Study on preparation and tribological properties of PTFE composite lubricant based on uniform design

-

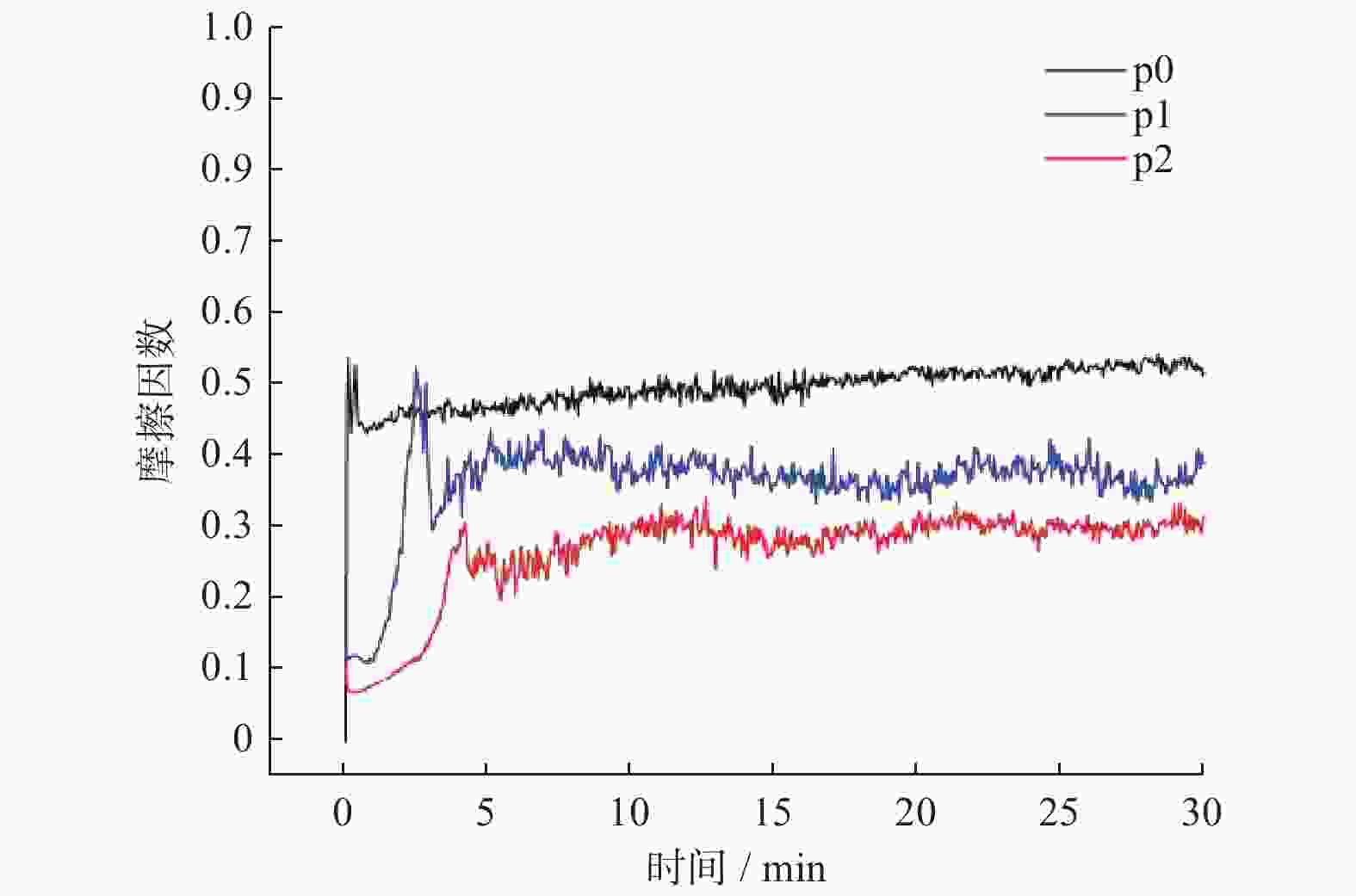

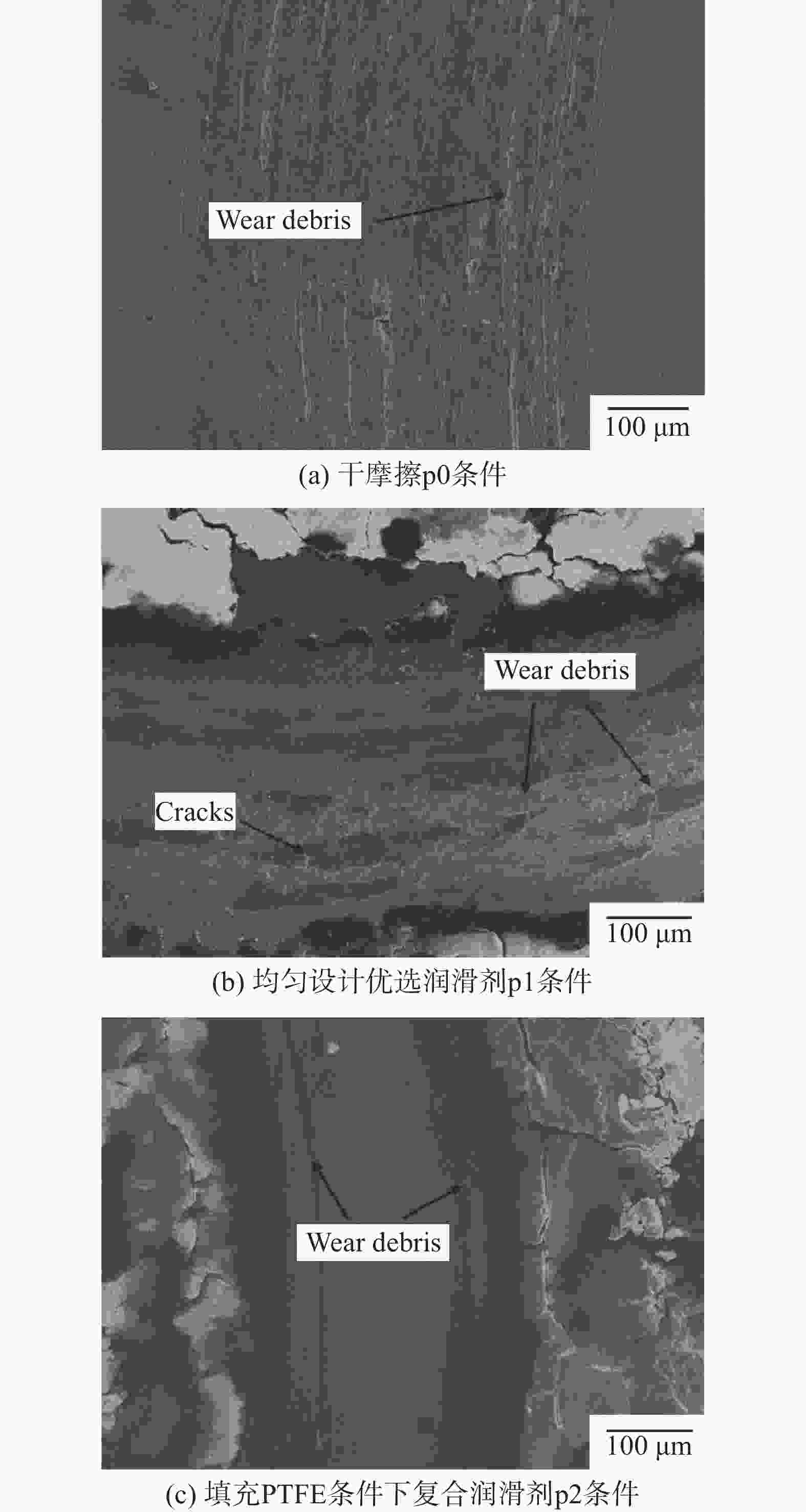

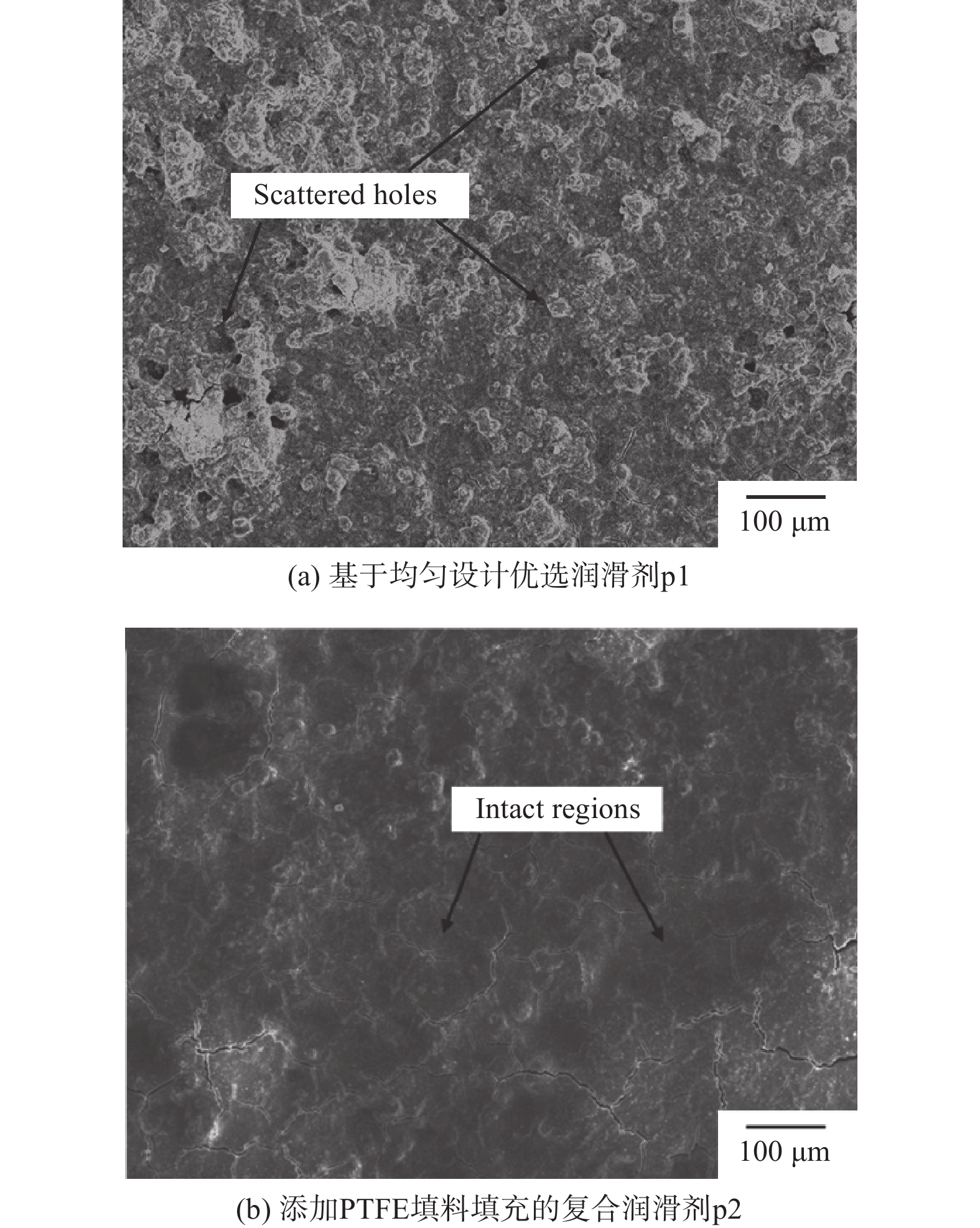

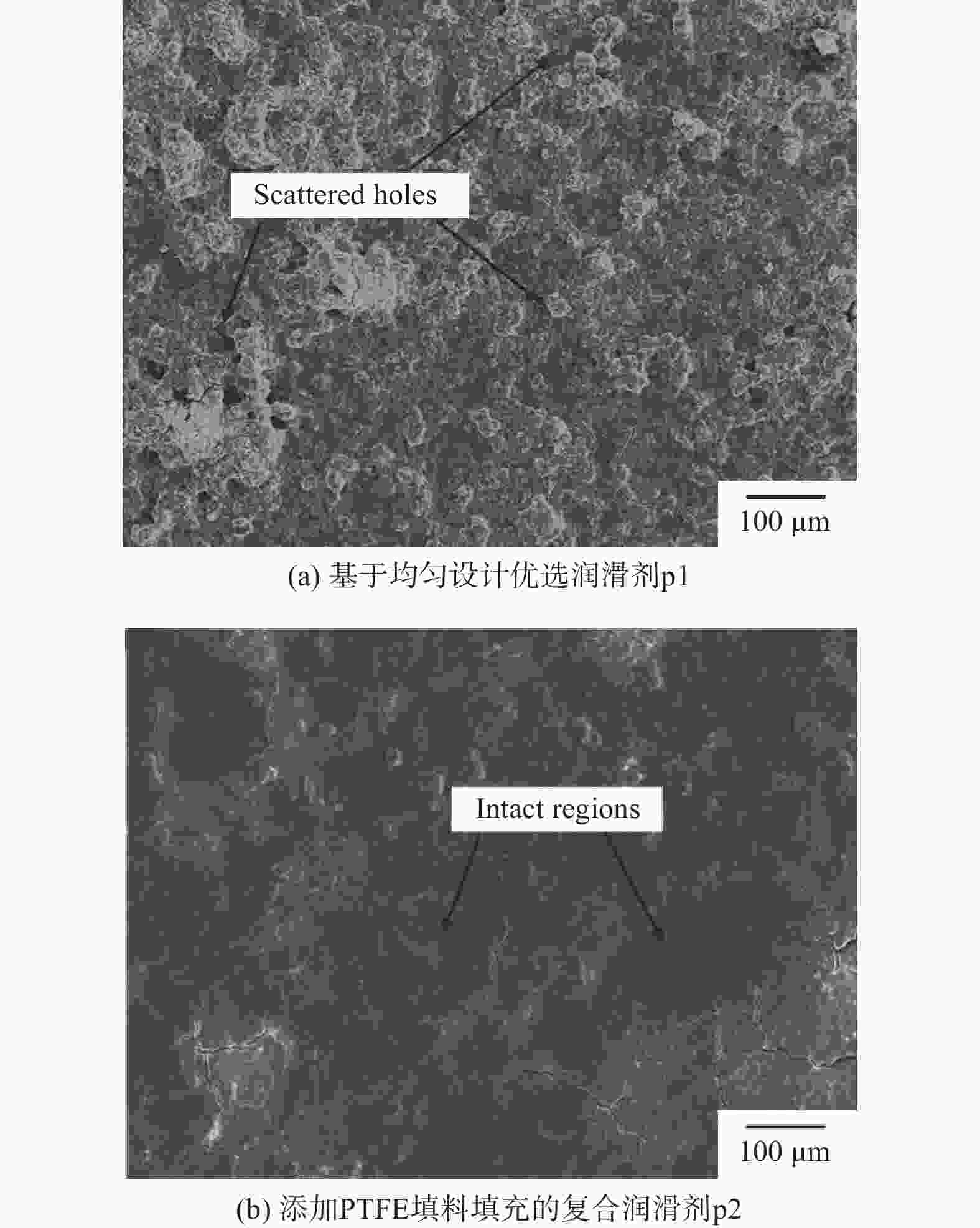

摘要: 制备新型复合润滑剂并研究其摩擦磨损特性. 通过均匀设计方法优选润滑剂配方,利用SPSS软件和Matlab软件建立数学模型,并对其结果进行直观分析与回归分析. 添加填充材料聚四氟乙烯制备新型复合润滑剂p2,对润滑剂的零件和模具接触面的接触摩擦状况进行分析,判断是否显著降低接触表面摩擦因数,对金属的各项性能进一步分析. 研究表明,添加了聚四氟乙烯材料的润滑剂p2,相较于干摩擦与润滑剂p1,摩擦因数分别降低51.26%和29.81% ;使用扫描电子显微镜观察磨痕的形貌发现,复合润滑剂在金属偶件表面形成均匀的摩擦膜,有效改善了润滑剂的性能,使成形过程中金属流动更均匀,降低了变形功及变形力,可有效避免多种成形缺陷的产生.Abstract: A new type of composite lubricant was prepared and its friction and wear characteristics were studied. The lubricant formula was optimized through the uniform design method, a model was established with SPSS and Matlab softwares, and results were analyzed by Intuitive analysis and regression analysis. The polytetrafluoroethylene (PTFE) was added to prepare a new type of composite lubricant p2, the lubricant contact friction status was analyzed to determine whether the friction coefficient of the contact surface had significantly reduced, and various properties of the metal were further analyzed. The results show that friction coefficients of lubricant p2 added with PTFE have reduced by 51.26% and 29.81% compared with dry friction and lubricant p1 respectively. Observing the morphology of the wear scars, it is found that the friction film can make the metal flow more uniform during the forming process, reduce the deformation force, and effectively avoid a variety of forming defects.

-

Key words:

- uniform design /

- polytetrafluoroethylene (PTFE) /

- lubricant /

- friction and wear

-

表 1 试验因素水平表U8*(85)及方案结果

Table 1. Test factor level table U8*(85) and scheme results

水平 PVDF

X1/%BN

X2/%CMC

X3/%NNO

X4/%MgO

X5/%平均摩擦

因数μ1 1(0.5) 2(1.1) 4(0.5) 7(1.7) 8(1.0) 0.50 2 2(0.6) 4(1.3) 8(0.9) 5(1.5) 7(0.9) 0.47 3 3(0.7) 6(1.5) 3(0.4) 3(1.3) 6(0.8) 0.53 4 4(0.8) 8(1.7) 7(0.8) 1(1.1) 5(0.7) 0.45 5 5(0.9) 1(1.0) 2(0.3) 8(1.8) 4(0.6) 0.36 6 6(1.0) 3(1.2) 6(0.7) 6(1.6) 3(0.5) 0.40 7 7(1.1) 5(1.4) 1(0.2) 4(1.4) 2(0.4) 0.58 8 8(1.2) 7(1.6) 5(0.6) 2(1.2) 1(0.3) 0.41 表 2 回归分析

Table 2. Regression analysis

自由度

df离均差平方和

SS均方

MSF值 Significance F 回归分析 5 0.036799 0.007360 41.919270 0.023462653 残差 2 0.000351 0.000176 总计 7 0.037150 -

[1] QIAN Y, GONG H Y, ZHAO X Y, et al. Experimental investigation on the tribological property of functionalized graphene lubricant against steel[J] . Industrial Lubrication and Tribology,2020,72(3):307 − 314. doi: 10.1108/ILT-08-2019-0344 [2] 李占君, 王霞, 何强. 润滑脂中极压抗磨添加剂的研究进展[J] . 润滑与密封,2018,43(3):123 − 128. [3] 苏畅. 聚合物基复合材料的摩擦学性能研究及其数值模拟[D]. 大庆: 东北石油大学, 2019. [4] ZHAO X, GONG H, ZHOU X, et al. Effects of friction and lubrication of new water-based nano-graphite lubricant and application during warm extrusion processing[C]// Proceedings of 2019 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM). Shanghai: Shanghai University of Engineering Science, 2019. [5] 郑哲, 方建华, 王建华, 等. 新型水溶性润滑添加剂的研究进展[J] . 摩擦学学报,2017,37(3):409 − 420. [6] CARTON J F, VANNEST A B, ZAMBELLI G, et al. An investigation of the fretting behaviour of low friction coatings on steel[J] . Tribology International,1996,26(9):445 − 455. [7] TIAN X M, QIAO H B, CHU X F. Wear performance of bonded composite coatings under dry sliding[J] . Surface and Coatings Technology,2014,240:191 − 196. [8] 高贵, 龚俊, 李瑞红, 等. 表面织构对PTFE复合材料摩擦磨损行为的影响[J] . 摩擦学学报,2020,40(200):14 − 23. [9] 夏路, 解挺. 基于正交实验的PTFE基复合材料摩擦学性能优化研究[J] . 功能材料,2019,50(5):5190 − 5193. [10] HWANG J S, KIM J H, KIM S K, ET AL. Effect of PTFE coating on enhancing hydrogen embrittlement resistance of stainless steel 304 for liquefied hydrogen storage system application[J] . International Journal of Hydrogen Energy,2020,45(15):9149 − 9161. doi: 10.1016/j.ijhydene.2020.01.104 [11] 蔡梦莹, 刘韦江, 左明明, 等. 稠化剂组成对聚脲润滑脂性能的影响[J] . 润滑与密封,2020,45(12):119 − 124. [12] LI B, JIANG X F, WAN H Q, et al. Environment-friendly aqueous PTFE based bonded solid lubricating coatings: Mechanical and tribological properties under diversified environments - ScienceDirect[J] . Progress in Organic Coatings,2019,137:104904. [13] WAN H Y, JIA Y L, YE Y P, et al. Tribological behavior of polyimideiepoxy resin-polytetrafluoroethylene bonded solid lubricant coatings filled with in situ-synthesized silver nanoparticles[J] . Progress in Organic Coatings: An International Review Journal,2017,106:111 − 118. doi: 10.1016/j.porgcoat.2017.02.018 [14] BASHANDEH K, LAN P X, MEYER J L, et al. Tribological performance of graphene and PTFE solid lubricants for polymer coatings at elevated temperatures[J] . Tribology Letters,2019,67(3). doi: 10.1007/s11249-019-1212-5 [15] 方开泰. 均匀设计及其应用[J] . 数理统计与管理,1994(4):54 − 56. [16] 王海波, 沙明, 邸学. 均匀设计法与正交设计法在复方工艺中应用比较[J] . 辽宁中医杂志,2005,32(1):71 − 72. [17] 李玲华, 祝侠丽, 刘黎明, 等. 均匀设计法优化亲水性纳米硫化铜的合成工艺[J] . 中国药师,2019,22(1):164 − 166. [18] LI Z, RAO Q H. Quantitative determination of PFC3D microscopic parameters[J] . Journal of Central South University,2021,28(3):911 − 925. doi: 10.1007/s11771-021-4653-6 [19] 李登万, 陈洪涛, 冯锦春, 等. 基于均匀设计法的精密车削参数优化[J] . 机械工程学报,2015,51(3):206 − 212. [20] 张勇强, 汪久根, 陈芳华, 等. 磨粒磨损的接触分析[J] . 润滑与密封,2018,43(3):11 − 16. -

下载:

下载: