Influence of ellipticity and tube inclination angle on thermal performance of tube-fin heat exchanger

-

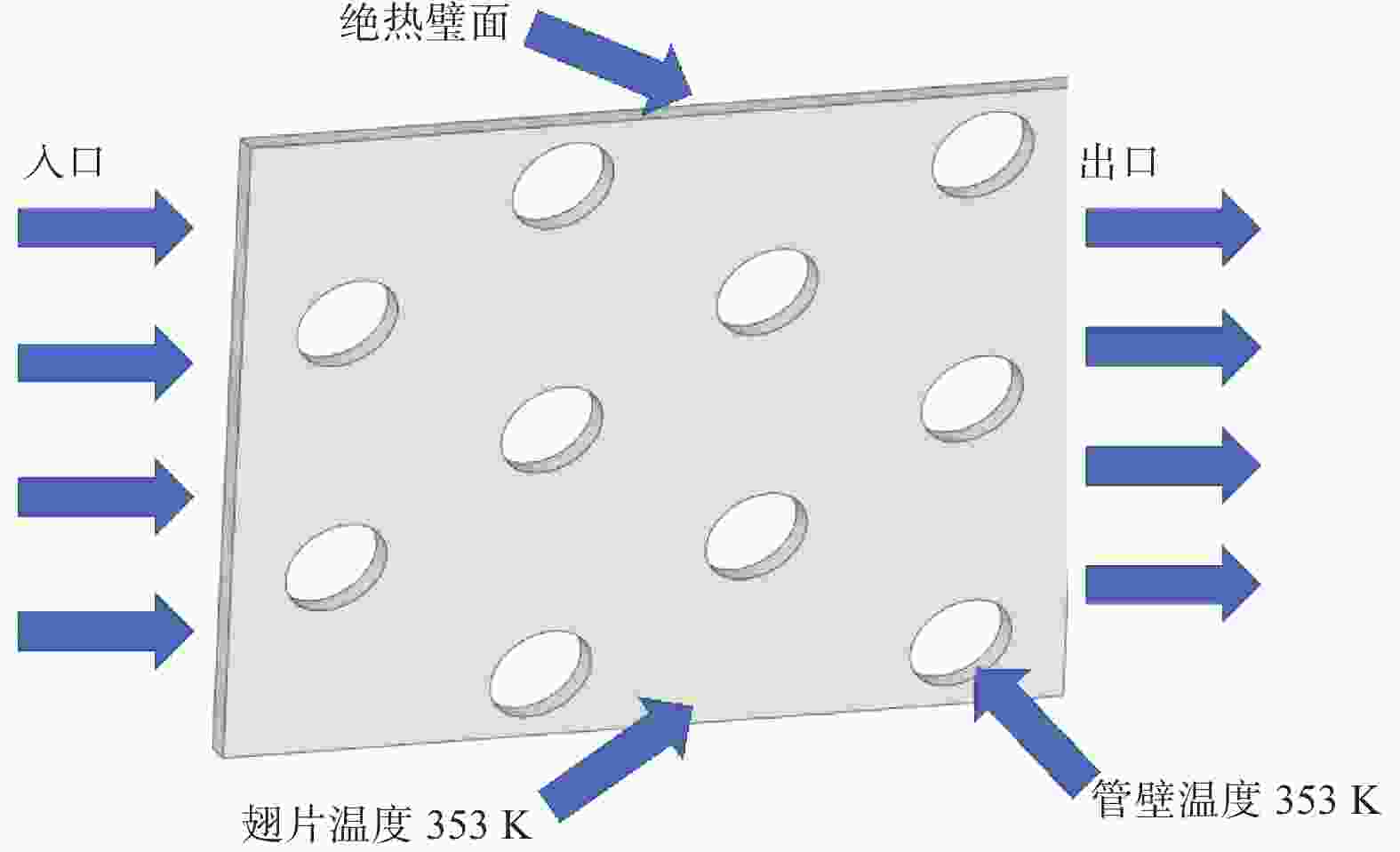

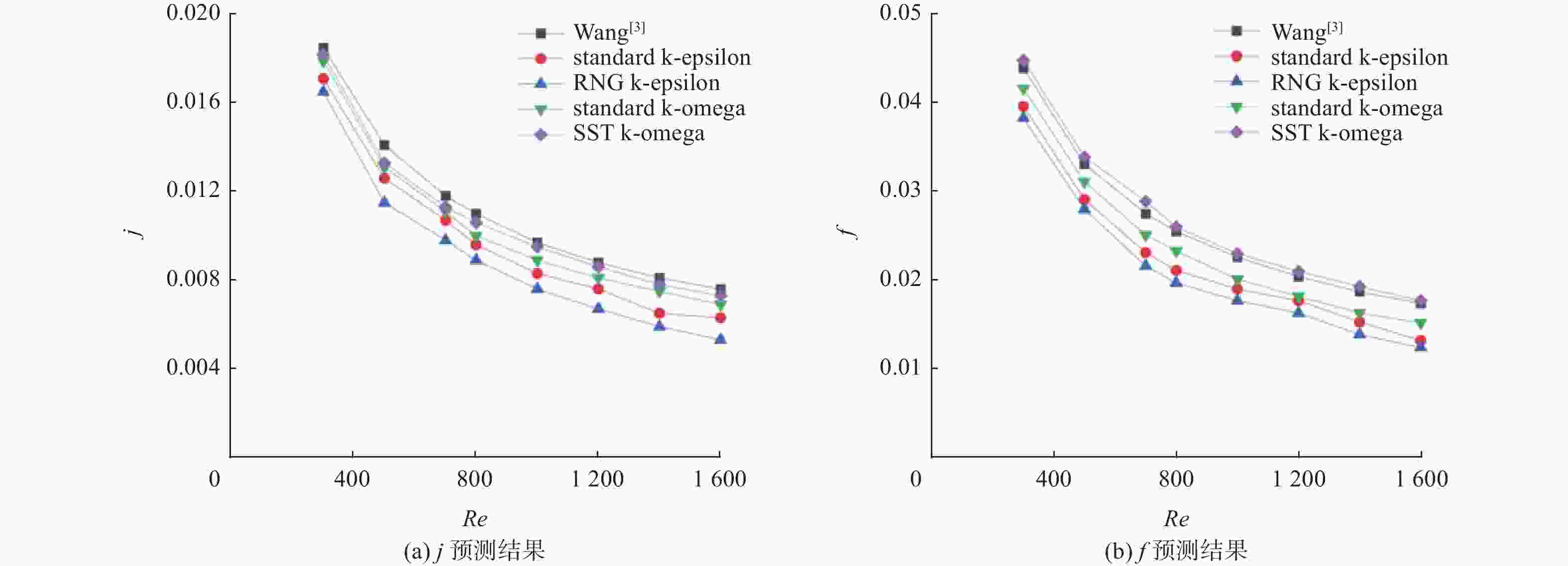

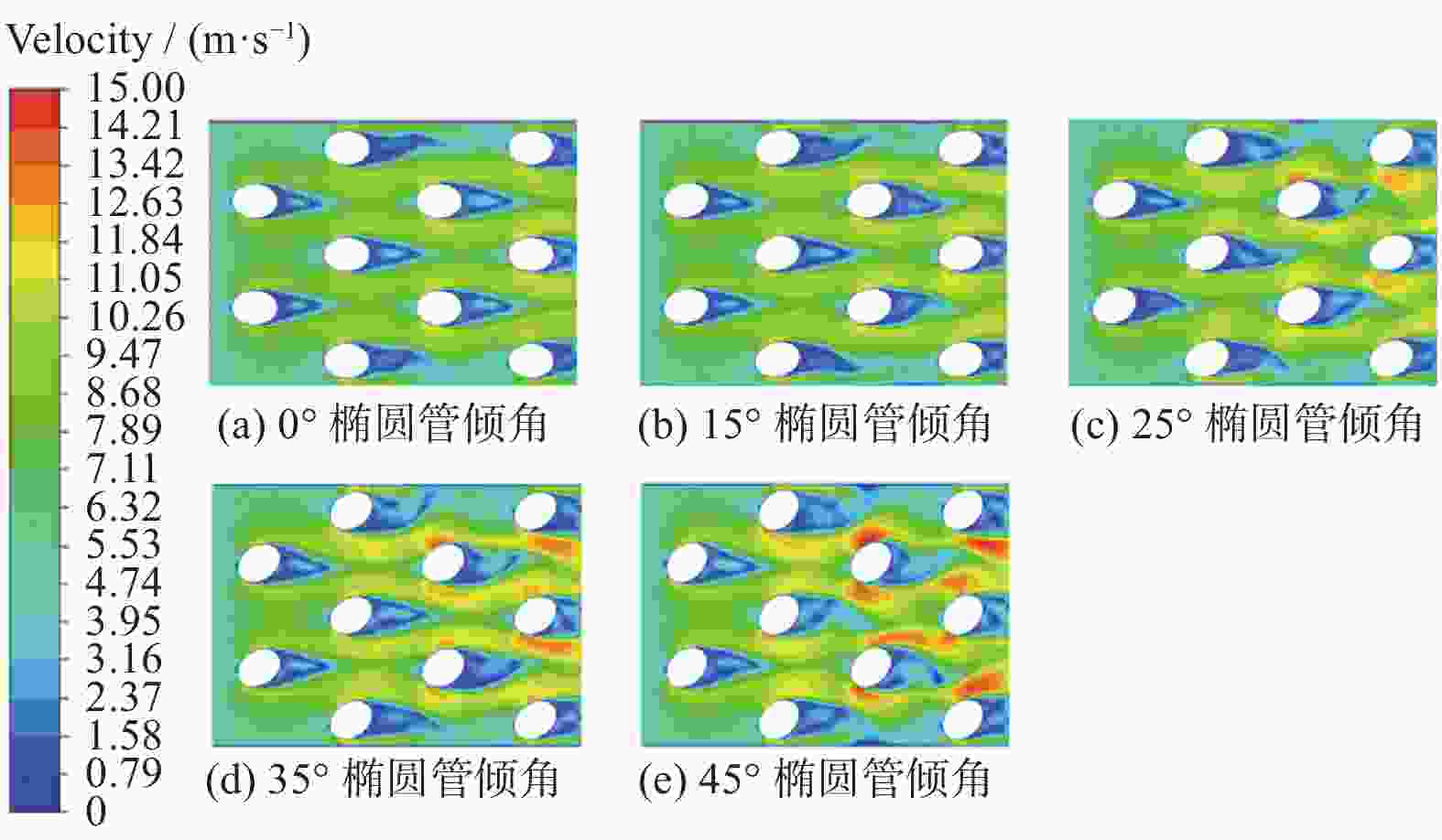

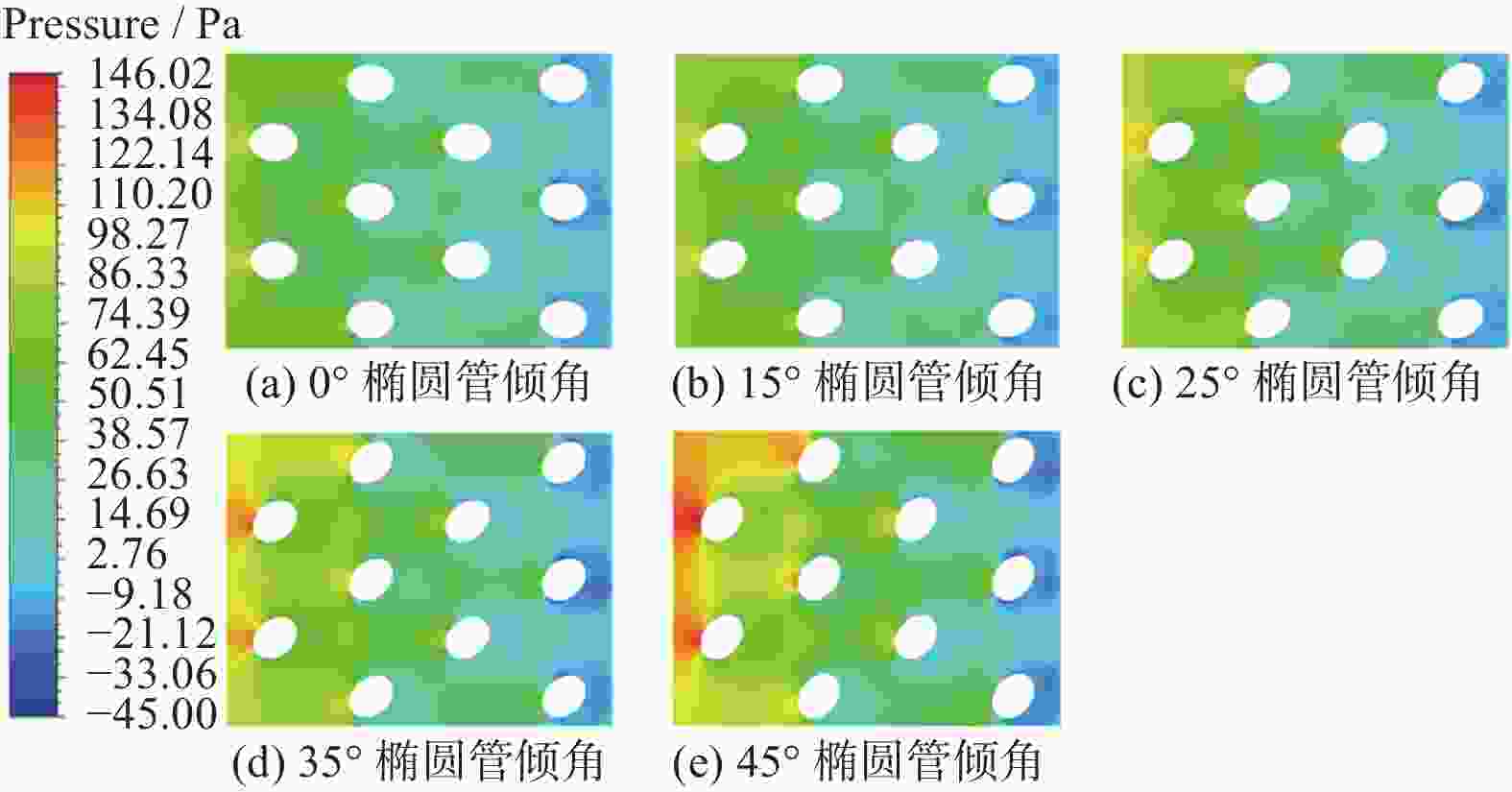

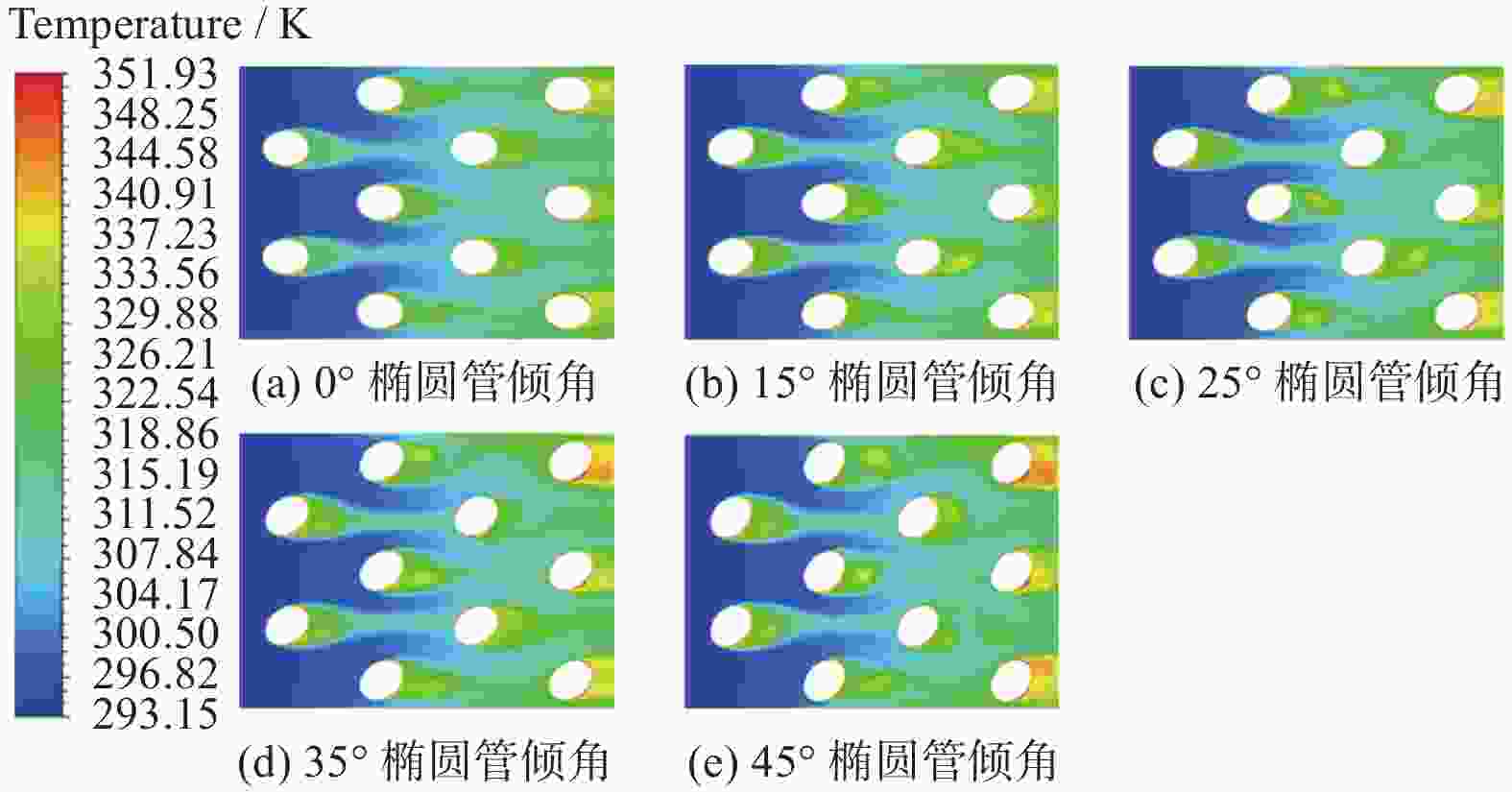

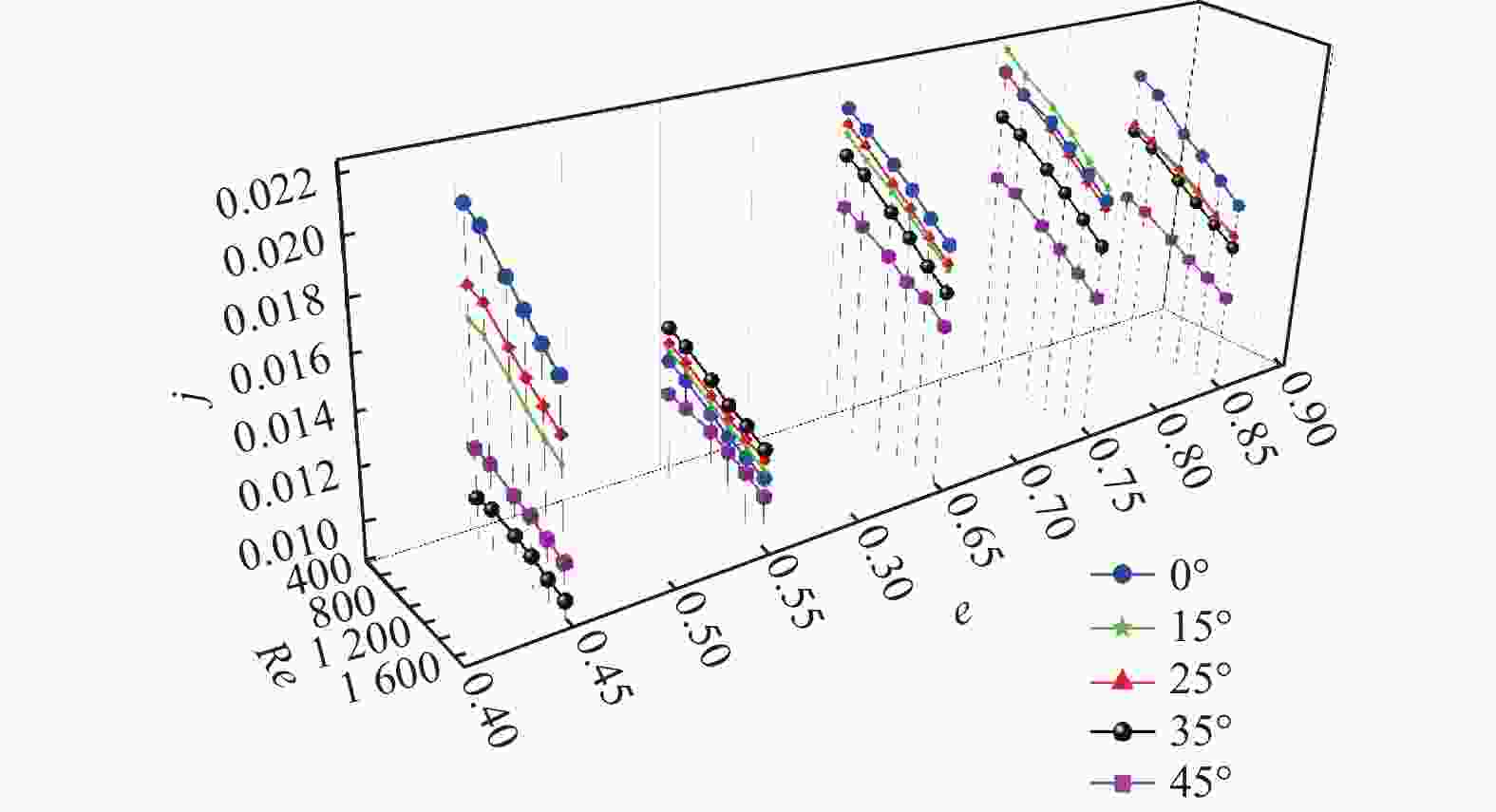

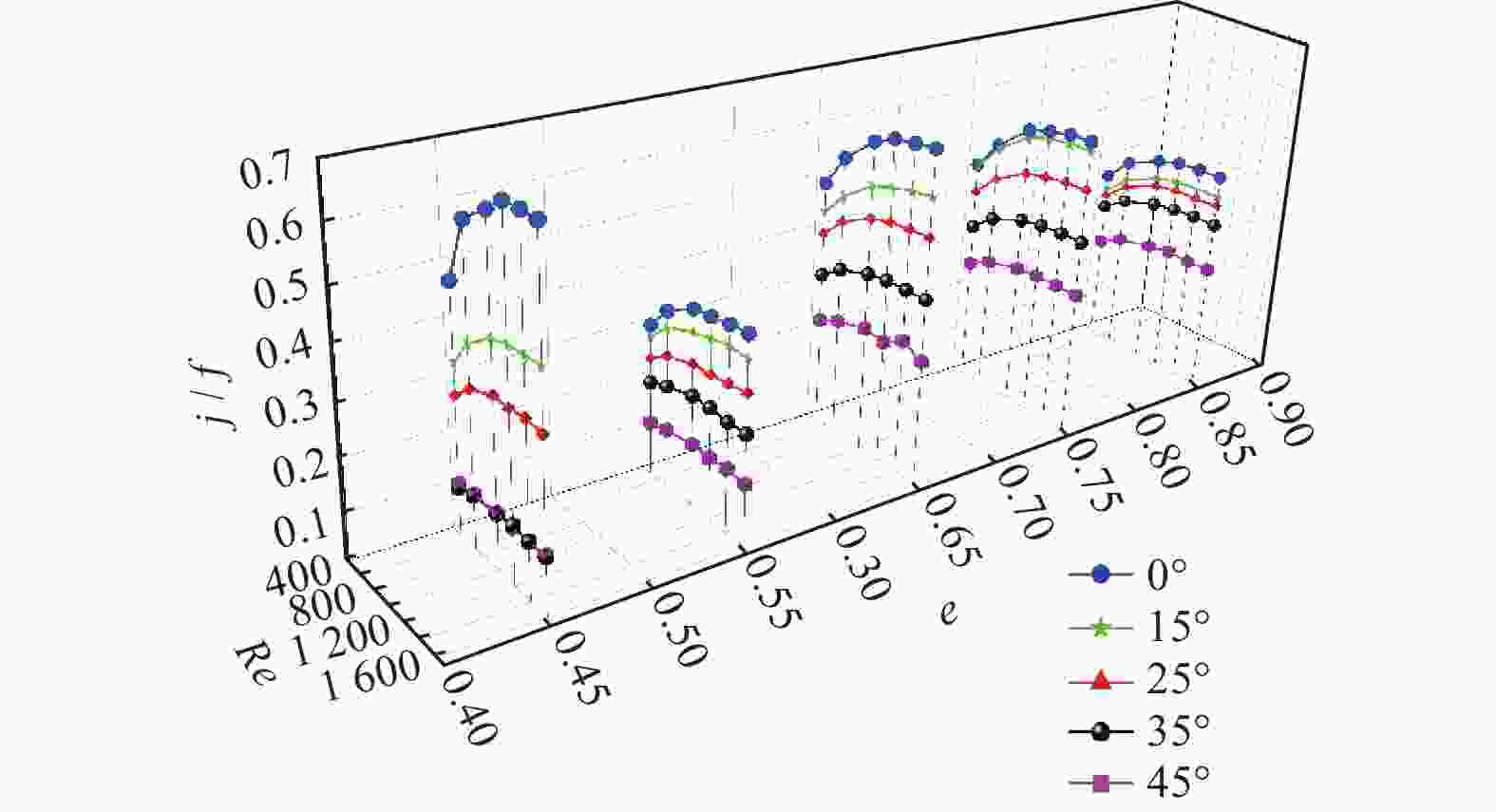

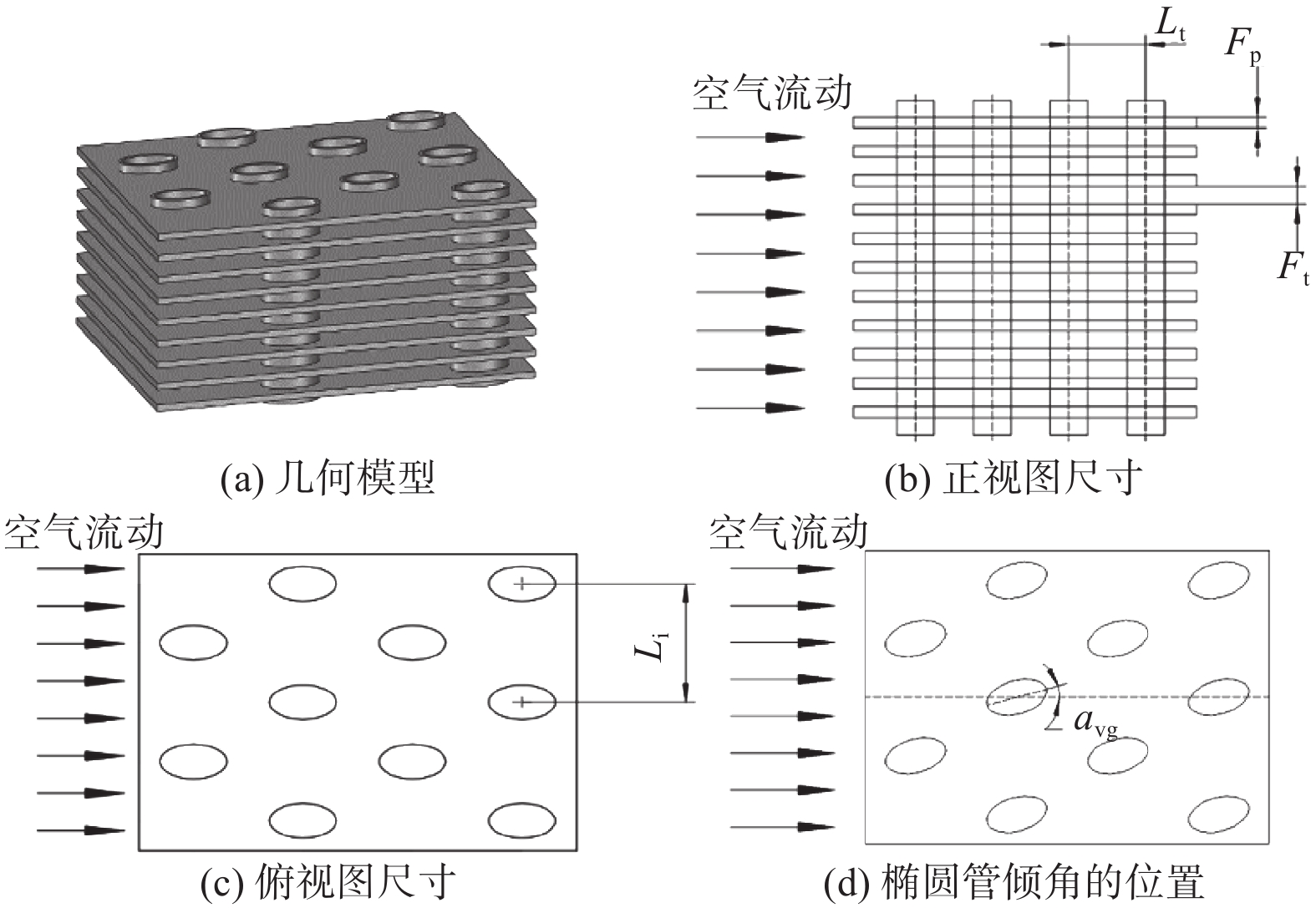

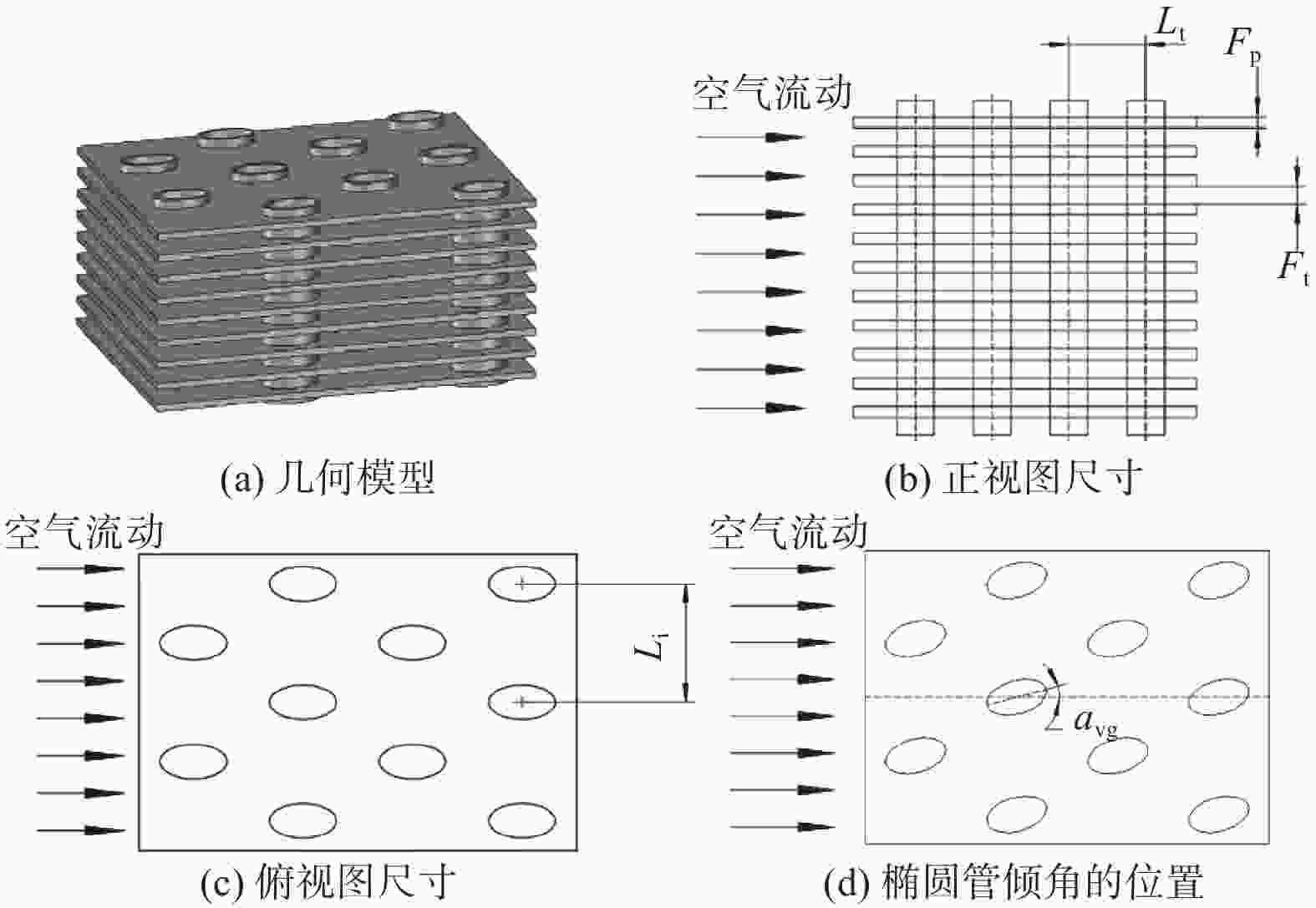

摘要: 建立管翅式换热器模型,在雷诺数Re为500~1600时,对不同椭圆率和管倾角下的管翅式换热器热工性能在3D CFD软件中进行数值分析. 分析椭圆率(0.45~0.85)和管倾角(0o~45o)对管翅式换热器的流动和传热特性以及Colburn因子j、摩擦因数f和效率指数j/f的影响. 结果表明,j、f随着Re的增大而降低,而j/f随Re的增大而上升,并逐渐趋于平缓;适当地倾斜椭圆管,有利于产生更多的湍流,强化对流换热. 当管翅式换热器的椭圆率为0.75,管倾角为15o~25o时,最有利于换热和流体流动特性.Abstract: The model of tube-fin heat exchanger was established, and thermal performances of tube-fin heat exchanger with different ellipticities and tube inclination angles were analyzed by 3D CFD sfotware when the Re was 500~1600. The effects of ellipticities (0.45~0.85) and tube inclination angles (0o~45o) on flow and heat transfer characteristics, colburn factor j, friction factor f and efficiency index j/f of tube-fin heat exchanger were analyzed. The results show that j and f decrease with the increase of Re, while j/f increase with the increase of Re and tend to be gentle. Proper tilt angle is beneficial to generate more turbulence and strengthen convective heat transfer. When the ellipticity of tube-fin heat exchanger is 0.75 and the inclination angle of the tube between 15o and 25o, the heat transfer and fluid flow characteristics are the most favorable.

-

Key words:

- ellipticity /

- tube inclination angle /

- Colburn factor /

- friction factor /

- efficiency index

-

表 1 椭圆管翅式换热器流体的相关参数

Table 1. Related parameters of elliptical tube-fin heat exchanger fluid

参数 数值 材料 空气 流体密度ρf·/(kg·m−3) 1.185 比热容/(J·kg−1·K−1) 1049 导热系数/(W·m−1·K−1) 0.0261 动力黏度/(kg·m−1·s−1) 1.831×10−5 -

[1] SADEGHIANIAHROMI A, WANG C C. Heat transfer enhancement in fin-and-tube heat exchangers: A review on different mechanisms[J] . Renewable and Sustainable Energy Reviews,2021,137:110470. doi: 10.1016/j.rser.2020.110470 [2] YAICI W, GHORAB M, ENTCHEV E. 3D CFD study of the effect of inlet air flow maldistribution on plate-fin-tube heat exchanger design and thermal–hydraulic performance[J] . International Journal of Heat and Mass Transfer,2016(101):527 − 541. [3] WANG C C, CHANG Y J, HSIEH Y C, et al. Sensible heat and friction characteristics of plate fin-and-tube heat exchangers having plane fins[J] . International Journal of Refrigeration,1996,19(4):223 − 230. doi: 10.1016/0140-7007(96)00021-7 [4] WU W L, LUO J E, LI D W, et al. Experimental Investigation of heat transfer performance of a finned-tube heat exchanger under frosting conditions[J] . Sustainable Cities and Society,2022,80:103752. doi: 10.1016/j.scs.2022.103752 [5] LIU X Q, WANG M, LIU H H, et al. Numerical analysis on heat transfer enhancement of wavy fin-tube heat exchangers for air-conditioning applications[J] . Applied Thermal Engineering,2021,199:117597. doi: 10.1016/j.applthermaleng.2021.117597 [6] SADEGHIANIAHROMI A, KHERADMAND S, NEMATI H, et al. Optimization of the louver fin-and-tube heat exchangers: A parametric approach[J] . Journal of Enhanced Heat Transfer,2020,27(4):289 − 312. doi: 10.1615/JEnhHeatTransf.2020033527 [7] 周俊杰, 陶文铨. 椭圆管开缝翅片换热表面特性的三维数值分析[J] . 机械工程学报,2005(41):89 − 93. doi: 10.3321/j.issn:0577-6686.2005.07.016 [8] 谭起滨, 蒋斌. 椭圆横管外降膜流动和换热特性分析[J] . 热能动力工程,2017(9):20 − 25. doi: 10.16146/j.cnki.rndlgc.2017.09.004 [9] 杨立军, 张凯峰, 杜小泽. 空冷凝汽器椭圆翅片椭圆管束外空气的流动与传热特性[J] . 动力工程,2008,28(6):911 − 914. [10] 冯丽丽, 杜小泽, 杨勇平, 等. 椭圆管矩形翅片间空气流动的扰流特征[J] . 工程热物理学报,2011,32(1):119 − 122. [11] 漆波, 李隆键, 崔文智, 等. 百叶窗式翅片换热器中的耦合传热[J] . 重庆大学学报 (自然科学版 ),2005,28(10):39 − 42. [12] 曹侃, 袁耀华, 王春艳, 等. 一种错列布孔型百叶窗翅片换热器的数值模拟[J] . 低温与超导,2021,49(11):41 − 46,51. doi: 10.16711/j.1001-7100.2021.11.008 [13] 刘妮, 崔强, 赖晓玲. 椭圆管翅式换热器空气侧传热和流动特性的数值模拟[J] . 热能动力工程,2020,35(6):136 − 142. doi: 10.16146/j.cnki.rndlgc.2020.06.019 [14] KEAWKAMROP T, ASIRVATHAM L G, DALKILIC A S, et al. An experimental investigation of the air-side performance of crimped spiral fin-and-tube heat exchangers with a small tube diameter[J] . International Journal of Heat and Mass Transfer,2021,178:121571. doi: 10.1016/j.ijheatmasstransfer.2021.121571 [15] MYONG J H, CHOI B N, GO M G, et al. Experimental investigation on the airside heat transfer and pressure drop of the fin-and-tube heat exchangers having oval tubes[J] . Experimental Heat Transfer,2022,35(4):484 − 499. doi: 10.1080/08916152.2021.1906357 [16] WANG Y C, ZHAO W S, WANG P F, et al. Thermal performance of elliptical fin-and-tube heat exchangers with vortex generator under various inclination angles[J] . Journal of Thermal Science,2021,30(1):257 − 270. doi: 10.1007/s11630-020-1305-3 [17] YOGESH S S, SELVARAJ A S, RAVI D K, et al. Heat transfer and pressure drop characteristics of inclined elliptical fin tube heat exchanger of varying ellipticity ratio using CFD code[J] . International Journal of Heat and Mass Transfer,2018,119:26 − 39. doi: 10.1016/j.ijheatmasstransfer.2017.11.094 [18] 陶文铨. 数值传热学[M]. 西安: 西安交通大学出版社, 2001: 136−176. -

下载:

下载: