Influence of Miller cycle and EGR coupling on performance of turbocharged diesel engine

-

摘要:

以某6缸四冲程两级增压船用柴油机为研究对象,建立两级增压柴油机米勒循环与废气再循环(Exhaust Gas Recirculation, EGR)耦合仿真模型,研究米勒循环和EGR耦合对两级增压柴油机燃油消耗率和NOx排放的影响. 结果表明,当米勒度为−40°CA时,燃油消耗率相对原机降低3.5%,NOx排放相对原机降低25.5%;EGR率为30%时,燃油消耗率相对原机增加5.0%,NOx排放降低98.7%;当米勒度为−30°CA与EGR率为20%时,燃油消耗率相对原机仅增加0.1%,NOx排放降低92.7%.

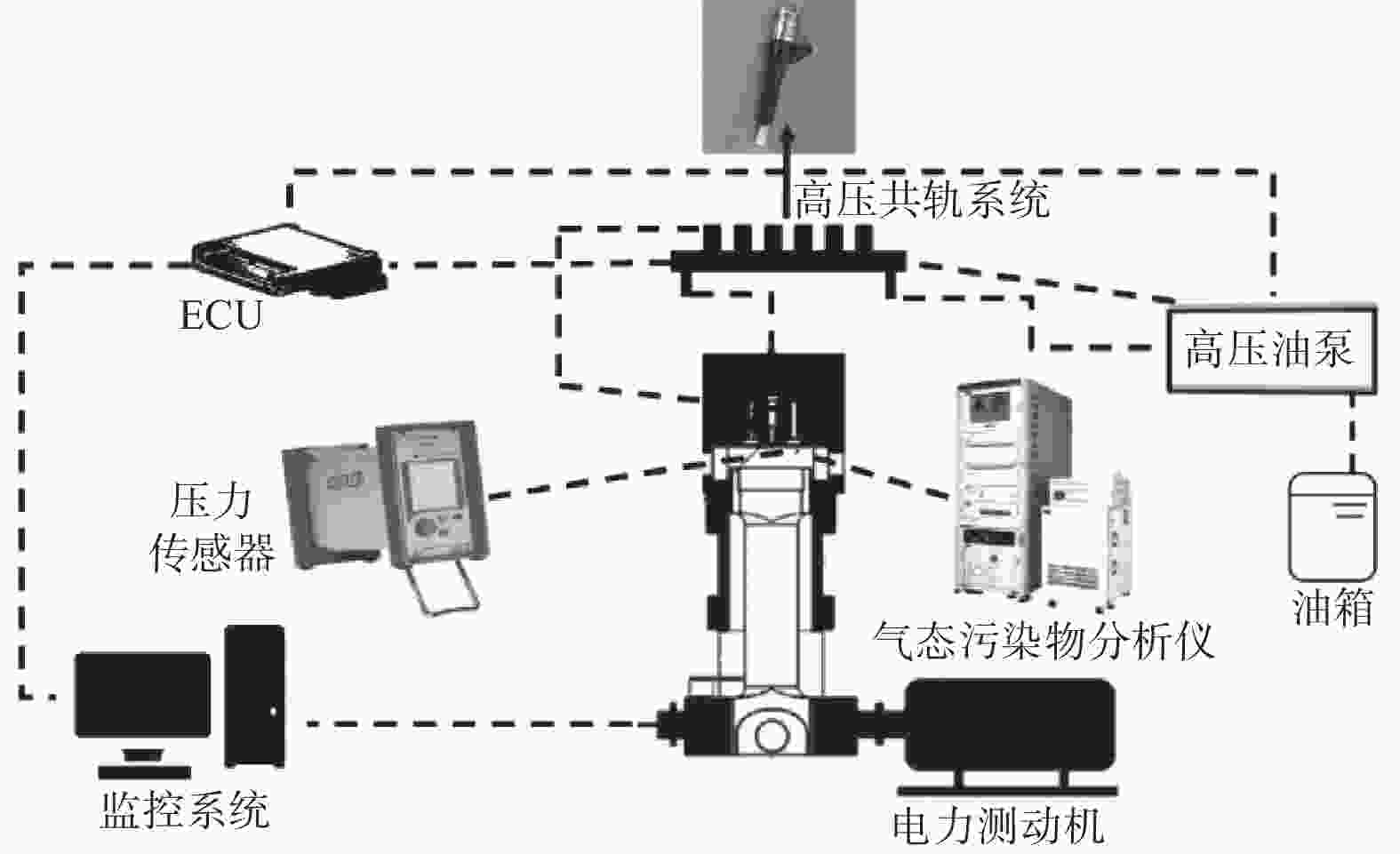

Abstract:Taking a 6-cylinder, four-stroke, two-stage turbocharged marine diesel engine as the research object, the coupled simulation model of Miller cycle and exhaust gas recirculation (EGR) of two-stage turbocharged diesel engine was established, and the influences of Miller cycle and EGR coupling on the fuel consumption rate and NOx emissions of the two-stage turbocharged diesel engine were studied. The results show that when the Miller timing is −40°CA, compared with the original engine, the fuel consumption rate is reduced by 3.5%, and the NOx emissions are reduced by 25.5%. When the EGR rate is 30%, the fuel consumption rate is increased by 5.0% and NOx emissions are reduced by 98.7%. When the Miller timing is −30°CA and EGR rate is 20%, compared with the original engine, the fuel consumption rate is only increased by 0.1% and NOx emissions are reduced by 92.7%.

-

表 1 柴油机主要技术参数

Table 1. Main technical parameters of diesel engine

参数 数值 机型 四冲程,直列6缸 气缸直径/mm 170 行程/mm 222 连杆长度/mm 379 排量/L 30.22 压缩比 15.5:1 点火顺序 1→5→3→6→2→4 最大爆发压力/MPa 25 低压级增压器转速/(r·min−1) ≤75000 高压级增压器转速/(r·min−1) ≤80000 中冷后空气温度/℃ 45 ± 5 喷孔数 8 喷孔直径/mm 0.3 表 2 主要试验数据

Table 2. Main experimental datas

参数 数值 功率/kW 507.7 转速/(r·min−1) 1365 转矩/(N·m) 3557.2 燃油消耗率/(g·(kW·h)−1) 213.2 进气流量/(kg·h−1) 4612.6 进气温度/℃ 28.7 NOx排放量 /(g·(kW·h)−1) 15.3 -

[1] 刘圣华, 周龙保. 内燃机学[M]. 4版. 北京: 机械工业出版社, 2017. [2] KALGHATGI G. Is it really the end of internal combustion engines and petroleum in transport?[J] . Applied Energy,2018,225:965 − 974. doi: 10.1016/j.apenergy.2018.05.076 [3] MITO M T, TEAMAH M A, EL-MAGHLANY W M, et al. Utilizing the scavenge air cooling in improving the performance of marine diesel engine waste heat recovery systems[J] . Energy,2018,142:264 − 276. doi: 10.1016/j.energy.2017.10.039 [4] RAJAK U, CHAURASIYA P K, NASHINE P, et al. Financial assessment, performance and emission analysis of Moringa oleifera and Jatropha curcas methyl ester fuel blends in a single-cylinder diesel engine[J] . Energy Conversion and Management,2020,224:113362. doi: 10.1016/j.enconman.2020.113362 [5] XIE Y K, LI Y Y, ZHAO Z C, et al. Microsimulation of electric vehicle energy consumption and driving range[J] . Applied Energy,2020,267:115081. doi: 10.1016/j.apenergy.2020.115081 [6] LI Y Y, WANG P, WANG S Q, et al. Quantitative investigation of the effects of CR, EGR and spark timing strategies on performance, combustion and NOx emissions characteristics of a heavy-duty natural gas engine fueled with 99% methane content[J] . Fuel,2019,255:115803. doi: 10.1016/j.fuel.2019.115803 [7] 李先南, 黄立, 张文正, 等. 两级增压对船用柴油机性能影响的试验[J] . 内燃机学报,2020,38(2):104 − 109. [8] 刘宏杰. EGR结合米勒循环降低二冲程柴油机氮氧化物排放的研究[D]. 上海: 上海交通大学, 2016. [9] 刘辰朋, 桂勇, 刘腾, 等. EGR率对船用低速柴油机缸内燃烧影响的仿真研究[J] . 船舶工程,2019,41(S1):154 − 157. [10] 汪齐富. 船用柴油机米勒循环可调二级涡轮增压系统的研究[D]. 上海: 上海交通大学, 2012. [11] STONE R. Introduction to internal combustion engines[M]. London: Macmillan, 1985. [12] GUAN W, PEDROZO V B, ZHAO H, et al. Miller cycle combined with exhaust gas recirculation and post–fuel injection for emissions and exhaust gas temperature control of a heavy-duty diesel engine[J] . International Journal of Engine Research,2020,21(8):1381 − 1397. doi: 10.1177/1468087419830019 [13] 刘秋颖. 柴油机两级涡轮增压系统选型与匹配[D]. 上海: 上海交通大学, 2011. [14] 刘博. 柴油机可调二级涡轮增压系统研究[D]. 上海: 上海交通大学, 2011. [15] 陆家祥. 柴油机涡轮增压技术[M]. 2版. 北京: 机械工业出版社, 2018. [16] WANG P, HU Z L, SHI L, et al. Experimental investigation of the effects of Miller timing on performance, energy and exergy characteristics of two-stage turbocharged marine diesel engine[J] . Fuel,2021,292:120252. doi: 10.1016/j.fuel.2021.120252 [17] 成晓北, 浦涵, 杨灿. 可调二级增压结合EGR策略对米勒循环柴油机性能的影响[J] . 车用发动机,2019(4):1 − 7. doi: 10.3969/j.issn.1001-2222.2019.02.001 [18] 王文超, 姚安仁, 任家潮, 等. 高低压废气再循环系统(EGR)对进气道喷醇式柴油甲醇双燃料发动机的影响[J] . 环境科学学报,2021,41(11):4467 − 4476. [19] 魏宇坤, 安士杰, 张志友. EGR率对船用柴油机中低负荷燃烧排放性能影响的仿真及试验研究[J] . 柴油机,2016,38(2):11 − 15. doi: 10.3969/j.issn.1001-4357.2016.02.003 [20] 史金钟, 鲍建军, 郭振杰, 等. EGR率和预喷时刻对柴油机NOx和CO排放的影响[J] . 拖拉机与农用运输车,2017,44(3):49 − 51,58. [21] 孙跃东, 张振东. 增压中冷柴油机EGR排放特性试验研究[J] . 农业机械学报,2004(5):47 − 50. doi: 10.3969/j.issn.1000-1298.2004.05.013 [22] WANG P, TANG X Y, SHI L, et al. Experimental investigation of the influences of Miller cycle combined with EGR on performance, energy and exergy characteristics of a four-stroke marine regulated two-stage turbocharged diesel engine[J] . Fuel,2021,300:120940. doi: 10.1016/j.fuel.2021.120940 -

下载:

下载: