Transient analysis of misaligned journal bearings based on fluid-structure interaction approach

-

摘要:

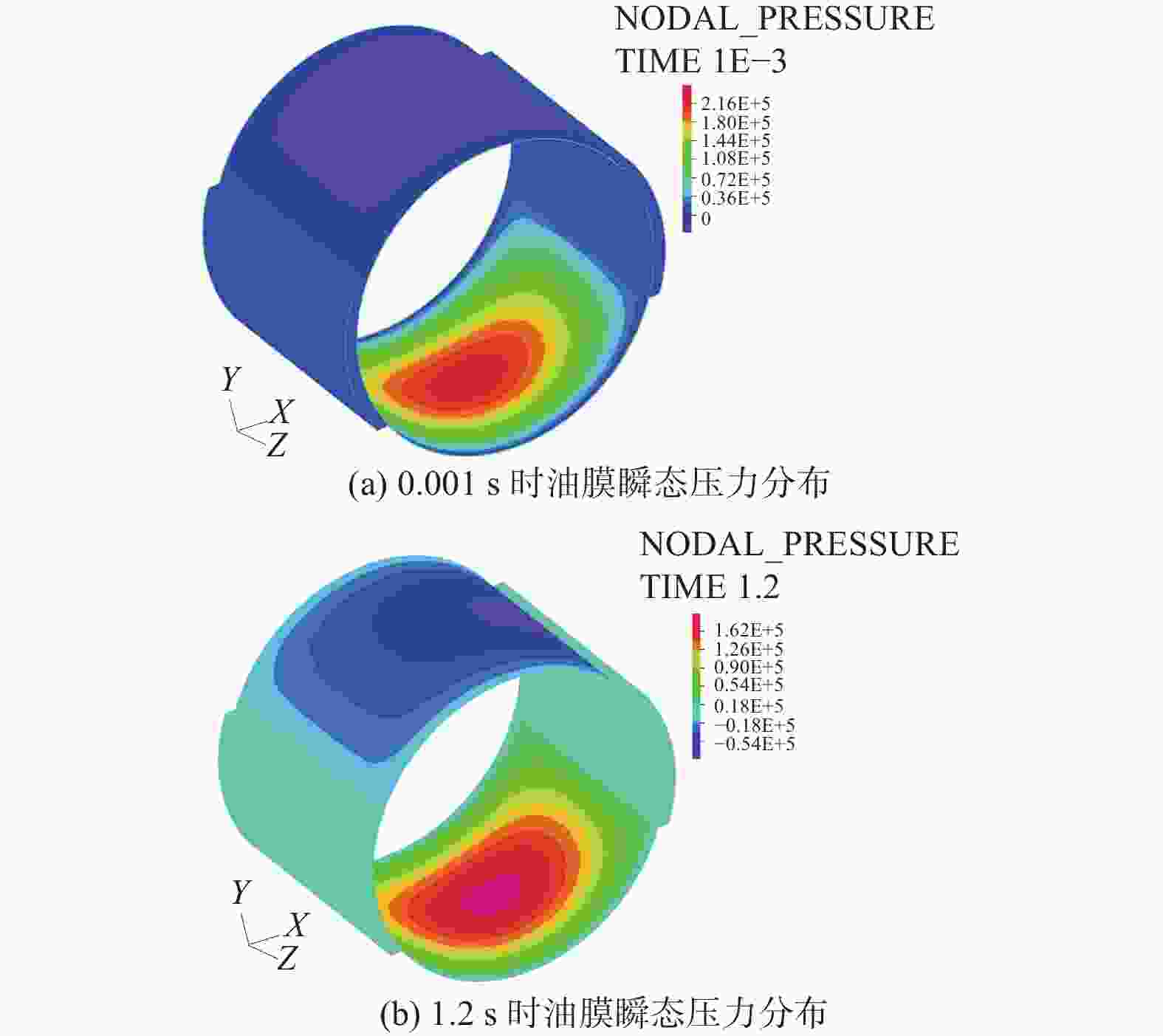

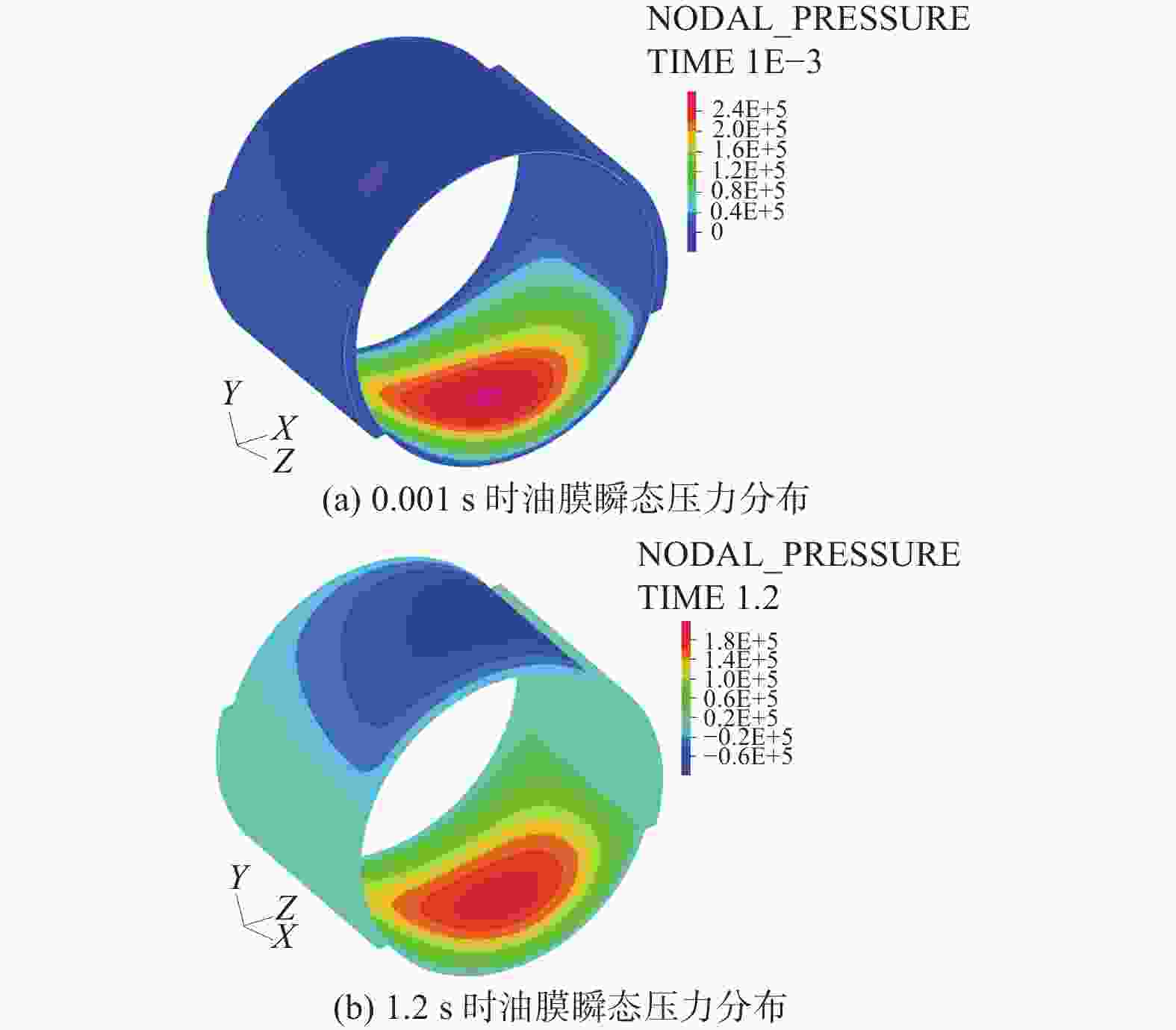

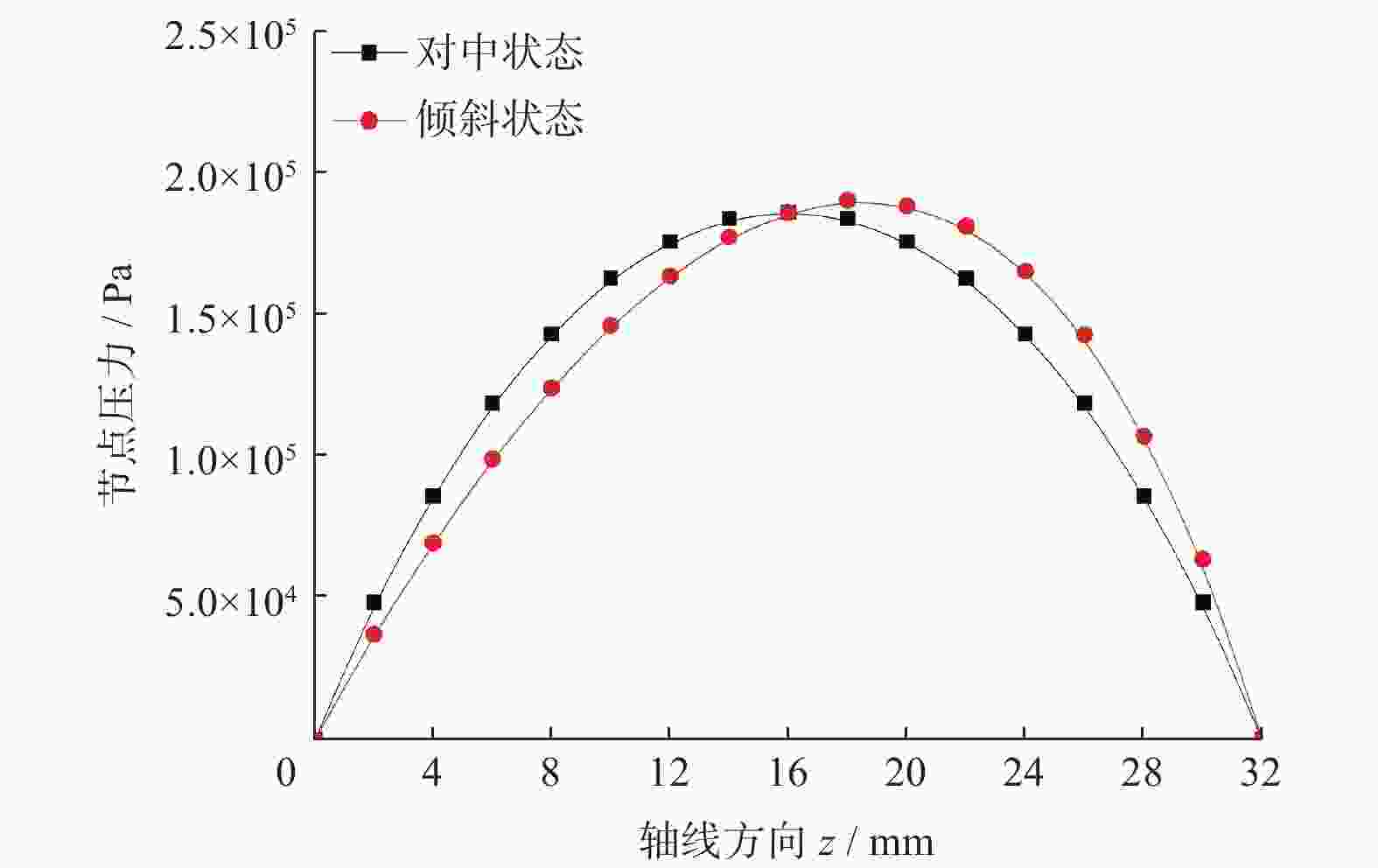

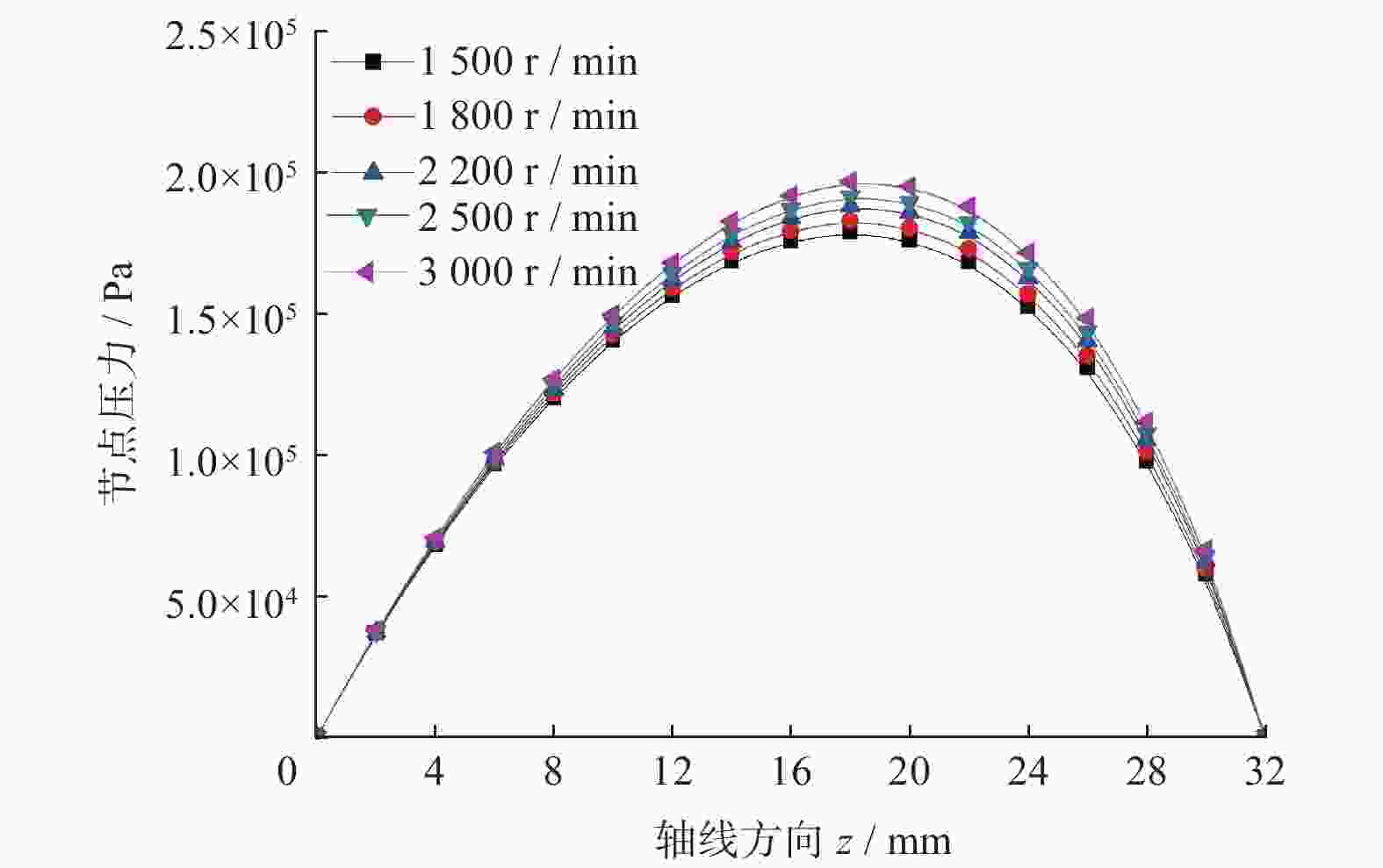

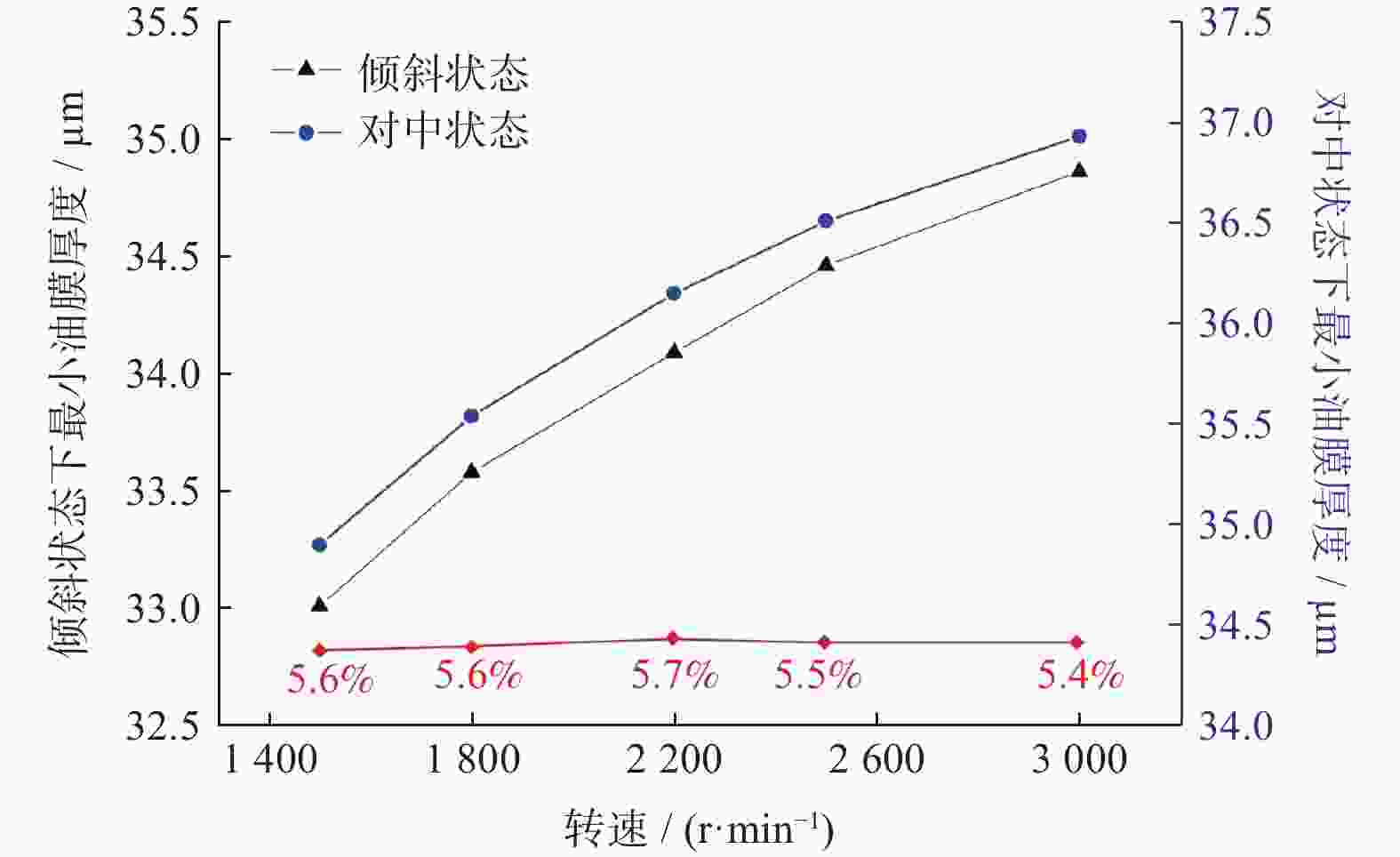

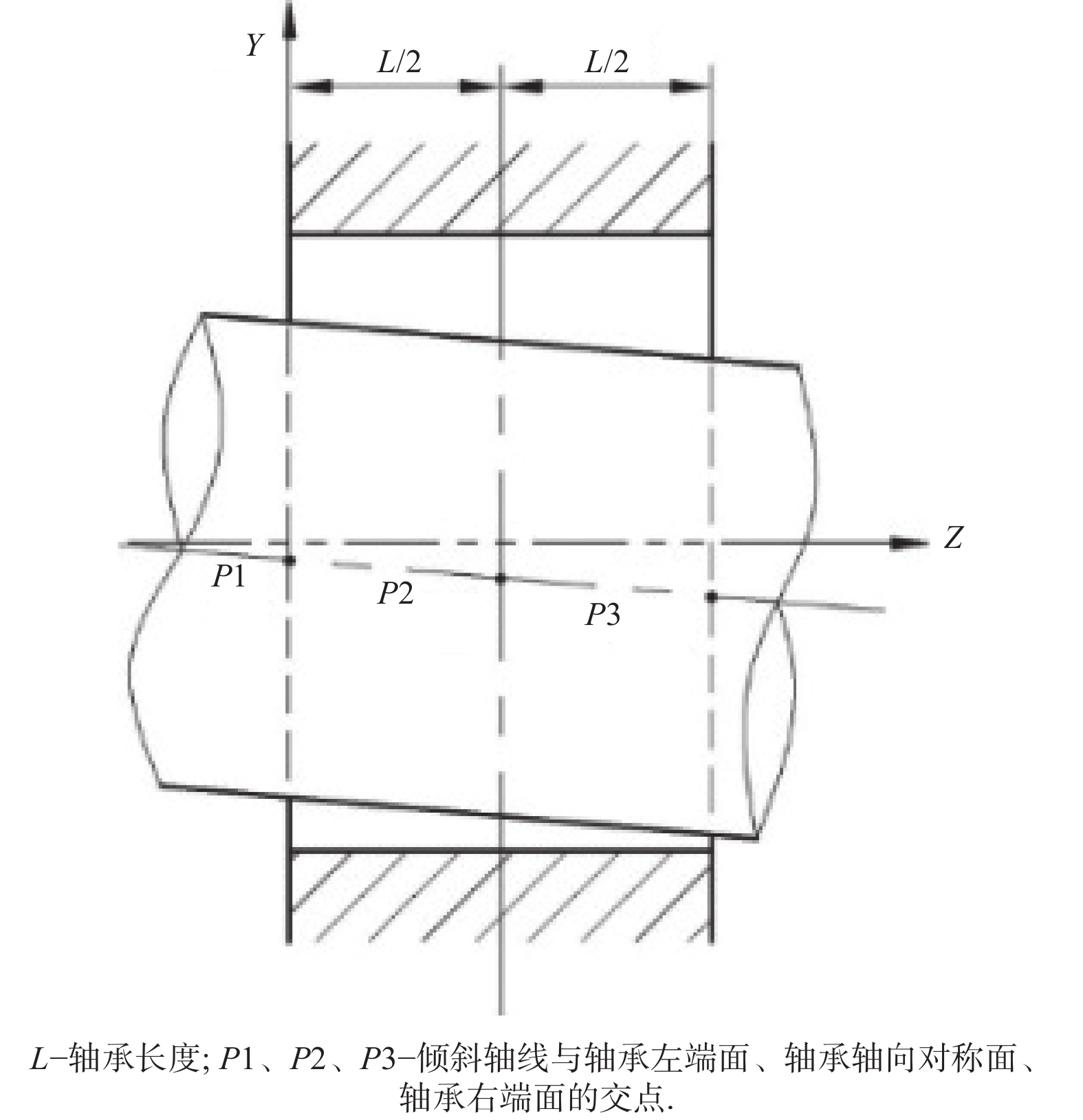

考虑轴受力产生变形引起的轴倾斜,采用流固耦合方法,直接求解Navier−Stokes方程,对滑动轴承系统中轴和润滑油膜进行三维瞬态分析,同时求解流场和固体域,得到油膜动态压力分布、轴心的运动轨迹和不同转速下油膜厚度分布. 结果表明,轴倾斜使油膜压力分布和轴心轨迹变化明显,最小油膜厚度减小,流场压力峰值增大. 通过对滑动轴承的三维瞬态分析可以预测轴承工作过程中实时的轴心轨迹、压力分布、油膜厚度等润滑特性,为滑动轴承的优化设计提供参考.

Abstract:The shaft is deformed with the action of load. The misalignment due to deformation caused by the action of load is considered. The fluid-structure interaction method was used. Navier-Stokes equation was solved directly. The three-dimensional transient analysis of shaft and oil film in journal bearing system was carried out. The flow field and solid domain were solved at the same time. Transient film pressure distribution, trajectory of journal center and minimum oil film thickness under different rotate speeds were solved. The results show that the oil film pressure distribution and thickness of oil film change obviously. The minimum oil film thickness decreases, the peak oil film pressure increased when misalignment was considered. The real-time trajectory of journal center, oil film thickness and transient film pressure distribution can be predicted by the transient analysis, which is very significant for the optimal design of journal bearing.

-

Key words:

- journal bearing /

- misalignment /

- transient analysis /

- oil film thickness

-

-

[1] MUKHERJEE A, RAO J S. Stiffness and damping coefficients of an inclined journal bearing[J] . Mechanism and Machine Theory,1977,12(4):339 − 355. doi: 10.1016/0094-114X(77)90010-6 [2] 孙丽军, 薛闯, 张立浩, 等. 倾斜轴颈重载轴承润滑性能分析及试验研究[J] . 润滑与密封,2016,41(7):107 − 111. doi: 10.3969/j.issn.0254-0150.2016.07.019 [3] ZHU S Y, SUN J, LI B, et a1. Thermal turbulent lubrication analysis of rough surface journal bearing with joumal misalignment[J] . Tribology International,2020,144:12. [4] 王亚兵, 刘洋洋, 王报龙, 等. 轴颈倾斜的水润滑橡胶艉轴承的静态特性[J] . 西安交通大学学报,2020,54(5):61 − 69. doi: 10.7652/xjtuxb202005009 [5] SUN J, GUI C L. Hydrodynamic lubrication analysis of journal bearing considering misalignment caused by shaft deformation[J] . Tribology International,2004,37(10):841 − 848. doi: 10.1016/j.triboint.2004.05.007 [6] LYU F R, JIAO C X, TA N, et al. Mixed-lubrication analysis of misaligned bearing considering turbulence[J] . Tribology International,2018,119:19 − 26. doi: 10.1016/j.triboint.2017.10.030 [7] LYU F R, ZOU D L, TA N, et a1. Influence of local turbulent flow on the performance of a mixed-lubrication bearing[J] . Proceedings of the Institution of Mechanical Engineers: Part J Journal of Engineering Tribology,2019,233(208/209/210):1029 − 1035. doi: 10.1177/1350650118818303 [8] 刘洋洋, 王亚兵, 祝长生, 等. 考虑轴颈倾斜的水润滑橡胶径向轴承的动力学特性[J] . 西安交通大学学报,2021, 55(1):101 − 108. doi: 10.7652/xjtuxb202101013 [9] GERTZOS K P, NIKOLAKOPOULOS P G, PAPADOPOULOS C A. CFD analysis of journal bearing hydrodynamic lubrication by Bingham lubricant[J] . Tribology International,2008,41(12):1190 − 1204. doi: 10.1016/j.triboint.2008.03.002 [10] MERUANE V, PASCUAL R. Identification of nonlinear dynamic coefficients in plain journal bearings[J] . Tribology International,2008,41(8):743 − 754. doi: 10.1016/j.triboint.2008.01.002 [11] LIU H P, XU H, ELLISON P J, et al. Application of computational fluid dynamics and fluid–structure interaction method to the lubrication study of a rotor–bearing system[J] . Tribology Letters,2010,38(3):325 − 336. doi: 10.1007/s11249-010-9612-6 [12] LIN Q Y, BAO Q K, LI K J, et al. An investigation into the transient behavior of journal bearing with surface texture based on fluid-structure interaction approach[J] . Tribology International,2018,118:246 − 255. [13] LIN Q Y, WEI Z Y, WANG N, et al. Analysis on the lubrication performances of journal bearing system using computational fluid dynamics and fluid-structure interaction considering thermal influence and cavitation[J] . Tribology International,2013,64:8 − 15. [14] 孙加丰. 基于压电薄膜传感器的滑动轴承动油膜压力分布实时测量方法研究[D]. 上海: 上海交通大学, 2013. [15] 朱希玲, 荆建平. 基于气穴模型的动压轴承动态油膜刚度计算方法[J] . 润滑与密封,2019,44(9):120 − 125. doi: 10.3969/j.issn.0254-0150.2019.09.020 [16] 刘鸿文. 材料力学[M]. 5版. 北京: 高等教育出版社, 2011: 125−126. -

下载:

下载: