Comparative analysis of two linear defects at R-angle of hot rolled H-beam

-

摘要:

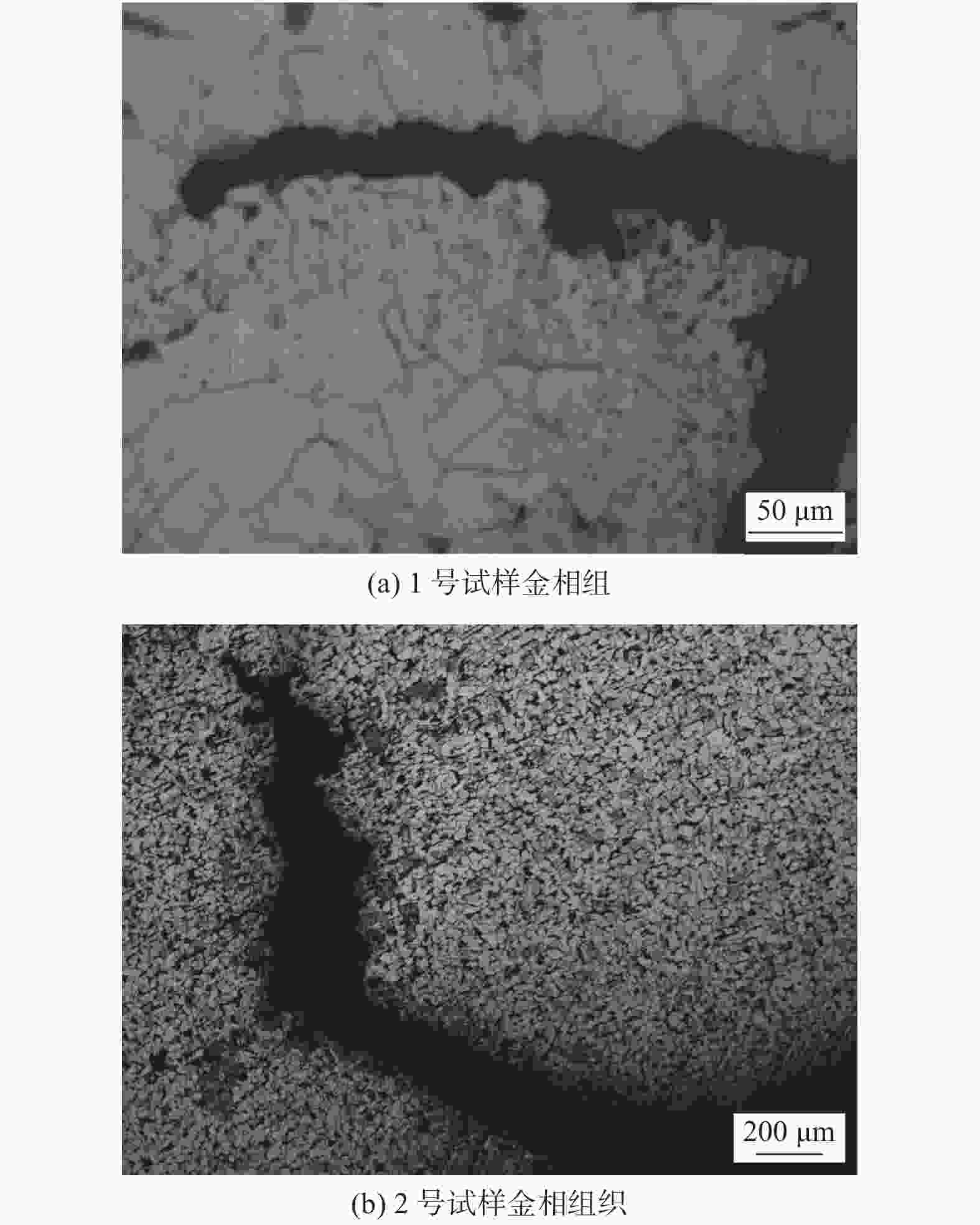

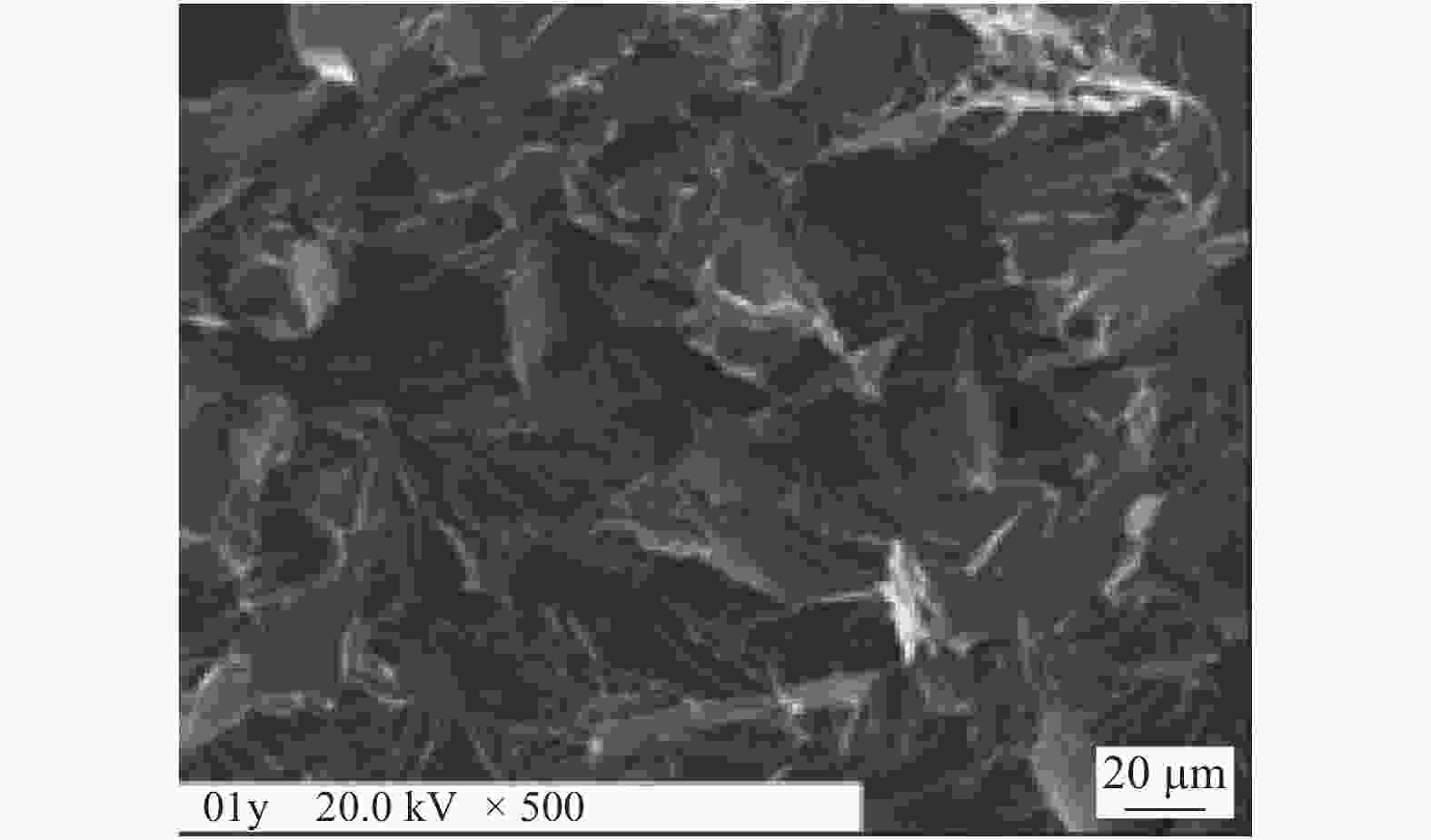

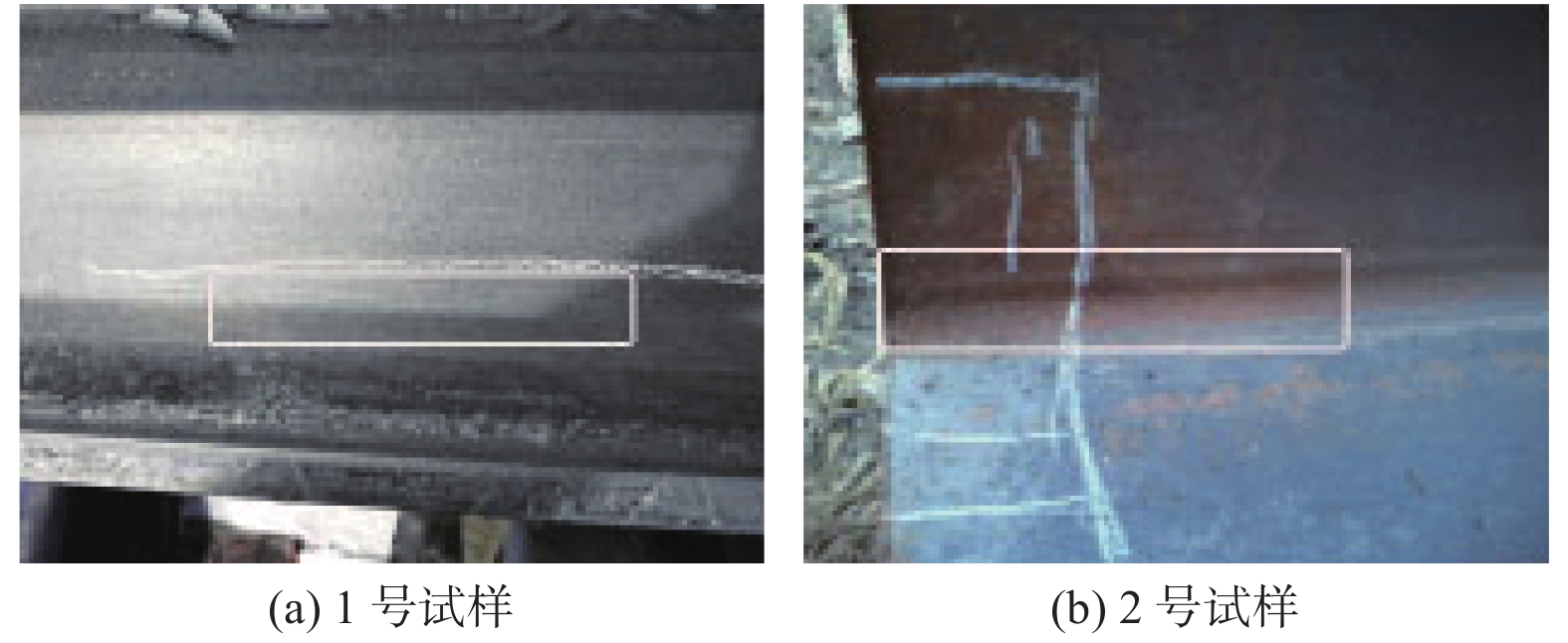

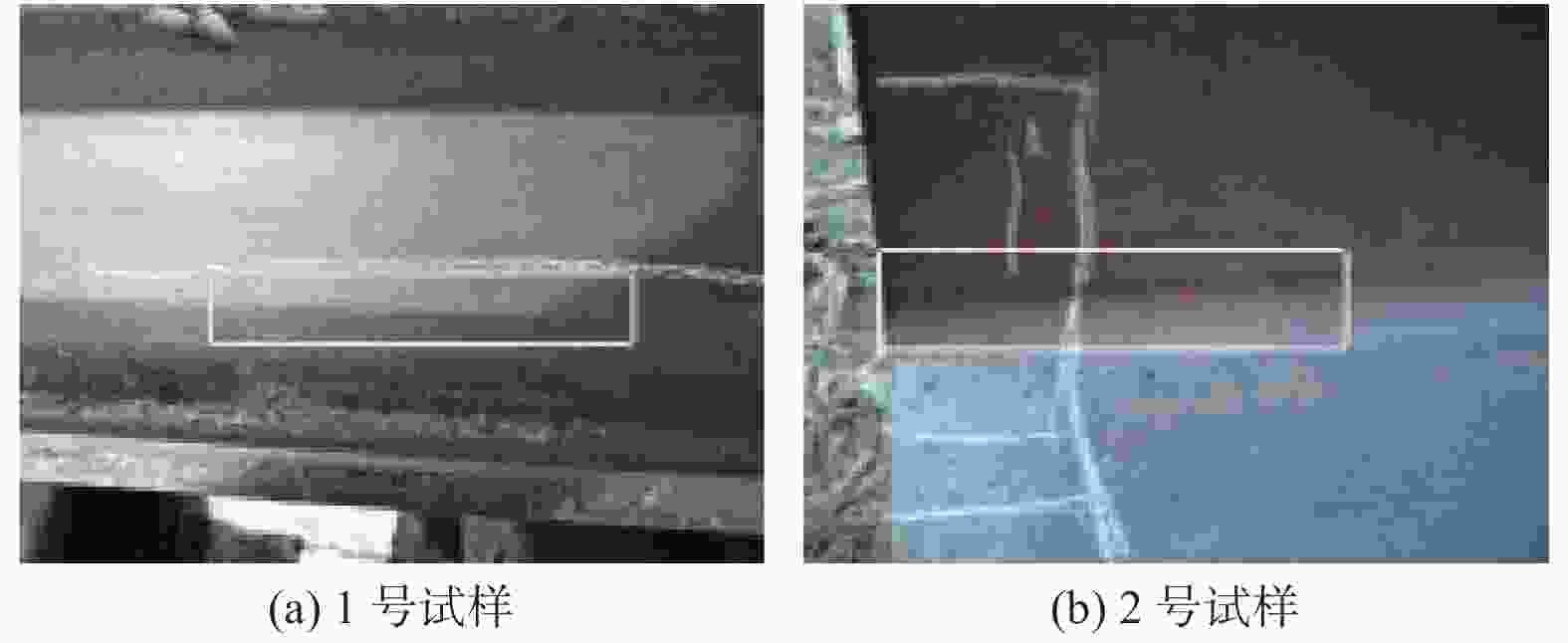

企业生产热轧H型钢过程中,在型钢腹板与翼板连接R角处且接近腹板一侧的位置,会出现两种位置相同、形貌相似的线形裂纹. 为有效区分这两种缺陷,通过现场取样、试验分析及生产数据统计等手段,采用金相观察、扫描电镜等分析方法,对两种线形缺陷组织进行宏观及微观分析. 研究结果表明,两种线形裂纹形成原因不同,产生工序也不同:一种为铸坯产生的热裂纹,后期加热轧制后形成R角处腹板裂纹;另一种为矫直工序产生的冷裂纹,在成品R角处形成矫直裂纹.

Abstract:During the production of hot rolled H-beam, two linear cracks with the same position and similar morphology will appear at the R-angle connecting the web and flange, and close to the side of the web. In order to distinguish these two kinds of defects effectively, the macro and micro analysis of the two kinds of linear defect structures were carried out by means of on-site sampling, experimental analysis, production data statistics, metallographic observation and scanning electron microscope. The results show that both the causes and the production processes of the two linear cracks are all different. One is the hot crack generated from the billet, and the web crack at the R-angle is formed after the later heating and rolling. The other is the cold crack generated by the straightening process, and the straightening crack is formed at the R-angle of the finished product.

-

Key words:

- hot rolled H-beam /

- linear crack /

- oxidation dot /

- web crack /

- straightening crack

-

表 1 氧化圆点化学成分

Table 1. Composition of oxidation dots

元素 质量分数/ % CK 6.76 OK 30.65 SiK 12.03 MnK 29.22 FeK 21.34 -

[1] 张鑫. H250×255×14×14 H型钢腹板裂纹调查和分析[J] . 山西冶金,2014,37(3):82 − 84. doi: 10.3969/j.issn.1672-1152.2014.03.030 [2] 王建锋, 段永卿, 师艳秋. H型钢腹板裂纹的形成原因分析及改进措施[J] . 钢铁研究,2014,42(5):51 − 53. [3] 邹冰梅, 阎建武, 彭晓华, 等. 异形坯生产主要质量缺陷分析及预防[J] . 炼钢,2013,29(1):74 − 78. [4] 吴坚, 汤寅波, 胡春林, 等. 钒微合金化h型钢表面裂纹研究与控制[J] . 安徽冶金科技职业学院学报,2015,25(3):14 − 17. doi: 10.3969/j.issn.1672-9994.2015.03.006 [5] 霍喜伟, 刘春伟, 孙晓庆, 等. H 型钢腹板裂纹内部异质颗粒形成机理研究[J] . 连铸,2015,40(2):64 − 66. [6] 谈群峰. H 型钢厚腹板工艺延迟裂纹原因分析[J] . 山西冶金,2021,44(2):57 − 58. [7] 华锋. H 型钢矫裂成因分析与改进[J] . 甘肃冶金,2021,43(4):57 − 59. doi: 10.3969/j.issn.1672-4461.2021.04.017 [8] 段永强, 王琨, 刘宏波. H 型钢矫裂缺陷的原因分析及对策[J] . 包钢科技,2017,43(6):23 − 25. doi: 10.3969/j.issn.1009-5438.2017.06.009 -

下载:

下载: