Research on method of liner inner diameter measurement based on machine vision

-

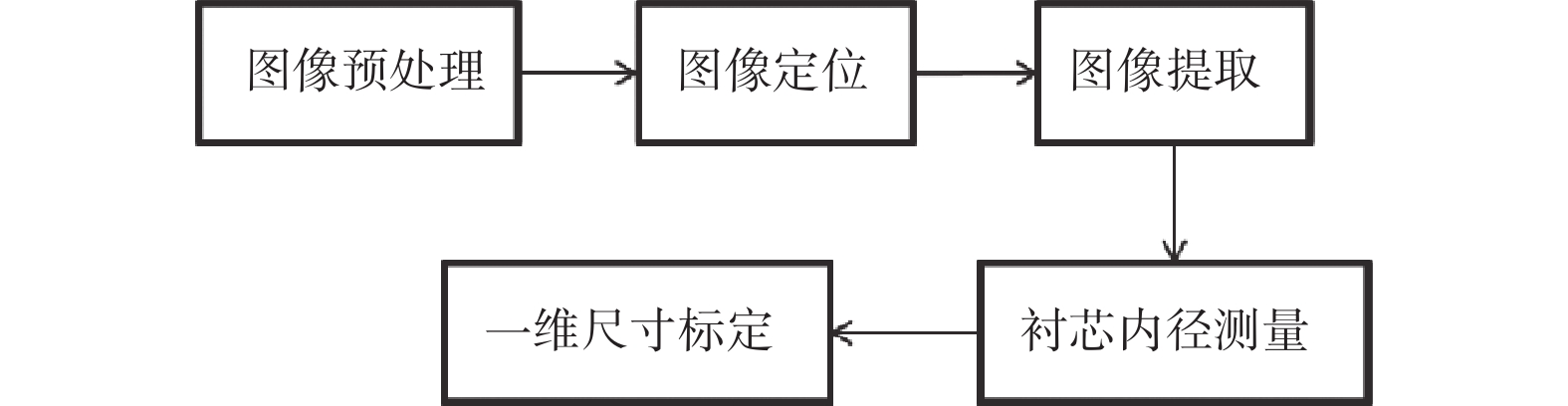

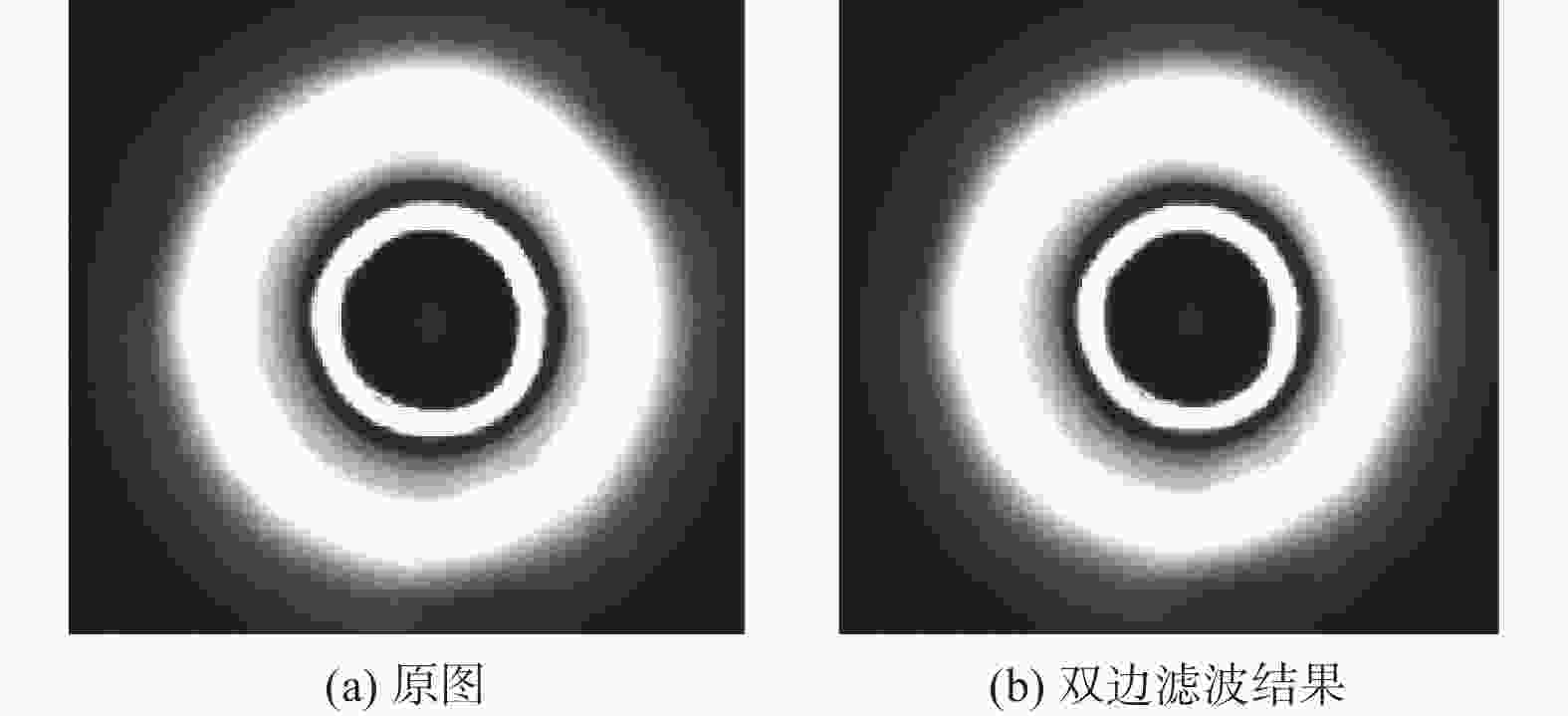

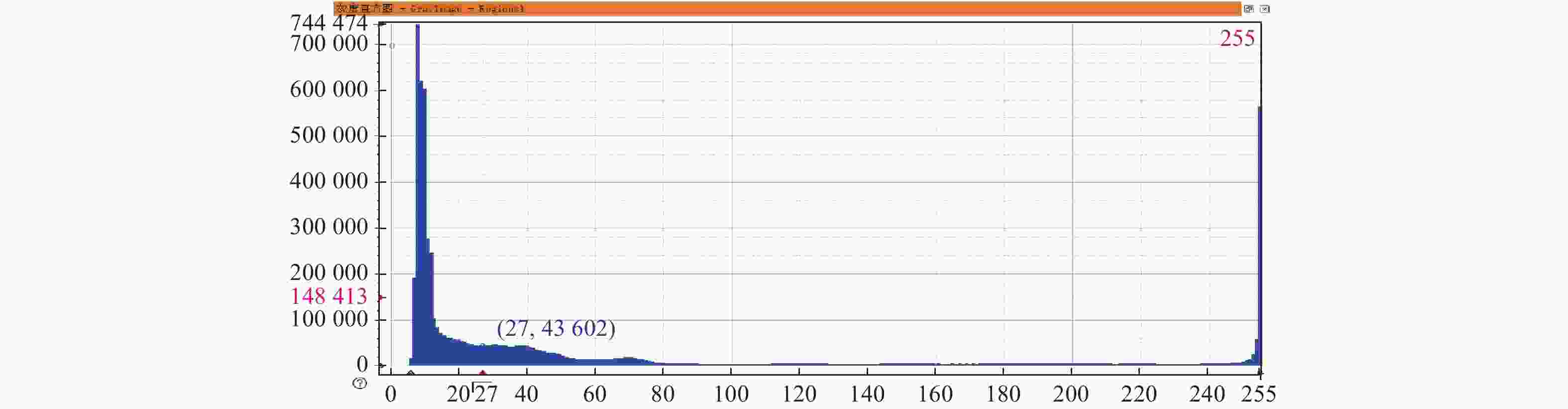

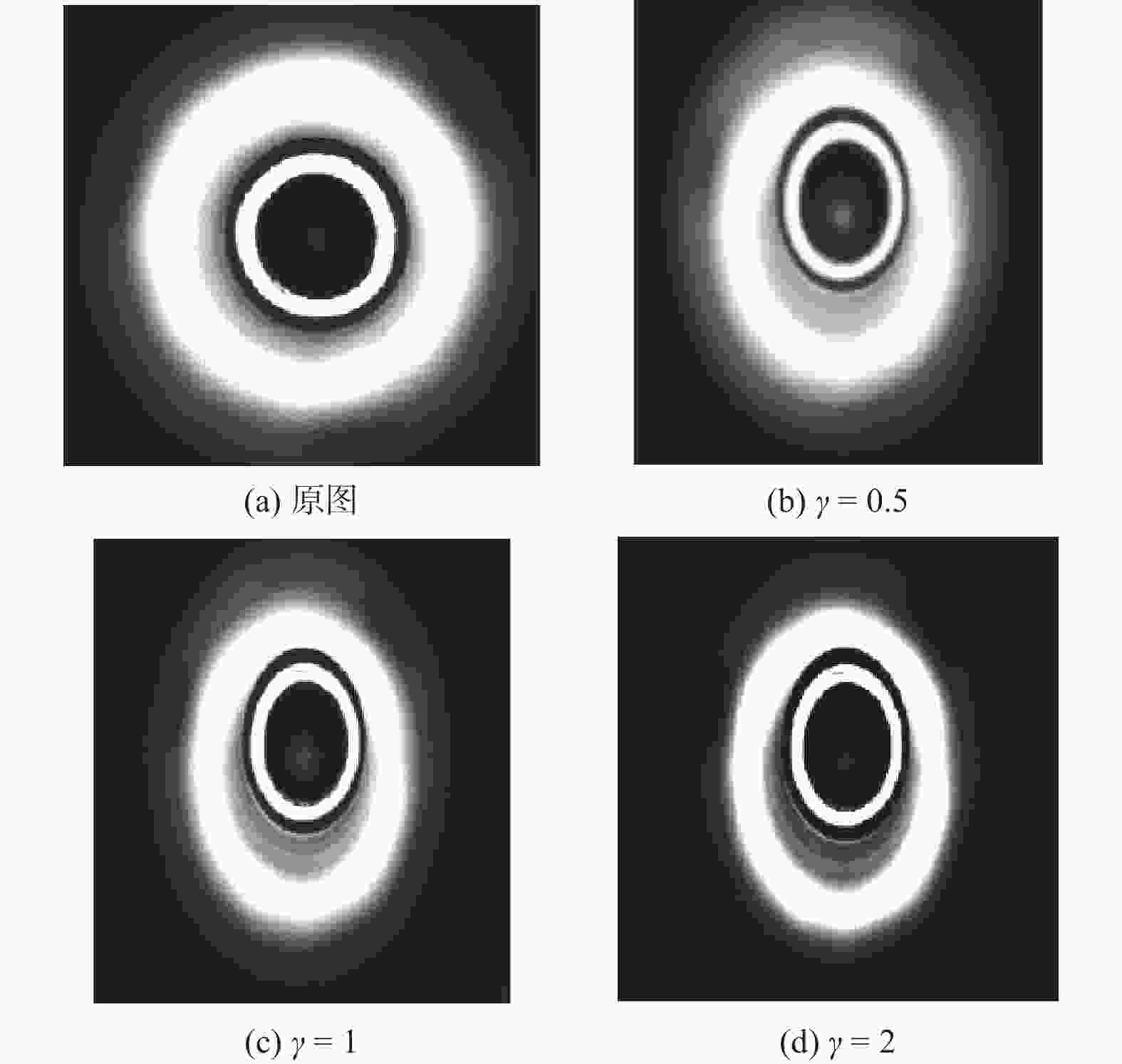

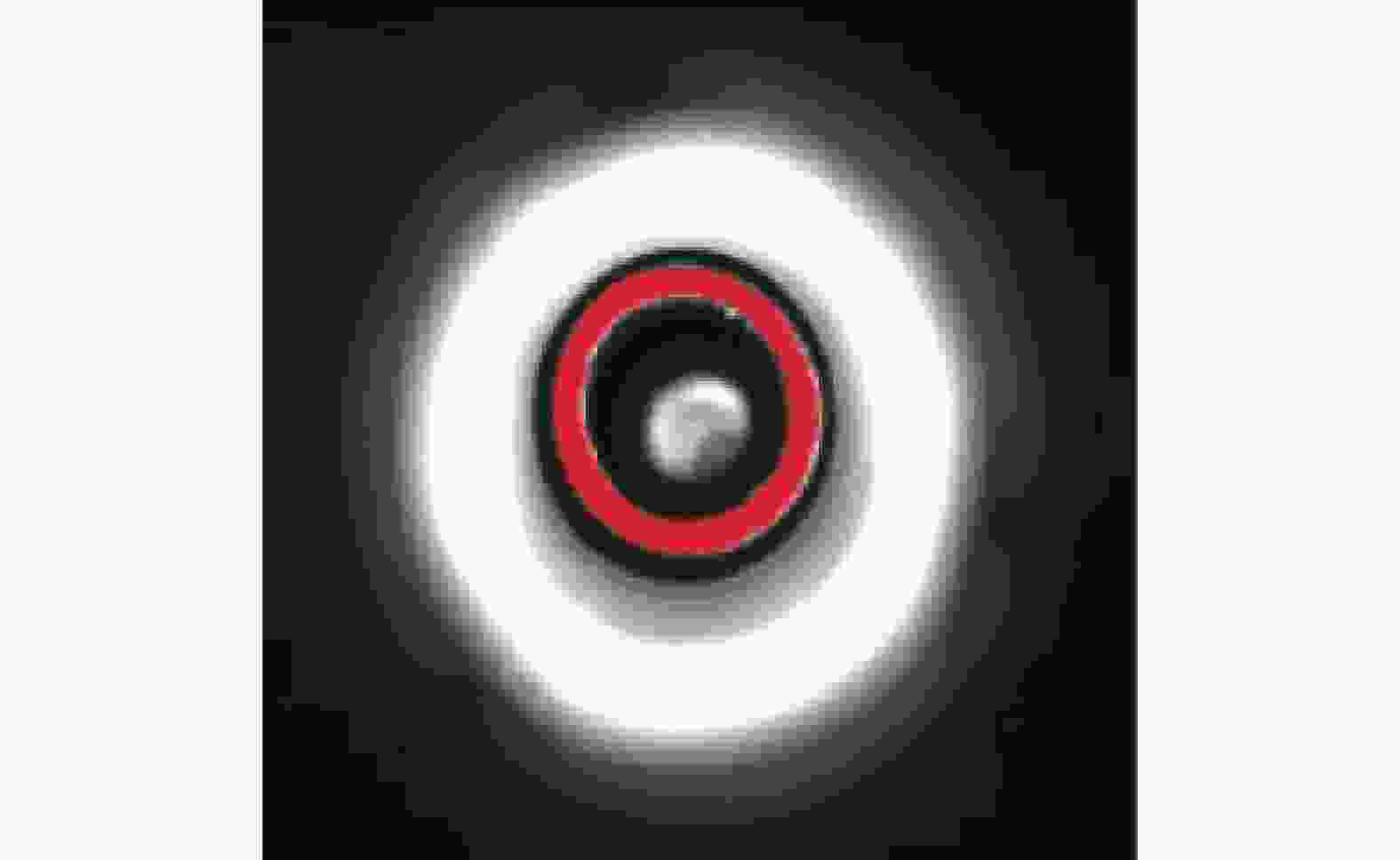

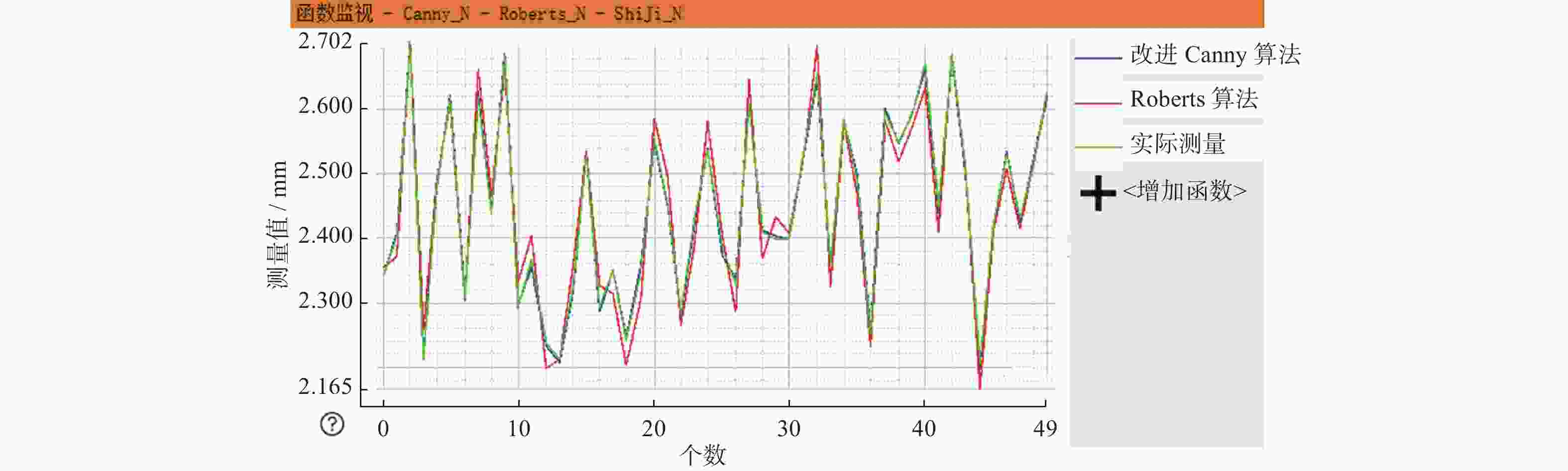

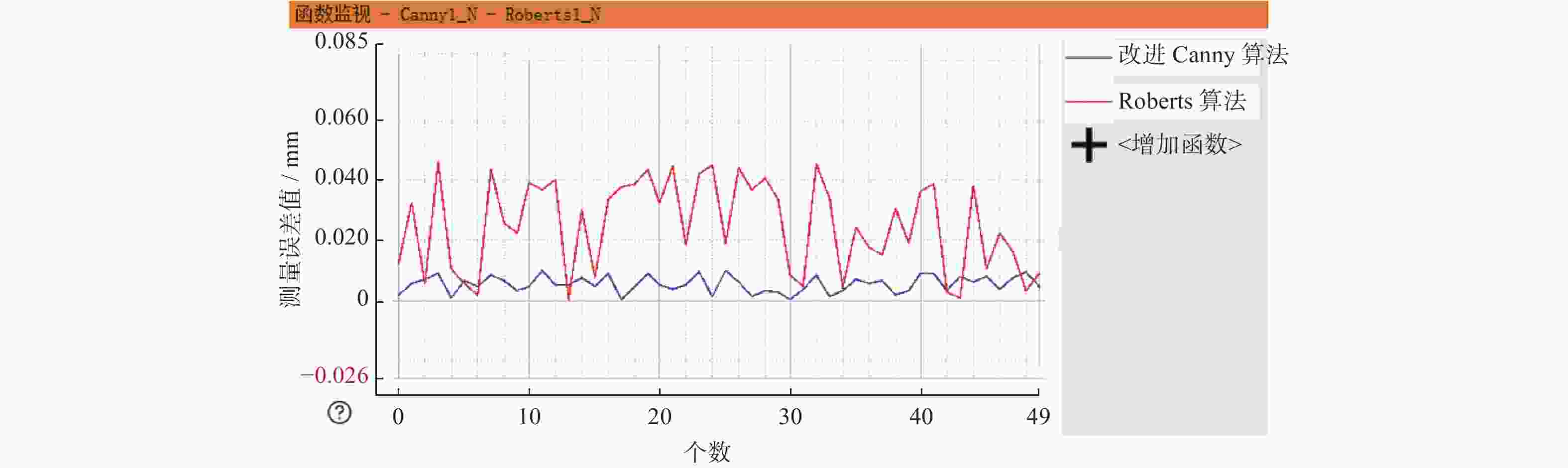

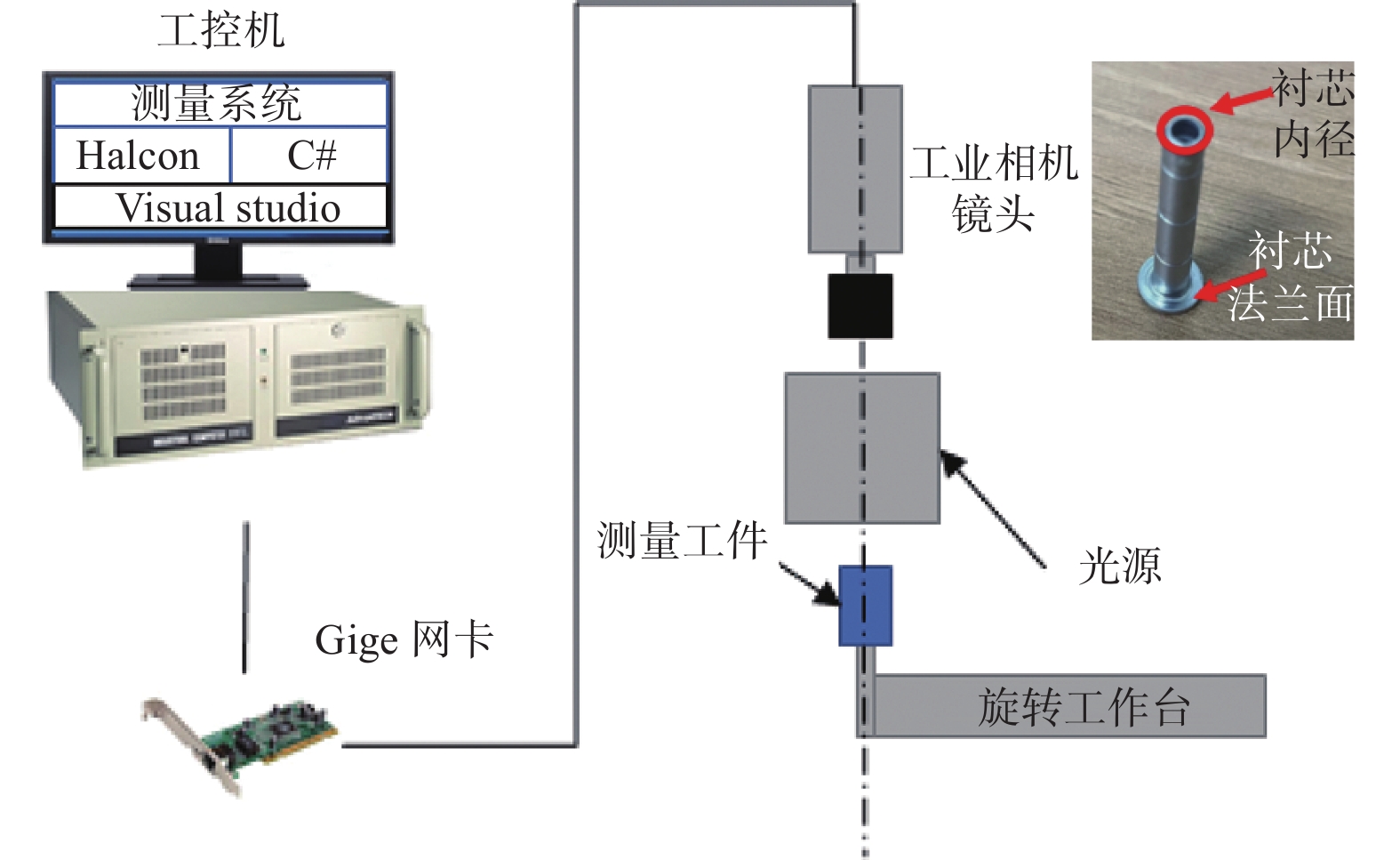

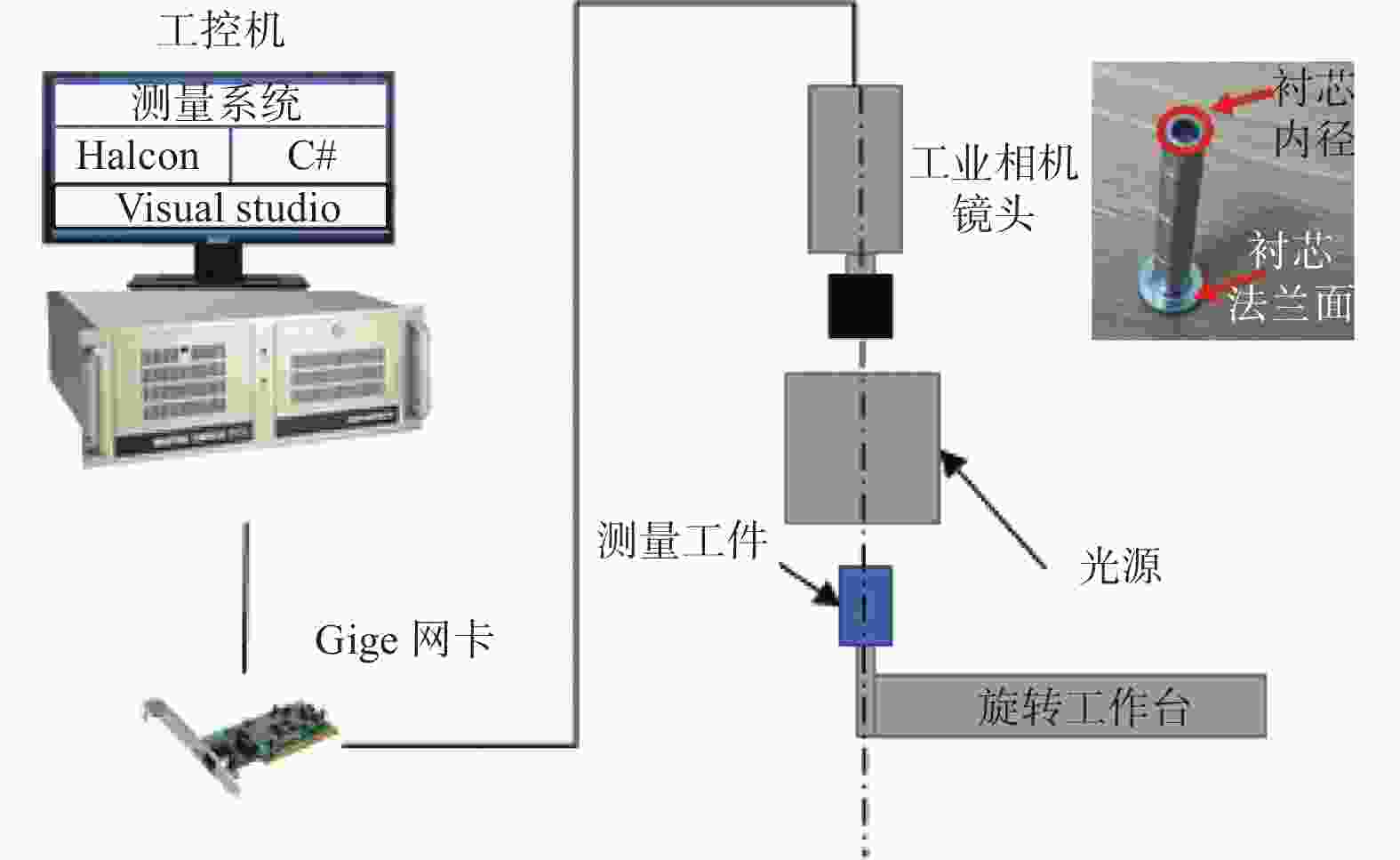

摘要: 衬芯是汽车制动系统中连接刹车油管与制动器的重要零部件,其内径超差会严重影响车辆刹车性能. 针对人工测量衬芯内径尺寸方法效率低、精度差、检测标准不一致等问题,提出基于机器视觉的衬芯内径尺寸测量方法. 利用双边滤波、改进的Otsu阈值法和形态学方法对衬芯内径进行预处理和定位,采用一种改进的Canny边缘检测算子提取内径轮廓点,并基于Tukey权函数实现最小二乘法拟合圆以计算内径尺寸. 试验验证该检测算法的测量误差在 ± 0.01 mm之内,测量准确率为98.9%、漏检率为0、过检率为1.1%,能够满足企业的实际测量要求.Abstract: Liner is an important component connecting brake oil pipe and brake in automobile brake system, and the oversize of inner diameter will seriously affect the brake performance of vehicles. Aiming at the problems of low efficiency, poor accuracy and inconsistent detection standards in the manual measurement of liner inner diameter, a method for measuring liner inner diameter based on machine vision was proposed. The inner diameter of liner was preprocessed and located by using bilateral filtering, improved Otsu threshold method and morphological method. An improved Canny edge detection operator was used to extract the inner diameter contour points, and the least square method was used to fit the circle based on Tukey weight function to calculate the inner diameter size. The experimental verification shows that the measurement error value of the detection algorithm is within ± 0.01 mm, the measurement accuracy is 98.9%, the missing rate is 0, and the passing rate is 1.1%, which can meet the actual measurement requirements of enterprises.

-

Key words:

- machine vision /

- image processing /

- dimension detection

-

表 1 标定板的参数

Table 1. Parameters of calibration board

规格/(mm×mm) 类型 阵列 圆心间距/mm 精度/mm 圆大小/mm 20×20 实心圆点 7×7 2.5 0.001 Ф1.25 表 2 改进Canny和Roberts算法测量结果比较

Table 2. Comparison of measurement results of improved Canny and Roberts algorithms

批次 检测数量 不合格数 漏检数 过检数 漏检率/% 过检率/% 准确率/% 检测时间/s Ca Ro Ca Ro Ca Ro Ca Ro Ca Ro Ca Ro Ca Ro 1 500 25 51 0 22 6 35 0 4.4 1.2 7.0 98.8 88.6 0.226 0.155 2 500 12 47 0 30 4 24 0 6.0 0.8 4.8 99.2 89.2 0.202 0.189 3 500 17 62 0 21 7 20 0 4.2 1.4 4.0 98.6 91.8 0.241 0.175 总计 1500 54 160 0 63 17 79 0 4.2 1.1 5.3 98.9 90.5 0.223 0.173 注:Ca为改进Canny算法;Ro为Roberts算法. -

[1] 左东祥, 陈晓荣. 基于Halcon的刹车片尺寸和表面缺陷检测系统[J] . 电子科技,2016,29(11):78 − 80. [2] 徐志玲, 胡琳丽, 陈杨, 等. 基于尺寸公差和图像处理的刹车尺寸检测[J] . 仪器仪表学报,2017,38(9):2317 − 2325. [3] XIAO G F, LI Y T, XIA Q X, et al. Research on the on-line dimensional accuracy measurement method of cylindrical spun parts based on machine vision technology[J] . Measurement,2019,148:10688. [4] SUN W F, YI J Y, MA G. A vision-based method for dimensional in situ measurement of cooling holes in aero-engines during laser beam drilling process[J] . International Journal of Advanced Manufacturing Technology,2022,119:3265 − 3277. doi: 10.1007/s00170-021-08463-8 [5] ZHU S P, GAO Y. Noncontact 3-D coordinate measurement of cross-cutting feature points on the surface of a large-scale workpiece based on the machine vision method[J] . IEEE Transactions on Instrumentation and Measurement,2010,59(7):1874 − 1887. doi: 10.1109/TIM.2009.2030875 [6] 刘昕宇, 王雪梅, 倪文波. 基于机器视觉的连通管液位测量方法研究[J] . 电子测量技术,2021,44(16):116 − 122. [7] 莫爵贤, 王宇, 吴智恒, 等. 一种基于机器视觉的机加工件尺寸测量系统设计[J] . 机电技术,2018(3):25 − 27. [8] 卢清华, 许重川, 王华, 等. 基于机器视觉的大幅面陶瓷地砖尺寸测量研究[J] . 光学学报,2013,33(3):172 − 178. [9] 王晓杰, 莫绪涛, 陶新宇, 等. 基于机器视觉的低对比度物体尺寸测量研究[J] . 光学技术,2022,48(1):27 − 33. [10] 程敏杰, 王建文. 利用机器视觉的直齿轮在线测量方法研究[J] . 机械设计,2020,37(3):19 − 22. [11] CANNY J. A computational approach to edge detection[J] . IEEE Transactions on Pattern Analysis & Machine Intelligence,1986,8(6):184 − 203. [12] 王蒙. 基于机器视觉的微小零件检测分类[D]. 汉中: 陕西理工大学, 2020. [13] 唐松, 杨其华, 刘刚海. 基于Halcon的阀芯尺寸亚像素级测量[J] . 计算机工程与应用,2017,53(3):237 − 241. [14] 龚渠, 张伟, 李丽. 基于Halcon的拨叉脚端面尺寸测量[J] . 工具技术,2020,54(9):86 − 89. doi: 10.3969/j.issn.1000-7008.2020.09.021 [15] 邓斌攸, 潘云峰, 池志强, 等. 基于机器视觉的家具板件尺寸在线测量系统[J] . 木材科学与技术,2021,3(35):63 − 67. doi: 10.12326/j.2096-9694.2020080 -

下载:

下载: