Application of computer vision technology in woven fabric structural parameters testing

-

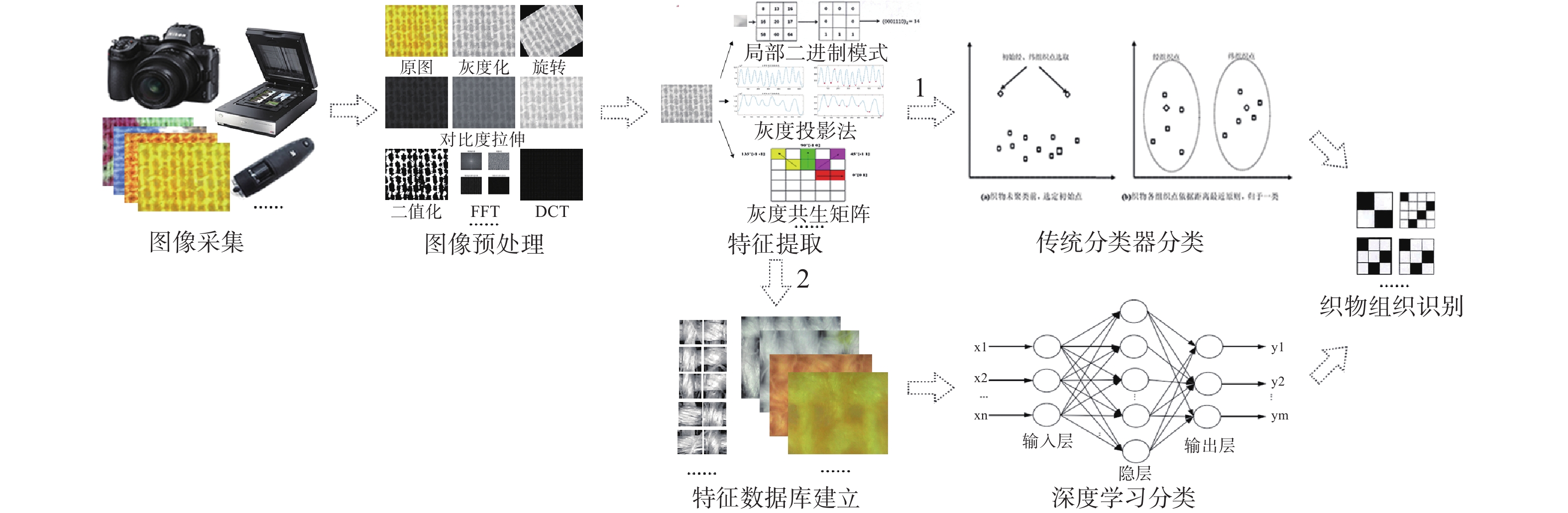

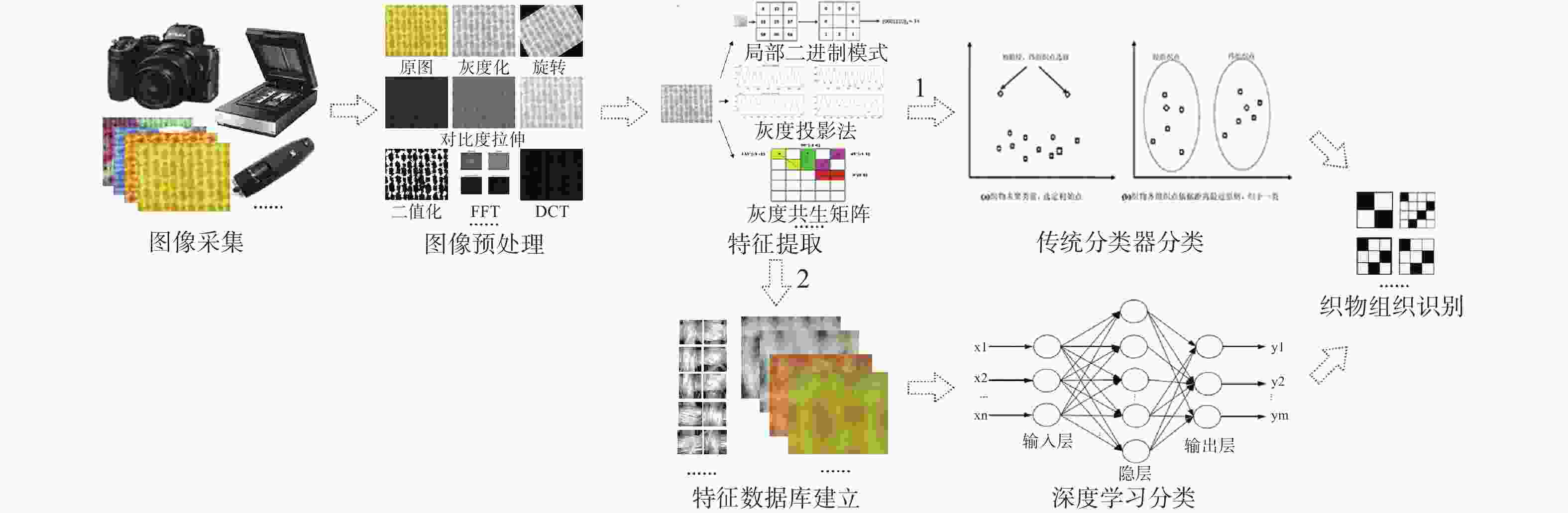

摘要: 机织物密度和组织结构参数是纺织品检测的两个重要数据,其检测指标决定机织物产品的质量. 由于织物结构的复杂性,纺织检验领域中对机织物结构参数的检测仍然依赖于人工分析. 随着计算机视觉技术的发展,其在机织物结构参数检测中的应用不断有新的研究进展. 详细阐述近五年国内外机织物密度和组织结构两个重要结构参数自动检测的研究现状和研究不足,认为建立在客观评价基础上的计算机视觉技术在机织物结构参数检测领域具有良好的发展前景.Abstract: The two structural parameters of woven fabric density and weave pattern are important data in textile testing, and their testing indicators determine the quality of woven fabric products. Due to the complexity of fabric structure, the testing of woven fabric structure parameters nowadays still depends on manual analysis. With the development of computer vision technology, its application in the testing of structural parameters of woven fabrics has been made new research progress. The research status of automatic testing of two important structural parameters of woven fabric density and weave pattern at home and abroad in recent five years was described in detail, and the shortcomings of the research were summarized. Finally, it is concluded that the computer vision technology based on objective evaluation has a great development prospect in the field of woven fabric structure parameter testing.

-

Key words:

- woven fabric /

- fabric density /

- weave pattern /

- textile testing /

- computer vision

-

表 1 计算机视觉技术在纺织检测中的应用

Table 1. Application of computer vision technology in textile testing

纤维方面 纱线方面 半制品 针、机织物方面 非织造物 纤维细度、长度、取向度 纱线的细度 棉条的条干均匀度 地毯磨损外观变化及磨损程度 取向度 单、多根纤维的直径 纱线中的纤维分布 棉网均匀度 光泽 孔隙率(孔洞大小) 棉纤维成熟度 纱线的捻度分布 棉结杂质的含量 起毛起球性能 形态分析 纤维卷曲频数及波幅 纱线毛羽 折皱性能 化学纤维的异性度与中空度 纱线力学性能 悬垂性能 动物鳞片及棉麻形态分析 纱线外观的均匀度 褶皱 纤维种类的鉴别 混纺比及混纺不匀 织物疵点 异纤含量(尤指化纤) 纱线疵点的分级和检验方法 机织物经纬密度、组织、配色模纹 表 2 常用基于学习的机织物组织识别分类方法

Table 2. Common learning-based methods for woven fabric weave pattern identification

大分类 小分类 特点 组成 优缺点 监督式 概率神经网络(PNN) 一种网络结构简单、训练时间短、基于概率统计原理的非线性分类神经网络. 包括输入层、模式层(样本层)、求和层和竞争层. 训练速度较快;在有足够的训练样本情况下,总能稳定收敛于贝叶斯优化解;高度泛化能力,即加入新的未知样本都能根据已建立的成功分类的网络进行预测识别 反向传播神经网络(BP) 一种按照误差逆向传播算法训练的多层前馈神经网络,是应用最广泛的神经网络 包括输入层、输出层和隐层,其中隐层可以是一层也可以是多层 高度泛化、非线性映射及联想记忆能力;

误差函数的收敛速度比较慢,网络的训练时间需求长卷积神经网络(CNN) 有监督和非监督两种学习方式,主要以监督式为主 包括卷积层,池化层,和全连接层,其中池化层有最大池化和平均池化两种方法 由于 CNN 隐含层内特殊的连接结构,使得网络能够以较小的计算量对音频和像素等格点化特征进行学习,且效果稳定;具有稀疏连接(稀疏权重或者稀疏交互)和权值共享的特征 支持向量机(SVM) 基于样本特征空间找到一个划分超平面,将不同类别的样本分开,也可把多个二分类器进行组合来实现多分类问题,常见有OVOSVM和OVASVM 包括线性可分和线性不可分两种情况 可解释强,不依靠统计方法;采用核技巧,可以处理非线性分类/回归任务;

训练时间和模型预测时间随样本量增加而增加,只适合小批量样本的任务无监督式 模糊 C 均值聚类(FCM) 根据相似性(或非相似性)准则对对象进行分类,使得具有相同或者相似性质的对象尽可能地被划分为一类,而不具有相似性质的对象尽可能地被划分到不同的类中 包括聚类数目,聚类常数,聚类中心,隶属度函数 需要找寻各个样本点到其聚类中心的加权和最小的值来得到最优的聚类结果点 -

[1] 周建, 潘如如, 高卫东. 机器视觉在纺织中的应用现状与发展趋势[J] . 棉纺织技术,2019,47(2):15 − 17. doi: 10.3969/j.issn.1001-7415.2019.02.004 [2] 张雷. 数字图像处理技术在纺织检测中的研究和应用[J] . 大众标准化,2020,325(14):217 − 218. doi: 10.3969/j.issn.1007-1350.2020.14.107 [3] 谭园园. 计算机图像处理技术在纺织工业的应用与分析[J] . 轻纺工业与技术,2020,49(10):111 − 112. doi: 10.3969/j.issn.2095-0101.2020.10.047 [4] 辛斌杰, 余序芬, 吴兆平. 应用图像分析技术自动识别织物的组织结构[J] . 东华大学学报 (自然科学版),2011,37(1):35 − 41.XIN B J, Yu X F, Wu Z P. Automatic Identifying the Woven Fabric Pattern by Image Analysis Technique[J]. Journal of Donghua University(Natural Science), 2011, 37(01): 35-41. [5] 洪乾耀. 基于图像处理的机织物密度自动检测方法研究[D]. 杭州: 浙江理工大学, 2015. [6] 辛斌杰, 余序芬, 吴兆平. 机织物经纬密测量的图像处理技术[J] . 中国纺织大学学报,1999(3):34 − 37. [7] ESCOFET J, MILLÁN MARÍA S, M RALLÓ. Modeling of woven fabric structures based on Fourier image analysis[J] . Applied Optics,2001,40(34):6170 − 6176. doi: 10.1364/AO.40.006170 [8] AJALLOUIAN F, TAVANAI H, PALHANG M, et al. A novel method for the identification of weave repeat through image processing[J] . Journal of the Textile Institute,2009,100(3):195 − 206. doi: 10.1080/00405000701660244 [9] XIN B J, HU J L, BACIU G, et al. Investigation on the classification of weave pattern based on an active grid model[J] . Textile Research Journal,2009,79(12):1123 − 1134. [10] PAN R R, GAO W D, LI Z J, et al. Measuring thread densities of woven fabric using the fourier transform[J] . Fibres & Textiles in Eastern Europe,2015,23(1):35 − 40. [11] ZHANG J, PAN R R, GAO W D. Automatic inspection of density in yarn-dyed fabrics by utilizing fabric light transmittance and Fourier analysis[J] . Applied Optics,2015,54(4):966 − 972. doi: 10.1364/AO.54.000966 [12] ZHANG J, PAN R R, WANG J A, et al. An efficient method for density measurement for high-tightness woven fabrics[J] . Textile Research Journal,2017,87(3):329 − 339. doi: 10.1177/0040517516629147 [13] ZHANG R, XIN B J. An investigation of density measurement method for yarn-dyed woven fabrics based on dual-side fusion technique[J] . Measurement Science and Technology,2016,27(8):085403. doi: 10.1088/0957-0233/27/8/085403 [14] XIANG Z, CHEN K F, QIAN M, et al. Yarn-dyed woven fabric density measurement method and system based on multi-directional illumination image fusion enhancement technology[J] . Journal of the Textile Institute,2020,111(10):1489 − 1501. doi: 10.1080/00405000.2019.1706222 [15] WU J, ZHONG P, LING J Y, et al. Design method of fabric density sensor based on the virtual grating with gradual constant[J] . IEEE Access,2019,7:160345 − 160362. doi: 10.1109/ACCESS.2019.2951233 [16] SCHNEIDER D, GLOY Y S, MERHOF D. Vision-based on-loom measurement of yarn densities in woven fabrics[J] . IEEE Transactions on Instrumentation and Measurement,2015,64(4):1063 − 1074. doi: 10.1109/TIM.2014.2363580 [17] SCHNEIDER D, MERHOF D. Blind weave detection for woven fabrics[J] . Pattern Analysis and Applications,2015,18(3):725 − 737. doi: 10.1007/s10044-014-0403-9 [18] 张瑞. 基于双面成像技术的色织物组织识别研究[D]. 上海: 上海工程技术大学, 2016. [19] ZHANG J, WANG J A, PAN R R, et al. A computer vision-based system for automatic detection of misarranged warp yarns in yarn-dyed fabric. Part I: Continuous segmentation of warp yarns[J] . Journal of the Textile Institute,2018,109(5):577 − 584. [20] ZHANG J, WANG J A, PAN R R. A computer vision-based system for automatic detection of misarranged warp yarns in yarn-dyed fabric. Part II: Warp region segmentation[J] . Journal of the Textile Institute,2019,110(9):1359 − 1367. [21] WANG J A, ZHANG J, WANG L, et al. A computer vision-based system for automatic detection of misarranged color warp yarns in yarn-dyed fabric. Part III: Yarn layout proofing[J] . Journal of the Textile Institute,2020,111(11):1614 − 1622. [22] MENG S, PAN R R, GAO W D, et al. A multi-task and multi-scale convolutional neural network for automatic recognition of woven fabric pattern[J] . Journal of Intelligent Manufacturing,2021,32(4):1147 − 1161. doi: 10.1007/s10845-020-01607-9 [23] SABUNCU M, OZDEMIR H. Recognition of fabric weave patterns using opticalcoherence tomography[J] . Journal of the Textile Institute,2016,107(11):1406 − 1411. doi: 10.1080/00405000.2015.1114791 [24] SABUNCU M, OZDEMIR H, AKDOGAN M U. Automatic identification of weavepatterns of checked and colored fabrics using optical coherence tomography[J] . IEEE Photonics Journal,2017,9(5):1 − 8. [25] 孟朔, 夏旭文, 潘如如, 等. 基于卷积神经网络的机织物密度均匀性检测[J] . 纺织学报,2021,42(2):101 − 106. doi: 10.13475/j.fzxb.20201008406 -

下载:

下载: