Research on colorless silicone oil injection measurement system for neutral pen-refill

-

摘要:

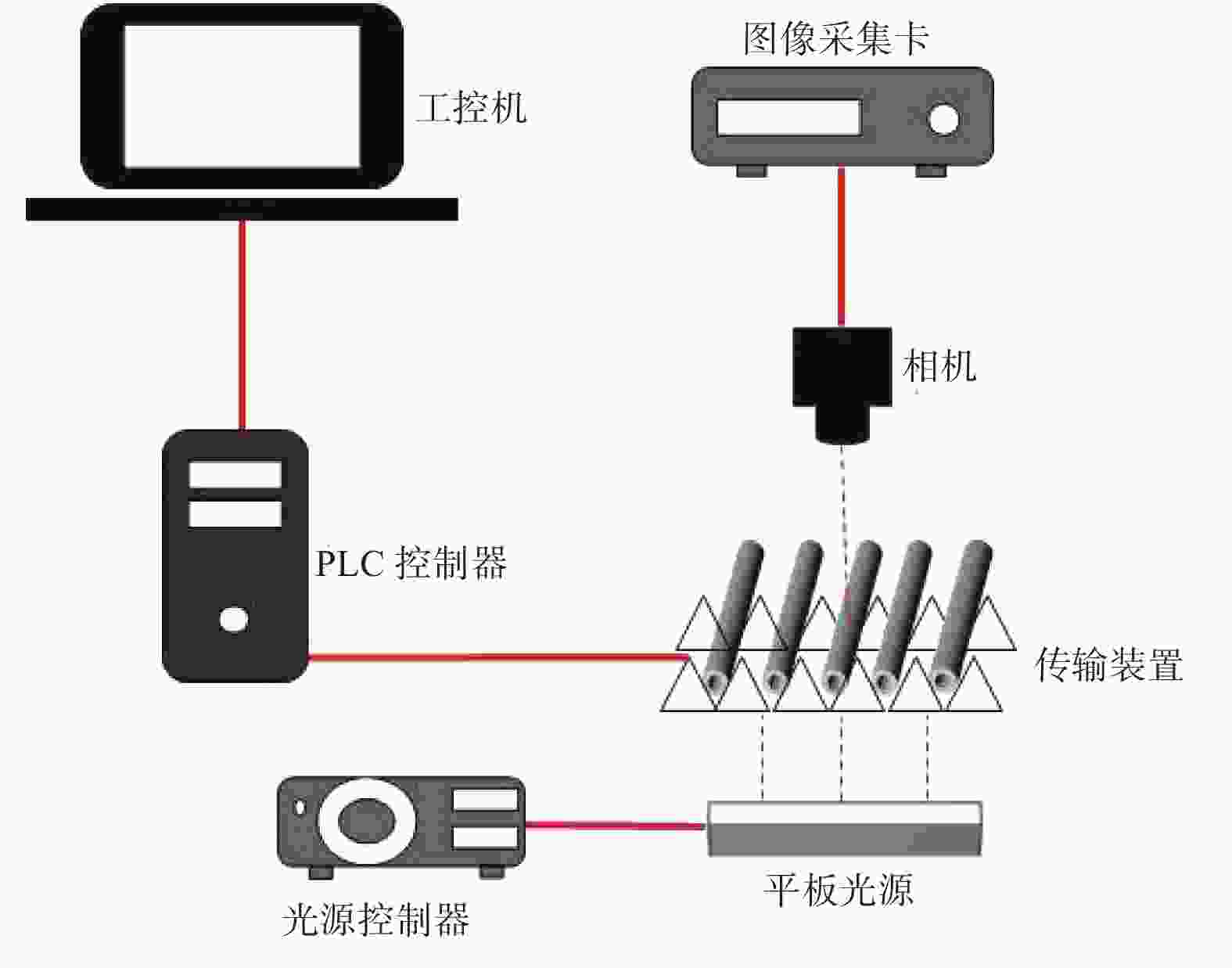

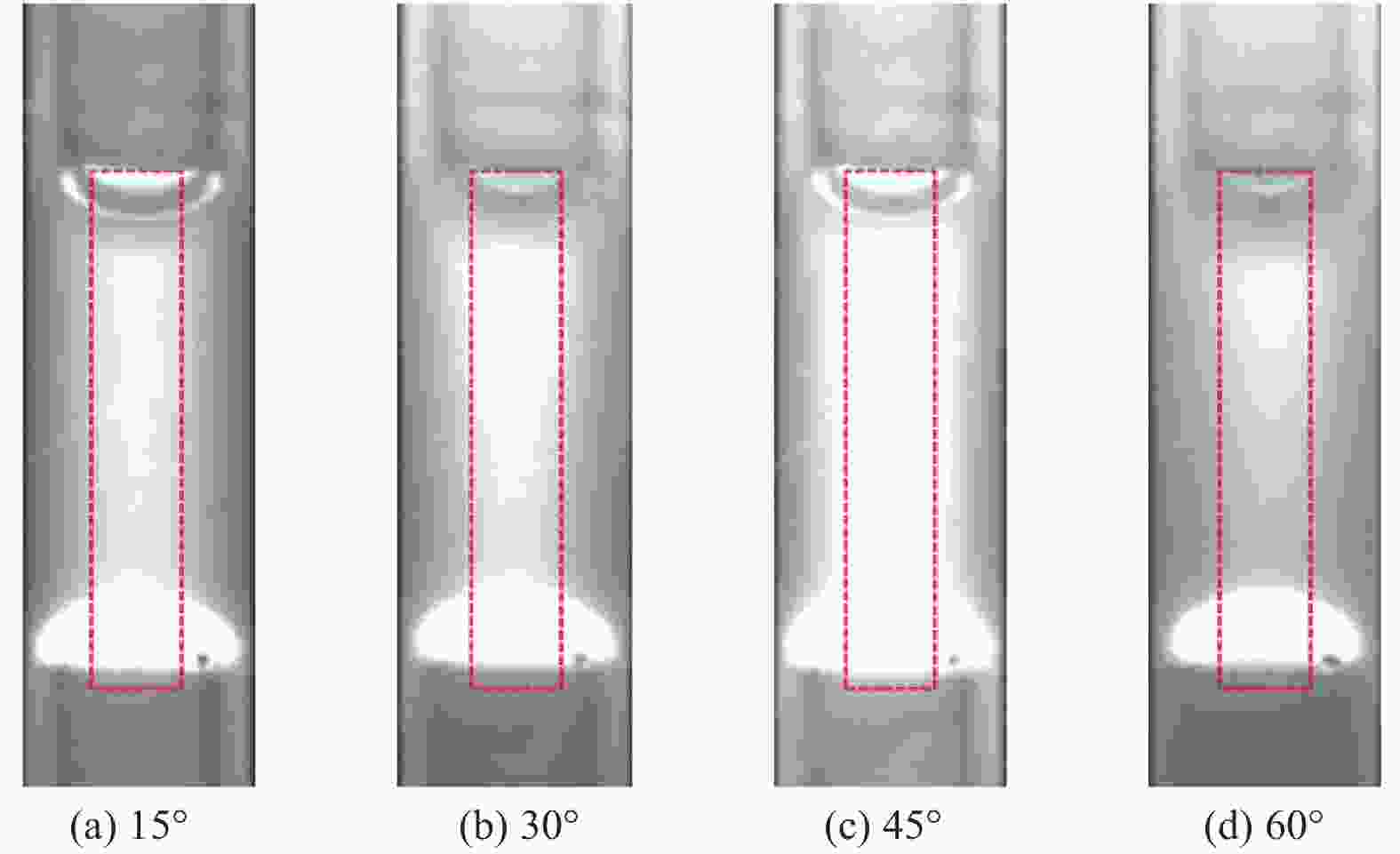

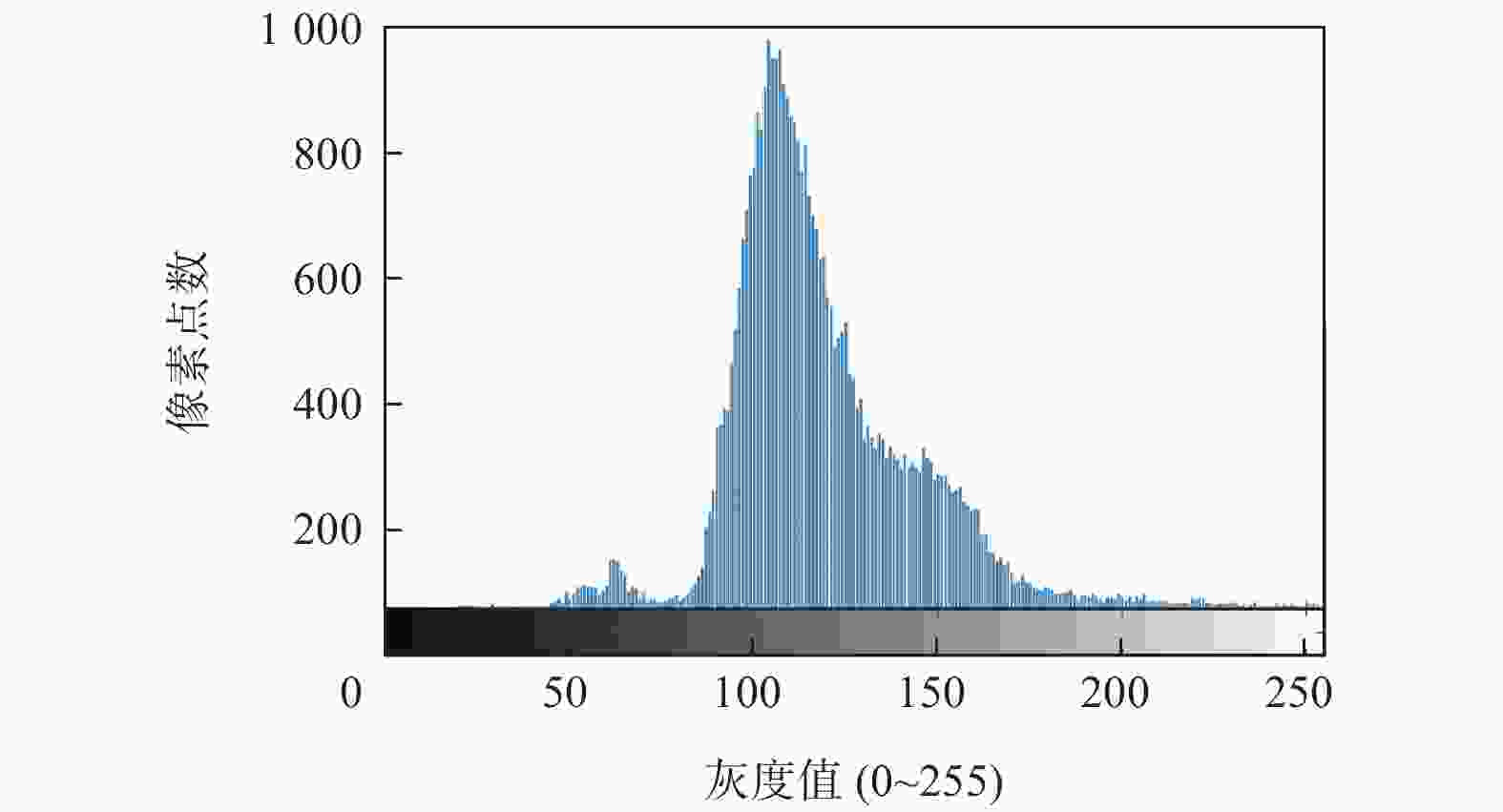

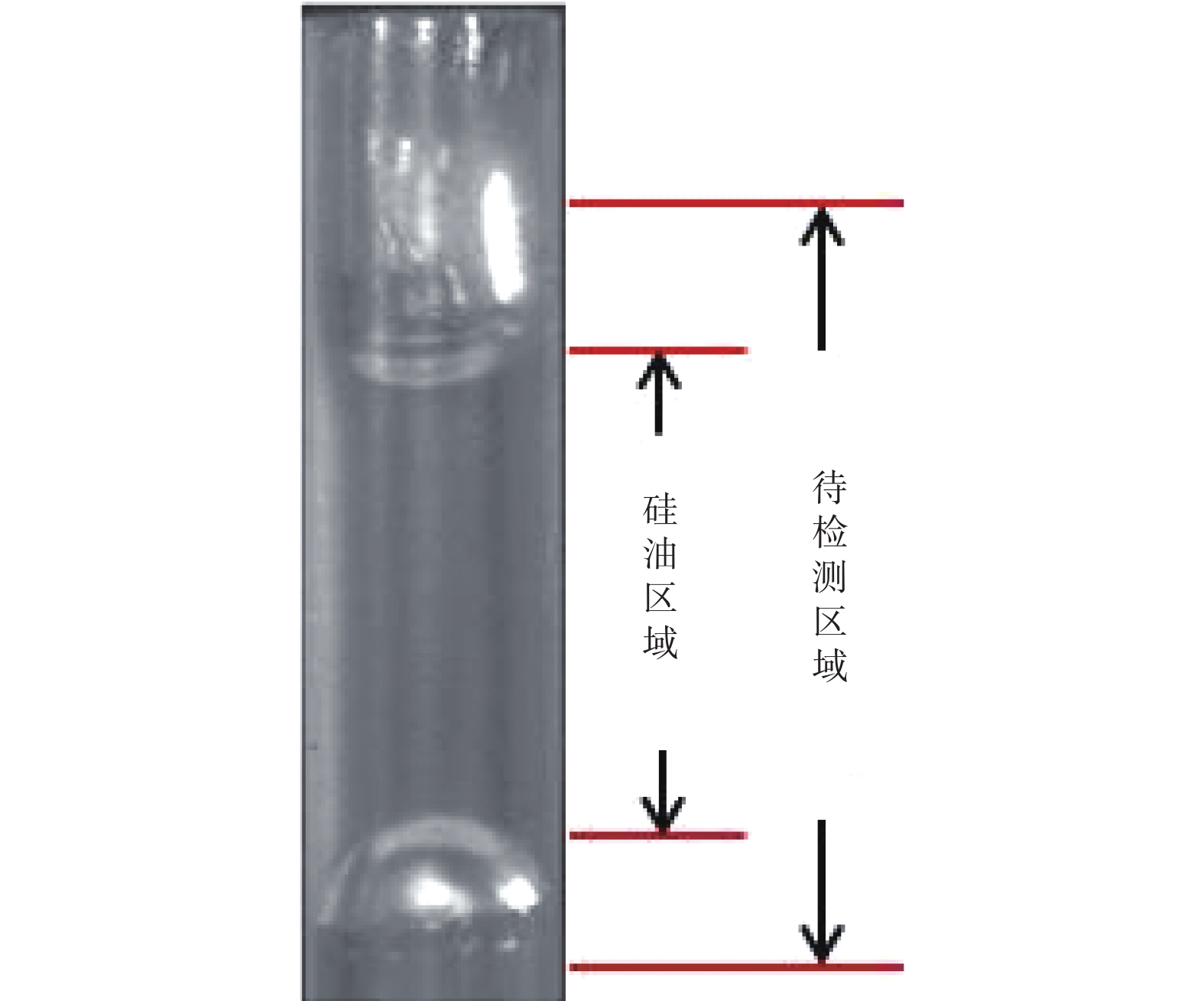

针对中性透明笔芯和无色硅油灰度差异小所导致的硅油注入量检测困难等问题,提出并设计一种基于机器视觉的无色硅油注入量检测方法与系统。该系统硬件部分主要包括图像采集单元和外部光源控制单元等,通过调节外部光源照射角度实现无色硅油区域灰度差异的增强;软件与算法部分运用一种灰度区域直方图算法,在搭建的人工交互界面上选取相应的感兴趣区域(ROI)及参数,实时显示长度检测结果。试验结果表明,该系统能准确检测硅油连续长度,系统的实时性及稳定性较好,准确率高,具有一定的推广应用价值。

Abstract:Aiming at the difficulty in detecting the amount of silicone oil injection caused by the small gray difference between the neutral transparent refill and the colorless silicone oil, a new method and system for detecting the injection amount of colorless silicone oil based on machine vision was proposed and designed. An image acquisition unit and an external light source control unit were the main hardware part of the system. By adjusting the illumination angle of the external light source, the enhancement of the gray difference in the colorless silicone oil area can be realized. In the part of software and algorithm, a gray region histogram algorithm was used to select the corresponding region of interest (ROI) and parameters on the constructed human interaction interface, and the length detection results were displayed in real time. The experimental results show that the system can accurately detect the continuous length of silicone oil, the system has good real-time performance and stability, high accuracy, and has a certain value of promotion and application.

-

Key words:

- colorless silicone oil /

- pen-refill /

- image filtering /

- grayscale difference /

- machine vision

-

表 1 混合矩阵评价指标

Table 1. Evaluation index of hybrid matrix

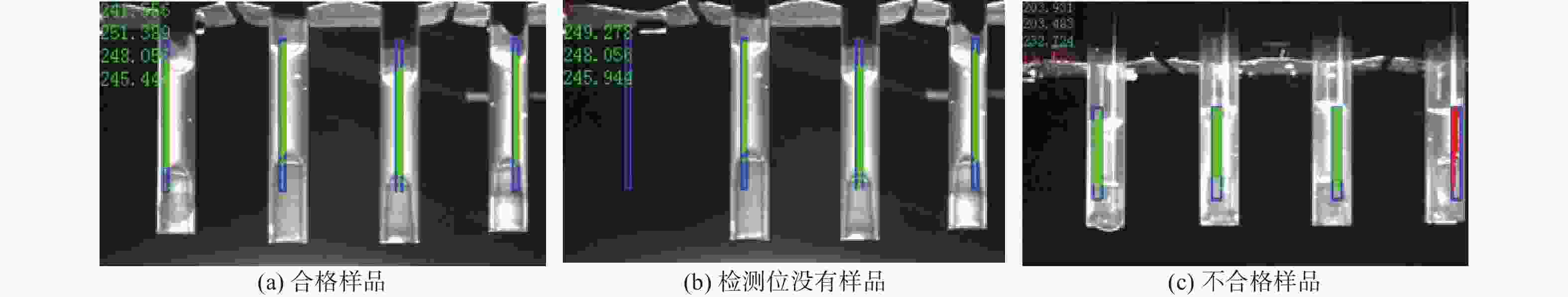

混合矩阵 检测样品 合格数量 缺陷数量 合格数量 TP FN 缺陷数量 FP TN 表 2 不同检测方法的混合矩阵

Table 2. Hybrid matrix of different detection methods

支 产品类别 本研究检测方法 人工检测方法 合格数量 缺陷数量 合格数量 缺陷数量 合格数量 298 2 283 17 缺陷数量 4 96 12 88 表 3 不同检测方法的真正率、真负率和准确率

Table 3. True rate, true negative rate and accuracy rate of different detection methods

% 不同方法 真正率 真负率 准确率 本研究检测方法 99.30 96.00 98.50 人工检测方法 94.30 88.00 92.75 表 4 不同ROI区域宽度测量的长度值

Table 4. Measured length value of different ROI area width

长度参数 ROI宽度/pixel 40 35 30 25 测量值/pixel 201 203 206 208 理论值/pixel 210 210 210 210 误差/% 4.30 3.30 1.90 0.95 -

[1] KIM K, PROCTOR R W, SALVENDY G. Emotional factors and physical properties of ballpoint pens that affect user satisfaction: Implications for pen and stylus design[J] . Applied Ergonomics,2020,85:103067. doi: 10.1016/j.apergo.2020.103067 [2] 姚鹤忠. 圆珠笔质量水平调查与评价报告(续)[J] . 中国制笔,2019(4):44 − 46. doi: 10.3969/j.issn.1001-7860.2019.04.007 [3] ROBINSON S L, MILLER R K. Automated inspection and quality assurance[M]. Boca Raton: CRC Press, 2017. [4] 吴志鹏, 黄丹平, 郭康, 等. 基于机器视觉的新型光缆节距检测方法研究[J] . 激光与光电子学进展,2020,57(8):321 − 328. [5] CHAUDHURY A, WARD C, TALASAZ A, et al. Machine vision system for 3D plant phenotyping[J] . IEEE/ACM transactions on computational biology and bioinformatics,2019,16(6):2009 − 2022. doi: 10.1109/TCBB.2018.2824814 [6] HOU Q L, SUN J, LYU Z Y, et al. An online tool wear detection system in dry milling based on machine vision[J] . The International Journal of Advanced Manufacturing Technology,2019,105(1/2/3/4):1801 − 1810. [7] 尹仕斌, 任永杰, 刘涛, 等. 机器视觉技术在现代汽车制造中的应用综述[J] . 光学学报,2018,38(8):11 − 22. [8] 汤勃, 孔建益, 伍世虔. 机器视觉表面缺陷检测综述[J] . 中国图象图形学报,2017,22(12):1640 − 1663. doi: 10.11834/jig.160623 [9] 艾永平, 唐巧兴, 王泽杰, 等. 基于机器视觉的割草系统青草识别研究[J] . 上海工程技术大学学报,2020,34(4):369 − 374. [10] 朱成德, 李志伟, 王凯, 等. 基于改进网格运动统计特征的图像匹配算法[J] . 计算机应用,2019,39(8):2396 − 2401. doi: 10.11772/j.issn.1001-9081.2018122590 [11] 张晓, 秦勃. 基于Canny算子的透明胶囊缺陷检测[J] . 计算机系统应用,2015,24(8):242 − 246. doi: 10.3969/j.issn.1003-3254.2015.08.044 [12] CANNY J. A computational approach to edge detection[J] . IEEE Transactions on pattern analysis and machine intelligence,1986, 8(6):679 − 698. [13] 关日钊, 吴磊, 徐焯基. 基于机器视觉的透明塑料件缺陷检测[J] . 装备制造技术,2018(3):167 − 171. doi: 10.3969/j.issn.1672-545X.2018.03.053 [14] 付兴勇, 任德均, 严扎杰, 等. 基于模板匹配的透明盒缺陷检测[J] . 软件导刊,2019,18(3):187 − 190. [15] 许长路, 李林升, 立济伟. 基于Gamma矫正与LOG算法融合的锂电池极片缺陷检测方法[J] . 机械设计与研究,2020,36(6):105 − 109. -

下载:

下载: