Simulation and experimental of temperature field of hybrid magnetizing magnetic gear composite motor

-

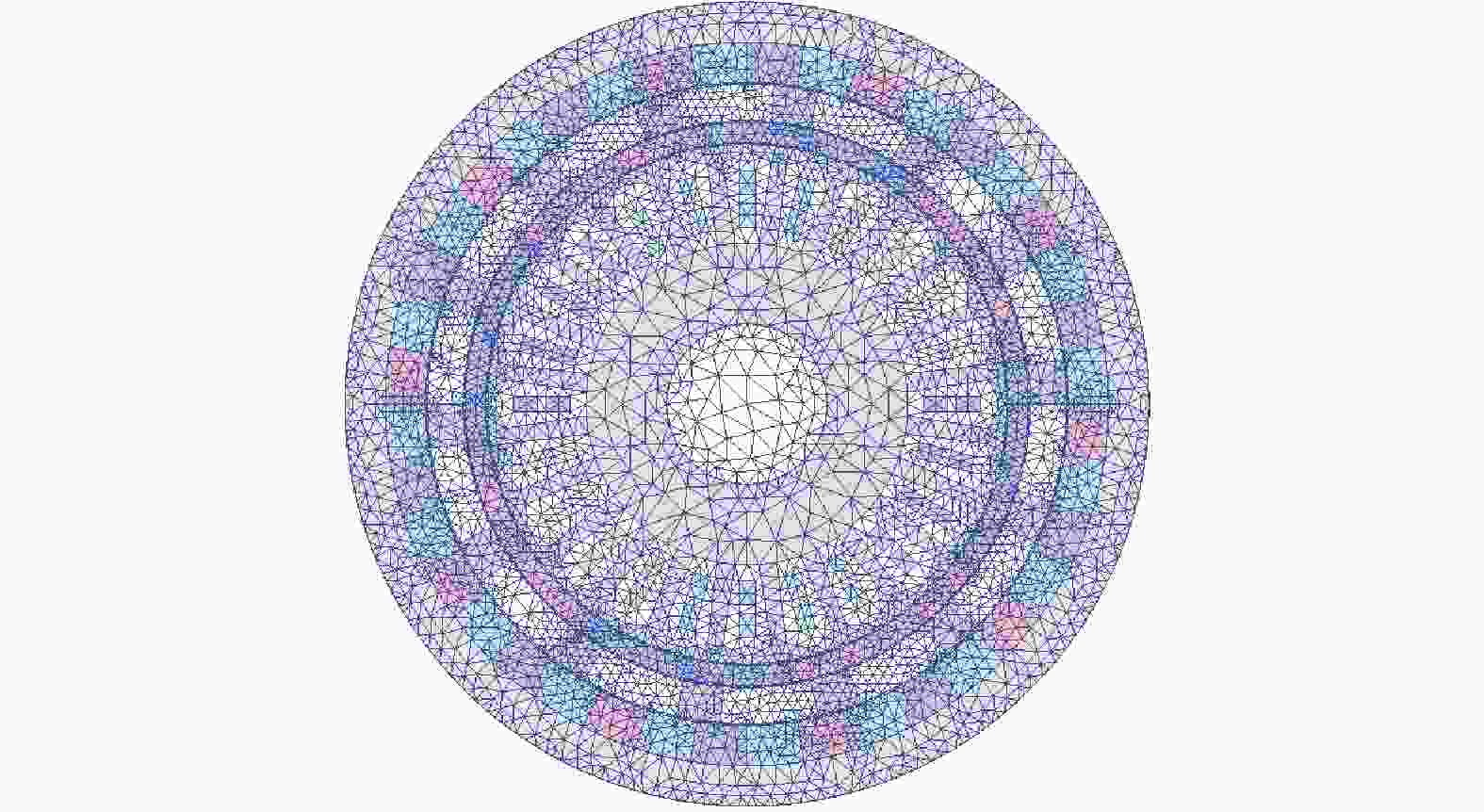

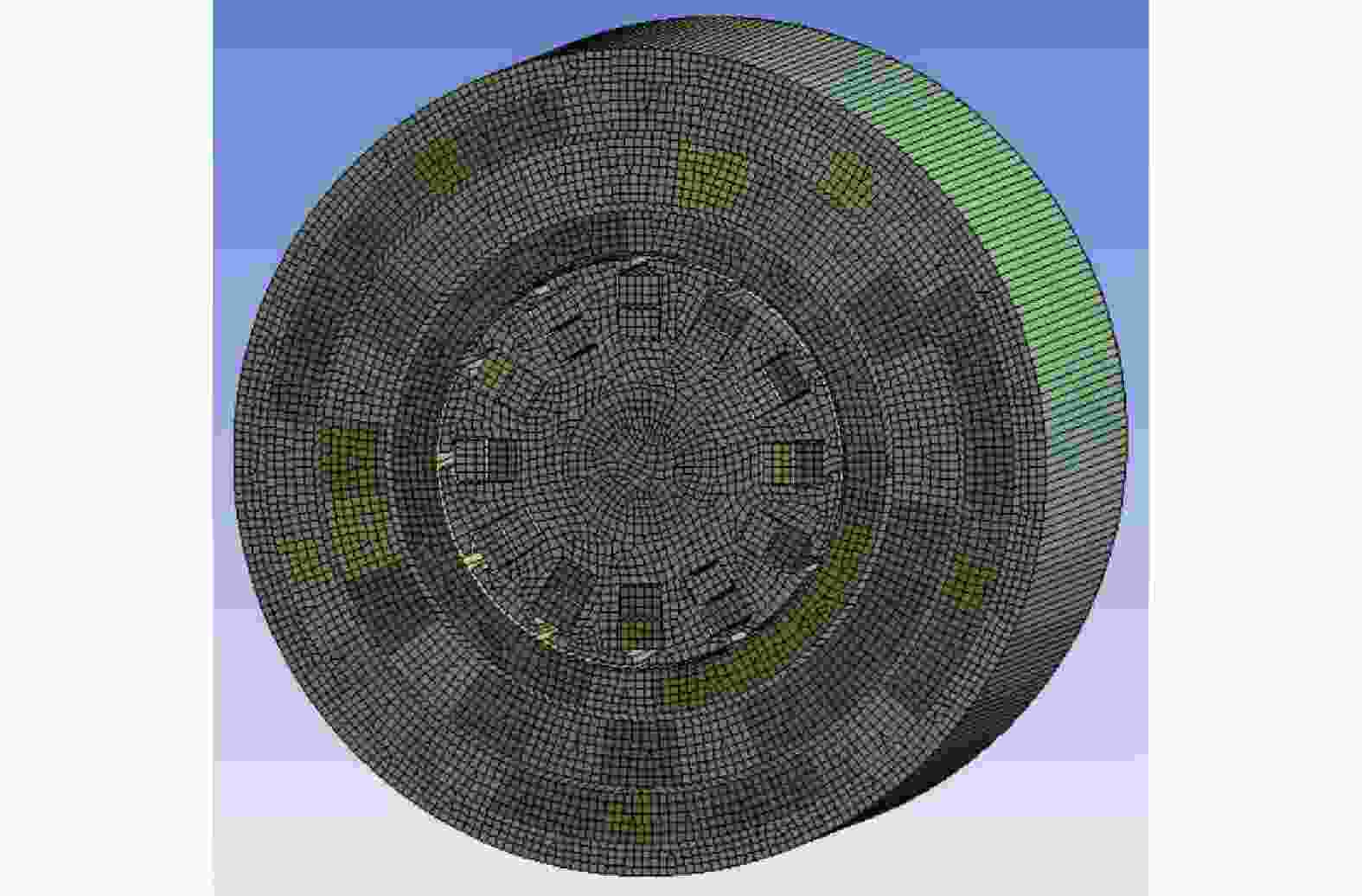

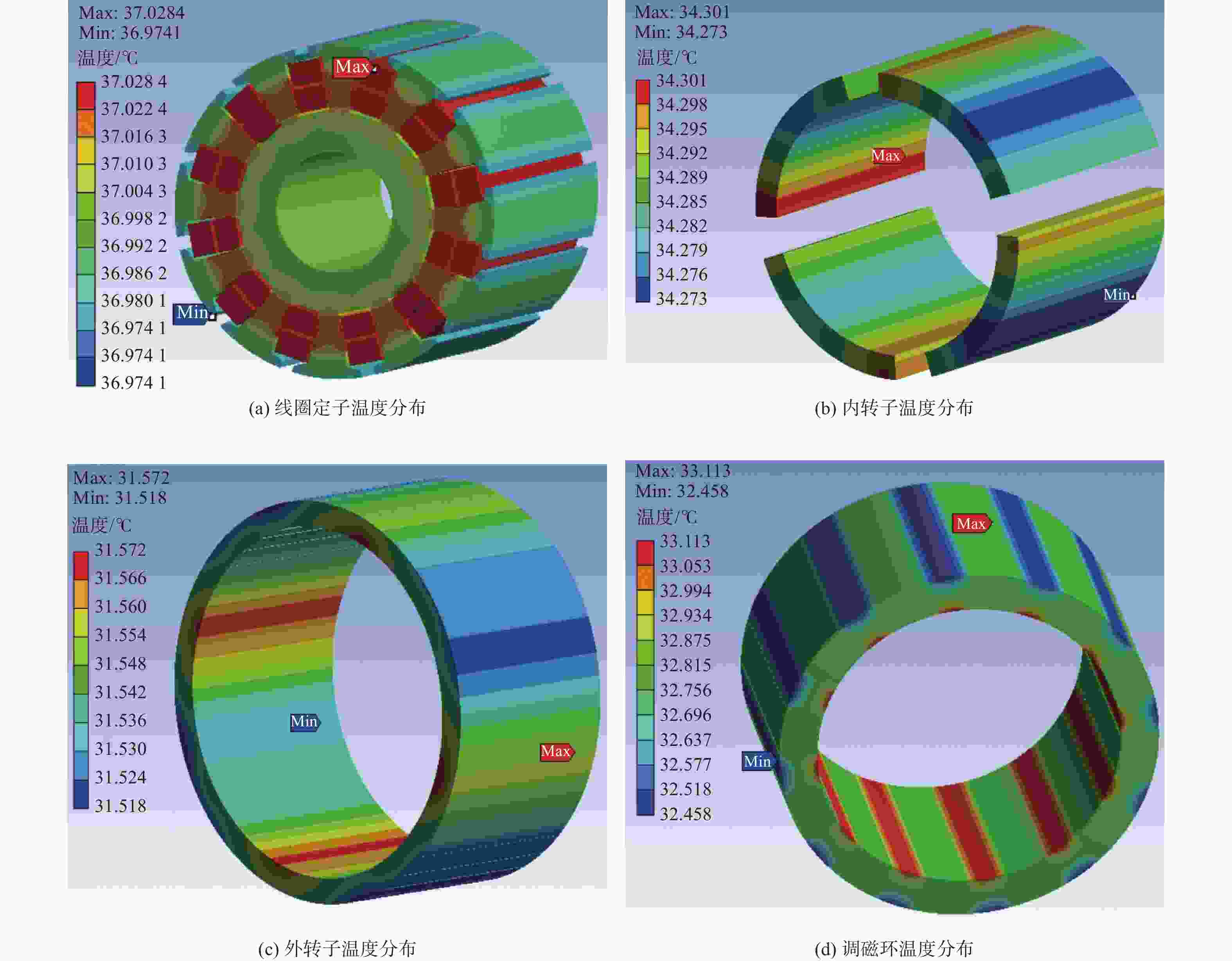

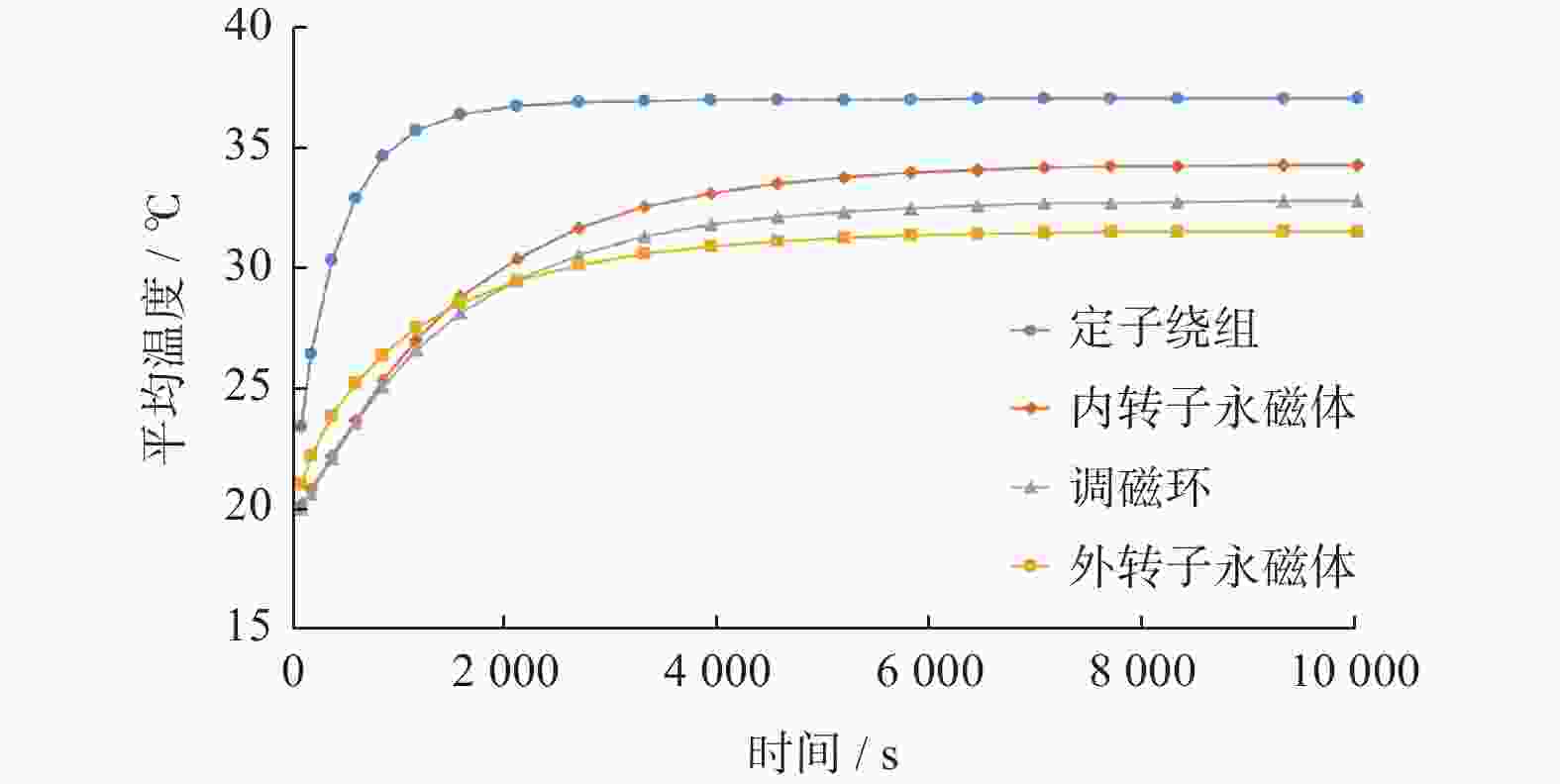

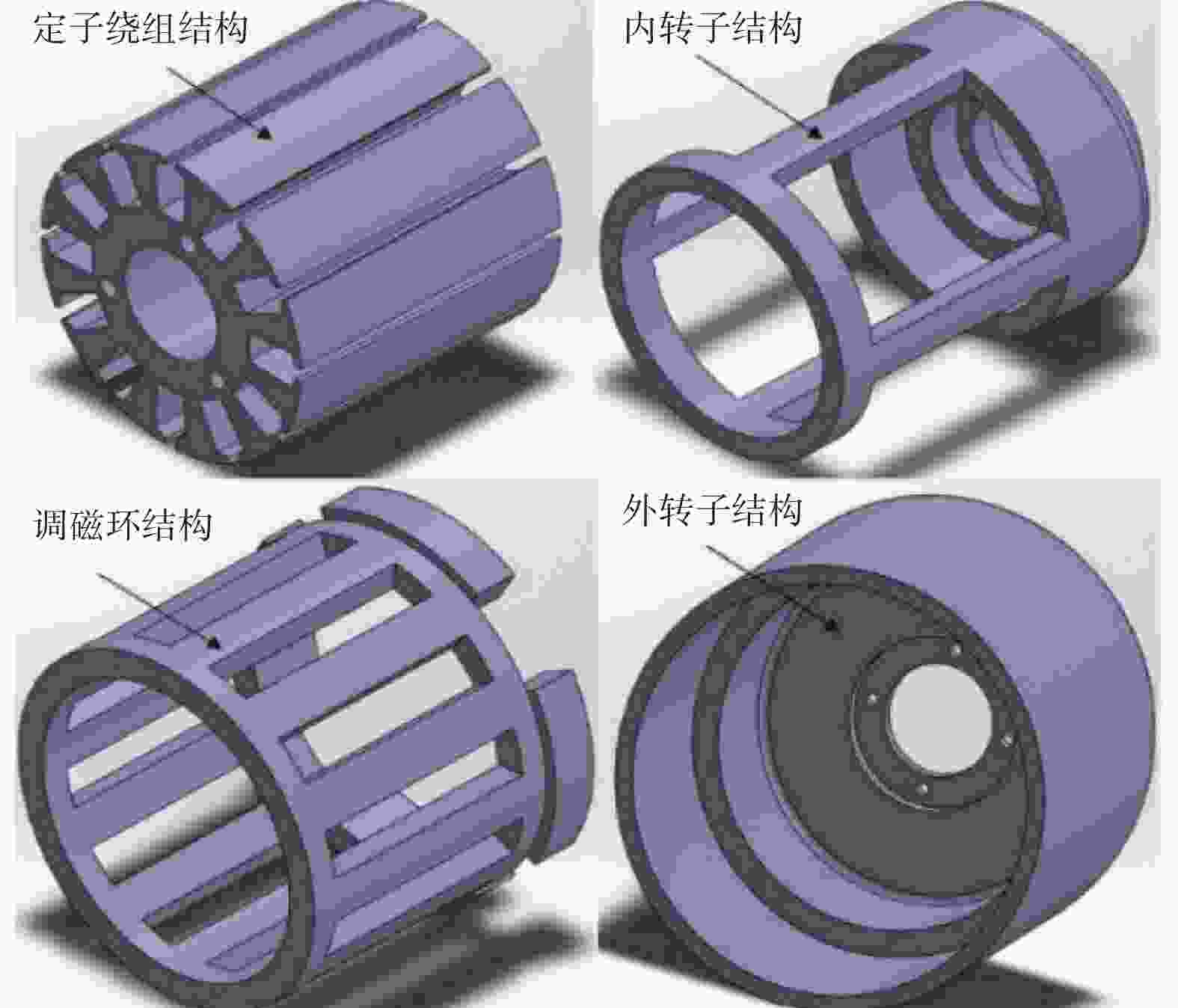

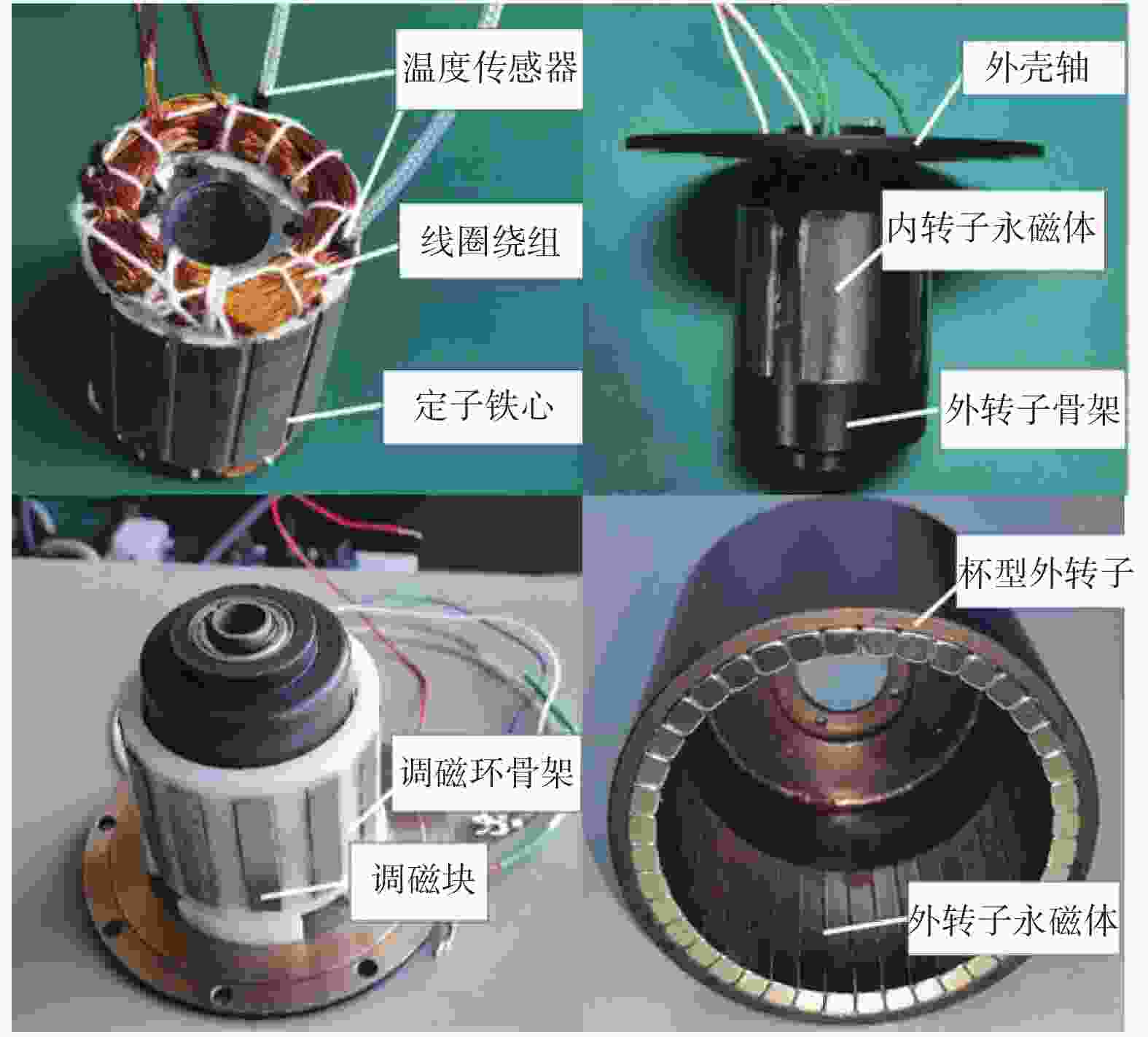

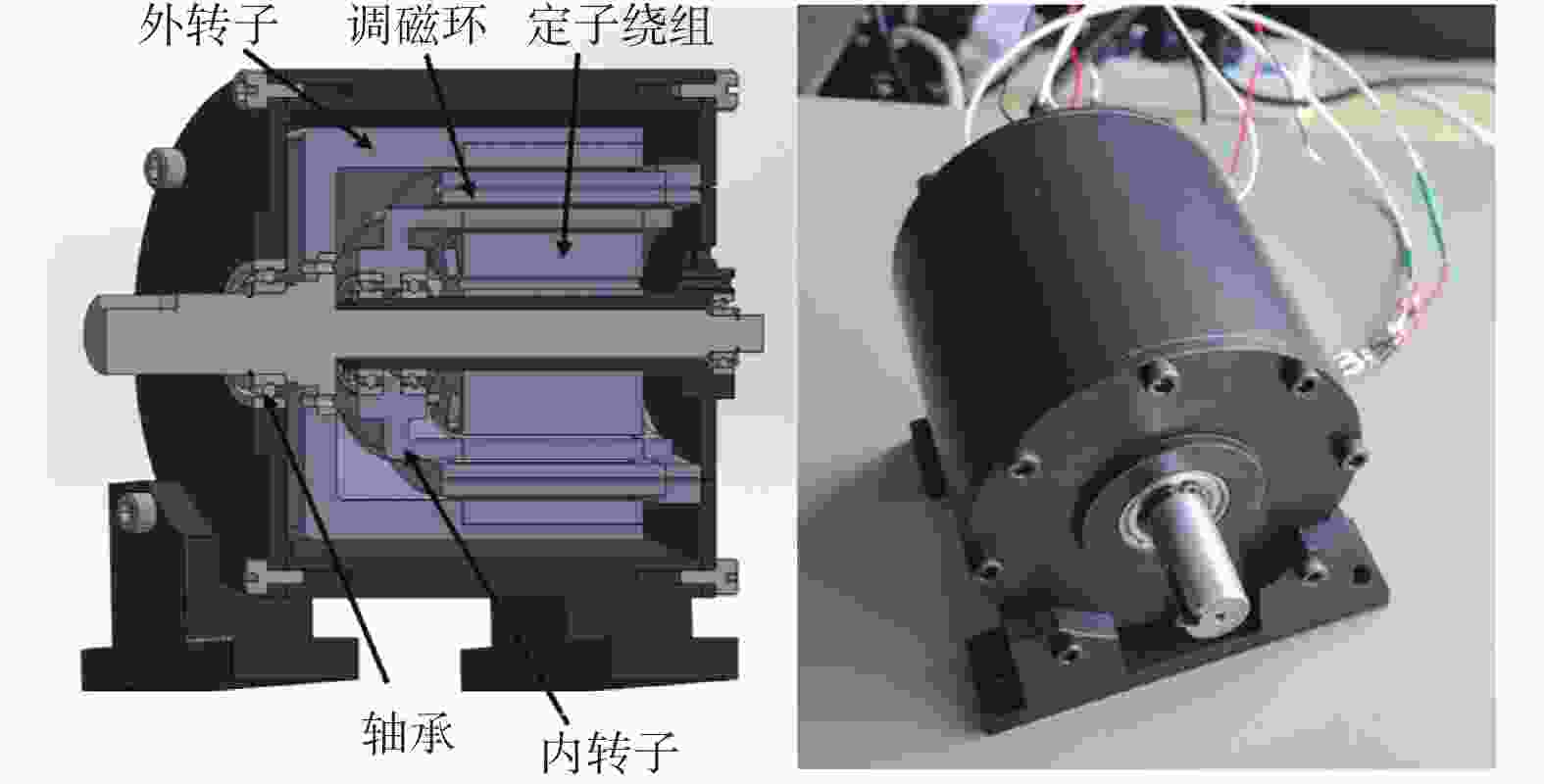

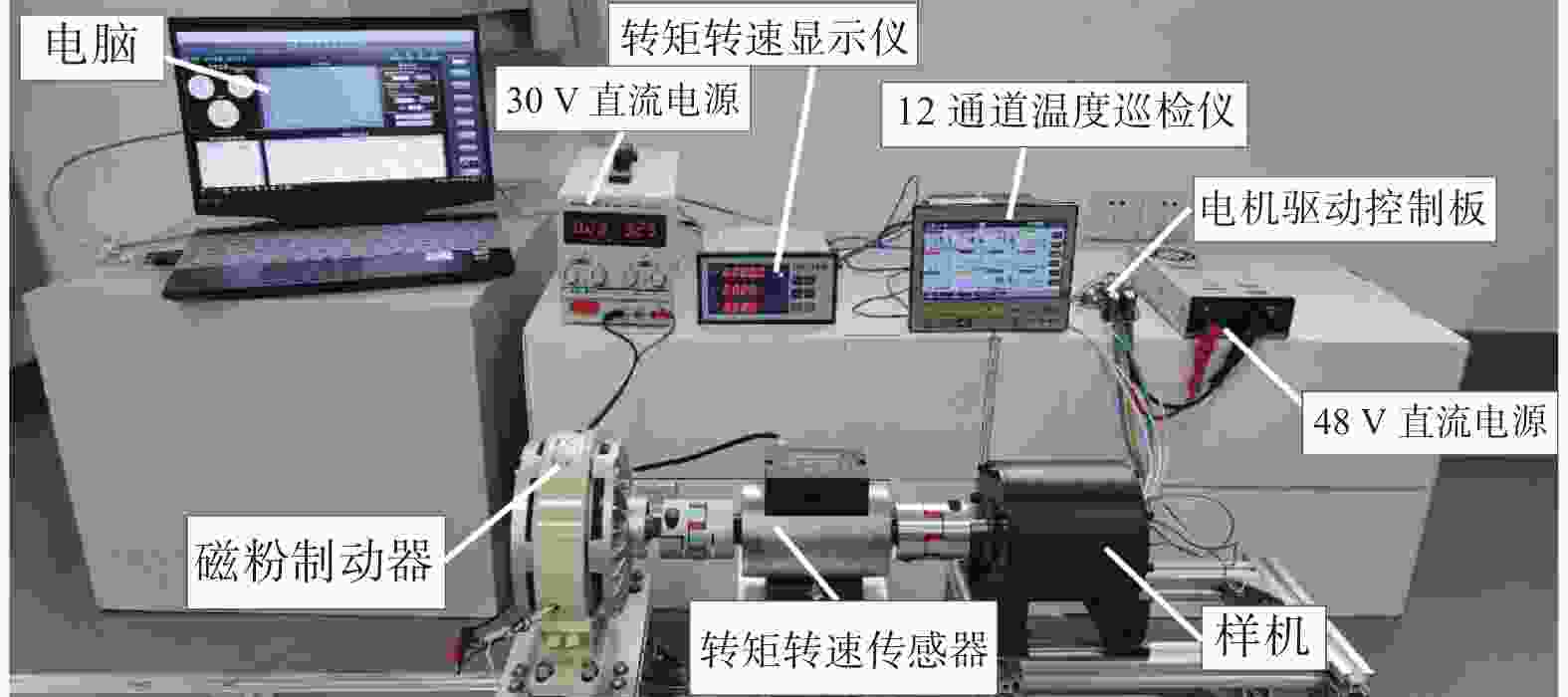

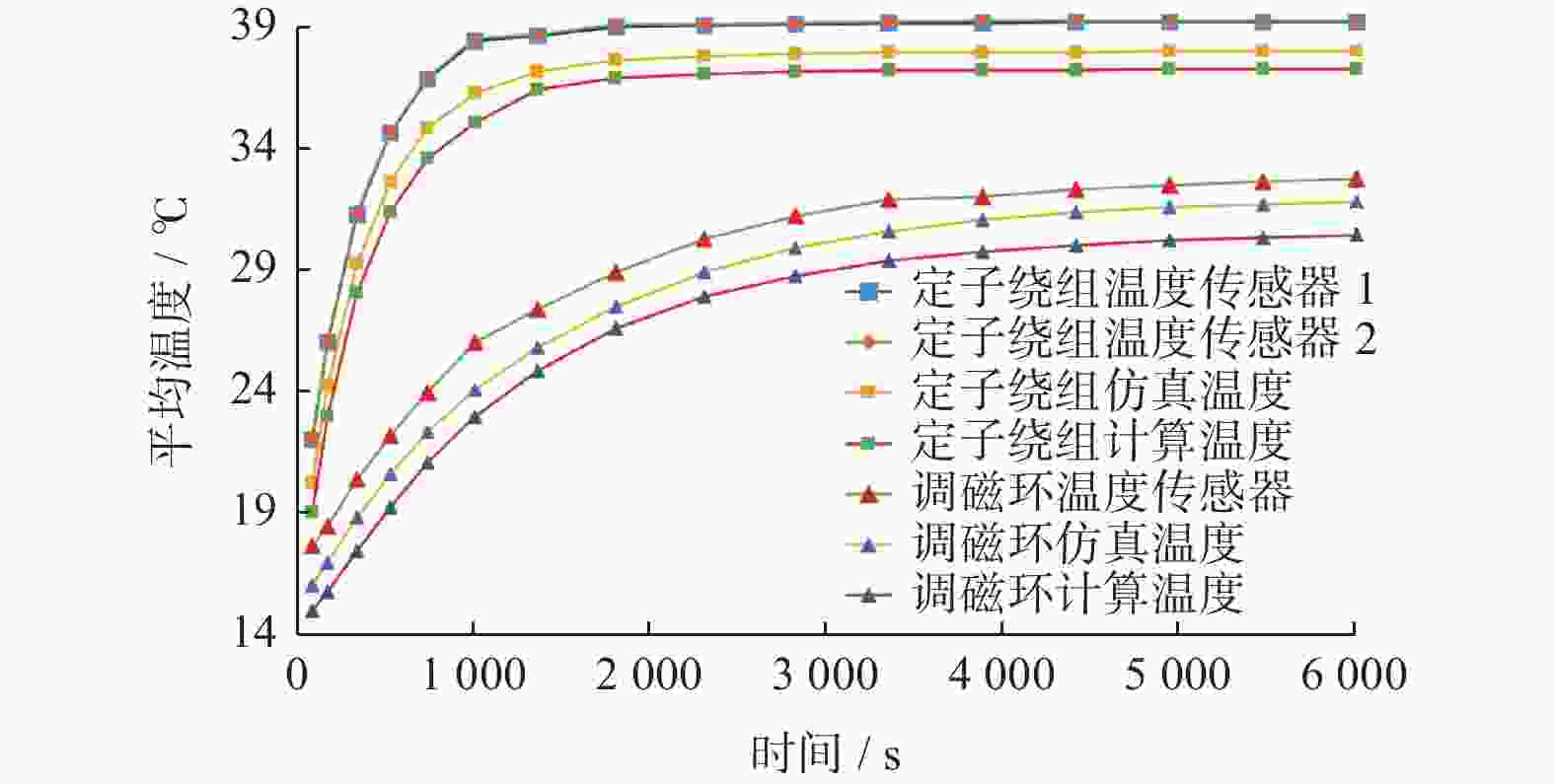

摘要: 研究一种混合充磁式磁齿轮复合电机的温度场,通过对磁齿轮复合电机仿真得到电机铜耗、铁耗以及涡流损耗. 将其结果设置为温度场仿真的热源,对简化的磁齿轮复合电机模型进行瞬态热分析,得到混合充磁式磁齿轮复合电机各部分温度场分布及温度随时间的变化情况. 搭建试验平台进行温度测试,由计算、仿真、试验得到电机各部分随时间变化的温升曲线可知:磁齿轮复合电机内最高温度点在定子绕组部分,温度在安全范围内,不会对电机造成影响.Abstract: The temperature field of a hybrid magnetizing magnetic gear compound motor, the copper, iron and eddy current losses of the motor were obtained by simulation of the magnetic gear compound motor, and the results were set as the heat source of temperature field simulation, and the transient thermal analysis of the simplified magnetic gear compound motor model was carried out. The temperature field distribution and temperature variation with time of the hybrid magnetizing magnetic gear composite motor were obtained. By setting up an experimental platform for temperature test, the temperature rise curve of each part of the motor with time change was obtained through calculation, simulation and test. It can be seen that the highest temperature point in the magnetic gear composite motor is in the stator winding part, and the temperature within the safe range, which will not affect the motor.or.

-

Key words:

- mixed magnetization /

- composite motor /

- loss /

- temperature field

-

表 1 混合充磁式磁齿轮复合电机设计参数

Table 1. Design parameters of hybrid magnetizing magnetic gear compound motor

参数 数值 参数 数值 定子铁心半径/mm 25 外转子永磁体外圆半径/mm 47 调磁环内圆半径/mm 32 外转子永磁体内圆半径/mm 41 调磁环外圆半径/mm 40 内转子永磁体外圆半径/mm 31 定子槽数 12 内转子永磁体内圆半径/mm 26 内转子极对数 2 内层气隙宽度/mm 1 外转子极对数 10 中层气隙宽度/mm 1 调磁块数 12 外层气隙宽度/mm 1 表 2 混合充磁式磁齿轮复合电机运行时各部件最高温度

Table 2. The maximum temperature of each component in operation of hybrid magnetizing magnetic gear compound motor

名称 定子绕组温度/℃ 调磁环温度/℃ 试验 39.28 32.71 仿真 38.01 31.79 计算 37.26 30.39 试验与仿真误差/% 3.37 2.89 试验与计算误差/% 5.42 7.63 仿真与计算误差/% 2.01 4.61 -

[1] 李和明, 李俊卿. 电机中温度计算方法及其应用综述[J] . 华北电力大学学报(自然科学版),2005,32(1):5. [2] ZHANG F G, WANG S Y, LIU G W, et al. Electromagnetic design and temperature field analysis of a high speed permanent magnet claw motor with outer rotor[C]//Proceedings of 2015 18th International Conference on Electrical Machines and Systems (ICEMS). Pattaya: EEAAT, 2015. [3] YANG C X, ZHANG Y, QIU H B. Influence of output voltage harmonic of inverter on loss and temperature field of permanent magnet synchronous motor[J] . IEEE Transactions on Magnetics,2019,55(6):1 − 5. [4] 吴尧辉, 方鑫. 不同负载下的电机温度场计算[J] . 微特电机,2020,48(12):27 − 31. doi: 10.3969/j.issn.1004-7018.2020.12.007 [5] CHU S, LIANG D, JIA S, et al. Research and analysis on design characteristics of high temperature and high- speed permanent magnet motor[C]//Proceedings of 2020 International Conference on Electrical Machines (ICEM). Gothenburg: [s.n.], 2020. [6] CHEN H, WANG K, YAN W, et al. Temperature analysis of switched reluctance motor based on equivalent heat circuit method[J] . IEEE Transactions on Applied Superconductivity,2021,31(8):1 − 4. [7] 刘金. 磁齿轮复合电机内转子涡流损耗分析与设计[D]. 镇江: 江苏大学, 2017. [8] 田野. 容错磁齿轮复合电机损耗特性研究及优化设计[D]. 镇江: 江苏大学, 2016. [9] 杨忠学. 油田抽油机用新型磁场调制式复合电机的设计研究[D]. 大庆: 东北石油大学, 2017. [10] 顾玲玲. 电动车用自减速永磁轮毂电机温度场及其优化设计研究[D]. 南京: 东南大学, 2015. [11] ARMOR A F, CHARI M V K. Heat flow in the stator core of large turbine-generators, by the method of three-dimensional finite elements (part I: Analysis by scalar potential formulation)[J] . IEEE Transactions on Power Apparatus and Systems,1976,95(5):1648 − 1656. doi: 10.1109/T-PAS.1976.32264 [12] EMANUEL A E. Estimating the Effects of Harmonic Voltage Fluctuations on the Temperature Rise of Squirrel-Cage Motors[J] . IEEE Transactions on Energy Conversion (Institute of Electrical and Electronics Engineers),1991,6(1):162 − 169. -

下载:

下载: