Oscillation characteristics of molten pool in ultra-thin plate pulsed micro-plasma arc welding

-

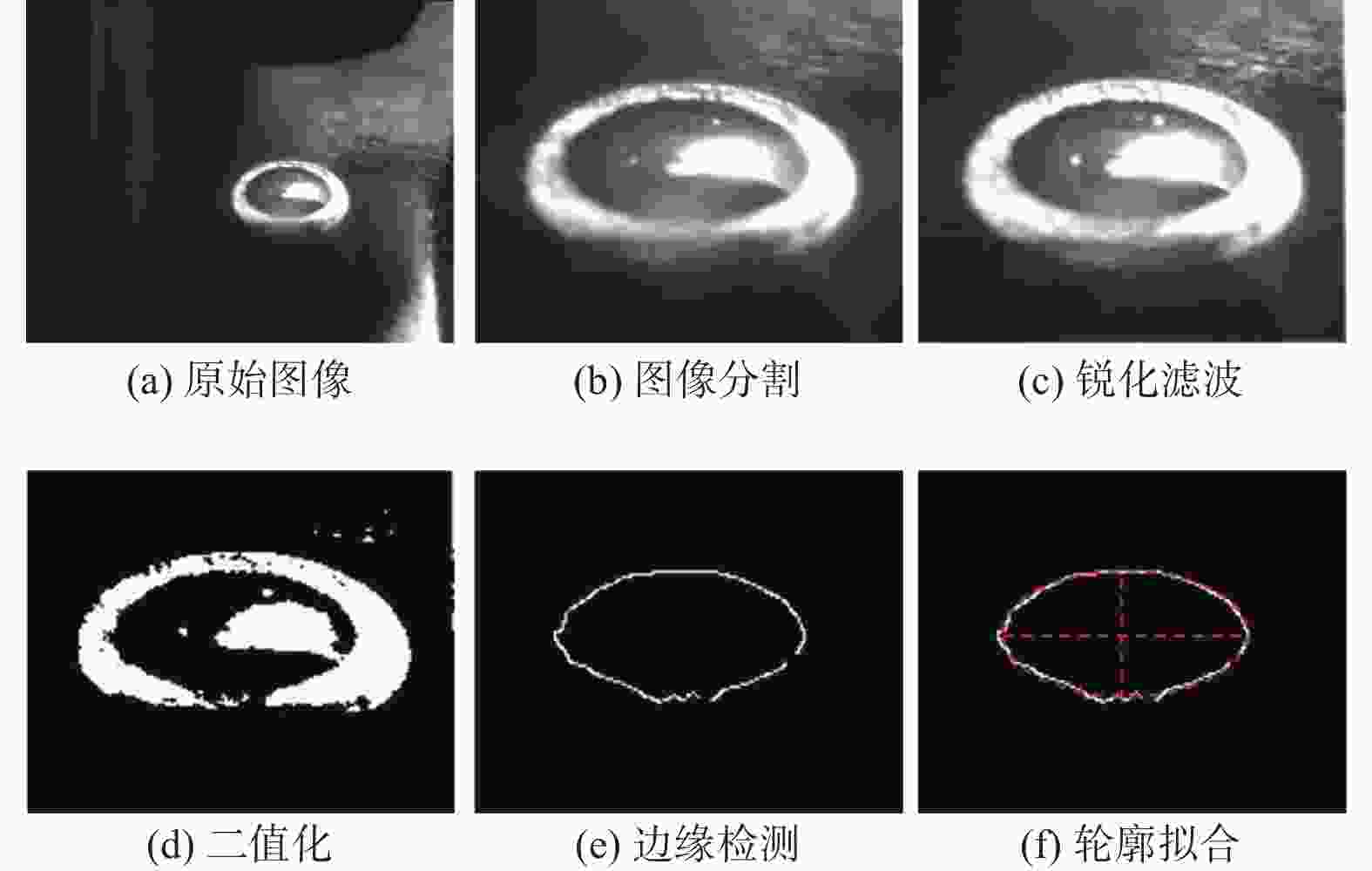

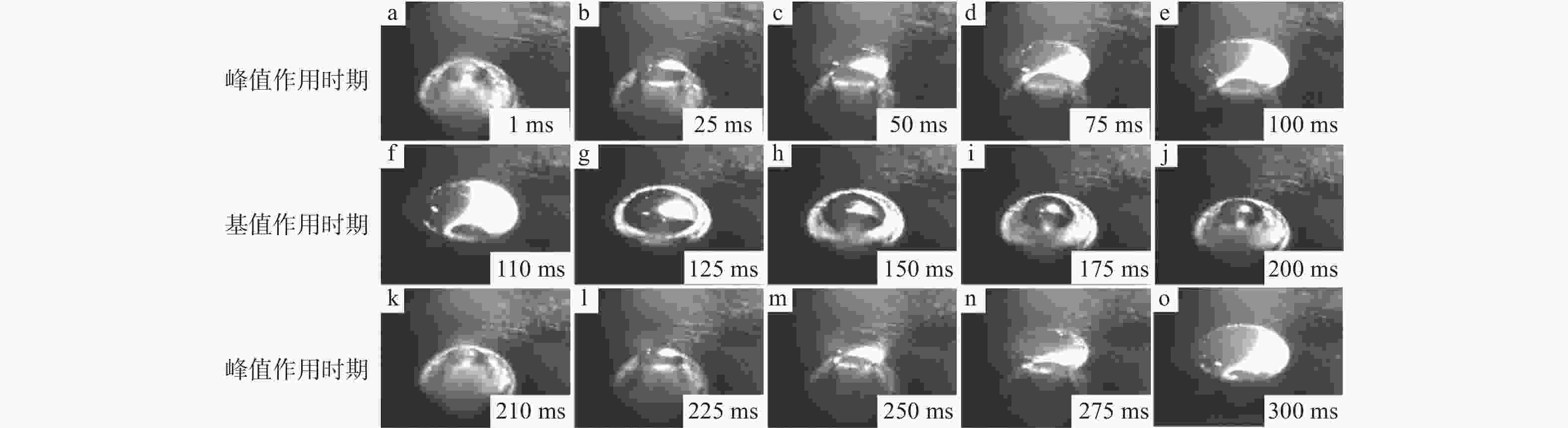

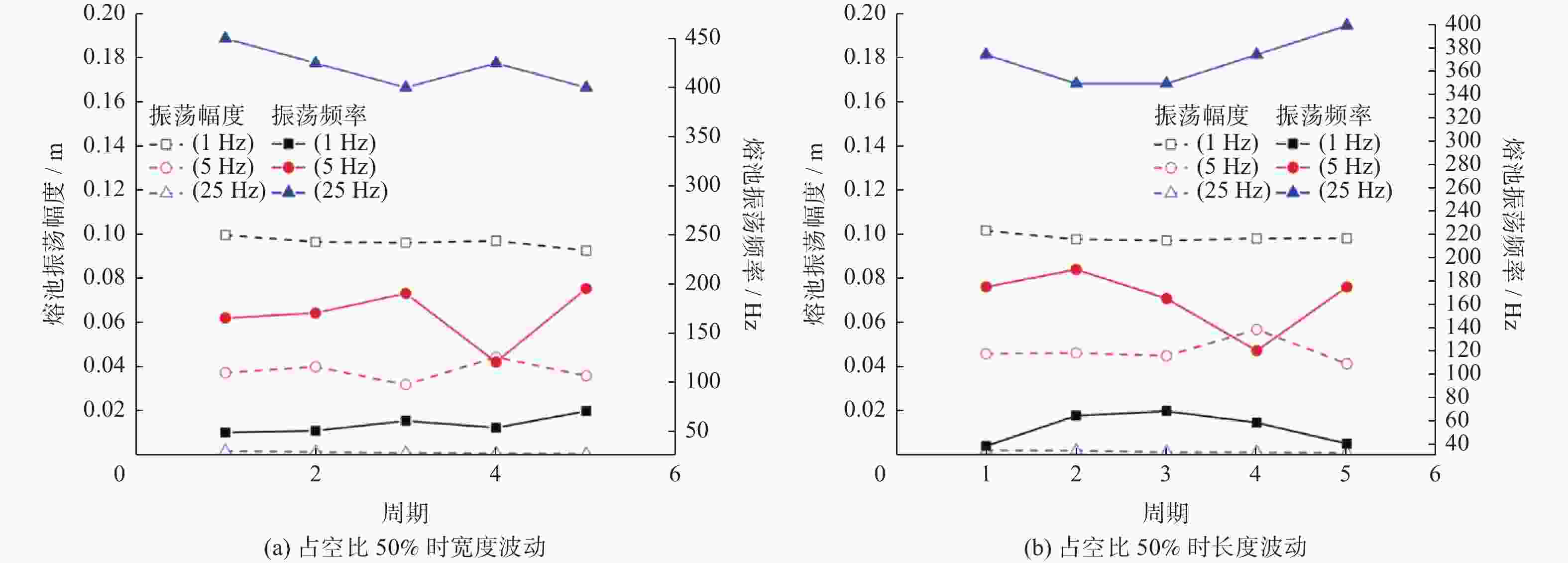

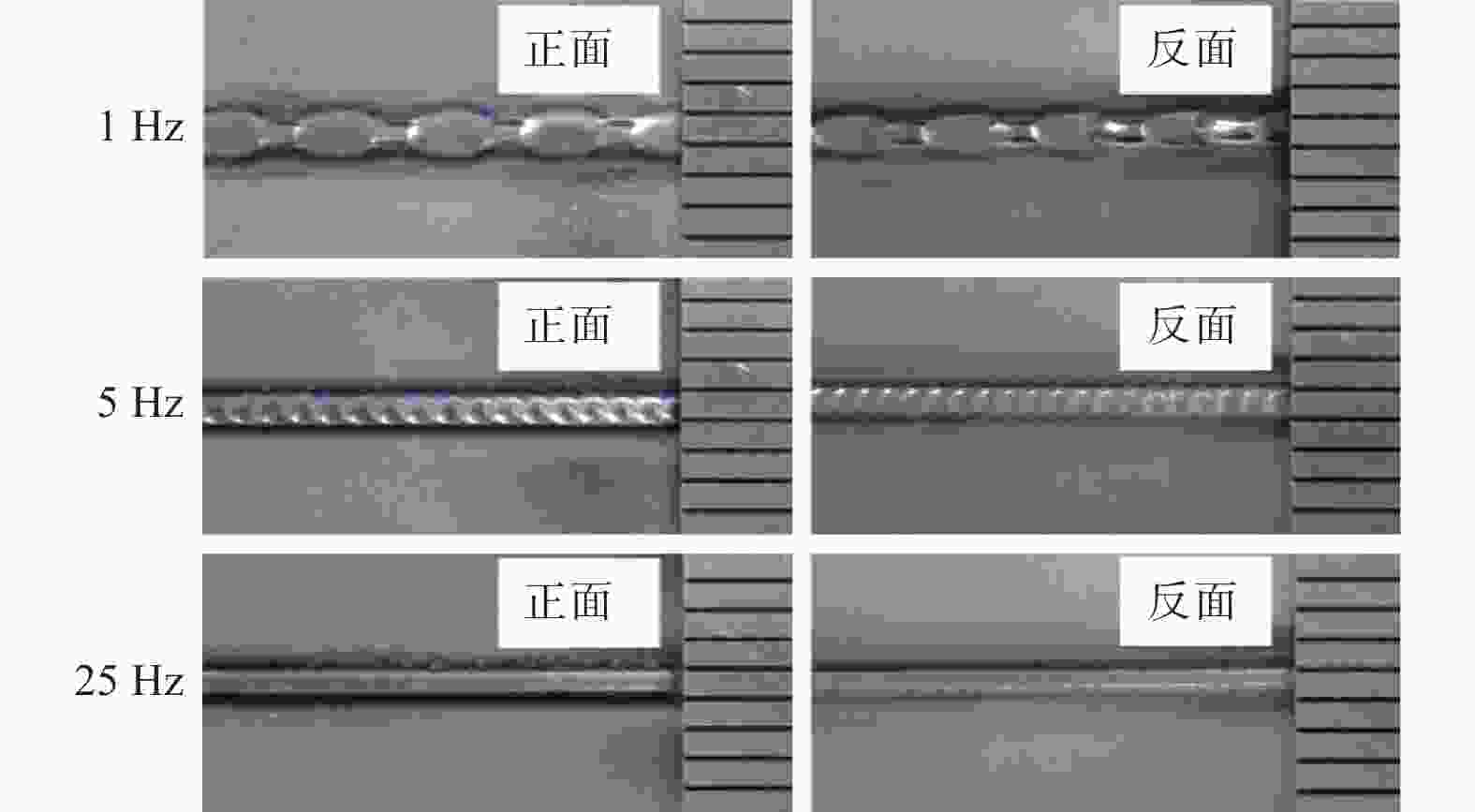

摘要: 由于熔池的振荡行为,熔池轮廓的动态变化具有一定的波动性. 基于视觉传感检测方法,研究0.1 mm厚超薄板不锈钢脉冲微束等离子弧焊接的熔池振荡行为,讨论焊接电流的不同脉冲参数对熔池振荡频率和振幅的影响. 结果表明,在基值电流和峰值电流作用期间,熔池的大小是小幅度波动的,这是由熔池振荡引起的;熔池的振荡频率在一定范围内随着脉冲电流的频率增加而增加,而熔池振荡幅度随脉冲电流频率的加大而减小. 熔池的振荡频率可以反映焊缝成形质量的好坏.Abstract: Due to the oscillation behavior of the molten pool, the dynamic change of the molten pool profile has a certain fluctuation. Based on the visual sensing detection method, the oscillation behavior of molten pool in pulsed micro-plasma arc welding of 0.1 mm thick ultra-thin stainless steel was studied, and the influence of different pulse parameters of welding current on the oscillation frequency and amplitude of molten pool was discussed. The results show that the size of molten pool fluctuates slightly during the action of base current and peak current, which is caused by molten pool oscillation. The oscillation frequency of the molten pool increases with the increase of the pulse current frequency in a certain range, while the oscillation amplitude of the molten pool decreases with the increase of the pulse current frequency. The oscillation frequency of the molten pool can reflect the quality of the weld seam forming.

-

表 1 焊接工艺参数

Table 1. Welding process parameters

焊接速度/

(mm∙s−1)焊接电流/

A离子气流量/

(L∙min−1)保护气流量/

(L∙min−1)焊炬高度/

mm4.2 1.8 0.5 3.5 2 表 2 脉冲参数

Table 2. Pulse parameters

占空比△/% 基值电流Ib /A 峰值电流Ip /A 脉冲频率f /Hz 30

30

30

50

50

50

70

70

700.80

1.20

1.50

0.80

1.20

1.50

0.80

1.20

1.504.12

3.20

2.50

2.80

2.40

2.10

2.22

2.06

1.921

5

25

1

5

25

1

5

25 -

[1] 赵先锐, 左敦稳, 张强勇, 等. 304不锈钢TIG焊接工艺及数值模拟[J] . 电焊机,2021,51(5):49 − 55. doi: 10.7512/j.issn.1001-2303.2121.05.09 [2] 张强勇, 赵先锐, 刘桂香, 等. 304不锈钢激光焊接工艺及数值模拟[J] . 电焊机,2021,51(4):1 − 7. doi: 10.7512/j.issn.1001-2303.2021.04.01 [3] 张嘉顺, 王锋, 吴东明. 手工钨极氩弧焊焊接不锈钢薄板的工艺方法[J] . 科技致富向导,2014(13):290, 346. doi: 10.3969/j.issn.1007-1547.2014.13.296 [4] HAO K A, LI G, GAO M, et al. Weld formation mechanism of fiber laser oscillating welding of austenitic stainless steel[J] . Journal of Materials Processing Technology,2015,225:77 − 83. doi: 10.1016/j.jmatprotec.2015.05.021 [5] 陈凯. 基于焊接参数及电弧声音的薄板CMT搭接质量监测研究[D]. 上海: 上海交通大学, 2019. [6] 周学凯. 金属超薄板光纤激光焊接工艺研究[D]. 武汉: 华中科技大学, 2017. [7] 蔡雅君. 高氮奥氏体不锈钢薄板焊接成形及组织性能控制研究[D]. 南京: 南京理工大学, 2017. [8] 高洪明, 樊重建, 吴林. 基于微束等离子弧的焊缝跟踪[J] . 焊接学报,2004,25(2):80 − 83. doi: 10.3321/j.issn:0253-360X.2004.02.020 [9] 张建宝. GTAW熔池流动行为及电弧压力分布规律研究[D]. 太原: 太原科技大学, 2016. [10] 陶旭阳, 何建萍, 徐磊. 基于LabView脉冲微束等离子弧焊熔池振荡信息提取[J] . 智能计算机与应用,2020,10(3):371 − 374. doi: 10.3969/j.issn.2095-2163.2020.03.081 [11] XIAO Y H, OUDEN G D. Weld pool oscillation during GTA welding of mild steel[J] . Welding Journal,1993,72(8):428 − 434. [12] SHI Y, LI C K, DU L M, et al. Frequency characteristics of weld pool oscillation in pulsed gas tungsten arc welding[J] . Journal of Manufacturing Processes,2016,24:145 − 151. doi: 10.1016/j.jmapro.2016.08.010 [13] HUANG J K, YANG M H, CHEN J S, et al. The oscillation of stationary weld pool surface in the GTA welding[J] . Journal of Materials Processing Technology,2018,256:57 − 68. doi: 10.1016/j.jmatprotec.2018.01.018 [14] 张云威. PAW熔池正面形状参数的视觉检测[D]. 济南: 山东大学, 2012. -

下载:

下载: