Influence analysis of parameters of bushing on oil film characteristics of piston/bushing interface in hydraulic piston pump

-

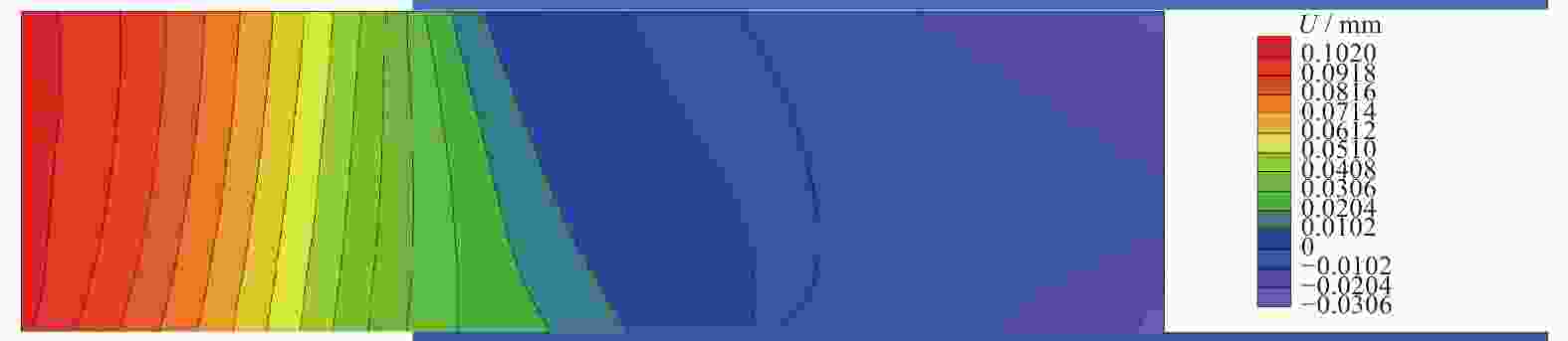

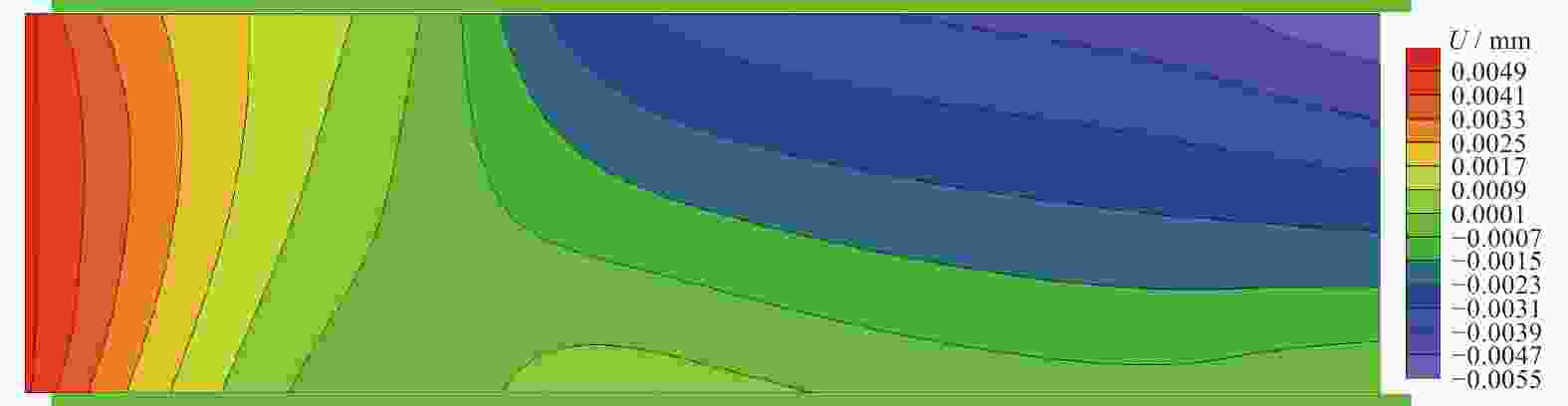

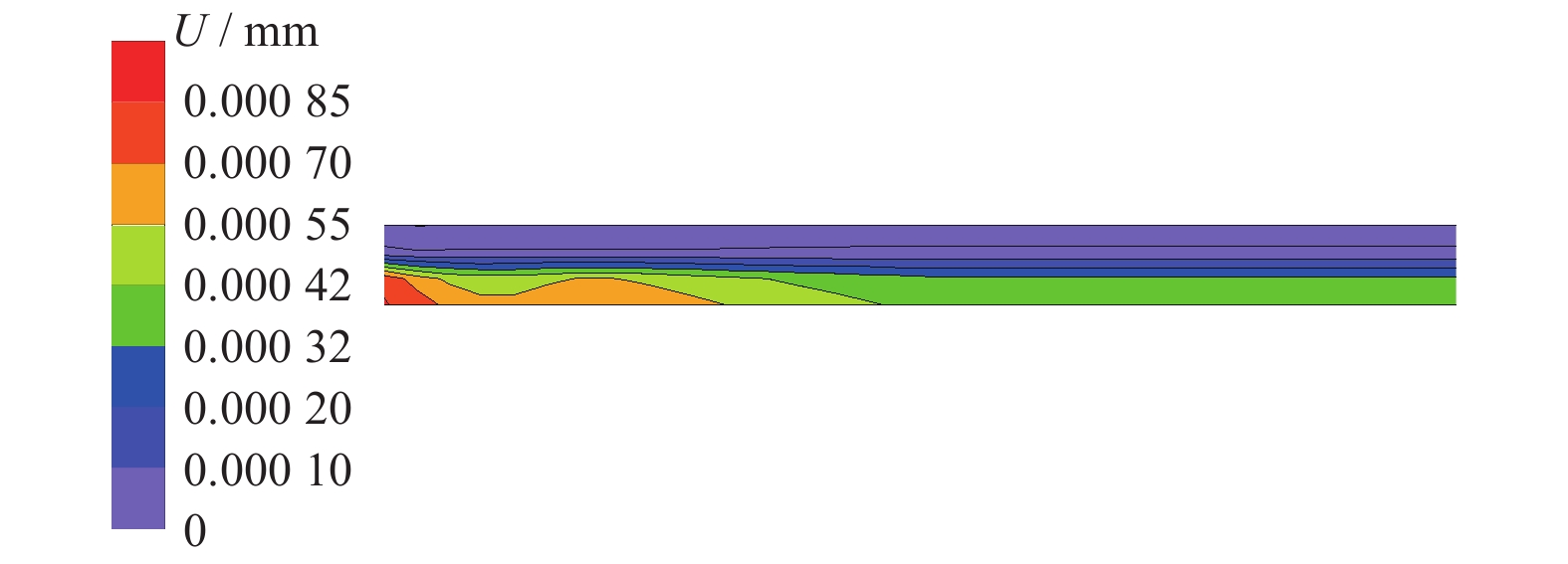

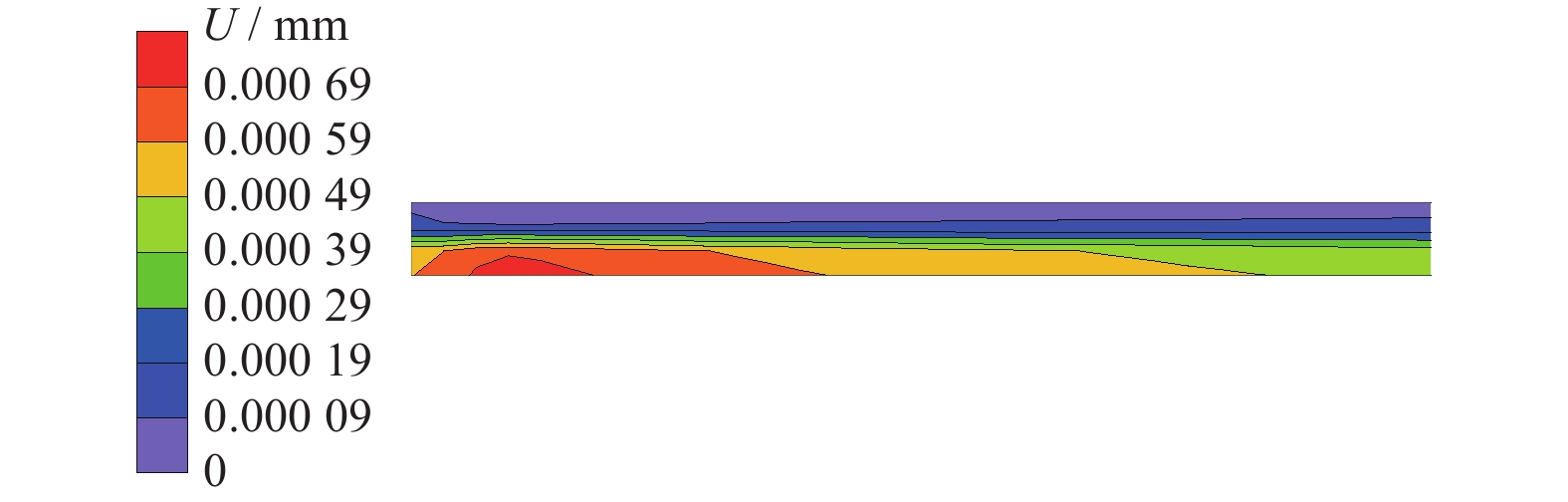

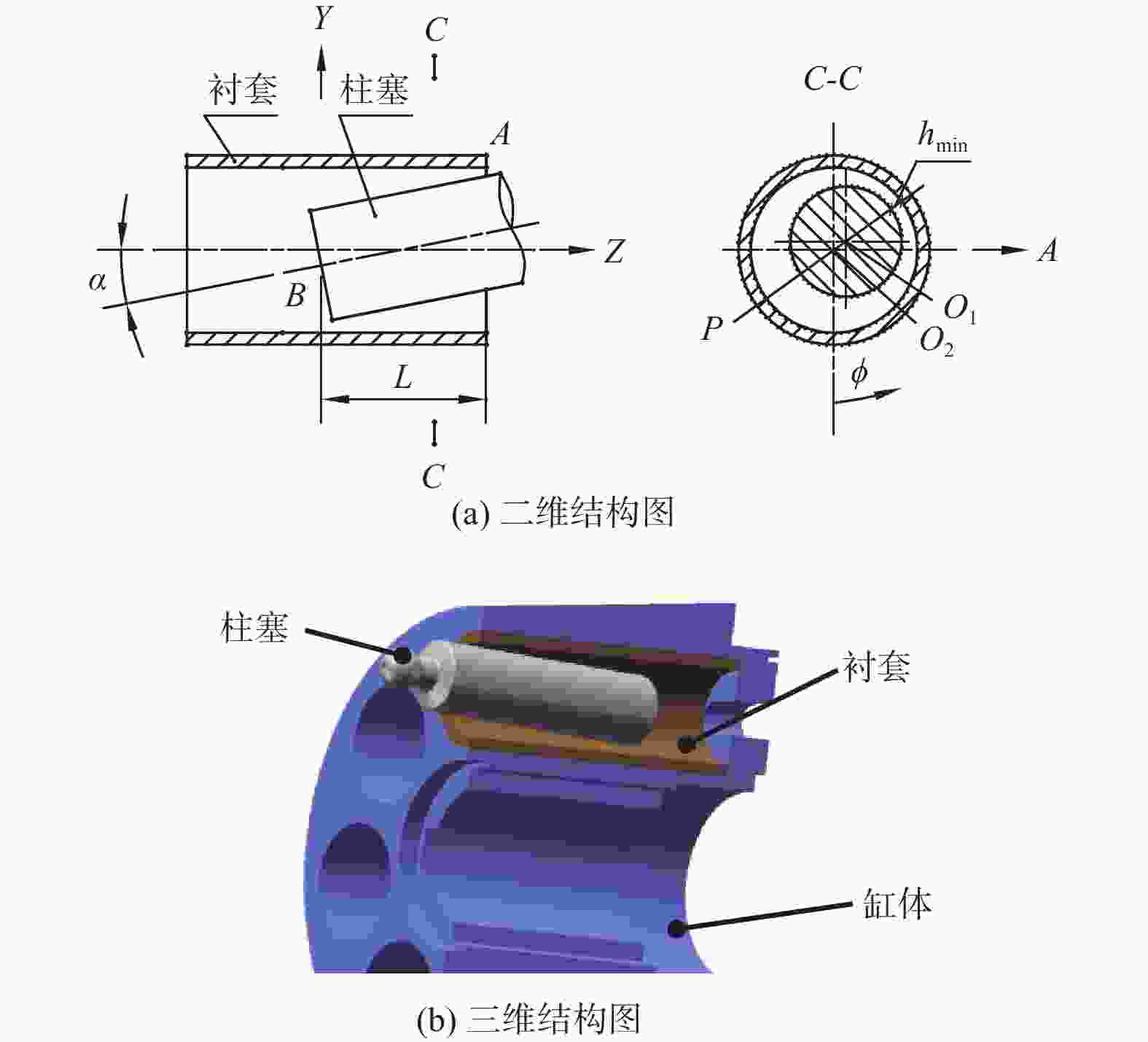

摘要: 为改善液压柱塞泵中柱塞副的磨损状况,建立流固耦合模型,求解流体域与固体域的相互作用。考虑柱塞变形和缸体孔衬套变形,讨论不同弹性模量的铜合金衬套材料和不同厚度的衬套对衬套变形和油膜厚度的影响。结果表明,衬套变形值随衬套材料弹性模量增加而减小,采用弹性模量小的铜合金衬套材料或适当增加衬套厚度能使油膜厚度增大,可以改善柱塞副润滑条件,延长柱塞泵的使用寿命。不同弹性模量的铜合金衬套材料和不同厚度的衬套对油膜厚度影响明显。研究结果为柱塞泵的优化设计提供一定的参考。Abstract: To better the wear condition of the piston/bushing interface, the fluid-structure model was created, the interaction between fluid domain and solid domain was studied, the elastic deformations of the piston and bushing were considered, the impact of different thickness of bushing and material with different elastic moduli on the film thickness and deformations of bushing was discussed. The results show that the deformations of bushing decrease with increasing modulus of elasticity, bushing of copper lining materials with smaller elastic modulus or increasing of thicknesses of the bushing properly can improve lubrication conditions of the piston/bushing interface and the service life of the piston pump. Elastic deformations of piston and bushing have significant influences on the film thickness. The results provide a reference for the optimization design of the piston pumps.

-

Key words:

- elastic deformations /

- piston pump /

- fluid-structure interaction /

- thickness of bushing

-

表 1 柱塞和衬套材料参数

Table 1. Material parameters of piston and bushing

材料参数 柱塞材料 衬套材料1 衬套材料2 弹性模量/Pa 2.1 × 1011 1.1 × 1011 0.9 × 1011 泊松比 0.3 0.3 0.3 密度/ (kg∙m−3) 7.8 × 103 8.9 × 103 8.9 × 103 表 2 模型参数

Table 2. Parameters of model

参数 数值 柱塞半径rp / mm 16 柱塞长度/ mm 100 柱塞副起始油膜长度L/ mm 60 柱塞副间隙c/ μm 0.03 常温下润滑油密度ρ/ (kg·m−3 ) 850 油液动力黏度µ/ (Pa·s) 0.027 斜盘倾角β/ (°) 12 工作压力P0 / MPa 50 斜盘转速n/ (r·min−1) 3600 -

[1] WANG D, SONG Y, TIAN J, et al. Research on the fluid film lubrication between the piston-cylinder interface[J] . AIP Advances,2018,8(10):105330. doi: 10.1063/1.5064382 [2] MA X, WANG Q J, LU X, et al. A transient hydrodynamic lubrication model for piston/cylinder interface of variable length[J] . Tribology International,2018,118:227 − 239. doi: 10.1016/j.triboint.2017.09.035 [3] YI F, MASATAKA S. Mixed lubrication characteristics between the pistonand cylinder in hydraulic piston pump-motor[J] . Journal of Tribology,1995,117(1):80 − 85. doi: 10.1115/1.2830610 [4] YAMAGUCHI A, TANIOKA Y. Motion of pistons in piston-type hydraulic machines: 1 st report: theoretical analysis[J] . Bulletin of the JSME,1976,19(130):402 − 407. doi: 10.1299/jsme1958.19.402 [5] KUMAR S, BERGADA J M. The effect of piston grooves performance in an axial piston pumps via CFD analysis[J] . International Journal of Mechanical Sciences,2013,66:168 − 179. doi: 10.1016/j.ijmecsci.2012.11.005 [6] MECHALIKH M, ZIDANE I, BENHAMOU A, et al. Modelling and analysis of slip conditions in hydrodynamic lubrication of a piston skirt-cylinder contact[J] . Industrial Lubrication and Tribology,2020,72(10):1181 − 1187. doi: 10.1108/ILT-11-2019-0483 [7] PELOSI M, IVANTYSYNOVA M. Heat transfer and thermal elastic deformation analysis on the piston/ cylinder interface of axial piston machines[J] . Journal of Tribology,2012,134(4):041101. doi: 10.1115/1.4006980 [8] PELOSI M, IVANTYSYNOVA M. The impact of axial piston machines mechanical parts constraint conditions on the thermo-elastohydrodynamic lubrication analysis of the fluid film interfaces[J] . International Journal of Fluid Power,2013,14(3):35 − 51. doi: 10.1080/14399776.2013.10801412 [9] JIANG J H, WANG K L, WANG Z B, et al. The impact of bushing thickness on the piston/cylinder interface in axial piston pump[J] . IEEE Access,2019,7:24971 − 24977. doi: 10.1109/ACCESS.2019.2900668 [10] NIE S L, GUO M, YIN F L, et al. Research on fluid-structure interaction for piston/cylinder tribopair of seawater hydraulic axial piston pump in deep-sea environment[J] . Ocean Engineering,2021,219:108222. doi: 10.1016/j.oceaneng.2020.108222 [11] 曹学鹏, 鞠健阳, 田富元, 等. 深水环境下压力补偿泵柱塞副的润滑特性分析[J] . 重庆大学学报,2022,45(10):62 − 76. [12] 杭旸, 闫康昊, 黄丹. 计入柱塞套弹性变形的柱塞副摩擦与密封特性分析[J] . 中国机械工程,2023,34(1):17 − 26. [13] LIU H P, XU H, PETER J. Ellison, et al. Application of computational fluid dynamics and fluid–structure interaction method to the lubrication study of a rotor–bearing system[J] . Tribology Letters,2010,38:325 − 336. doi: 10.1007/s11249-010-9612-6 [14] LIN Q Y, BAO Q K, LI K J, et al. An investigation into the transient behavior of journal bearing with surface texture based on fluid-structure interaction approach[J] . Tribology International,2018,118:246 − 255. doi: 10.1016/j.triboint.2017.09.026 [15] XU B, ZHANG J, YANG H, et al. Investigation on the radial micro-motion about piston of axial piston pump[J] . Chinese Journal of Mechanical Engineering,2013,26(2):325 − 333. doi: 10.3901/CJME.2013.02.325 [16] LYU F, ZHANG J, SUN G, et al. Research on wear prediction of piston/cylinder pair in axial piston pumps[J] . Wear,2020,456:203338. -

下载:

下载: