Analysis of influence mechanism of milling stability based on posture of ball end milling cutter

-

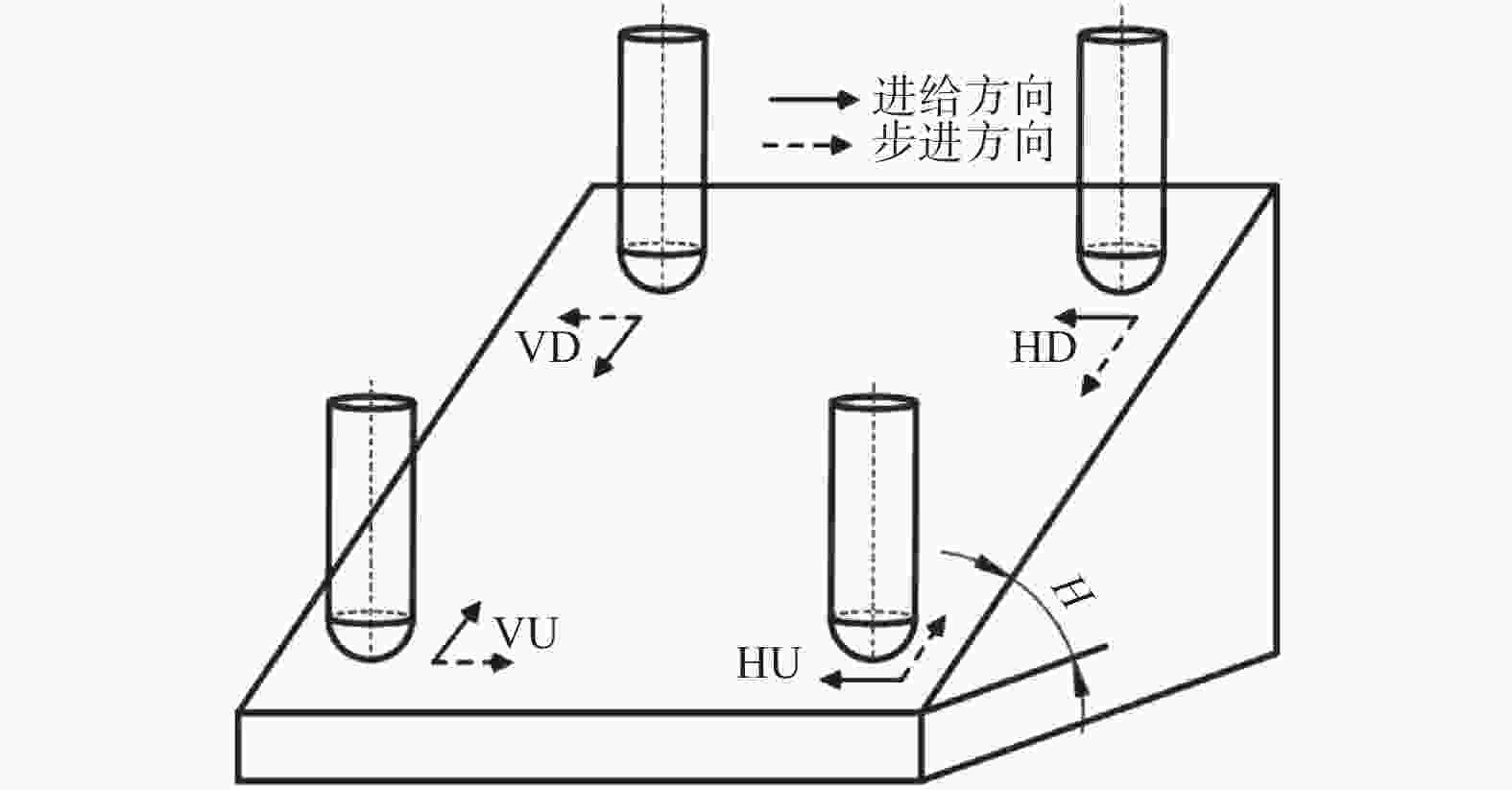

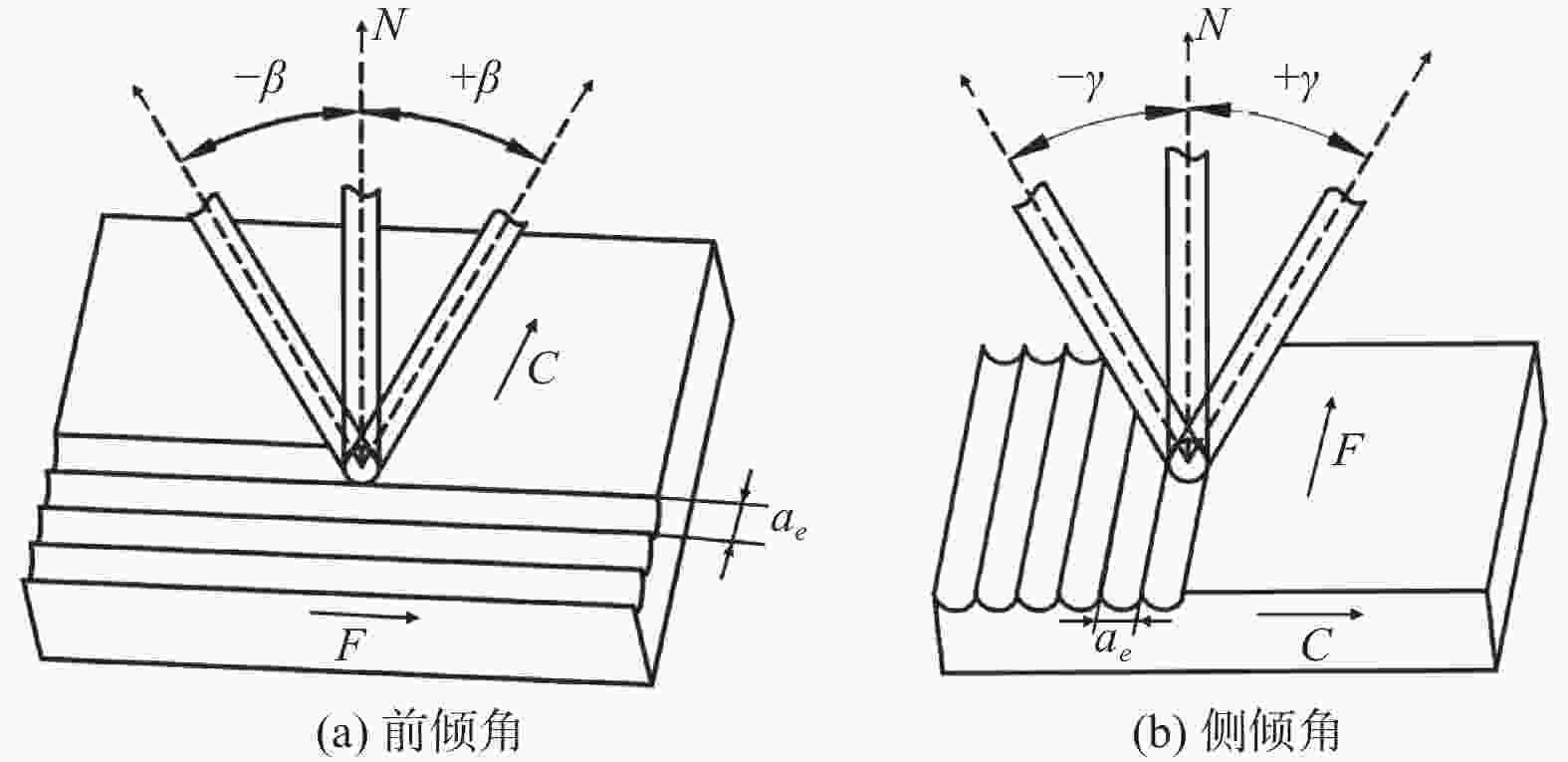

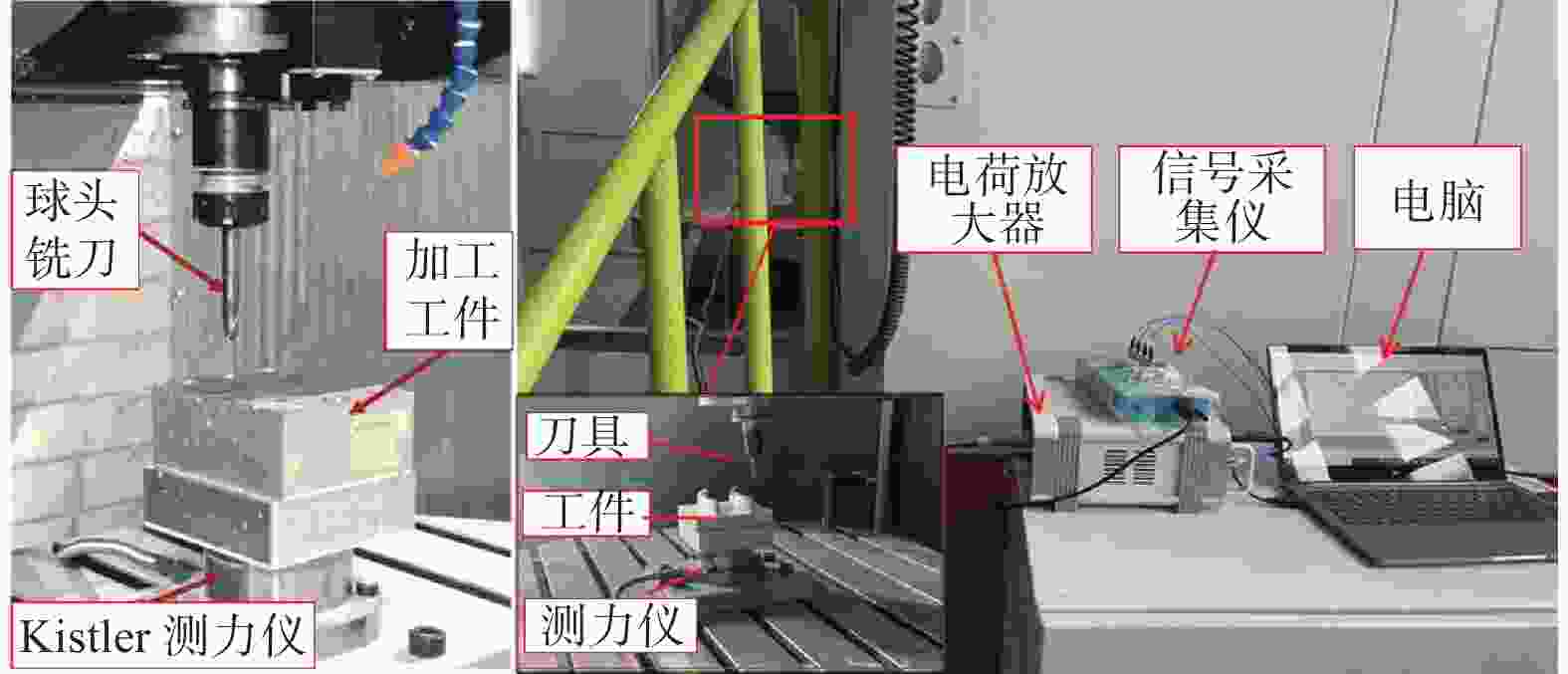

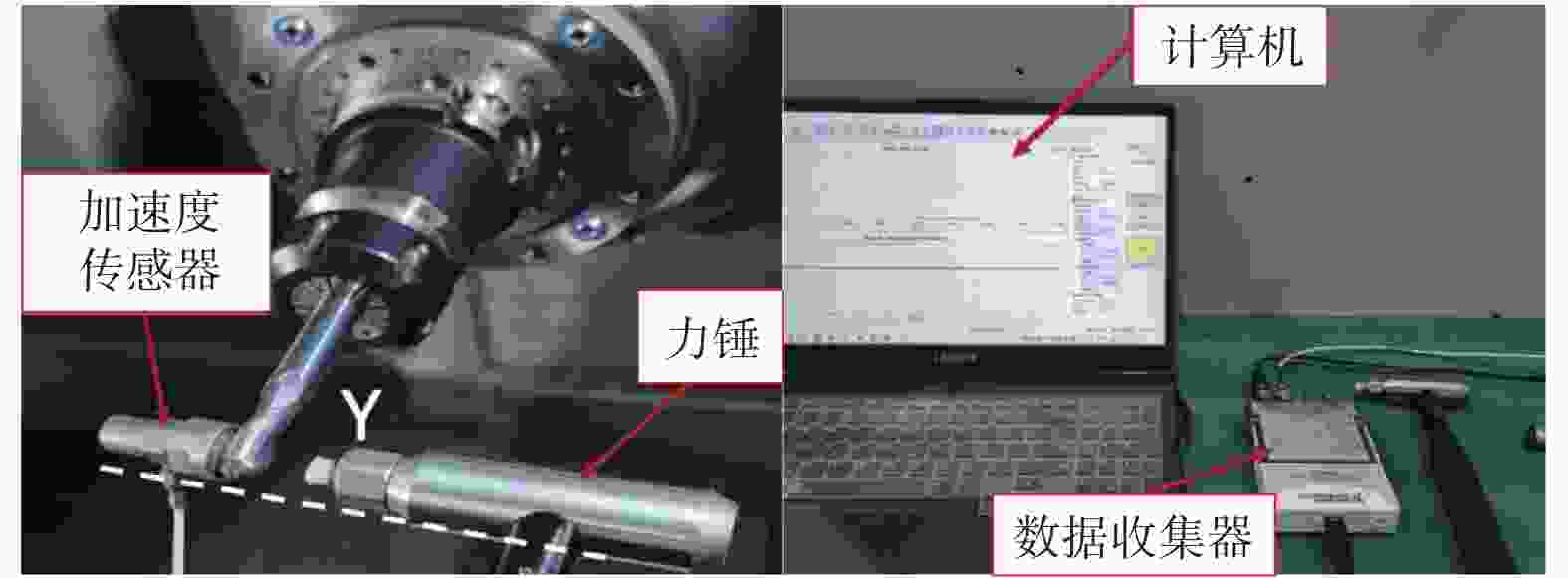

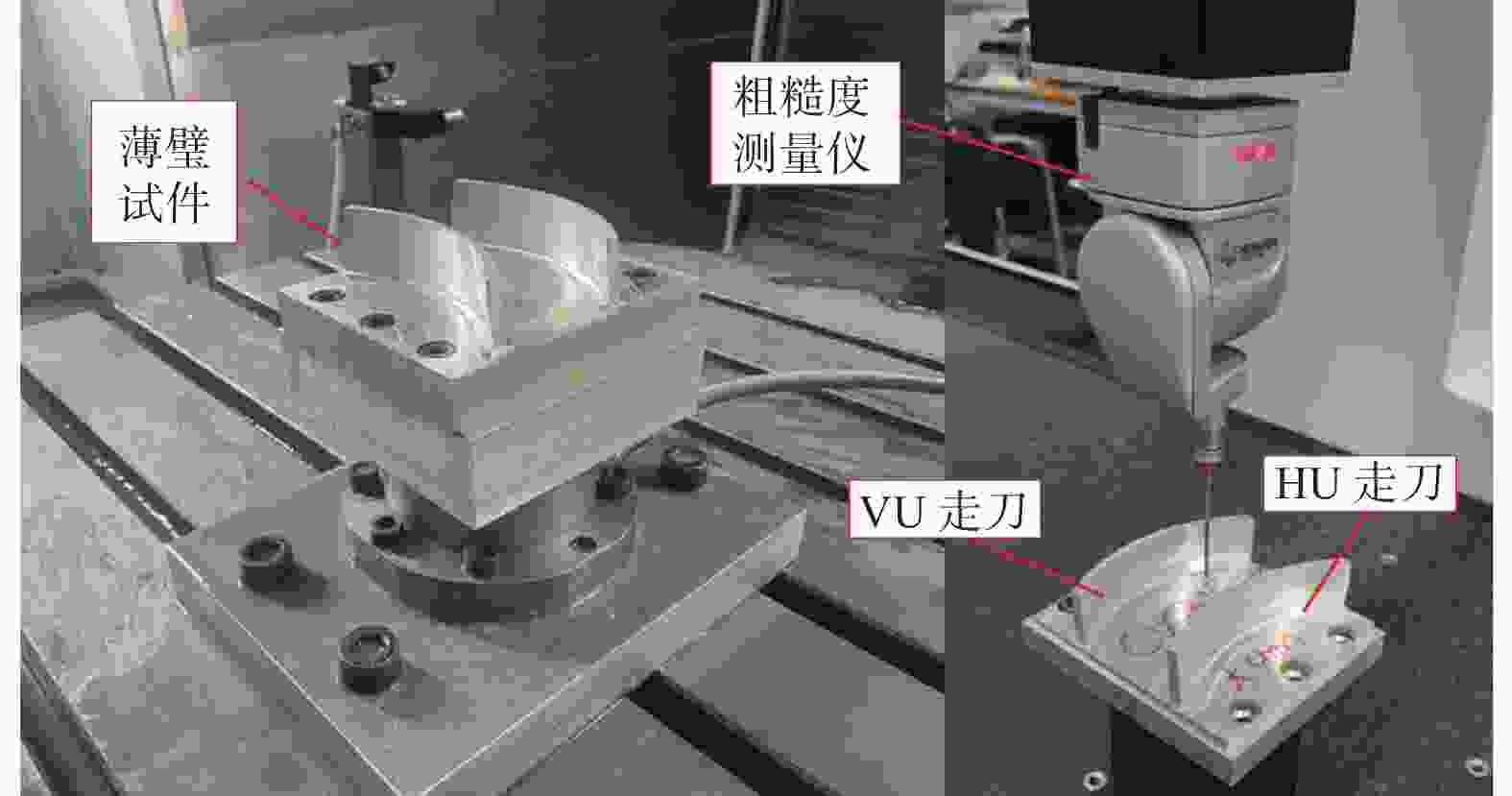

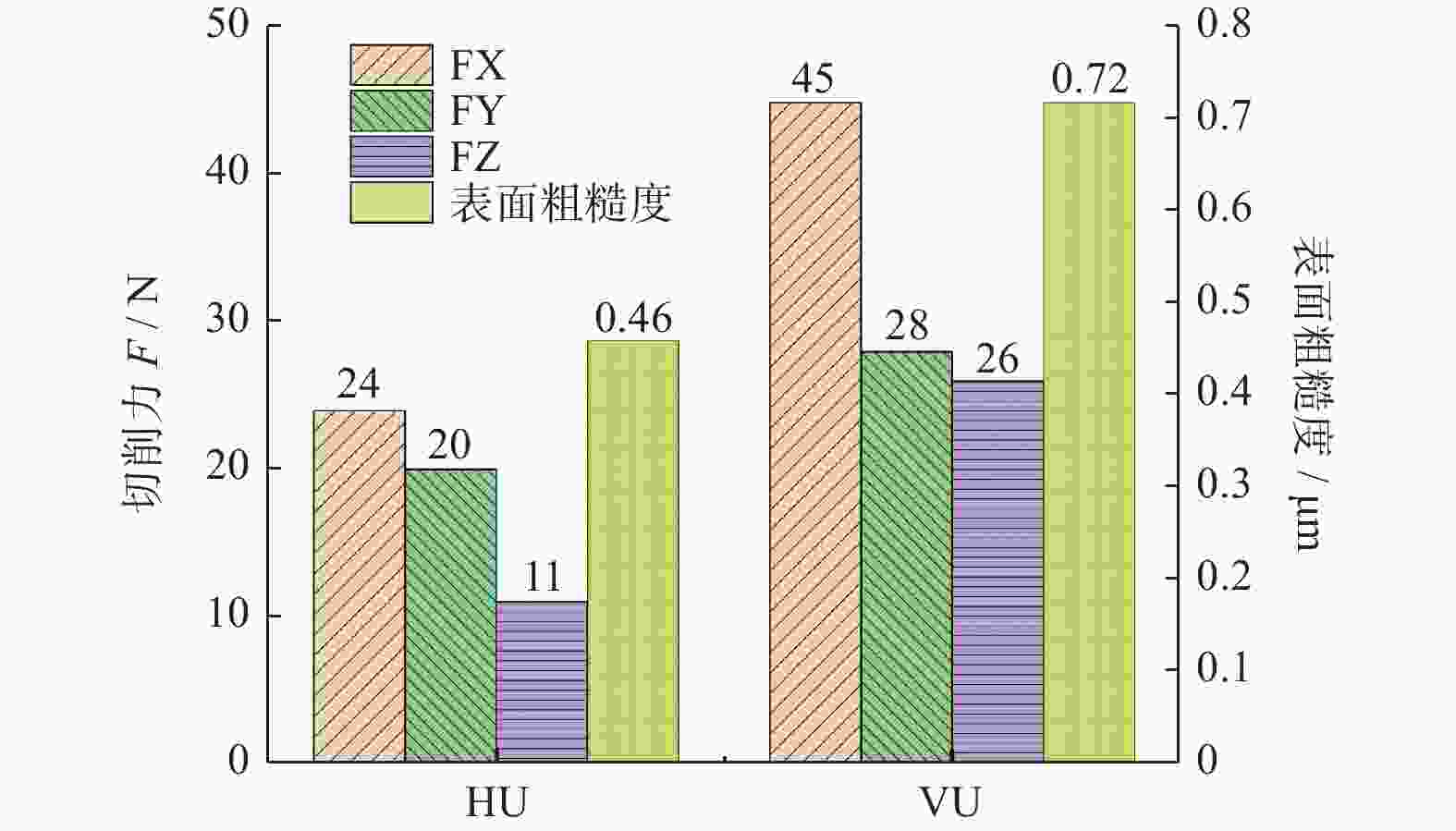

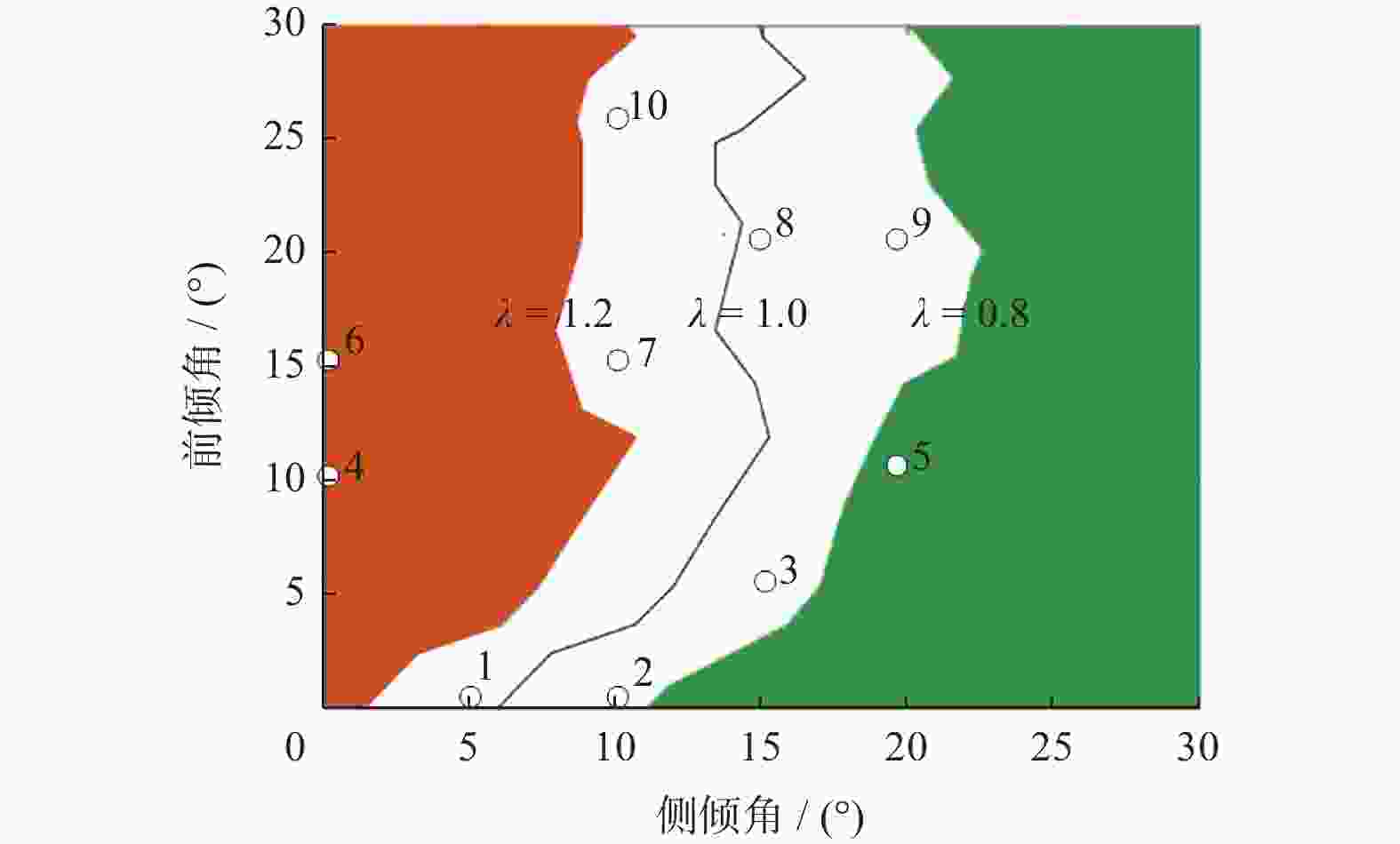

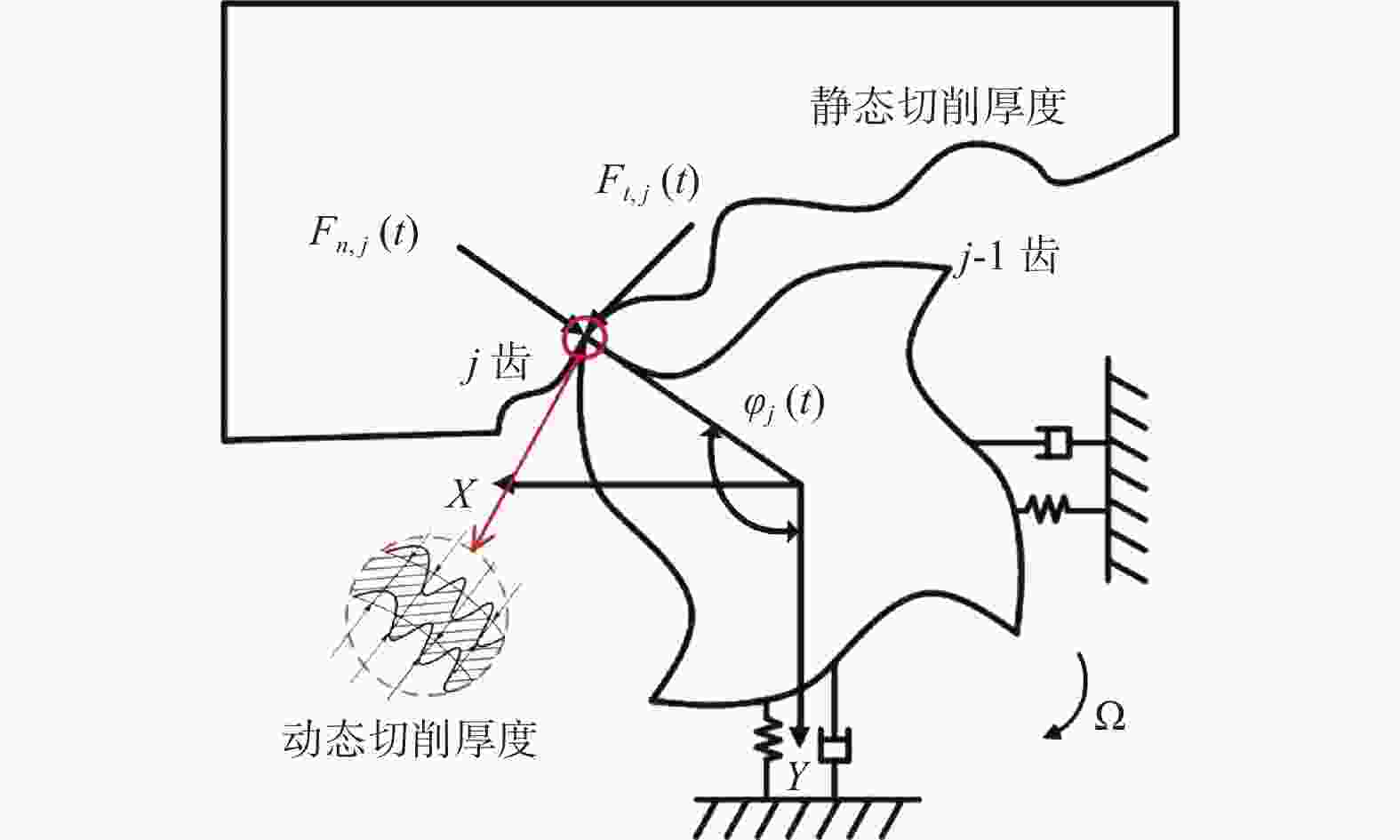

摘要: 铣削颤振不仅会导致加工零件表面产生振纹,降低加工零件的表面质量,而且会加剧刀具的磨损和降低机床的寿命. 针对加工过程中球头铣刀的刀具姿态对颤振的影响,构建刀具姿态影响下的铣削动力学模型,运用三阶牛顿−埃尔米特插值全离散法对铣削动力学模型进行求解,得到系统状态转移矩阵. 用Floquet理论判断铣刀在不同刀具姿态下的铣削稳定性,构建球头铣刀的刀具姿态稳定性预测图. 试验确定水平向上走刀方式稳定性最好,工件表面粗糙度最低,验证了稳定性预测图的有效性.Abstract: Milling chatter will not only cause chatter marks on the surface of the machined parts and reduce the surface quality of the machined parts, but also aggravate tool wear and reduce the life of the machine tool. According to the influence of the tool posture of the ball-end milling cutter affecting on the flutter generated during the machining process, the milling dynamics model under the influence of the tool posture was built. The milling dynamic model was solved by the third-order Newton-Hermite interpolation fully discrete method, and the state transition matrix of the system was obtained. The Floquet theory was used to judge the milling stability of the milling cutter under different tool postures, and the tool posture stability prediction map of the ball-end milling cutter was constructed. The experiment determines that the horizontal upward cutting method has the best stability and the lowest surface roughness of the workpiece, which could verify the validity of the stability prediction map.

-

Key words:

- ball end mill /

- tool posture /

- tool path /

- stability prediction

-

表 1 切削力系数

Table 1. Cutting force coefficients

N/mm2 Ktc Krc Kac Kte Kre Kae 865.36 566.48 328.60 18.96 15.32 4.98 表 2 刀具模态参数

Table 2. Tool modal parameters

方向 模态质量

/kg固有频率

$ {\omega _{\text{n}}}/{\text{Hz}} $阻尼比

$ \zeta $X方向 0.1696 487.8662 0.6237 Y方向 0.1624 485.1536 0.6628 表 3 预测结果和试验结果对比

Table 3. Comparison of predicted results with experimental results

序号 前倾角 侧倾角 预测结果 试验结果 试验结果图 1 0 5 不稳定 不稳定

2 0 10 稳定 稳定

3 5 15 稳定 稳定

4 10 0 不稳定 不稳定

5 10 20 稳定 稳定

6 15 0 不稳定 不稳定

7 15 10 不稳定 不稳定

8 20 15 稳定 稳定

9 20 20 稳定 稳定

10 25 10 不稳定 不稳定

-

[1] 王英鹏. 运动学约束的五轴加工刀轴矢量优化研究[D]. 大连: 大连理工大学, 2019. [2] OZTURK E, TUNC L T, BUDAK E. Investigation of lead and tilt angle effects in 5-axis ball-end milling process[J] . International Journal of Machine Tools and Manufacture,2009,49(14):1053 − 1062. [3] 谭靓, 刘维伟, 姚倡锋, 等. 球头铣刀刀具姿态对钛合金加工表面完整性的影响[J] . 工具技术,2015,49(12):39 − 43. doi: 10.3969/j.issn.1000-7008.2015.12.010 [4] 黄涛, 刘志兵, 王西彬, 等. 刀轴侧倾角对薄壁叶片加工变形的影响[J] . 兵工学报,2018,39(3):577 − 582. doi: 10.3969/j.issn.1000-1093.2018.03.020 [5] 蔡元元, 刘维伟, 李锋, 等. 球头铣刀加工倾角对薄壁件切削振动和变形的影响研究[J] . 航空精密制造技术,2012(6):1 − 4, 9. doi: 10.3969/j.issn.1003-5451.2012.06.001 [6] 程德俊, 全宏杰, 张春燕. 球头铣刀切削加工表面形貌仿真技术研究[J] . 江苏科技大学学报(自然科学版),2021,35(4):38 − 43. [7] 谭勇军, 王玉涛, 唐清春, 等. 五轴联动加工刀具姿态的优化策略[J] . 汽轮机技术,2018,60(4):317 − 320. doi: 10.3969/j.issn.1001-5884.2018.04.021 [8] HUANG C, YANG W A, HUANG J C, et al. A full-discretization method for milling stability prediction based on third-order Newton-Hermite interpolation[J] . Aeronautical Manufacturing Technology,2021,64(8):92 − 101. [9] LI H K, DAI Y B, FAN Z F. Improved precise integration method for chatter stability prediction of two–DOF milling system[J] . The International Journal of Advanced Manufacturing Technology,2019,101(5/6/7/8):1235 − 1246. [10] 高强, 谭述君, 钟万勰. 精细积分方法研究综述[J] . 中国科学: 技术科学,2016,46(12):1207 − 1218. [11] 杨昀, 张卫红, 党建卫, 等. 航空薄壁件铣削加工动力学仿真技术[J] . 航空制造技术,2018,61(7):42 − 47. doi: 10.16080/j.issn1671-833x.2018.07.042 [12] 李忠群, 石晓芳, 党剑涛, 等. 铣削加工过程动力学建模、仿真研究现状与展望[J] . 航空制造技术,2018,61(16):16 − 22. [13] 植俊杰, 张立强, 杨青平, 等. 基于接触区域的球头刀五轴加工无颤振刀具姿态的研究[J/OL]. 计算机集成制造系统.(2021-12-29)[2022-03-01]. https://kns.cnki.net/kcms/detail/11.5946.TP.20211228.1502.022.html. -

下载:

下载: