Experimental study on stiffness characteristics of Vossloh W300 fastener system under assembly state

-

摘要:

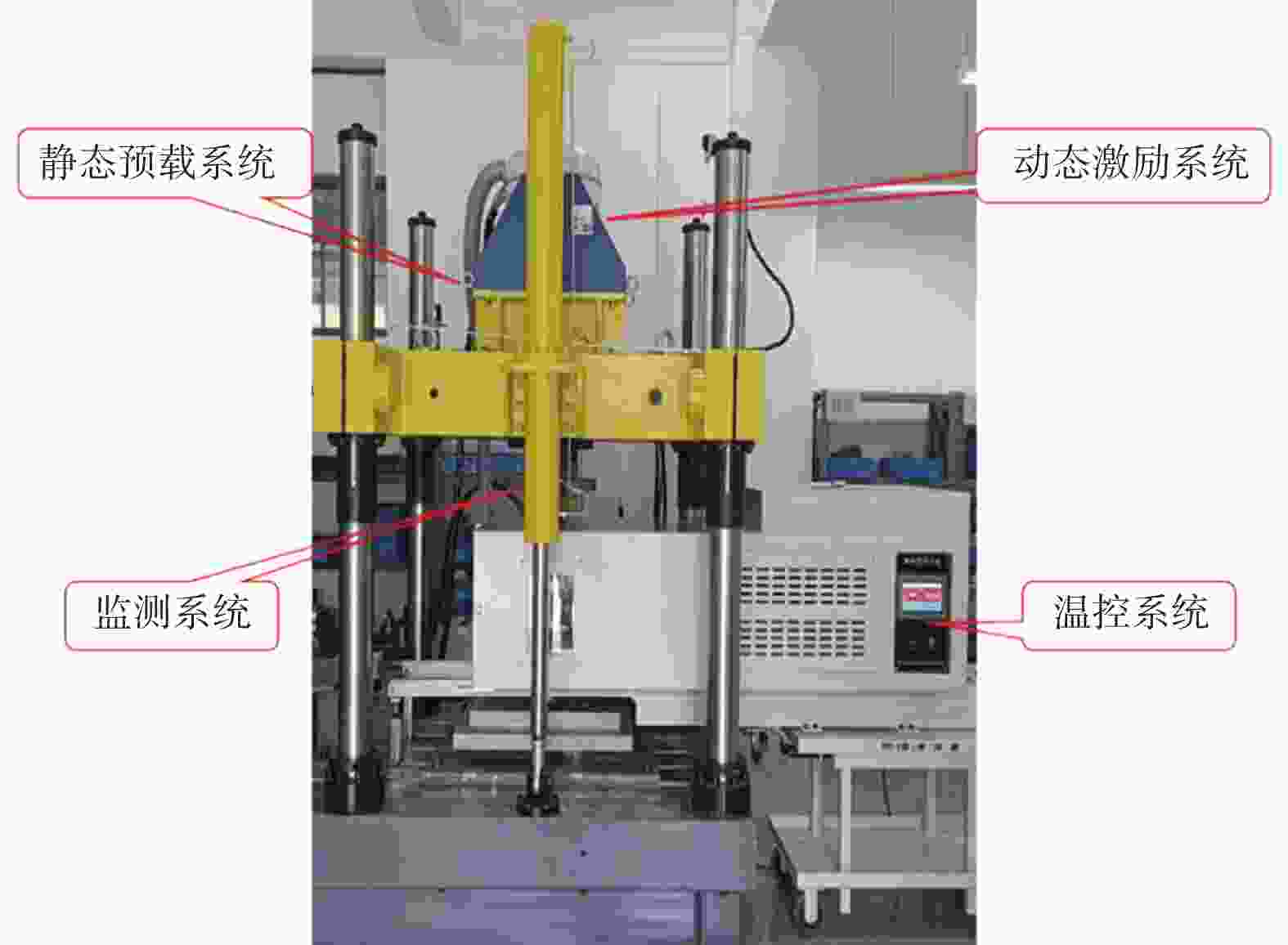

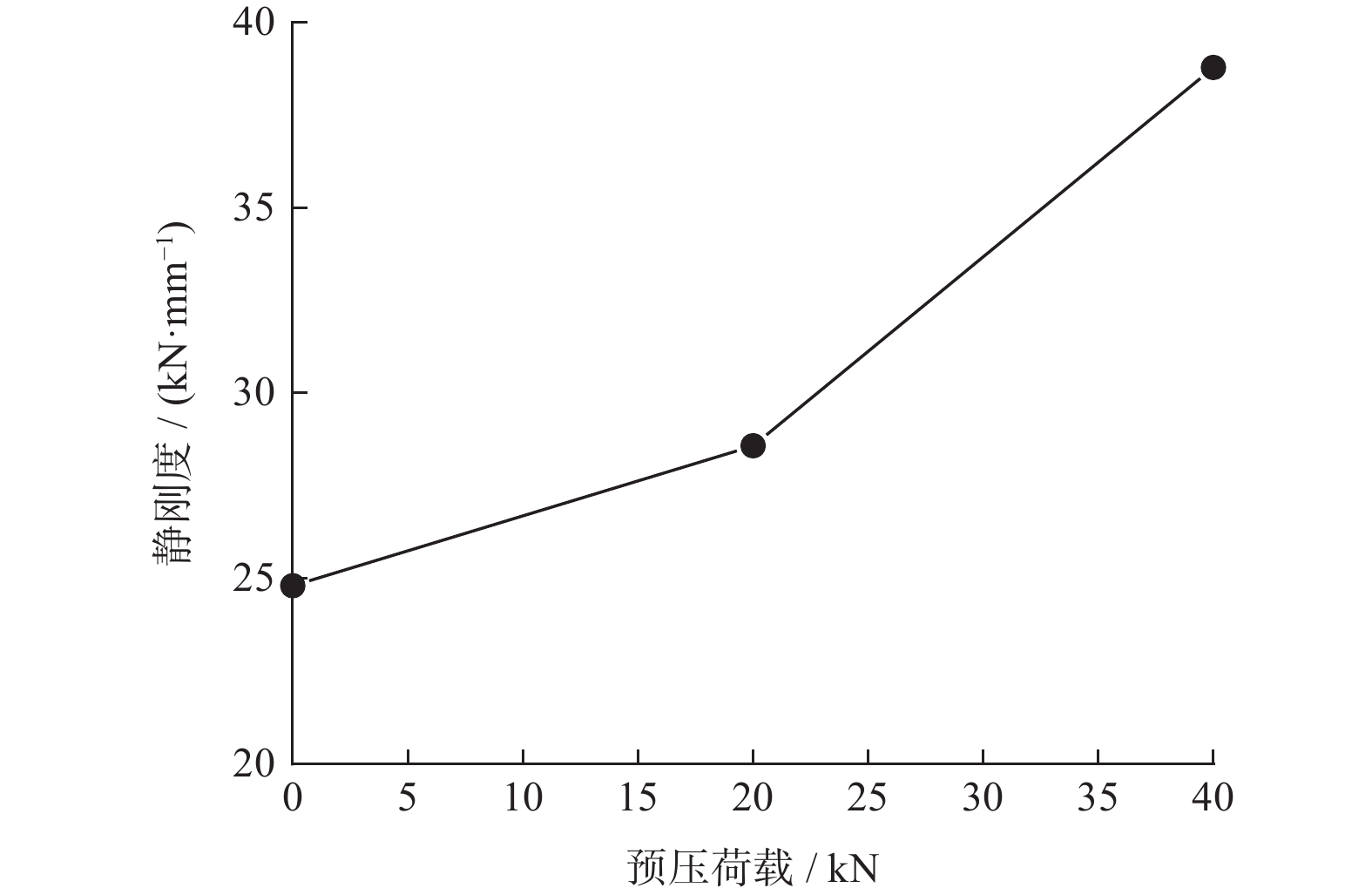

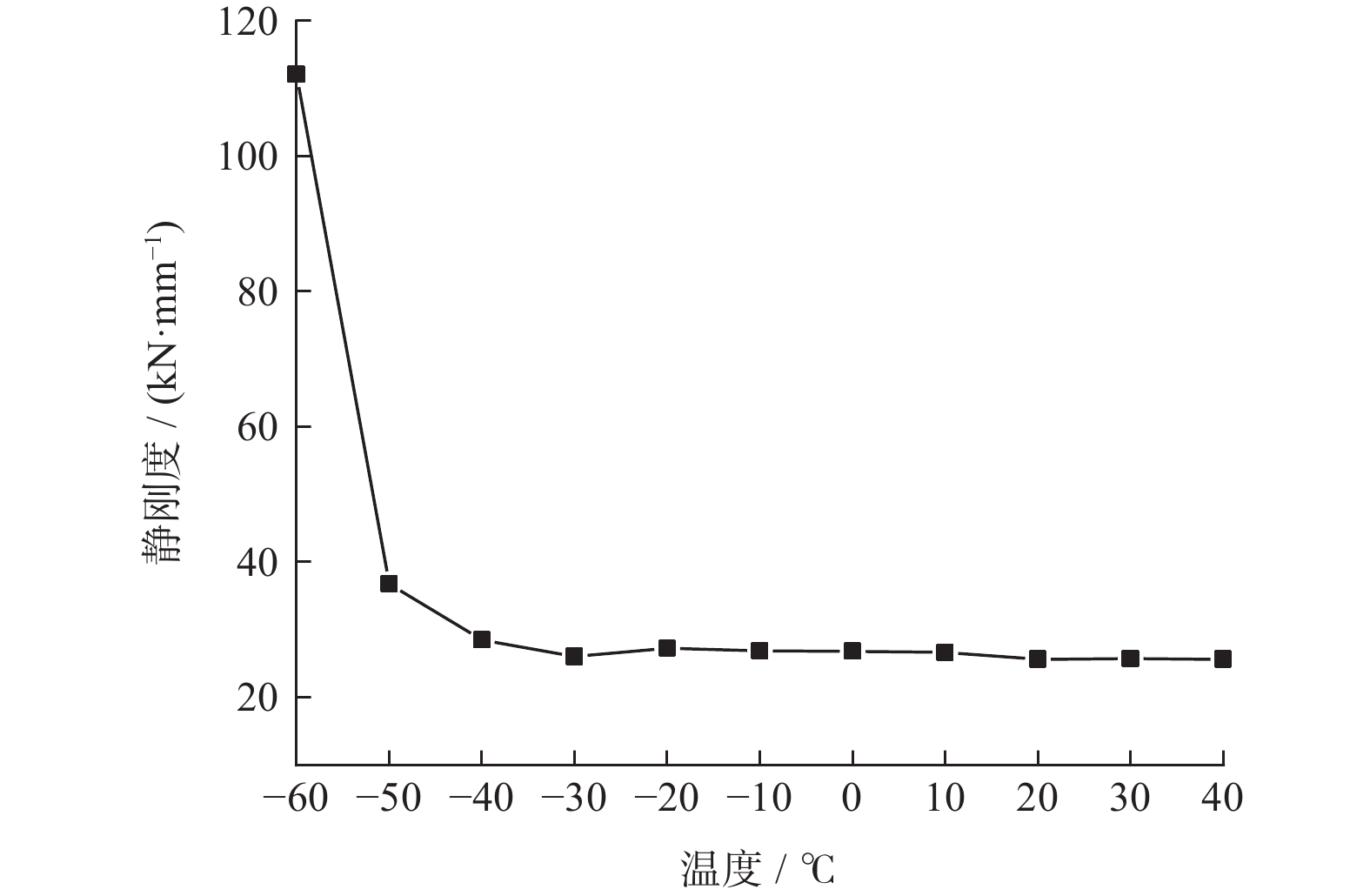

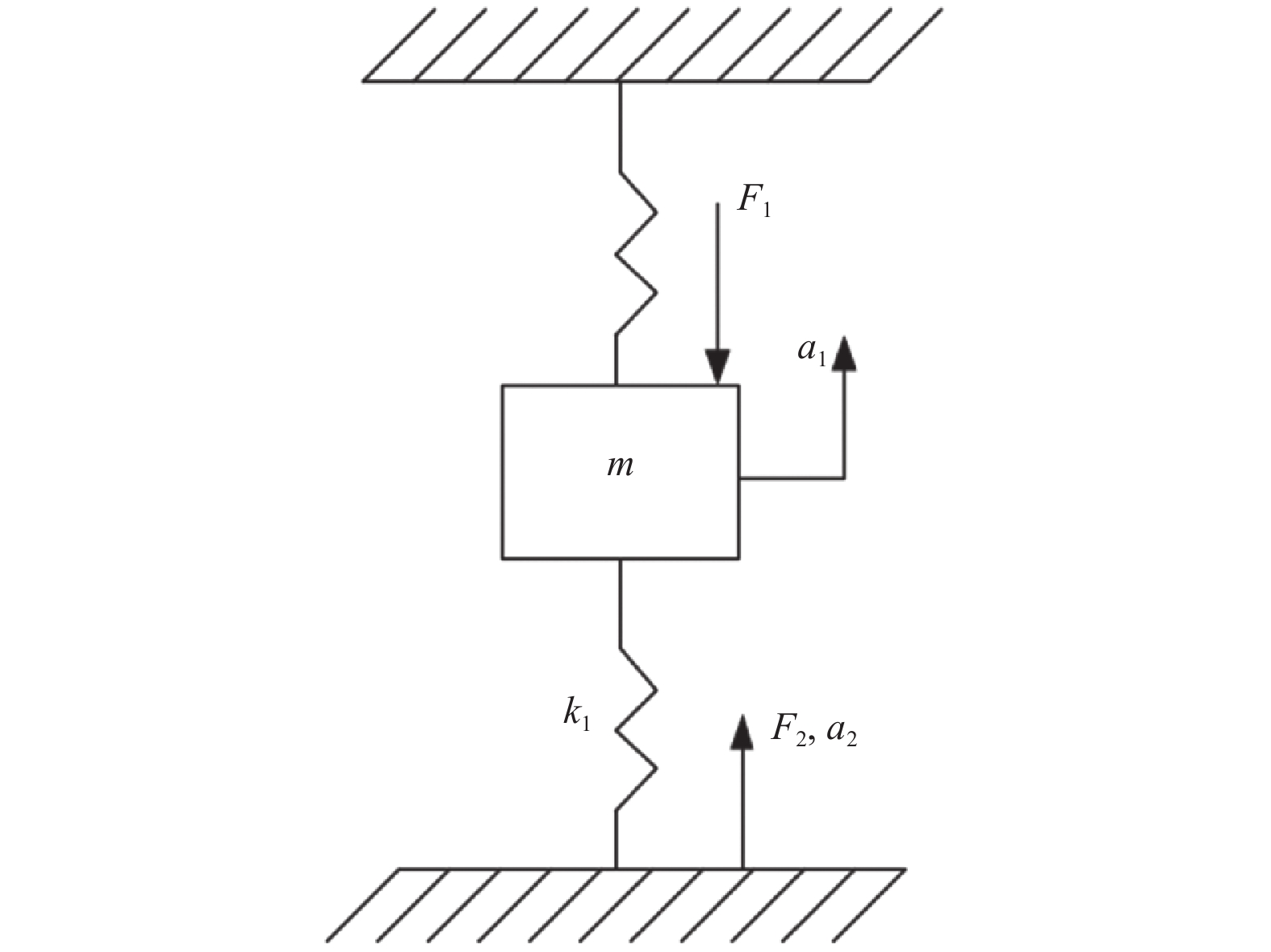

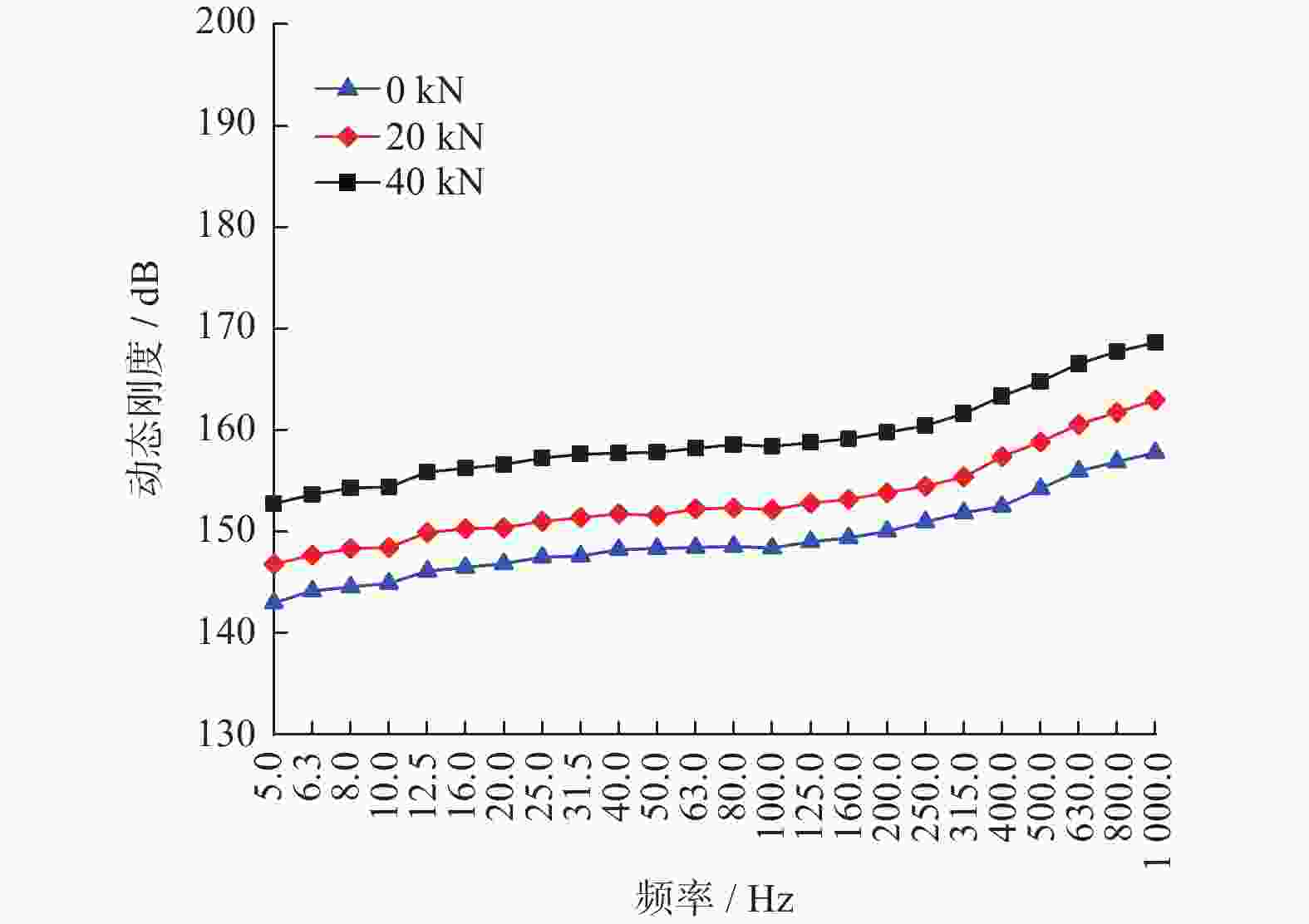

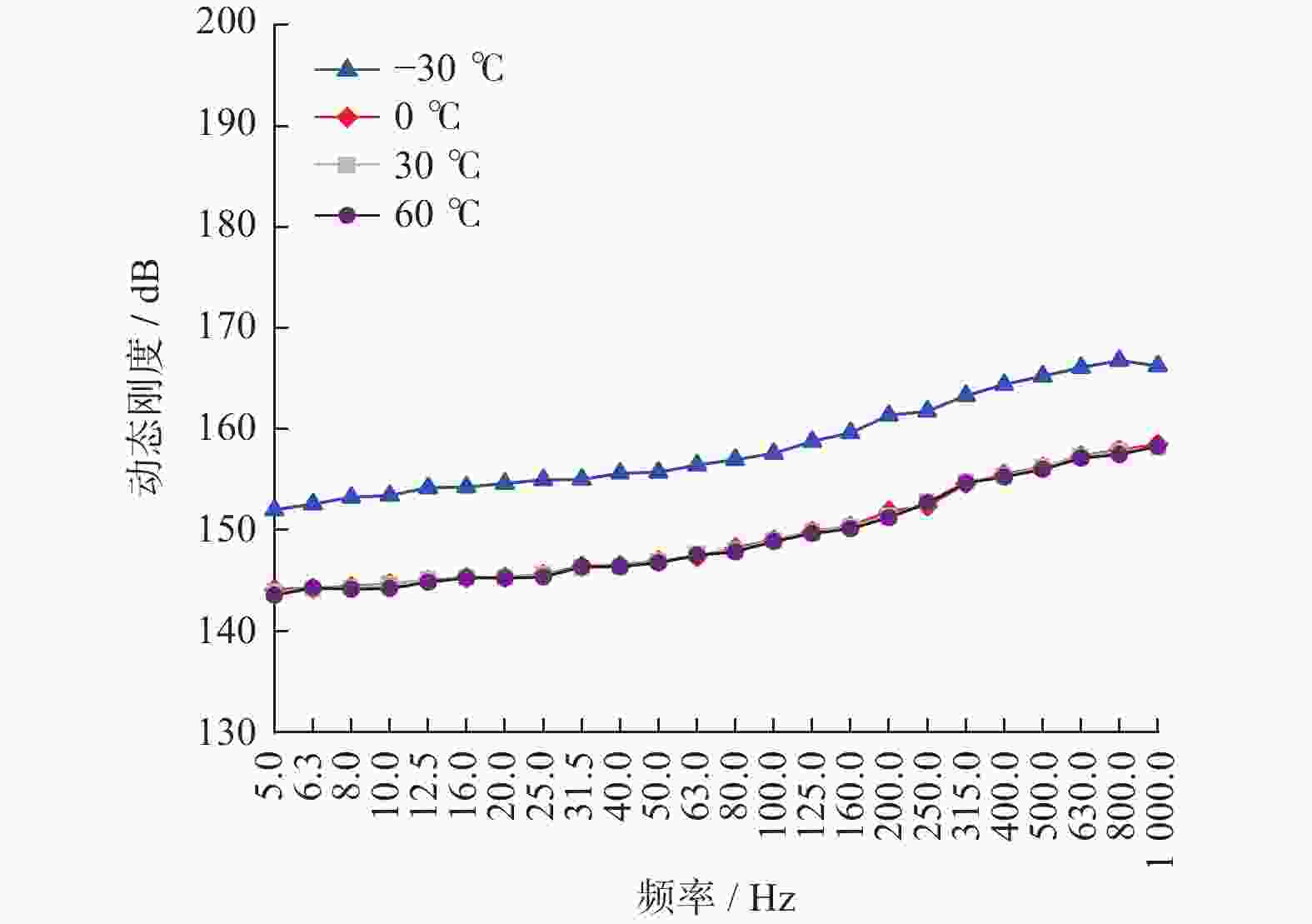

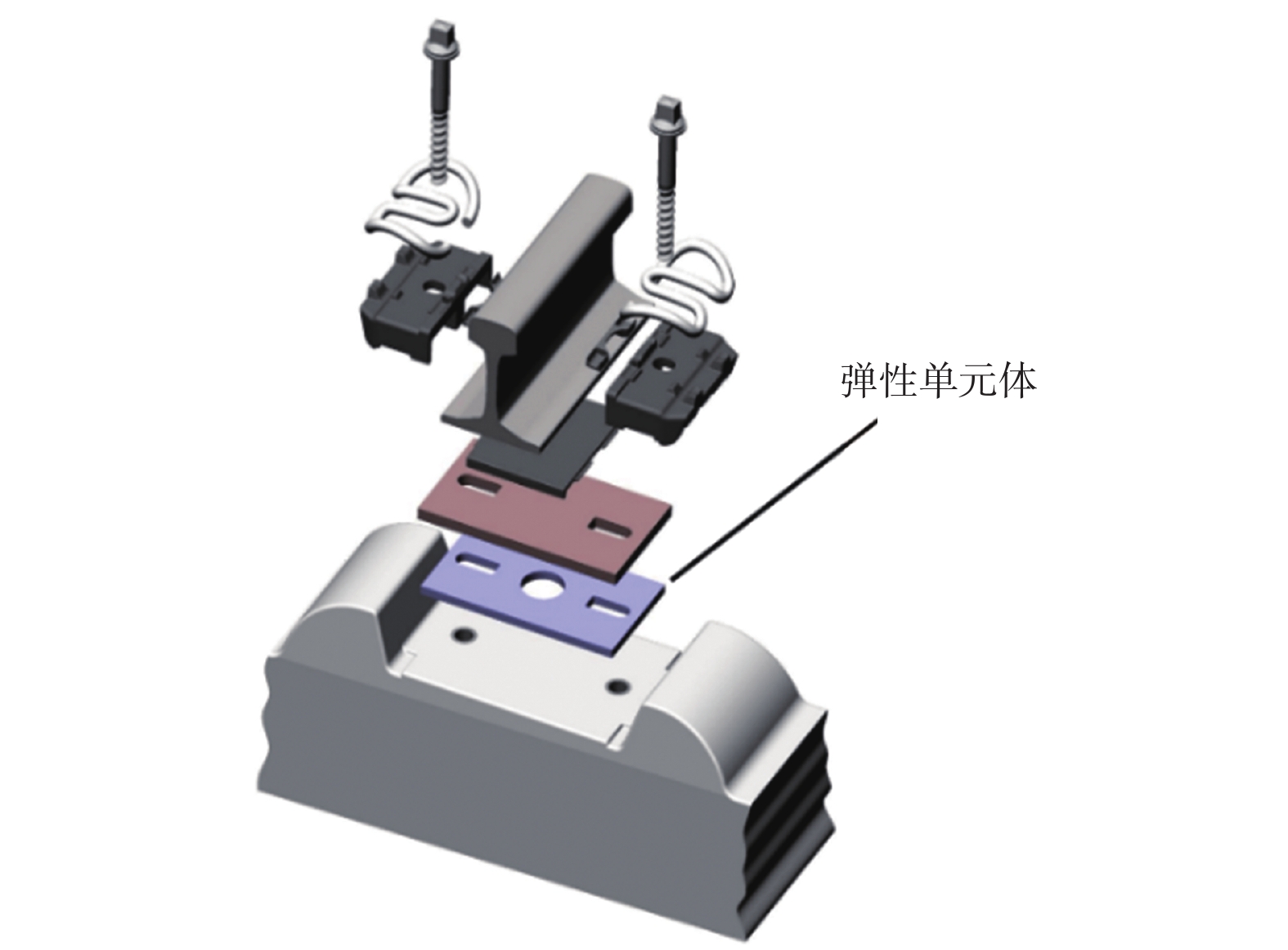

利用高频疲劳动刚度试验平台,结合高速铁路实际运行状况,对福斯罗W300扣件系统组装状态下刚度特性进行研究,得到以下结果. 1)不同预压荷载下,静态和动态刚度有相同增长趋势,20 kN(40 kN)预压荷载下静刚度值比无预压荷载下增大17.7% (59.5%),40 kN下静刚度值明显超出扣件系统静刚度设计限值. 20 kN(40 kN)预压荷载下动态刚度比0 kN下增大4 dB(10 dB). 2)扣件系统静态和动态刚度均表现出低温敏感性,当温度低于20 ℃时,静刚度值随温度降低而上升,特别是在−30 ℃到−60 ℃时静刚度值急剧上升,−50 ℃(−60 ℃)时静刚度是20 ℃时的1.4(4.4)倍. −30 ℃下,其动态刚度比30 ℃时增大8~10 dB,弹性单元体丧失弹性,直接影响扣件系统减振效果. 3)扣件系统刚度在5~1000 Hz时有明显频变特性,预载一定时,动态刚度随频率增大而增大,1000 Hz下动态刚度值比国家标准5 Hz下增大15 dB.

Abstract:Using the high-frequency fatigue dynamic stiffness test platform and combining with the actual operation conditions of high-speed railway, the stiffness characteristics of Vossloh W300 fastener system under assembly state were studied, and following results were obtained. 1) Under different preloading loads, the static and dynamic stiffness have the same growth trend, and the static stiffness under 20 kN (40 kN) preloading load is 17.7% (59.5%) higher than that without preloading load, the static stiffness corresponding to 40 kN obviously exceeds the design limit of the overall static stiffness of the fastener system. The dynamic stiffness under 20 KN (40 kN) preloading load is 4 dB (10 dB) greater than that under 0 kN. 2) Both the static and dynamic stiffness of the fastener system show low temperature sensitivity. When the temperature is lower than 20 ℃, the static stiffness increases with the decrease of temperature, especially the static stiffness increases sharply from −30 ℃ to −60 ℃, and the static stiffness at −50 ℃ (−60 ℃) is 1.4 (4.4) times that of 20 ℃. The dynamic stiffness at −30 ℃ is 8~10 dB greater than that at 30 ℃, and the elastic unit loses elasticity, which directly affects the vibration reduction effect of the fastener system. 3) The fastener system stiffness has obvious frequency variation characteristics within 5~1000 Hz. When the preload is certain, the dynamic stiffness increases with the increase of frequency, and the dynamic stiffness value at 1000 Hz is 15 dB higher than that at 5 Hz in the national standard.

-

-

[1] 石培泽. 钢轨嵌入式钢弹簧浮置板轨道减振性能分析[J] . 铁道建筑,2019,59(10):114 − 118. doi: 10.3969/j.issn.1003-1995.2019.10.27 [2] SAINZ-AJA J, CARRASCAL I, POLANCO J A, et al. Self-compacting recycled aggregate concrete using out-of-service railway superstructure wastes[J] . Journal of Cleaner Production,2019,230:945 − 955. doi: 10.1016/j.jclepro.2019.04.386 [3] 韦凯, 赵泽明, 欧灵畅, 等. WJ-8型扣件弹性垫板低温动力性能及其影响研究[J] . 铁道工程学报,2018,35(3):31 − 37. doi: 10.3969/j.issn.1006-2106.2018.03.006 [4] ESVELD C. 现代铁路轨道[M]. 王平, 陈嵘, 井国庆, 译. 北京: 中国铁道出版社, 2014. [5] 于春华. 铁路钢轨扣件发展综述[J] . 铁道标准设计,2006(S1):188 − 191. [6] SADEGHI J, SEYEDKAZEMI M, KHAJEHDEZFULY A. Nonlinear simulation of vertical behavior of railway fastening system[J] . Engineering Structures,2020,209:110340. doi: 10.1016/j.engstruct.2020.110340 [7] THOMPSON D J, VLIET W J V, VERHEIJ J W. Developments of the indirect method for measuring the high frequency dynamic stiffness of resilient elements[J] . Journal of Sound & Vibration,1998,213(1):169 − 188. [8] 韦凯, 周昌盛, 王平, 等. 扣件胶垫刚度的温变性对轮轨耦合随机频响特征的影响[J] . 铁道学报,2016,38(1):111 − 116. doi: 10.3969/j.issn.1001-8360.2016.01.018 [9] 张攀. 高铁无砟轨道扣件系统弹性垫板温/频变动力特征及其影响研究[D]. 成都: 西南交通大学, 2016. [10] 刘迪辉, 范迪, 欧阳雁峰, 等. 温度对橡胶隔振器力学性能的影响[J] . 噪声与振动控制,2014,34(3):203 − 206, 210. doi: 10.3969/j.issn.1006-1335.2014.03.043 [11] 白晓鹏. 微孔聚氨酯弹性材料力学性能研究及应用[D]. 株洲: 湖南工业大学, 2015. [12] 韦凯, 杨帆, 王平, 等. 扣件胶垫刚度的频变性对地铁隧道环境振动的影响[J] . 铁道学报,2015,37(4):80 − 86. doi: 10.3969/j.issn.1001-8360.2015.04.012 [13] 张树峰. 无砟轨道扣件系统力学性能分析[D]. 成都: 西南交通大学, 2016. [14] 豆银玲, 杨麒陆, 王平. Vossloh300型扣件胶垫刚度频变特性对高铁高频振动的影响[J] . 中国铁路,2017(7):68 − 74. [15] 国家铁路局. 高速铁路扣件系统试验方法: TB/T 3396.3—2015[S]. 北京: 中国铁道出版社, 2015. [16] 英国国家标准学会. 声学和振动: 弹性元件的振动−声学传输性能的实验室测量: 第2部分 连续变换活动用弹性支架动态刚性的测定直接法: BS EN ISO 10846−2—2008[S/OL]. [2021−09−30]. http://www.bsi-global.com. -

下载:

下载: