Comparative study on common methods for elastic force modeling and modal simulation of beam elements with absolute nodal coordinates

-

摘要:

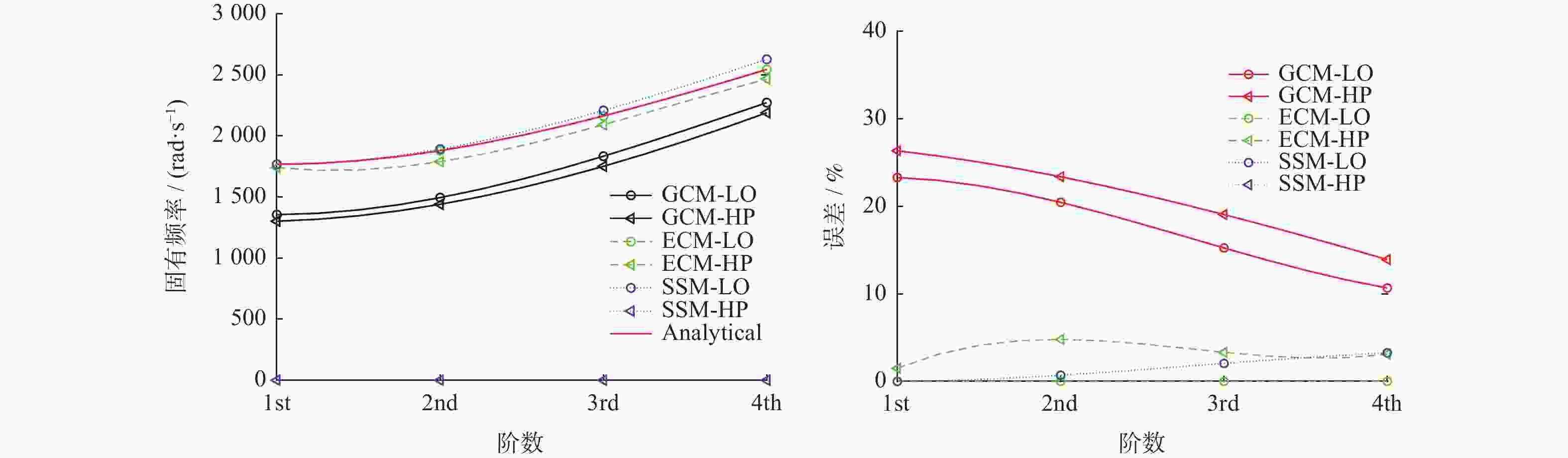

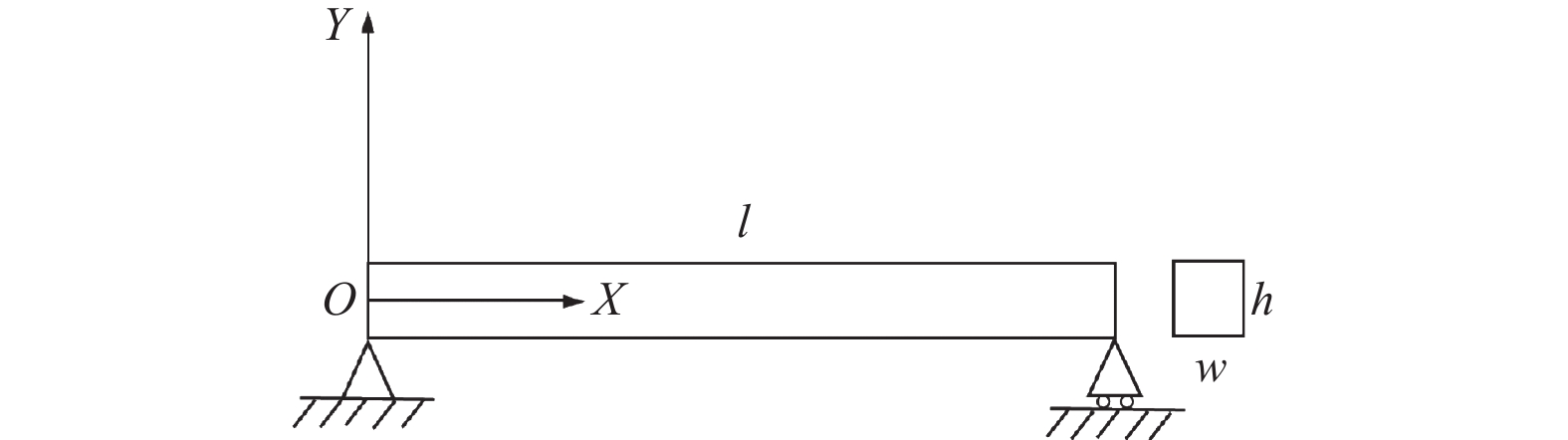

通过理论推导和数值分析,研究二维绝对节点坐标梁单元在不同弹性力建模方法下的模态参数. 介绍连续介质力学、增强连续介质力学以及应变分解法,并推导应变分解法应用的局限性,从理论角度说明了3种方法的特点. 基于广义特征方程得到不同弹性力建模方法下的绝对节点坐标梁单元的4种固有模态,以简支梁结构为例,分析绝对节点坐标梁单元弹性力建模方法对4种固有模态的作用规律. 不同弹性力建模方法下,横向低阶单元的4种固有频率相较横向高阶单元更高,表现得更“刚”. 连续介质力学方法下,各单元的低阶剪切固有频率与解析解存在20%~30%误差,而应变分解法和增强连续介质力学方法能够将剪切固有频率的误差控制在4%内,提高单元收敛精度.

-

关键词:

- 绝对节点坐标法 /

- 固有频率计算 /

- 应变分解法 /

- 增强连续介质力学方法 /

- 连续介质力学方法

Abstract:By theoretical derivation and numerical analysis, the modal parameters of two-dimensional absolute nodal coordinate beam elements under different elastic force modeling methods were studied. The continuum mechanics, enhanced continuum mechanics and strain splitting method were introduced, and the limitations of the application of the strain splitting method were deduced, and the characteristics of the three methods were explained from the theoretical point of view. Based on the generalized characteristic equations, the four natural modes of the absolute nodal coordinate beam element under different elastic force modeling methods were obtained. Taking the simply supported beam structure as an example, the effects of the absolute nodal coordinate beam element elastic force modeling method on the four natural modes were analyzed. Under different elastic force modeling methods, the four natural frequencies of the transverse low-order elements were higher than those of the transverse high-order elements, and the performance was more "rigid". For the continuum mechanics method, there is an error of 20%~30% between the low-order shear natural frequency of each element and the analytical solution, while the strain decomposition method and the enhanced continuum mechanics method can control the error of the shear natural frequency within 4%, and improve the element convergence accuracy.

-

表 1 梁单元位移模式

Table 1. Displacement mode of beam element

单元位移模式 LO $ {a_0} + {a_1}x + {a_2}y + {a_3}xy + {a_4}{x^2} + {a_5}{x^3} $ HP $ {a_0} + {a_1}x + {a_2}y + {a_3}xy + {a_4}{x^2} + {a_5}{y^2} + {a_6}x{y^2} + {a_7}{x^3} $ 表 2 不同方法下,单元前4阶弯曲固有频率及其振型

Table 2. The first four-order bending natural frequencies of element and its mode shape under different methods

阶次/(rad•s−1) 一般连续介质力学 增强连续介质力学ECM 应变分裂法SSM 解析解

AnalyticalGCM−LO GCM−HP ECM−LO ECM−HP SSM−LO SSM−HP 1阶 96.68

92.53

95.64

95.34

102.49

95.63 2阶 315.27

303.27

332.26

329.23

351.38

332.23 3阶 572.41

552.60

635.78

626.34

664.51

635.70 4阶 838.55

809.56

965.92

946.56

1000.40

965.74 表 3 不同方法下单元前4阶轴向固有频率及其振型

Table 3. The first four order axial natural frequencies of the element and its mode shape under different methods

阶次/(rad•s−1) 一般连续介质力学 增强连续介质力学 应变分裂法 解析解

AnalyticalGCM−LO GCM−HP ECM−LO ECM-HP SSM−LO SSM−HP 1阶 280.24

256.15

280.25

259.39

280.26

280.32 2阶 838.55

768.59

838.93

777.20

839.37

840.96 3阶 1389.33

1278.87

1391.42

1290.46

1393.77

1401.60 4阶 1922.95

1776.64

1930.48

1788.00

1938.46

1962.24 表 4 不同方法下单元前4阶剪切固有频率及其振型

Table 4. The first four orders of shear natural frequencies of the element and its mode shapes under different methods

阶次/(rad•s−1) 一般连续介质力学 增强连续介质力学 应变分裂法 解析解 GCM−LO GCM−HP ECM−LO ECM−HP SSM−LO SSM−HP 1阶 1355.48

1301.59

1766.99

1740.43

1766.99

1767.0 2阶 1494.61

1439.69

1878.88

1788.73

1892.26

1878.9 3阶 1833.47

1750.94

2163.39

2091.25

2207.82

2163.3 4阶 2272.39

2189.80

2544.14

2465.01

2627.13

2543.9 表 5 不同方法下单元的1阶厚度固有频率及其振型

Table 5. Natural frequency of the 1st order thickness of the element and its mode shape under different methods

阶次/(rad•s−1) 一般连续介质力学 增强连续介质力学 应变分裂法 解析解 GCM−LO GCM−HP ECM−LO ECM−HP SSM−LO SSM−HP 1阶 3243.06

3243.79

3246.76

3221.32

3238.66

3227.84 表 6 计算效率对比

Table 6. Comparison of calculation efficiency

耗时/s 一般连续介质力学GCM 增强连续介质力学ECM 应变分裂法SSM GCM−LO GCM−HP ECM−LO ECM−HP SSM−LO SSM−HP 8单元 12.21 24.83 7.88 26.23 31.28 16单元 22.55 46.99 13.15 47.18 58.69 32单元 44.82 98.24 25.51 98.42 112.68 -

[1] SHABANA A A. An absolute nodal coordinate formulation for the large rotation and large deformation analysis of flexible bodies[R]. Chicago: University of Illinois at Chicago, 1996. [2] SCHIEHLEN W. Technishce dynamik stuttgrt teubner[M]. Stuttgrt: Teubner, 1986. [3] KANE T R, LEVINSON D. Dynamics, theory and applications[M]. New York: McGraw-Hill, 1985. [4] HAUG E J. Computer-aided kinematics and dynamics of mechanical systems: Basic methods[M]. Boston: Allyn and Bacon, 1989. [5] GARCIA J J, BAYO E. Mechanical engineering Series[M]. New York: Springer, 1994. [6] TURCIC D A, MIDHA A. Dynamic analysis of elastic mechanism systems, Part I: Applications[J] . Journal of Dynamic Systems Measurement & Control,1984,106(4):249 − 254. [7] OMAR M A, SHABANA A A. A two-dimensional shear deformable beam for large rotation and deformation problems[J] . Journal of Sound and Vibration,2001,243(3):565 − 576. doi: 10.1006/jsvi.2000.3416 [8] 张大羽, 罗建军, 王辉, 等. ANCF/CRBF平面梁闭锁问题及闭锁缓解研究[J] . 力学学报,2021,53(3):874 − 889. doi: 10.6052/0459-1879-20-296 [9] SHEN Z X, LI P, LIU C, et al. A finite element beam model including cross-section distortion in the absolute nodal coordinate formulation[J] . Nonlinear Dynamics,2014,77(3):1 − 15. [10] ZHAO C H, BAO K W, TAO Y L. Transversally higher-order interpolating polynomials for the two-dimensional shear deformable ANCF beam elements based on common coefficients[J] . Multibody System Dynamics,2021,51(3):1 − 21. [11] PATEL M, SHABANA A A. Locking alleviation in the large displacement analysis of beam elements: the strain split method[J] . Acta Mechanica,2018,229(7):2923 − 2946. doi: 10.1007/s00707-018-2131-5 [12] GERSTMAYR J, MATIKAINEN M K, MIKKOLA A M. A geometrically exact beam element based on the absolute nodal coordinate formulation[J] . Multibody System Dynamics,2008,20(4):359 − 384. doi: 10.1007/s11044-008-9125-3 [13] SCHWAB A L, MEIJAARD J P. Comparison of three-dimensional flexible beam elements for dynamic analysis: finite element method and absolute nodal coordinate formulation[J] . Journal of Computational and Nonlinear Dynamics,2009,5(1):11010. [14] 范纪华, 章定国, 谌宏. 基于绝对节点坐标法的弹性线方法研究[J] . 力学学报,2019,51(5):1455 − 1465. doi: 10.6052/0459-1879-19-076 -

下载:

下载: