[J] . Metallurgical & Materials Transactions A,2014,45(7):3064 − 3073. -

下载:

下载: