Total cost of ownership of fuel cell vehicles in China under carbon neutral target scenario

-

摘要:

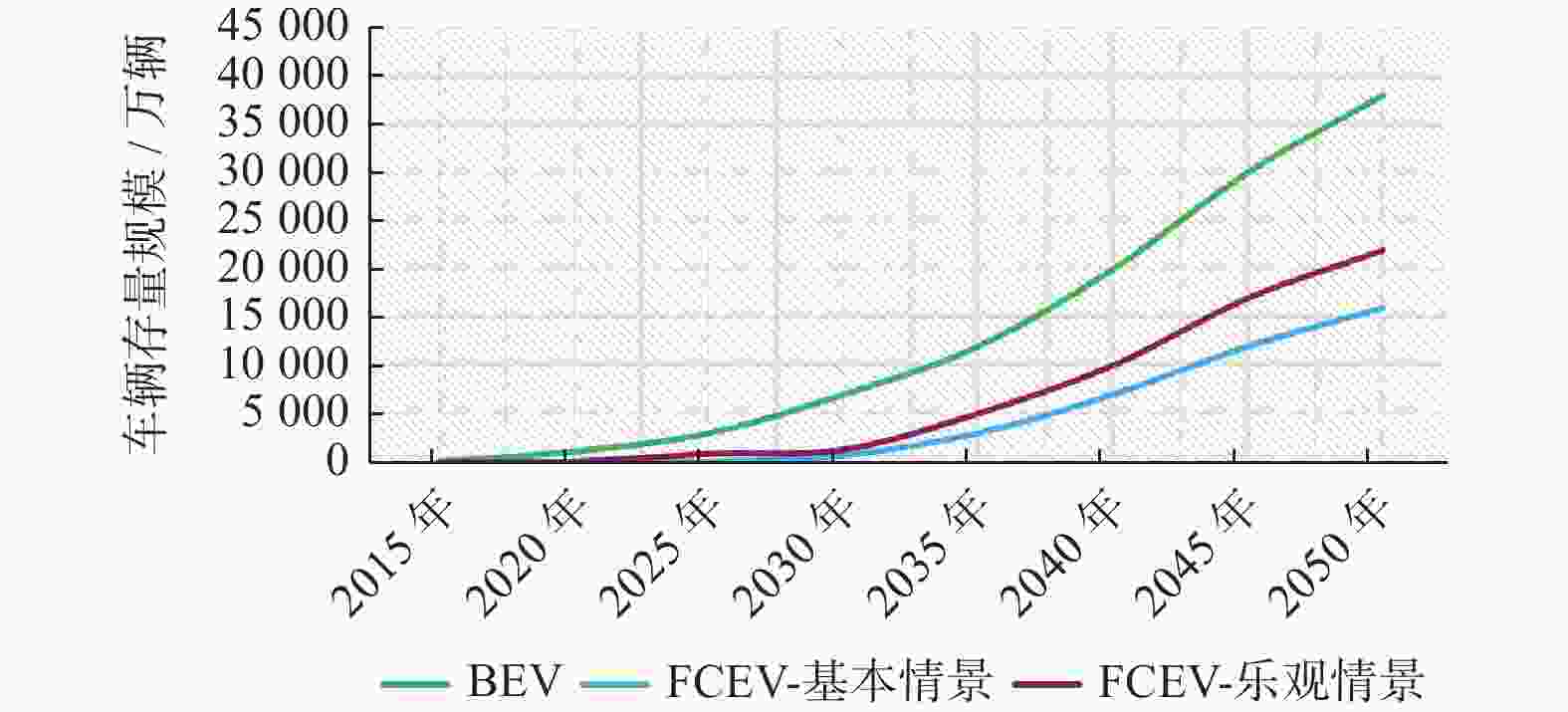

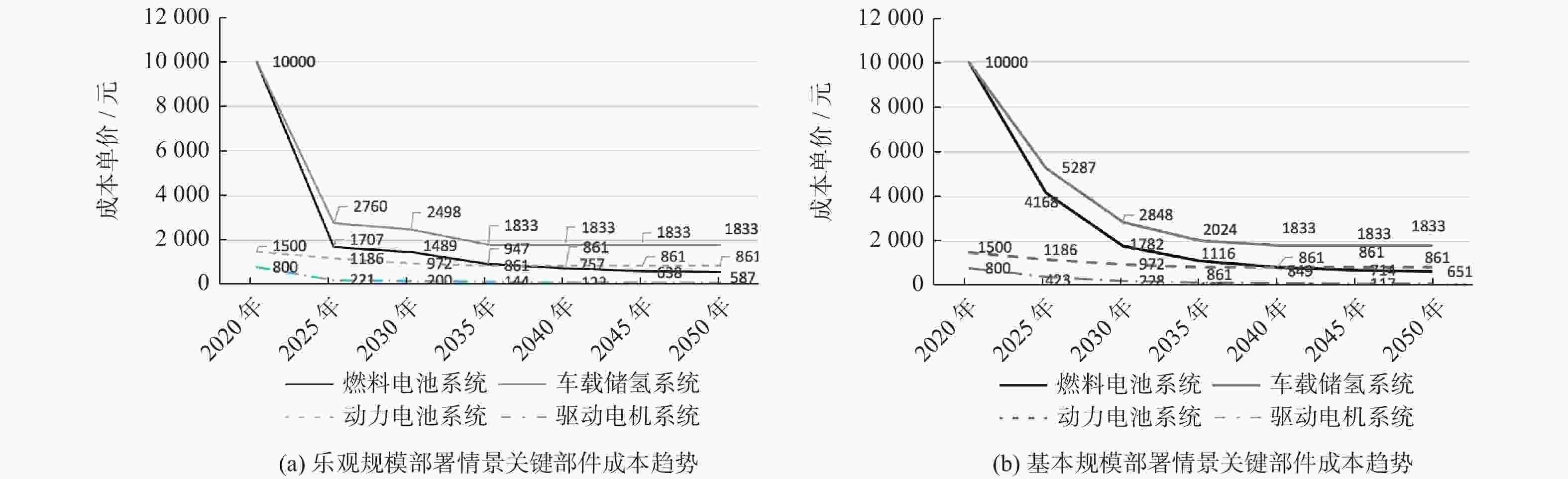

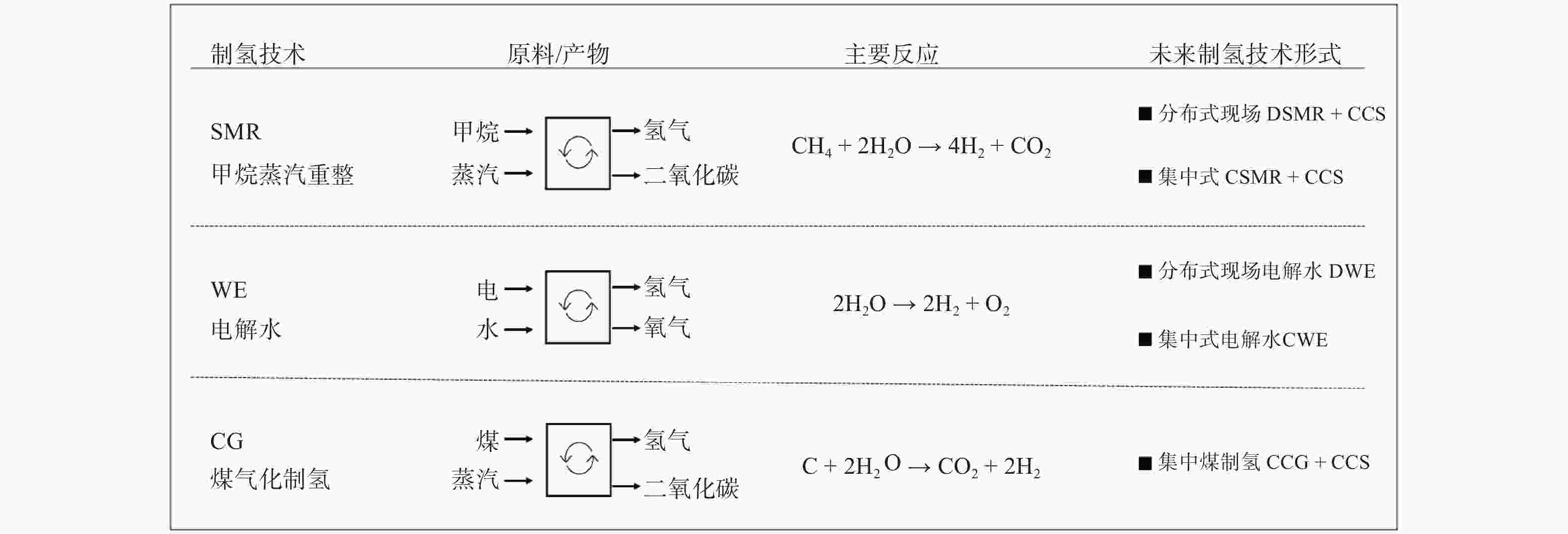

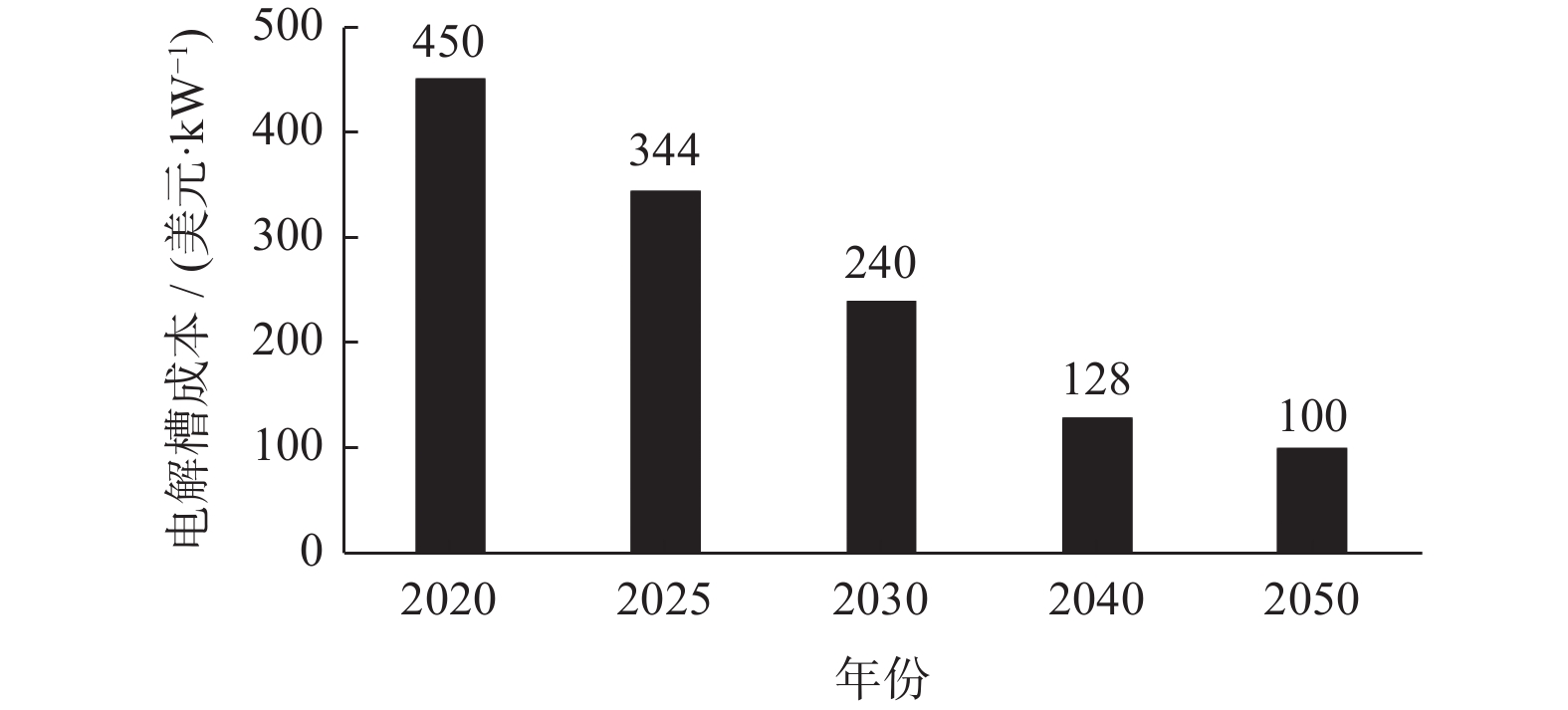

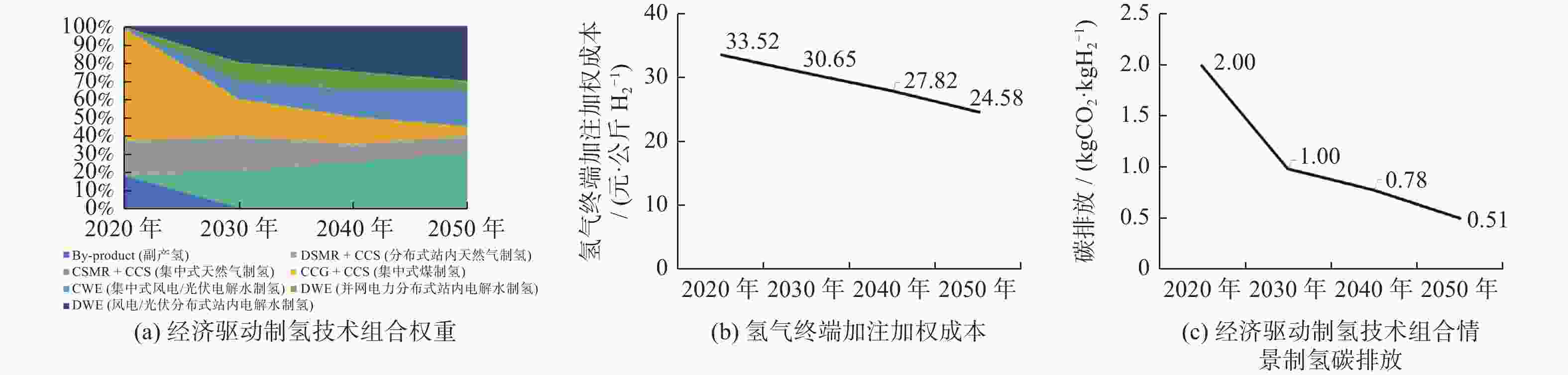

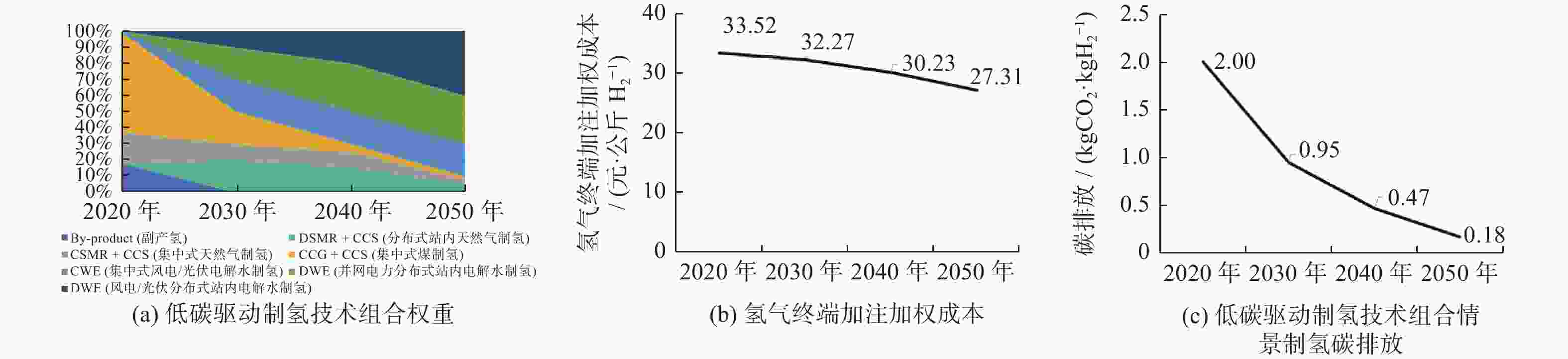

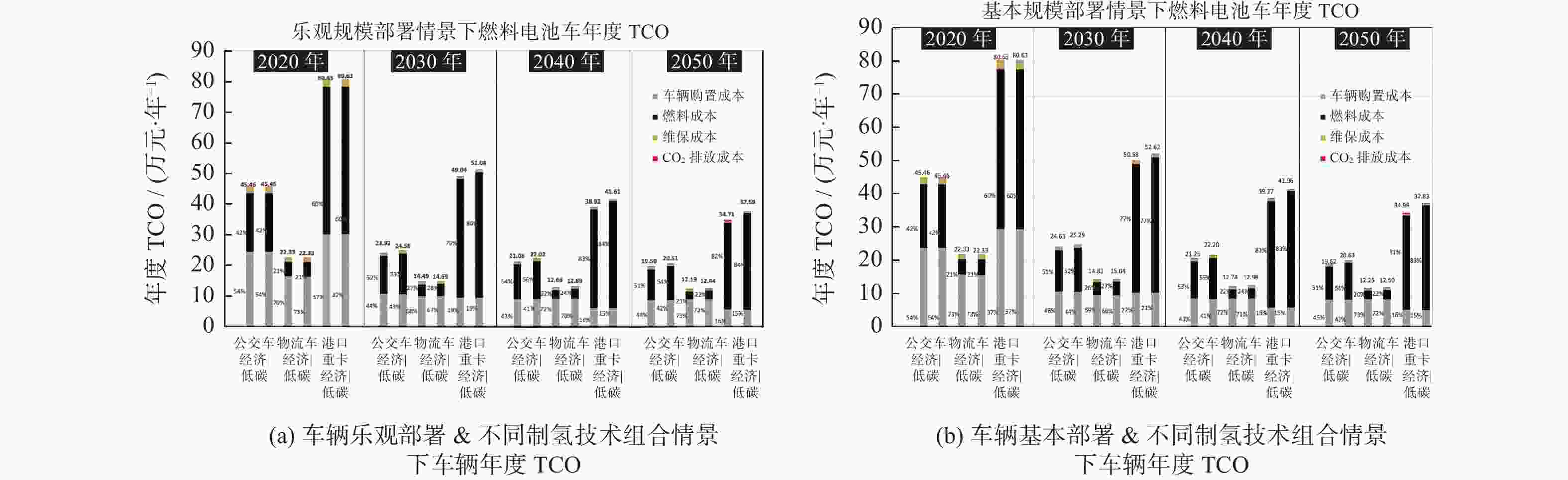

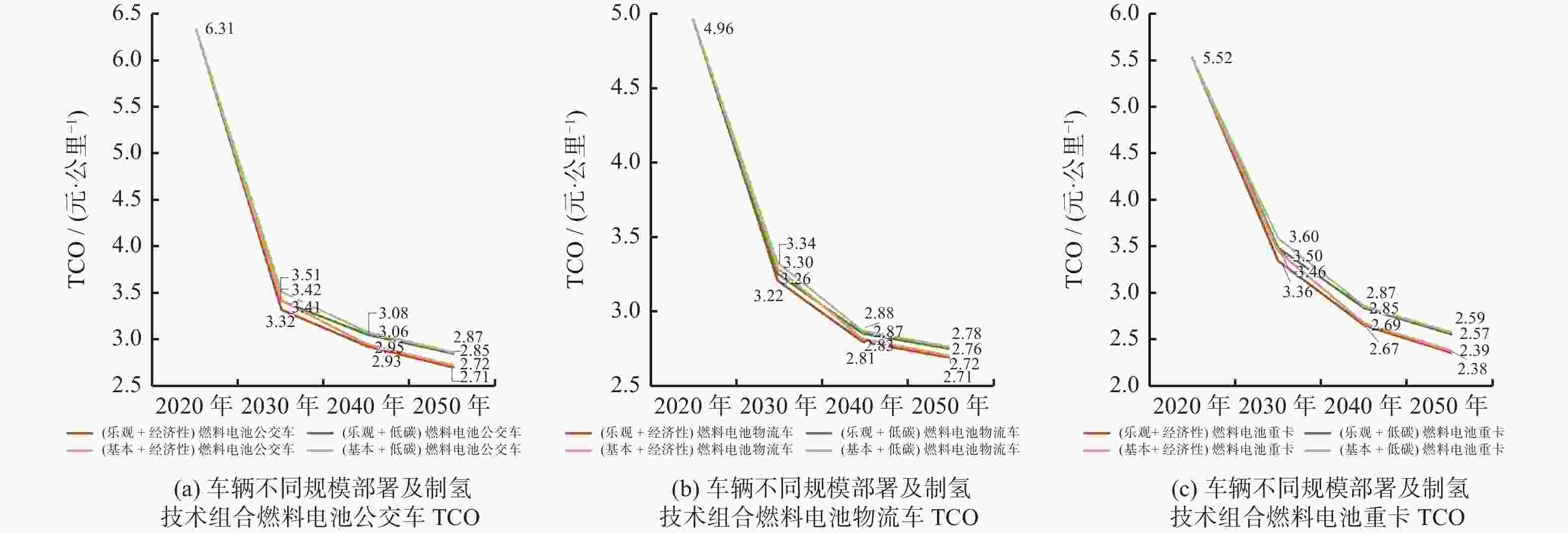

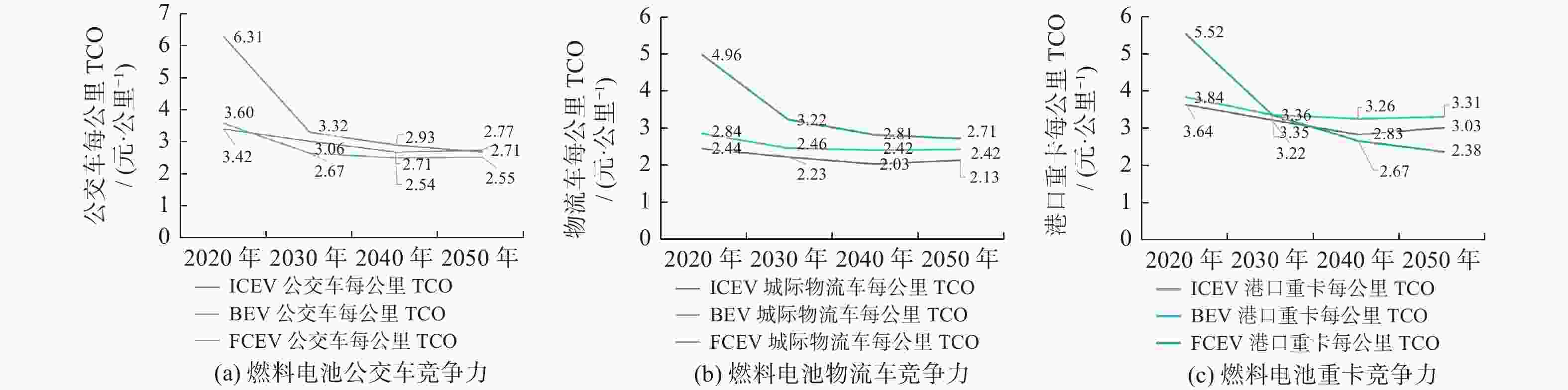

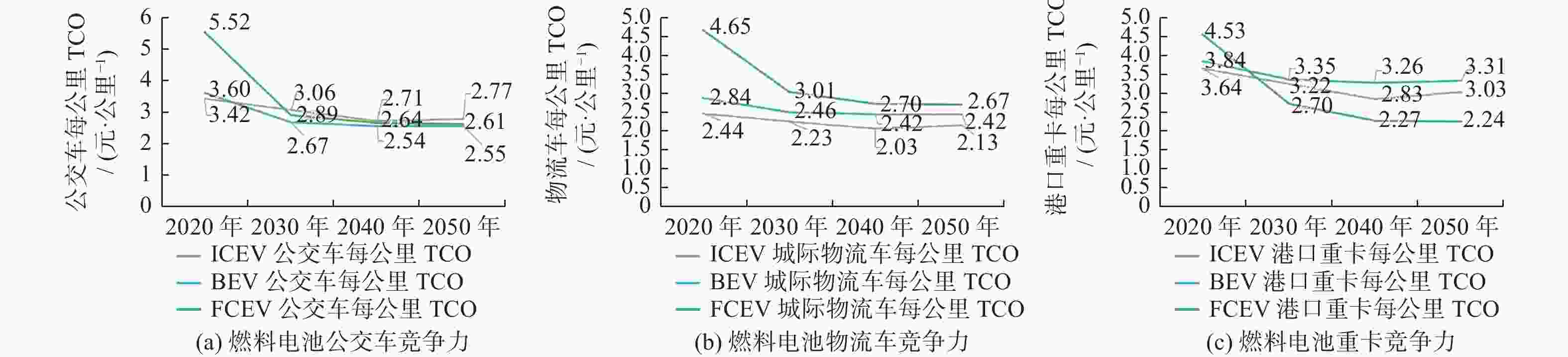

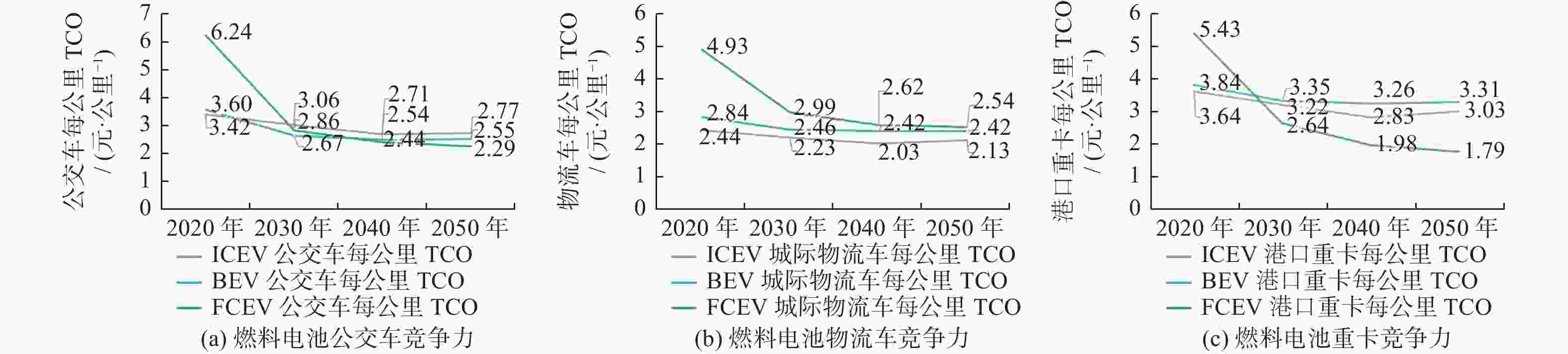

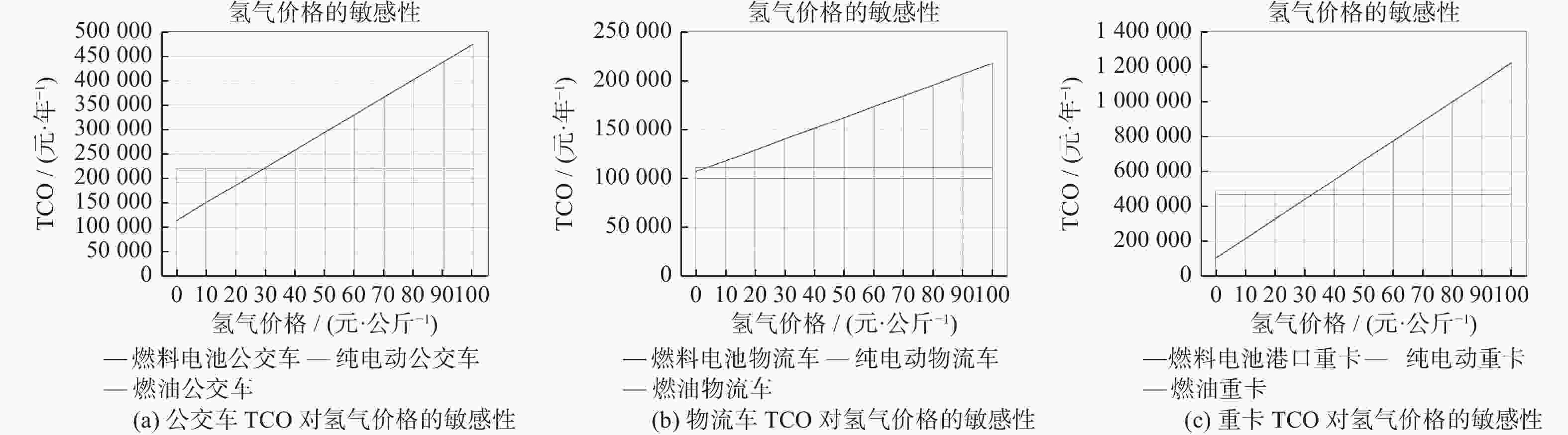

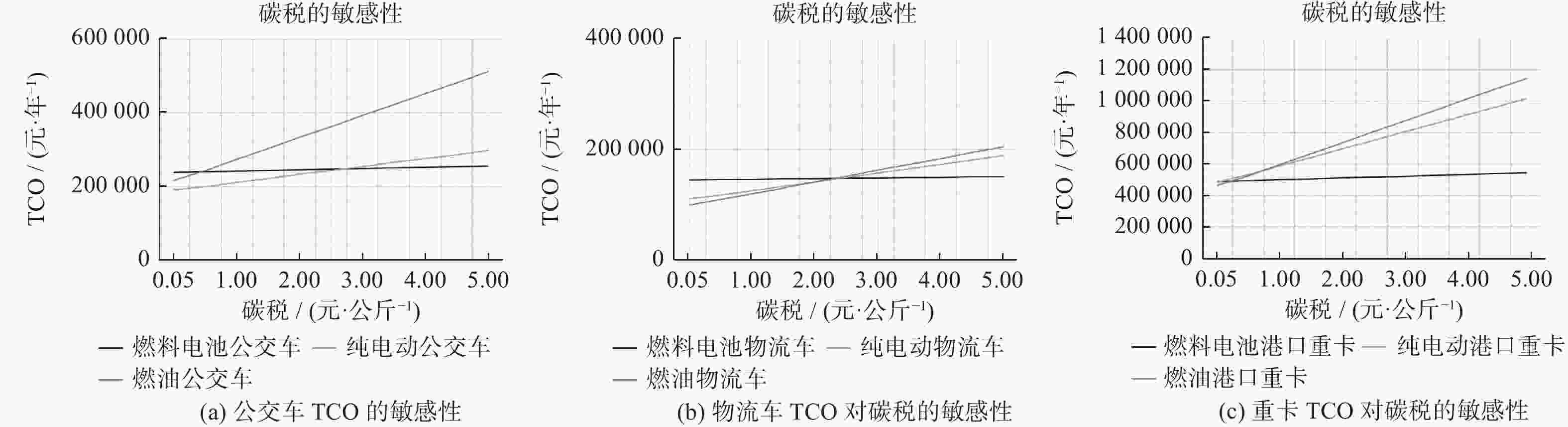

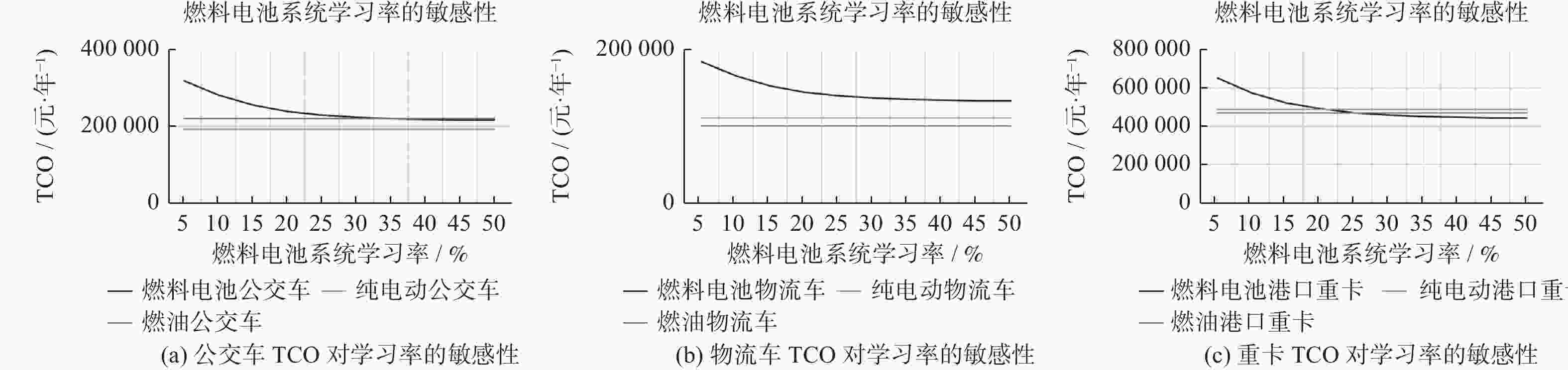

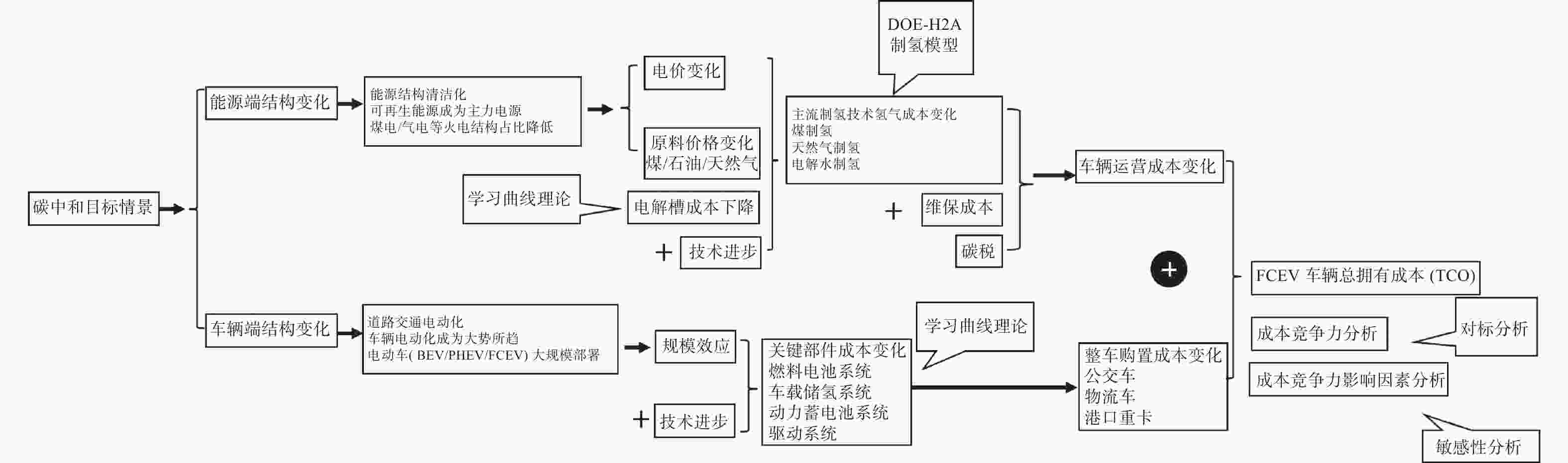

以碳中和目标为情景,建立燃料电池车总拥有成本(Total Cost of Ownership, TCO)计算模型;应用学习曲线理论预测构成燃料电池车的关键部件的成本变化趋势;讨论当下主流制氢技术路径的未来制氢成本;通过TCO反映我国燃料电池车未来成本趋势、竞争力及关键影响因素.

Abstract:In the carbon neutral target scenario, a calculation model for total cost of ownership (TCO) of fuel cell vehicles was developed, and the learning curve theory was applied to predict the cost trend of the key components of fuel cell vehicles. The future cost of hydrogen production for the current mainstream technology path was predicted. TCO was used to represent the future cost trend, competitiveness and key influencing factors of China’s fuel cell vehicles.

-

表 1 典型工况的我国燃料电池车购置成本结构

Table 1. Purchase cost structure of fuel cell vehicles in China for typical working conditions

项目 燃料电池客车 燃料电池物流车 燃料电池港口重卡 整车购置成本(不含补贴)/万元 195 130 150 燃料电池系统成本/(万元•kW−1) 1.1 1.5 1.0 燃料电池系统成本占比/% 53 58 53 车载储氢系统成本/(万元•kg−1) 1.10 1.33 0.71 车载储氢系统成本占比/% 12 11 17 动力电池系统成本/(万元•(kWh)−1) 0.15 0.23 0.15 动力电池系统成本占比/% 8 4 10 驱动电机系统成本/(万元•kW−1) 0.110 0.080 0.047 驱动电机系统成本占比/% 10 4 7 车身及其他设施成本占比/% 17 23 13 表 2 关键部件成本及学习率设置

Table 2. Key component cost and learning rate

关键部件 初始成本 底线成本 学习率/% 燃料电池系统/(元•kW−1) 10000 206 20 车载储氢系统/(元•kg−1) 10000 1833 15 动力电池系统/(元•(kWh)−1) 1500 861 15 驱动电机系统/(元•kW−1) 800 37 15 表 3 我国天然气制氢成本(含CCS)预测

Table 3. Cost forecast of hydrogen production from natural gas (including CCS) in China

元/kg 制氢类型 2020年 2030年 2040年 2050年 DSMR分布式站内天然气制氢 11.65 11.21 10.85 10.67 CSMR集中式天然气制氢 12.27 11.79 11.40 11.21 表 4 我国集中式煤制氢成本(含CCS)预测

Table 4. Cost forecast of hydrogen centralized production from coal (including CCS) in China

元/kg 制氢类型 2020年 2030年 2040年 2050年 CG集中式煤制氢成本 17.16 16.06 15.75 15.54 表 5 不同电力来源及形式的电解水制氢成本预测

Table 5. Cost prediction of hydrogen production from electrolysis of water by different power sources and forms

元/kg 制氢类型 2020年 2025年 2030年 2040年 2050年 DWE(并网电力分布

式站内电解水制氢)成本— 33.22 28.48 27.98 28.34 CWE(风电/光伏集中

式电解水制氢)成本20.28 14.30 10.10 7.03 5.10 DWE(风电/光伏分布

式站内电解水制氢)成本— 14.82 10.62 7.55 5.61 表 6 车辆TCO竞争力分析框架

Table 6. Competitiveness analysis framework of total cost of ownership for vehicles

-

[1] McKinsey & Company. A portfolio of power-trains for Europe: A fact based analysis[J]. [S.l.: s.n.], 2010. [2] JAMES B D, HUYA-KOUADIO J M, HOUCHINS C, et al. Mass production cost estimation of direct H2 PEM fuel cell systems for transportation applications (2012—2016)[R]. Arlington: Strategic Analysis Inc., 2016. [3] COX B, BAUER C, BELTRAN A M, et al. Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios[J] . Applied Energy,2020,269:115021. doi: 10.1016/j.apenergy.2020.115021 [4] MAO S Y, BASMA H, RAGON P L, et al. Total cost of ownership for heavy trucks in China: Battery electric, fuel cell, and diesel trucks[R]. Washington: International Council on Clean Transportation, 2021. [5] 陈志祥. 学习曲线及在工业生产运作研究中的应用综述[J] . 中国工程科学,2007(7):82 − 88,94. [6] IEA. Entering the decade of electric drive[J]. Paris: International Energy Agency, 2020. [7] DOE U. Multiyear research development and demonstration plan: planned program activities for 2011—2020[J] . Office DFCT,2017,3:4. [8] KÖRNER A, TAM C, BENNETT S, et al. Technology roadmap-hydrogen and fuel cells[J]. Paris: International Energy Agency, 2015. [9] MARCINKOSKI J, VIJAYAGOPAL R, ADAMS J, et al. DOE advanced truck technologies: Subsection of the electrified powertrain roadmap technical targets for hydrogen-fueled long-haul tractor-trailer trucks[EB/OL]. (2019-10-31)[2022-01-30]. https://www.hydrogen.energy.gov/pdfs/19006_hydrogen_class8_long_haul_truck_targ ets. pdf. [10] MAYER T, KREYENBERG D, WIND J, et al. Feasibility study of 2020 target costs for PEM fuel cells and lithium-ion batteries: A two-factor experience curve approach[J] . International Journal of Hydrogen Energy,2012,37(19):14463 − 14474. doi: 10.1016/j.ijhydene.2012.07.022 [11] NYKVIST B R, NILSSON M N. Rapidly falling costs of battery packs for electric vehicles[J] . Nature Climate Change,2015,5(4):329 − 332. doi: 10.1038/nclimate2564 [12] National Research Council. Transitions to alternative vehicles and fuels[M]. Washington: National Academies Press, 2013. [13] BOUCKAERT S, PALES A F, MCGLADE C, et al. Net zero by 2050: A roadmap for the global energy sector[R]. Washington: IEA, 2021. [14] Hydrogen and Fuel Cell Technologies Office. DOE H2A Analysis[EB/OL].[2021-12-20]. https://www.energy.gov/eere/fuelcells/doe-h2a-analysis. [15] CHINA E R I. 2050 High renewable energy penetration scenario and roadmap study[R]. Beijing: Energy Research Institute, 2015. [16] 国家发改委能源研究所, 隆基股份, 山西煤业化工集团. 中国2050年光伏发展展望[C]//Proceedings of UNFCCC COP25. Madrid: United Nations Climate Change Conference, 2019. [17] International Renewable Energy Agency. Green hydrogen cost reduction: Scaling up electrolysers to meet the 1.5 ℃ climate goal[R]. Abu Dhabi: International Renewable Energy Agency, 2020. [18] CRETI A , KOTELNIKOVA A , MEUNIER G, et al. A cost benefit analysis of fuel cell electric vehicles[EB/OL]. [2021-12-20]. https://hal.archives-ouvertes.fr/hal-01116997. [19] 张希良. 面向2060年碳中和的能源经济转型 [EB/OL]. (2021-04-01)[2021-12-26]. https://www.mee.gov.cn/home/ztbd/2020/wfcsjssdgz/wfcsxwbd/ylgd/202104/P020210401595660592840.pdfjssdgz/wfcsxwbd/ylgd/202104/P020210401595660592840.pdf [20] KÖRNER A, TAM C, BENNETT S, et al. Technology roadmap: Hydrogen and fuel cells[R]. Paris: International Energy Agency, 2015. -

下载:

下载: