Structural optimization of cathode steel bar for 400 kA aluminum electrolytic cell

-

摘要:

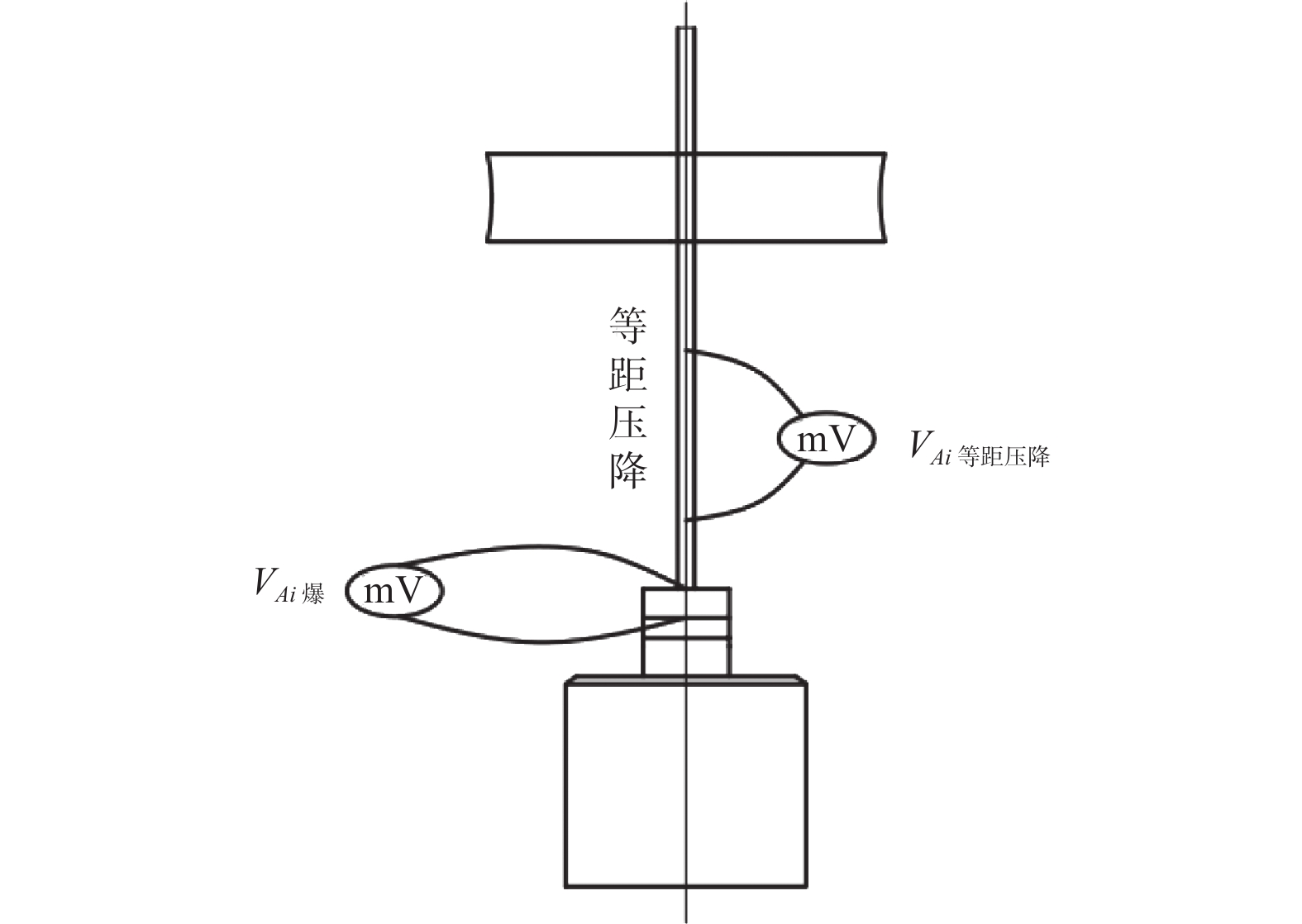

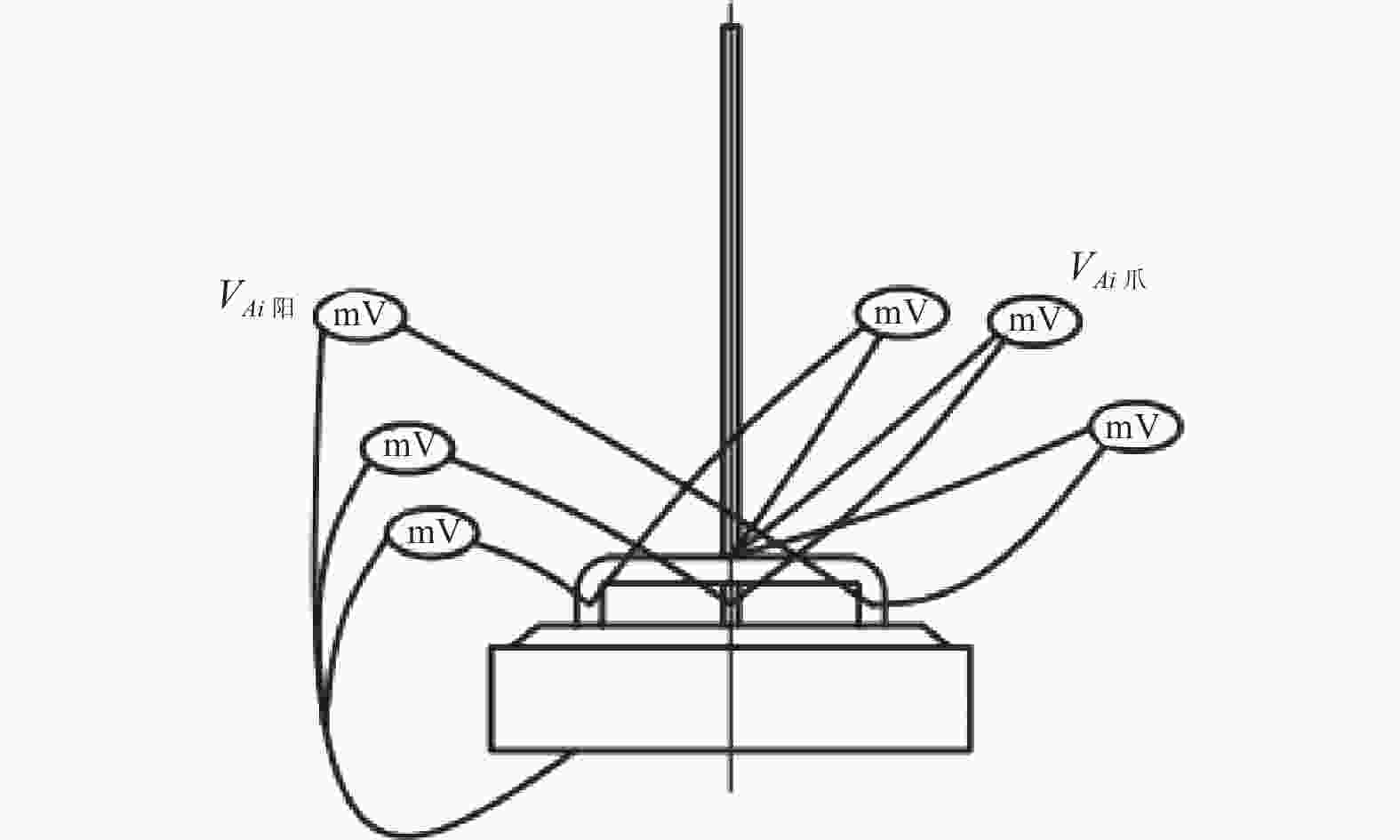

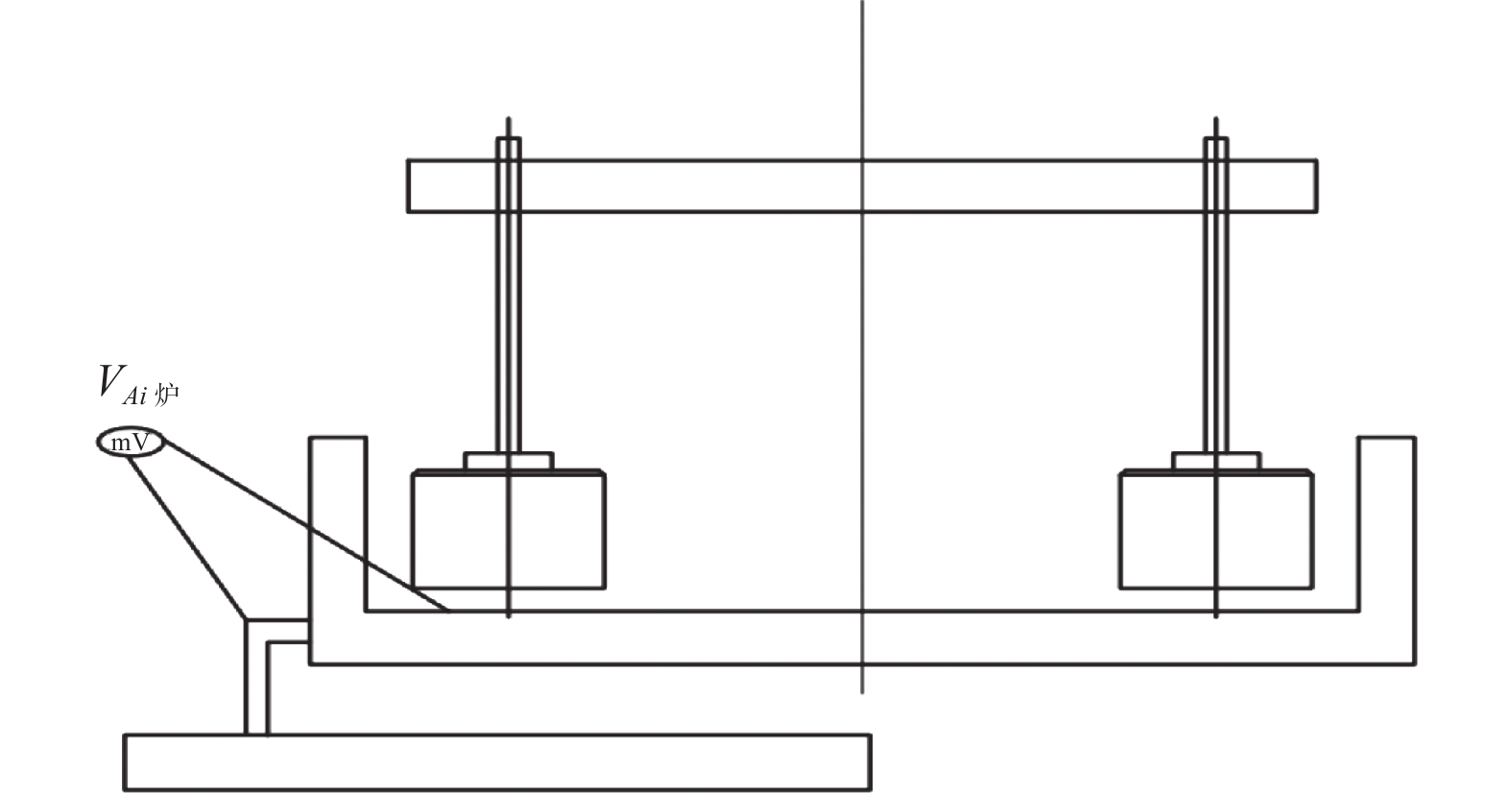

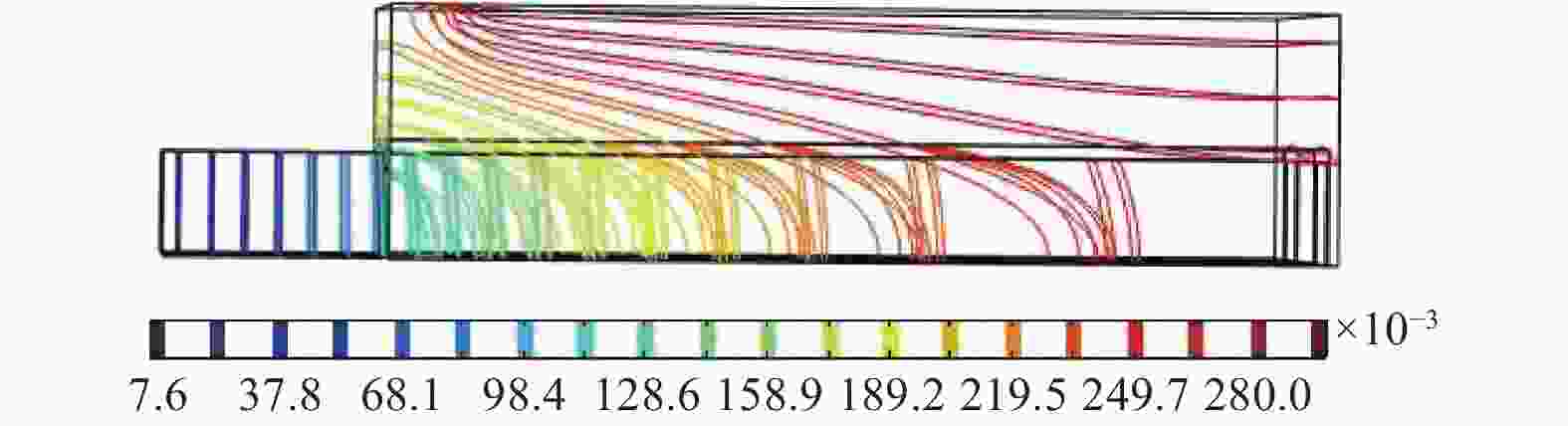

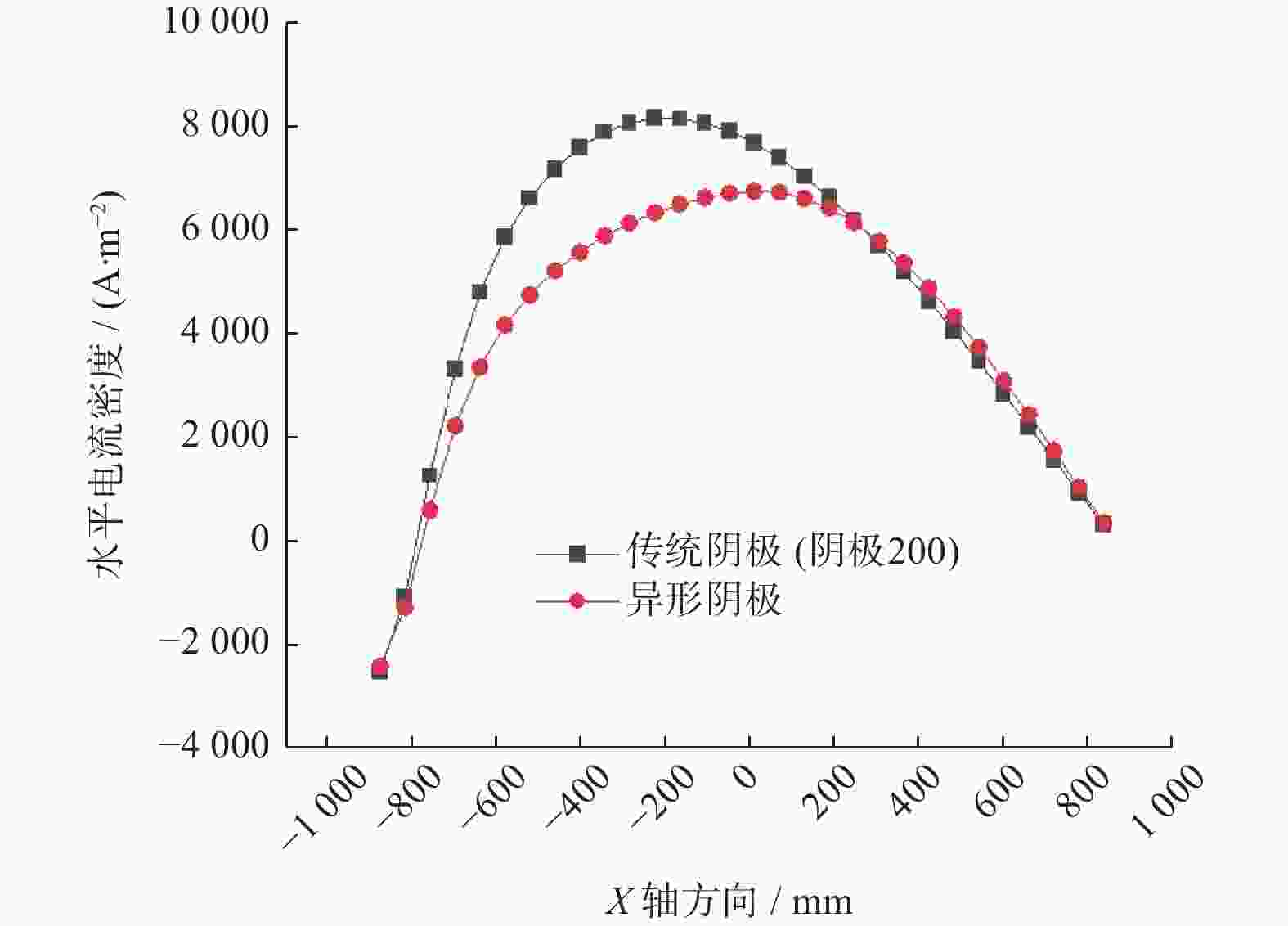

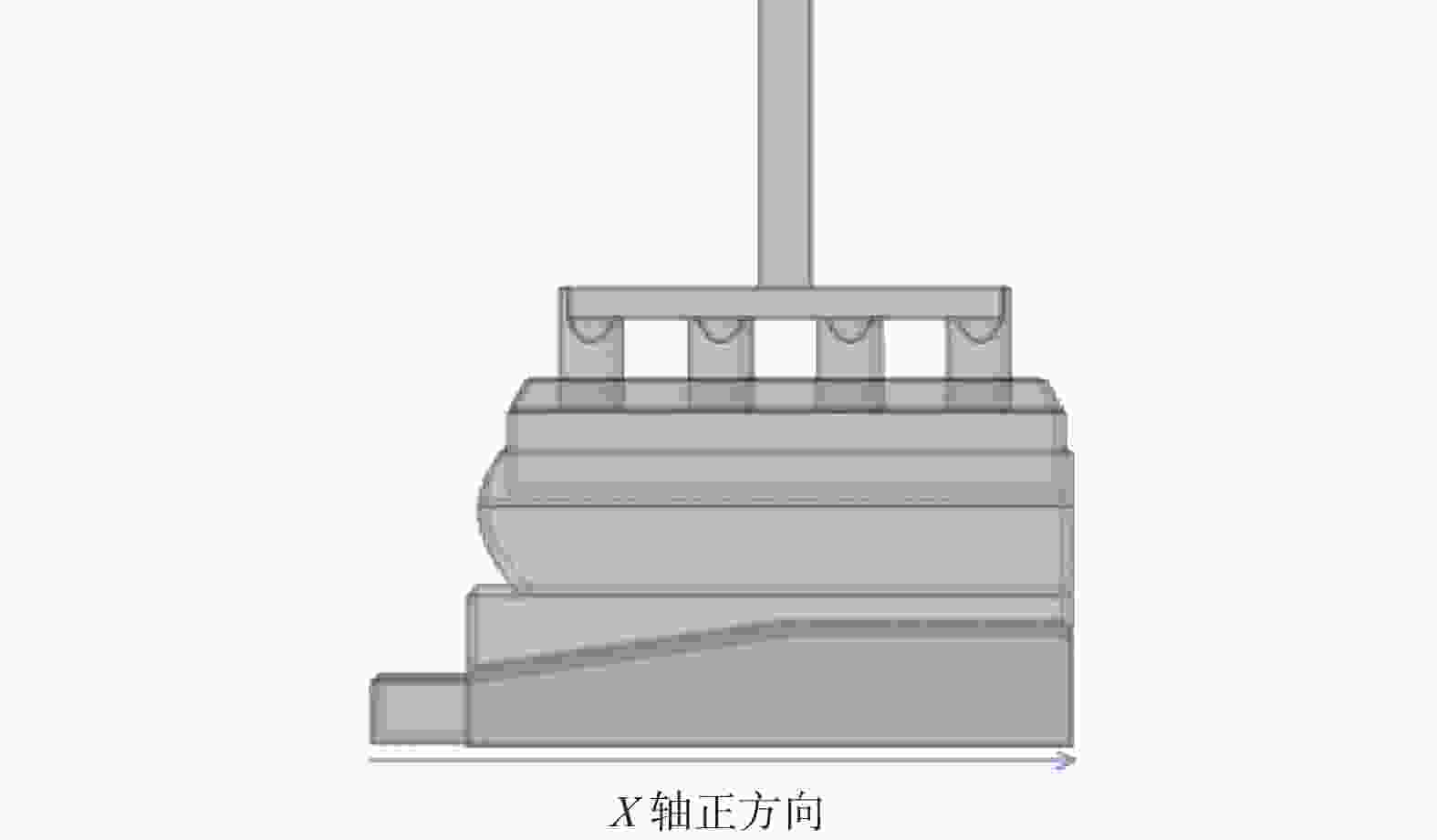

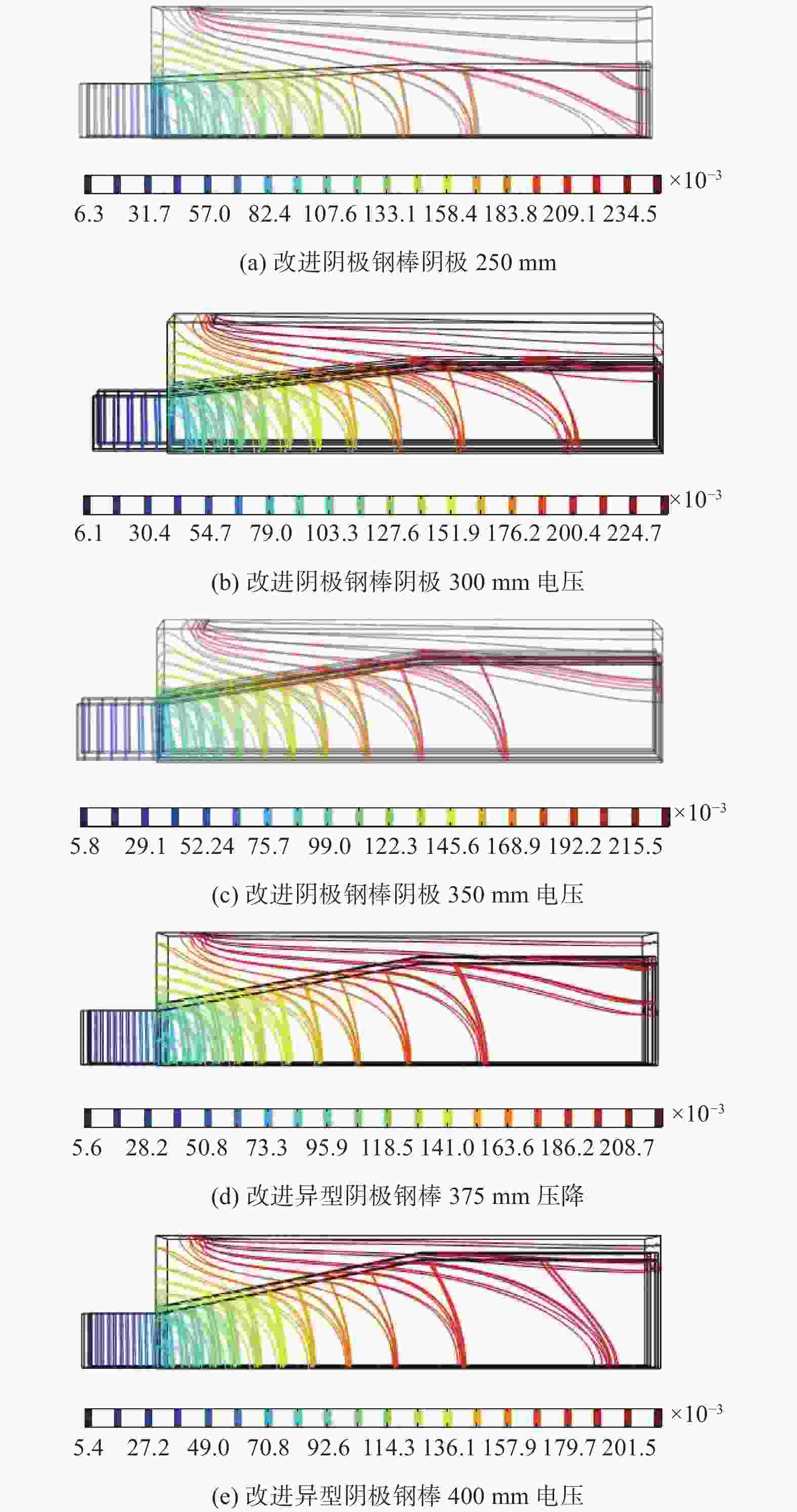

采用有限元仿真计算法对400 kA铝电解槽进行传统阴极钢棒结构和异型阴极钢棒结构下电场仿真模拟,主要包括阴极电压压降和铝液水平电流大小. 通过分析异型阴极钢棒结构,提出一种改进阴极钢棒结构,此阴极钢棒具有凸起并延伸的特点. 研究表明,改进阴极钢棒使铝电解槽电压和铝液水平电流进一步降低,提高了电解槽电流效率,单个槽子能耗降低约33.6 kW•h,改善了电解铝的稳定性.

Abstract:Finite element simulation method was used to simulate the electric field of 400 kA aluminum electrolytic cell under the traditional cathode steel bar structure and the special-shaped cathode steel bar structure, which mainly included the cathode voltage drop and the level current of aluminum liquid. An improved structure of cathode steel bar was proposed by analyzing the abnormal structure of the cathode steel bar. The cathode steel bar has the characteristics of bulge and extension. The result shows that the improved cathode steel bar can further reduce the voltage and level current of aluminum electrolytic cell, thus improving the current efficiency of electrolytic cell, reducing the energy consumption of a single cell by about 33.6 kW•h, and improving the stability of electrolytic aluminum.

-

Key words:

- aluminum electrolytic cell /

- cathode steel bar /

- cathode voltage /

- level current

-

表 1 材料参数

Table 1. Material parameters

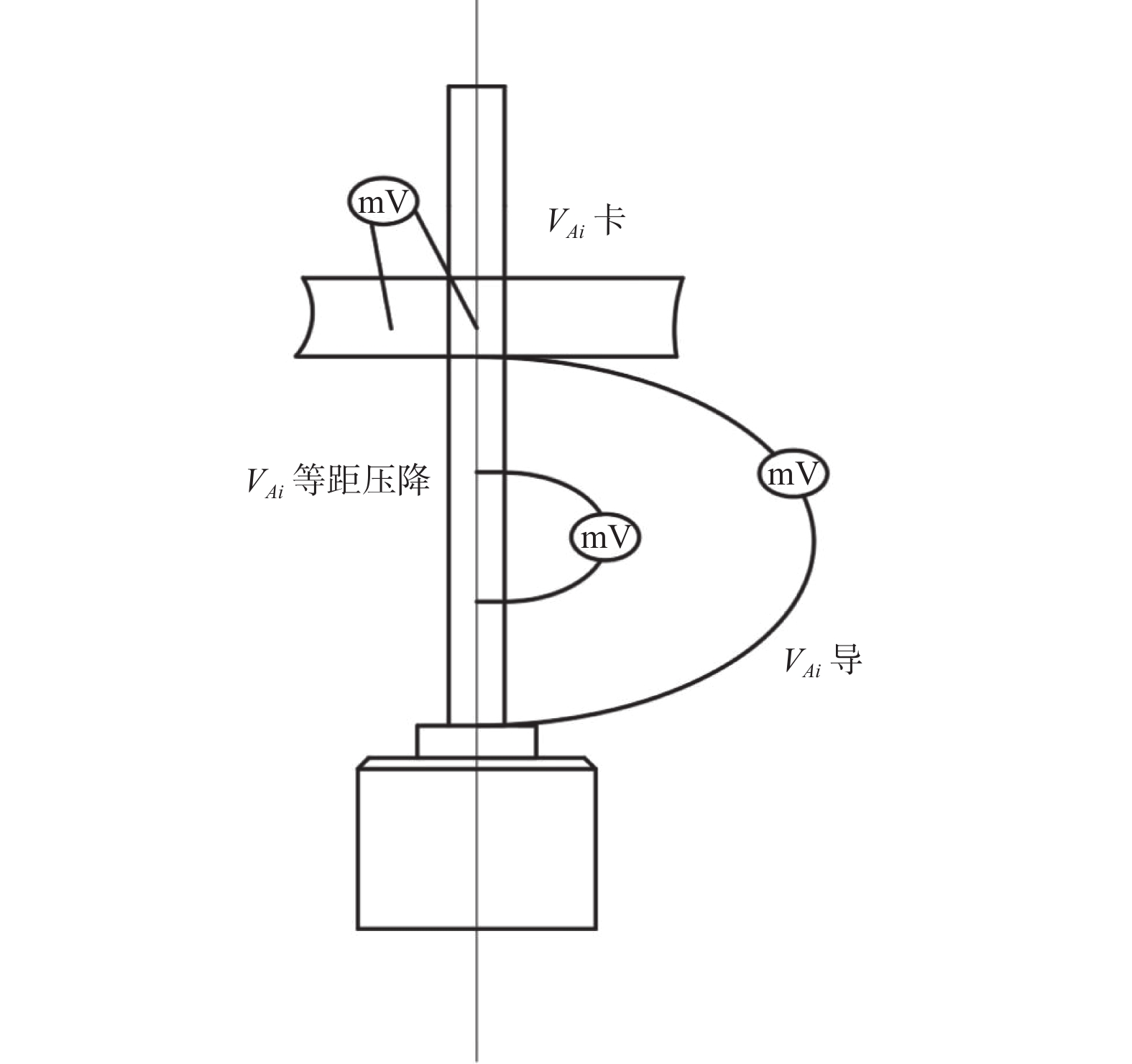

参数 铝导杆 钢爪 磷生铁 阳极炭块 电解质 铝液 阴极炭块 阴极钢棒 电导率/(S•m−1) 2.6×107 3.3×106 2.96×105 3.9×104 2.1×102 4.2×106 2.6×104 1.3×106 表 2 电压测量值与仿真计算值

Table 2. Voltage measured value and simulation calculated value

部位 电压测量值/mV 电压仿真计算值/mV 阳极 — 265.0 电解质及铝液 — 1480.0 阴极 299.2 295.1 总压降 2056.0 2040.1 -

[1] 张琨, 曹曦. 超低能耗铝电解技术研究和经济效益分析[J] . 有色冶金节能,2020,36(2):22 − 25. [2] 边韩国. 电解槽寿命的影响因素[J] . 中国有色金属,2014(8):60 − 61. [3] YANG S, LI J, XU Y J, et al. Optimization of horizontal current in metal pad by using cathode with heightened collector bars in aluminum reduction cell[J] . The Chinese Journal of Nonferrous Metals,2012,22(10):2951 − 2958. [4] BAN Y G , LIU J, MAO Y, et al. Cathode structure optimization research for aluminum reduction cell[M]//MARTIN O. Light metals 2018. Cham: Springer, 2018: 1345 − 1352. DOI:10.1007/978-3-319-72284-9_176. [5] 罗伟林. 330KA铝电解槽生产过程中电流效率的提升研究[J] . 中国金属通报,2019(2):16 − 17. doi: 10.3969/j.issn.1672-1667.2019.02.009 [6] 王俊伟, 周云峰, 方斌, 等. 降低水平电流减少铝液动态波动铝电解节能技术研究[J] . 有色金属(冶炼部分),2020(4):26 − 29. [7] WANG Q, LI B K, WANG F, et al. Magnetohydrodynamic model coupling multiphase flow in aluminum reduction cell with innovative cathode protrusion[M]//SADLER B A. Light Metals 2013. Cham: Springer, 2013: 615 − 619. [8] INGO B, RINGSBY O B. Composite collector bar: US8273224 B2[P]. 2012-05-17. [9] 李劫, 张红亮, 徐宇杰, 等. 一种可控调节铝液中水平电流的铝电解槽阴极结构: CN201110089796.9[P]. 2011-09-14. [10] 李劼, 程迎军, 赖延清, 等. 大型预焙铝电解槽电、热场的有限元计算[J] . 计算物理,2003,20(4):351 − 355. doi: 10.3969/j.issn.1001-246X.2003.04.013 [11] 陈喜平, 梁学民, 郭龙. 一种铝电解阴极炭块与阴极钢棒组装结构: CN201320325426.5[P]. 2013-12-04. [12] SONG Y, FENG N X, PENG J P, et al. The Influence of Cathode Shape on Current Density and Metal Heave in 300 kA Aluminum Reduction Cell[M]//HYLAND M. Light Metals 2015. Cham: Springer, 2015: 827 − 830. [13] 曾水平, 王沙沙, 王蓉娟. 300 kA预焙阳极铝电解槽物理场的计算机仿真[J] . 系统仿真学报,2015,27(5):935 − 942. -

下载:

下载: