Finite element simulation of step drilling Inconel718 based on Deform−3D

-

摘要:

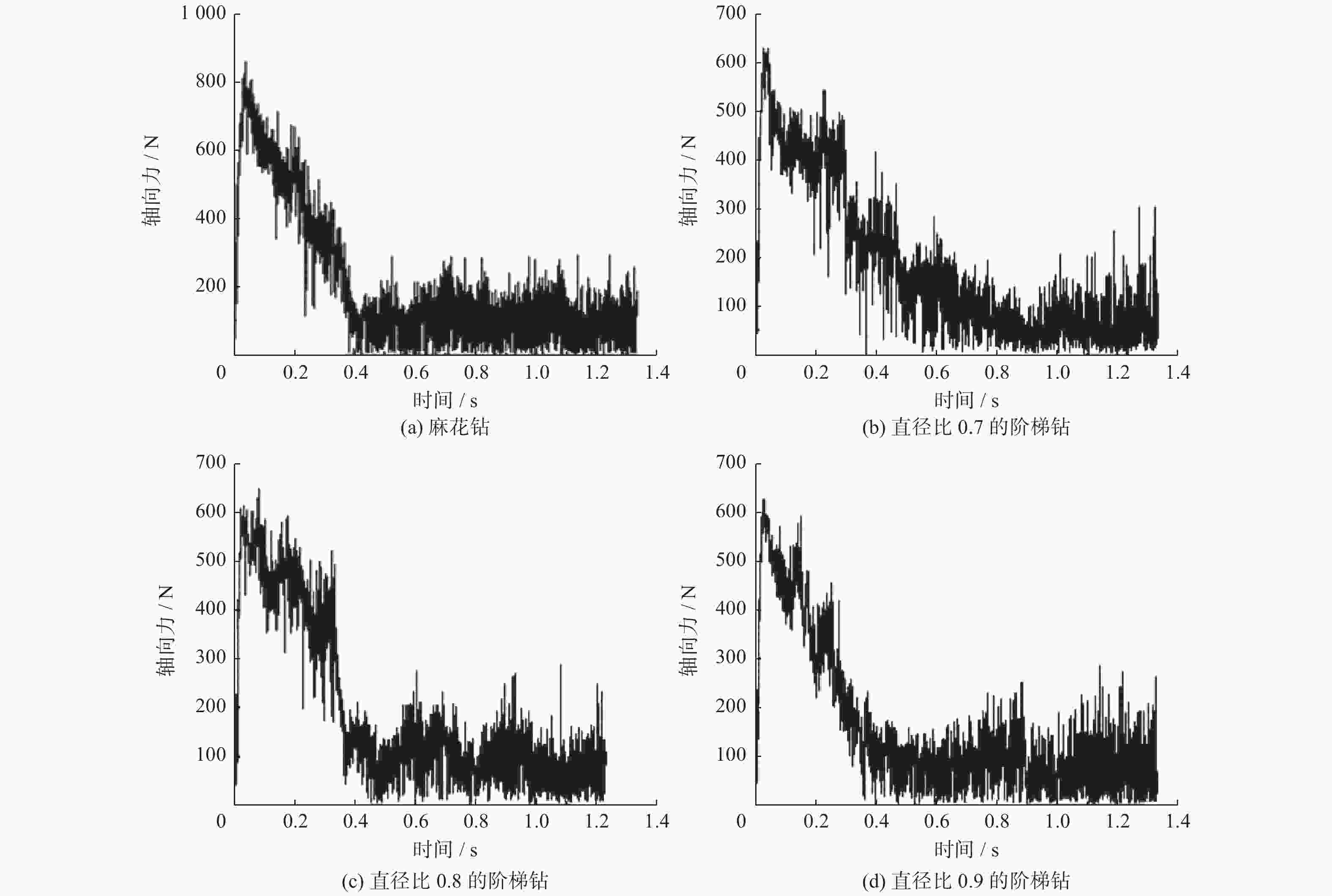

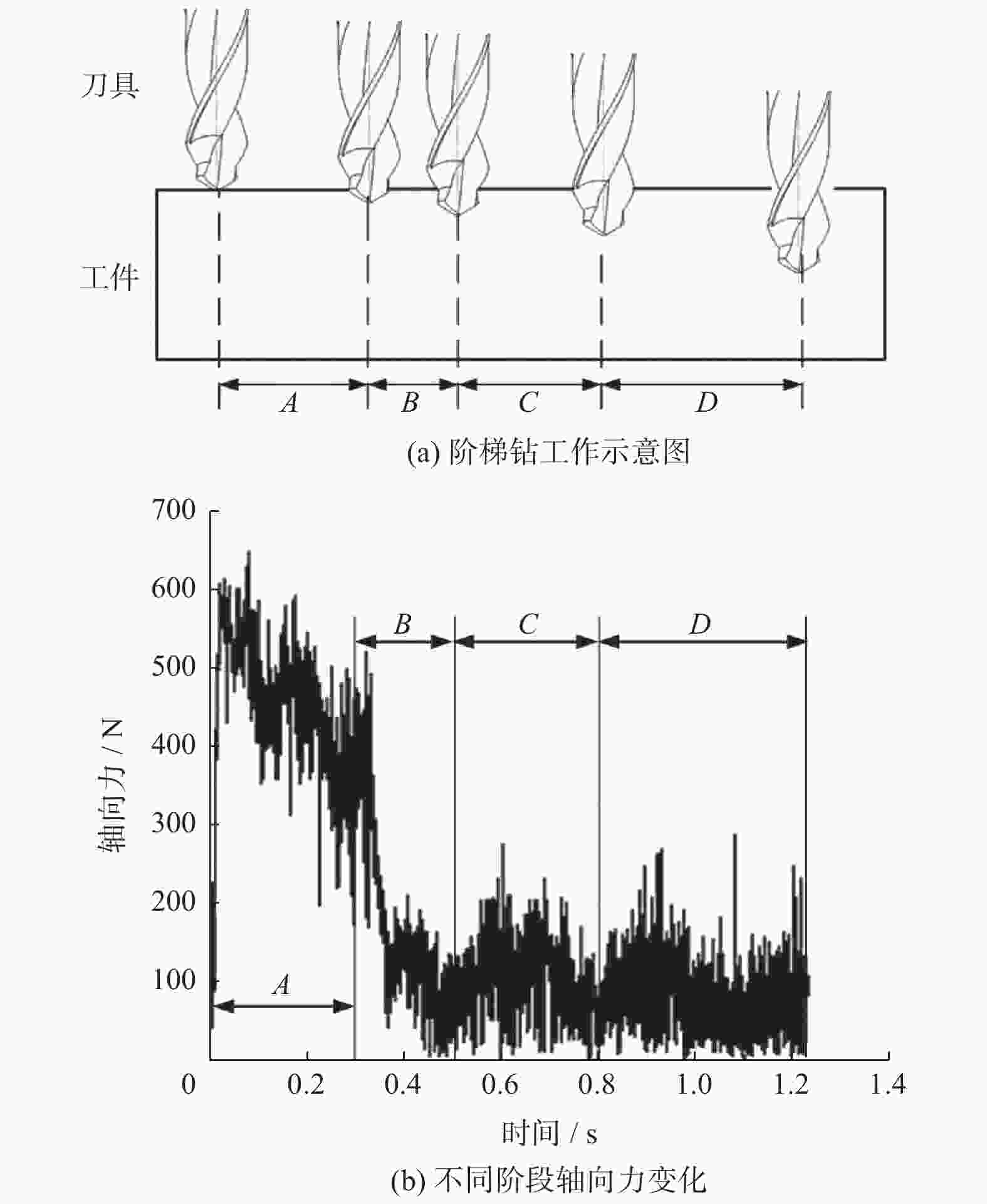

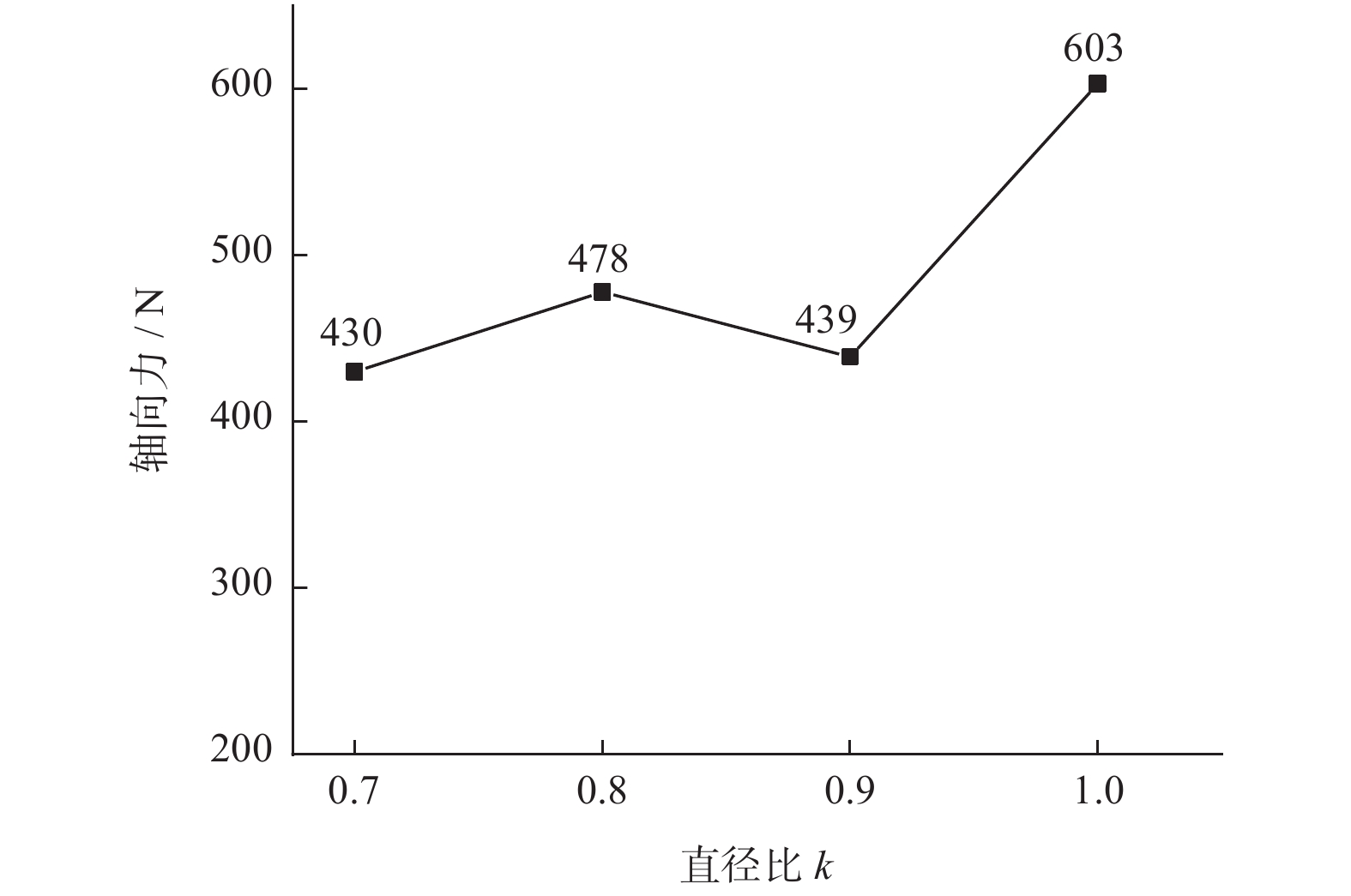

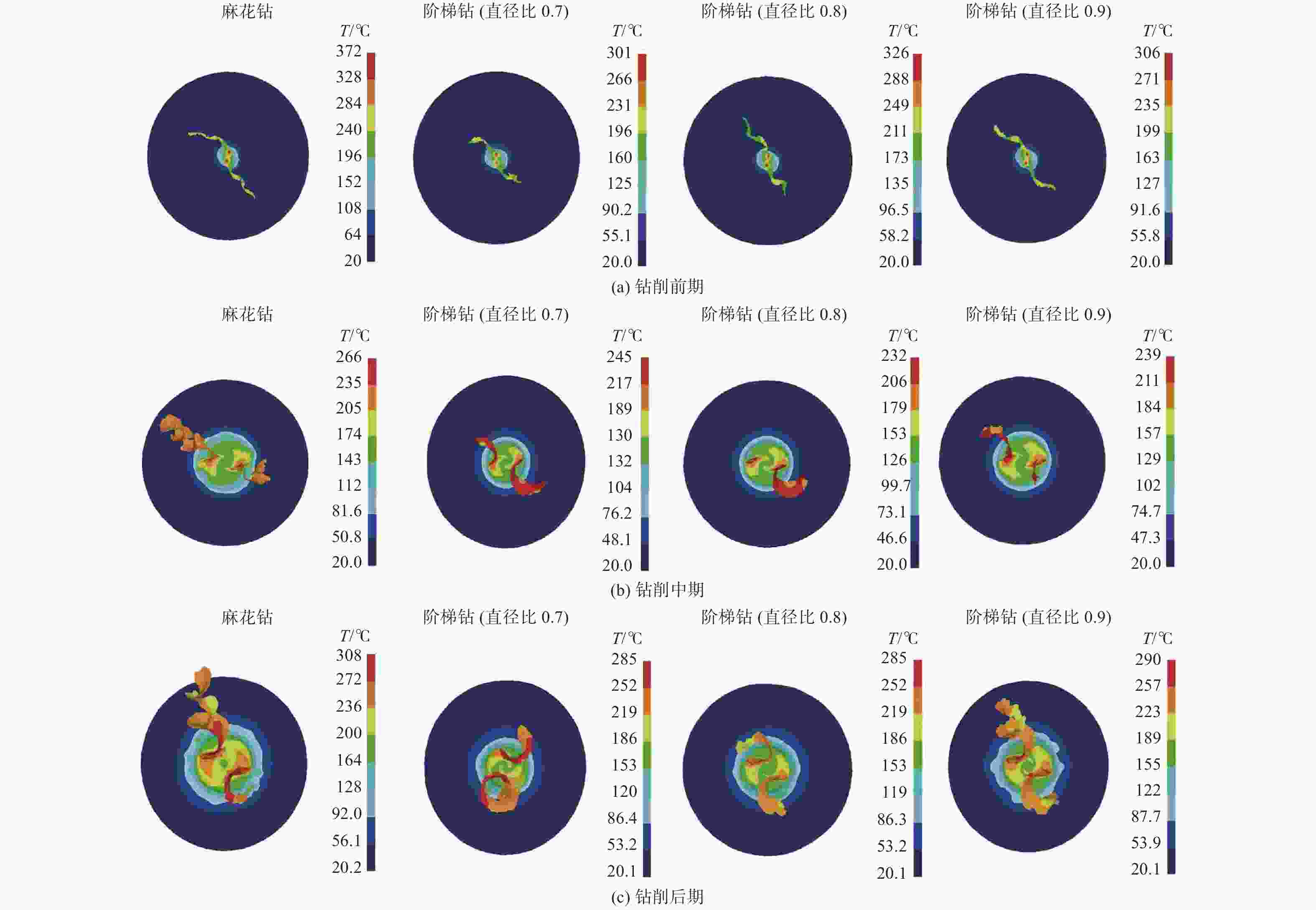

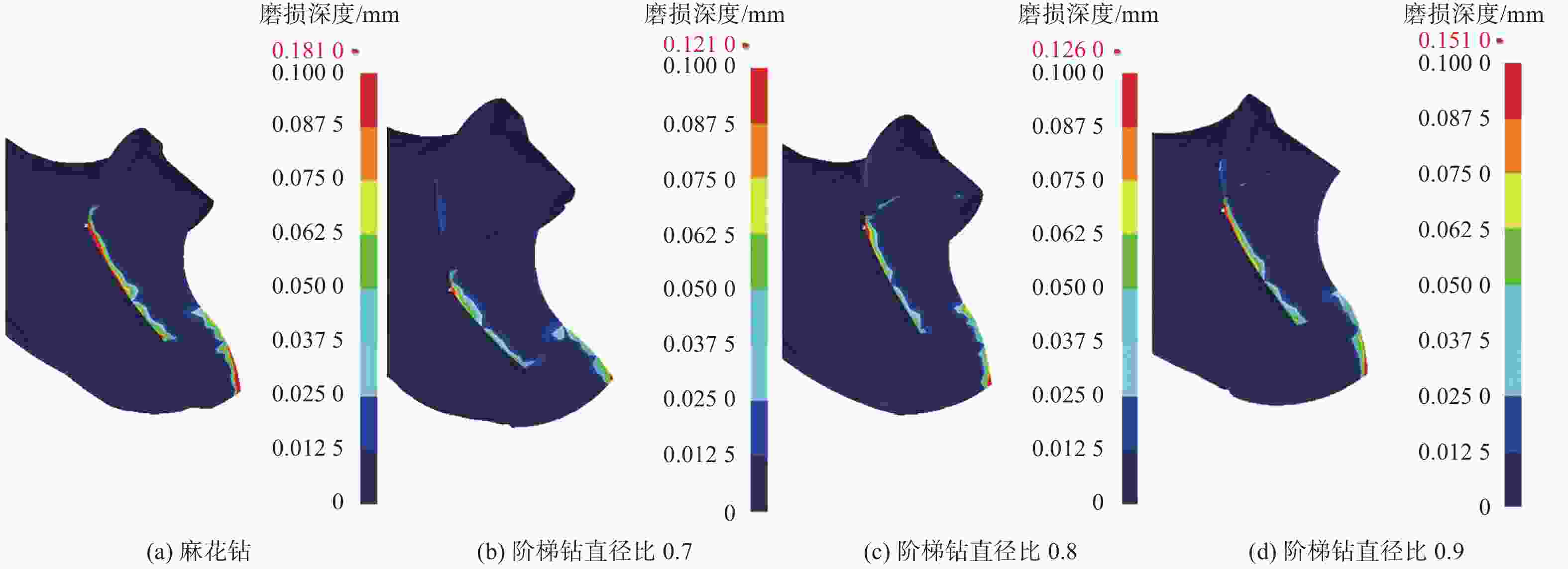

镍基高温合金Inconel718在600 ℃以上的高温环境下能够保持优秀的机械性能,被广泛应用于航空航天等重要科技工业领域. 但其钻削过程中易出现钻削力大、钻削区域温度过高、刀具磨损较大等现状,属于难加工材料. 针对此,以麻花钻为基础设计一种阶梯钻头,引入直径比(第1阶梯与第2阶梯直径之比)概念,并利用Deform−3D软件对两种钻头钻削Inconel718的过程进行有限元仿真. 结果显示,相比麻花钻,在同样的钻削环境下,阶梯钻平均能降低25.5%的轴向力,刀具磨损最大降低33.9%,工件钻削区域温度更低且钻头温度分布更理想.

Abstract:Nickel-based superalloy Inconel718 can maintain excellent mechanical properties at high temperatures above 600 ℃, so it is widely used in aerospace and other important scientific and industrial fields. It is a difficult-to-process material for situations of large drilling force, high temperature in drilling area and large tool wear during drilling process. A step drill was designed based on twist drill and the concept of diameter ratio (the ratio of the diameter of the first step to the second step) was introduced, and finite element simulations of Inconel718 drilling with two kinds of drill bits were carried out by using Deform−3D software. The results show that the step drilling can reduce the axial force by 25.5% on average compared with twist drilling, the maximum tool wear can reduced by 33.9%, the temperature of the workpiece drilling area was more lower and the bit temperature distribution under the same drilling environment was more better.

-

Key words:

- step drill /

- superalloy /

- diameter ratio /

- axial force /

- tool wear

-

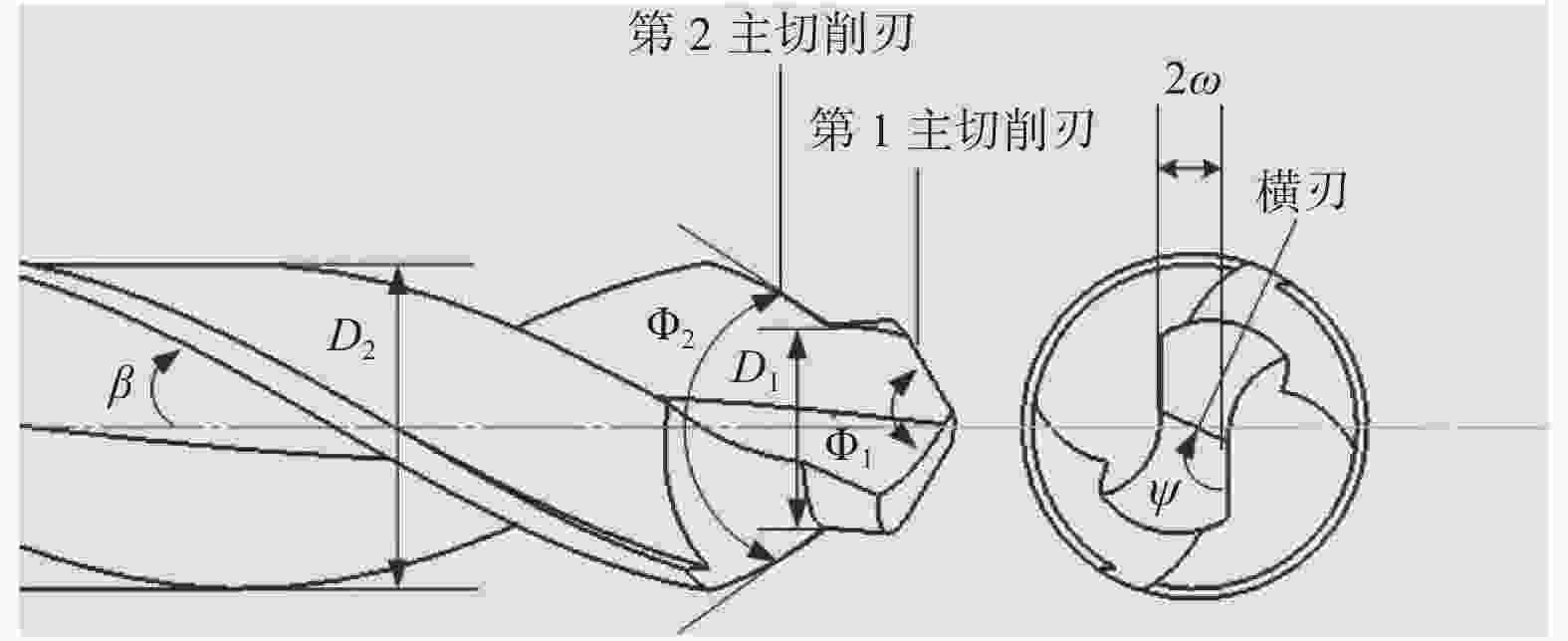

表 1 阶梯钻和麻花钻参数

Table 1. Parameters of step drill and twist drill

刀具 第1钻顶角Φ1/(°) 第2钻顶角Φ2/(°) 第1阶梯直径$ {D}_{1}/{\rm{mm}} $ 第2阶梯直径$ {D}_{2}/{\rm{mm}} $ 螺旋角$ \beta /$(°) 横刃补角ψ/(°) 刃带宽$ b/{\rm{mm}} $ 刃带高$ c/{\rm{mm}} $ 阶梯钻 118 90 3.5/4.0/4.5 5 30 126 0.2 0.55 麻花钻 118 — — 5 30 126 0.2 0.55 A/MPa B/MPa C m n 1012 513 0.0271 2.54 0.422 表 3 刀具材料的性能参数

Table 3. Performance parameters of tool materials

名称 弹性模量/GPa 泊松比 密度/(kg•m−3) 热导率/(W·m−1•K−1) 比热容/(J·kg−1•K−1) 抗弯强度/MPa 硬度(HRA) YG8 600 0.22 14500 75.4 220 4470 89 表 4 工件材料的性能参数

Table 4. Performance parameters of workpiece materials

名称 弹性模量/GPa 泊松比 密度/(kg•m−3) 热导率/(W·m−1•K−1) 比热容/(J·kg−1•K−1) 抗拉强度/MPa 屈服强度/MPa Inconel718 210 0.3 8280 14.6 435 $1\;430$ 1110 -

[1] 王哲, 李磊, 沈雪红. Inconel 718镍基高温合金车削切削力和切削温度分析[J] . 工具技术,2019,53(11):51 − 54. doi: 10.3969/j.issn.1000-7008.2019.11.012 [2] ULUTAN D, OZEL T. Machining induced surface integrity in titanium and nickel alloys: A review[J] . International Journal of Machine Tools and Manufacture,2011,51(3):250 − 280. doi: 10.1016/j.ijmachtools.2010.11.003 [3] EZUGWU E O. Key improvements in the machining of difficult-to-cut aerospace superalloys[J] . International Journal of Machine Tools and Manufacture,2005,45(12-13):1353 − 1367. doi: 10.1016/j.ijmachtools.2005.02.003 [4] KHANNA N, AGRAWAL C, GUPTA M K, et al. Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy[J] . Tribology International,2020,143:106084. [5] UCAK N, ÇICEK A. The effects of cutting conditions on cutting temperature and hole quality in drilling of Inconel 718 using solid carbide drills[J] . Journal of Manufacturing Processes,2018(31):662 − 673. [6] SINGH M, SINGH H. Modulation assisted drilling of inconel-718 ni-based superalloy[J] . Materials Today: Proceedings,2019(18):812 − 821. [7] PANG K, WANG D Z. Study on the performances of the drilling process of nickel-based superalloy Inconel 718 with differently micro-textured drilling tools[J] . International Journal of Mechanical Sciences,2020,180:105658. [8] BEER N, ÖZKAVA E, BIERMANN D. Drilling of Inconel 718 with geometry-modified twist drills[J] . Procedia CIRP,2014(24):49 − 55. [9] 冷小龙, 李鹏南, 邱新义, 等. 阶梯钻钻削钛合金实验[J] . 宇航材料工艺,2018,48(4):75 − 79. doi: 10.12044/j.issn.1007-2330.2018.04.015 [10] 杨凯, 卢文壮, 张吴晖. 阶梯钻头钻削 CFRP/TC4 钛合金叠层材料研究[J] . 工具技术,2018,52(8):19 − 22. doi: 10.3969/j.issn.1000-7008.2018.08.020 [11] 马未未, 曹岩, 付雷杰, 等. 基于 DEFORM 的高强度钢钻削仿真分析[J] . 工具技术,2018,52(9):78 − 84. doi: 10.3969/j.issn.1000-7008.2018.09.030 [12] GRZESIK W, NIESLONY P, LASKOWSK P. Determination of material constitutive laws for Inconel 718 superalloy under different strain rates and working temperatures[J] . Journal of Materials Engineering and Performance,2017,26(12):5705 − 5714. doi: 10.1007/s11665-017-3017-8 [13] 刘海, 王明红, 刘雪勇. 复合涂层刀具钻削Inconel 718 的磨损性能研究[J] . 农业装备与车辆工程,2022,60(1):65 − 69. -

下载:

下载: