Research on axial U-shaped water channel cooling structure of hub motor

-

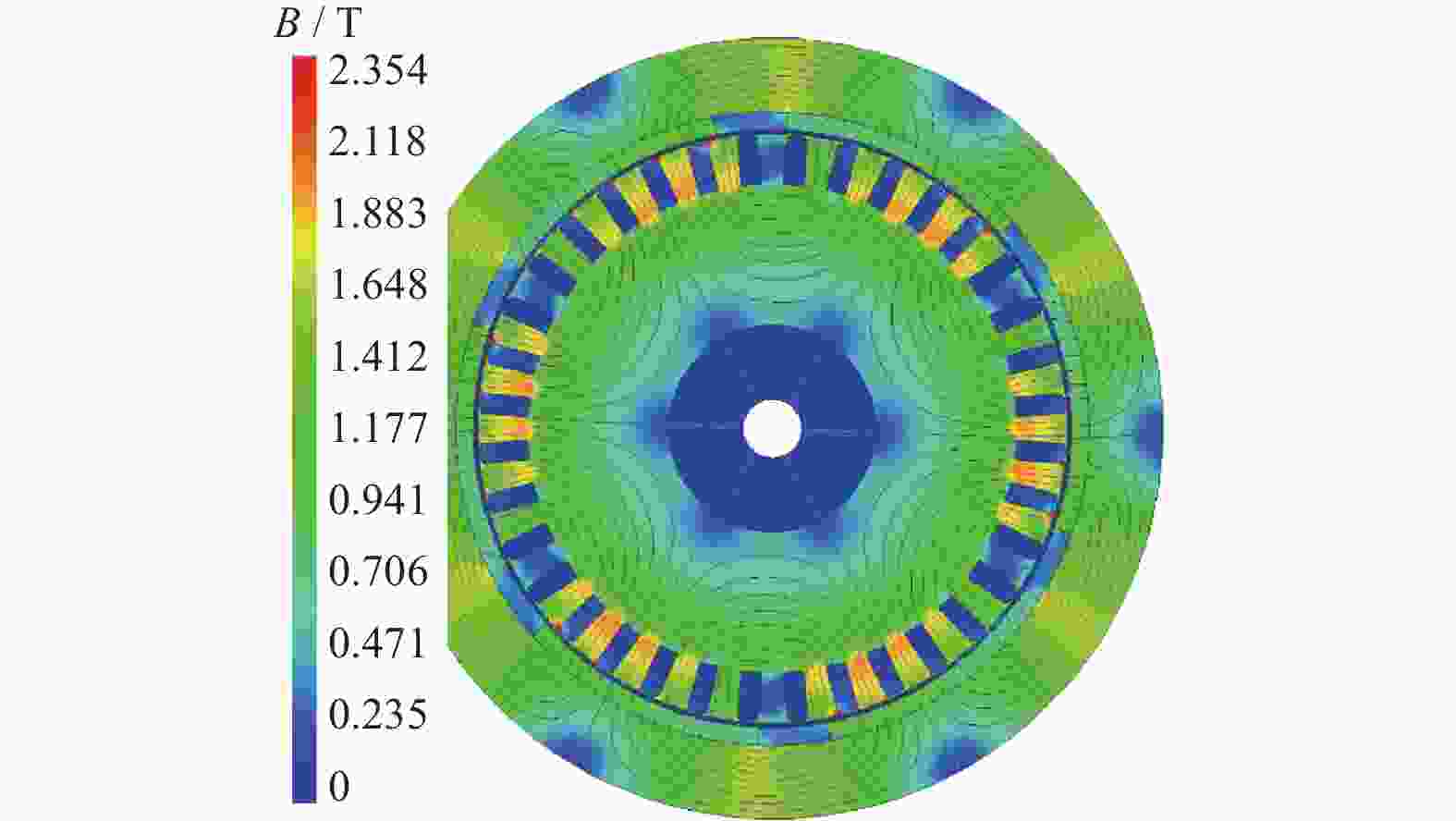

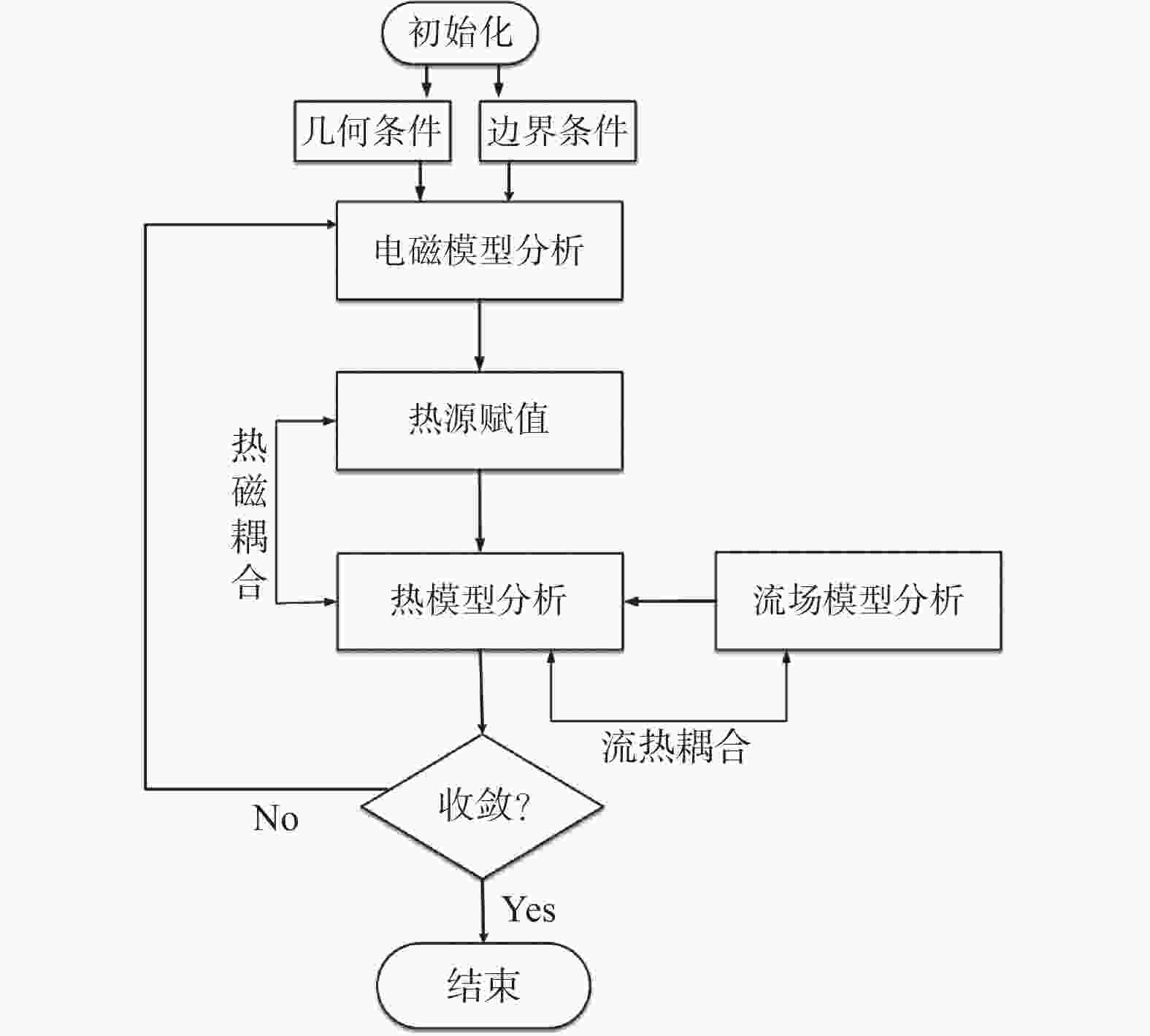

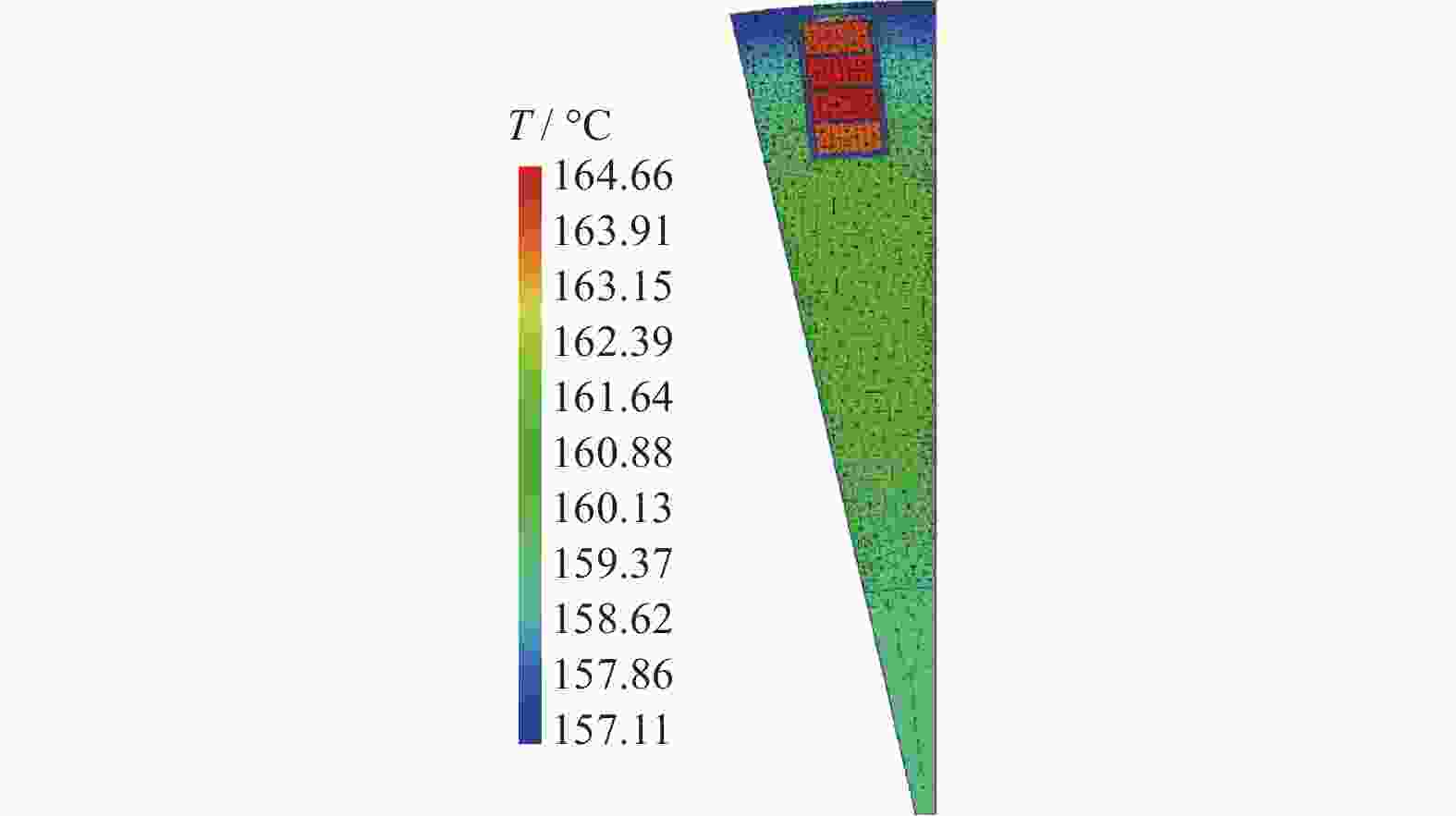

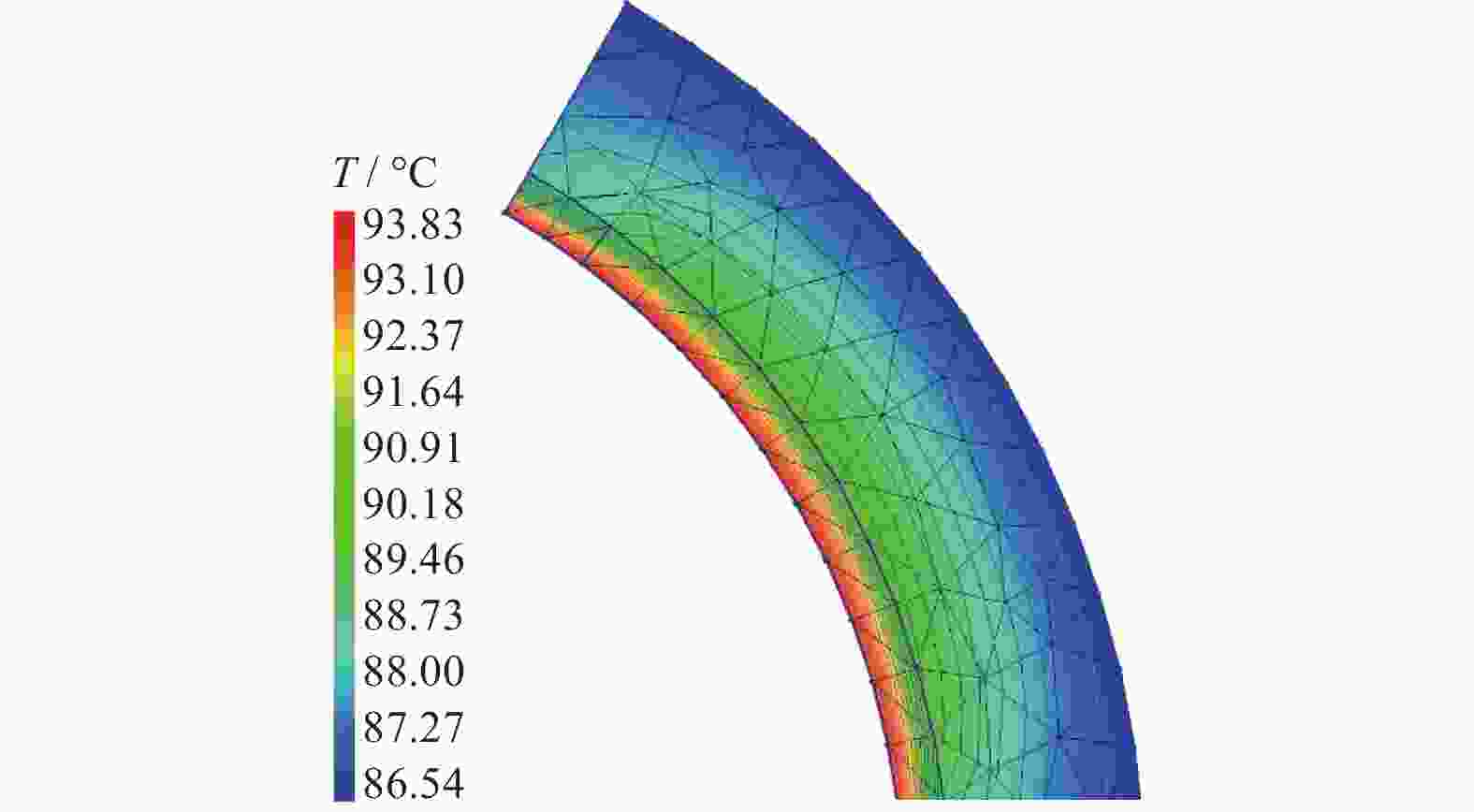

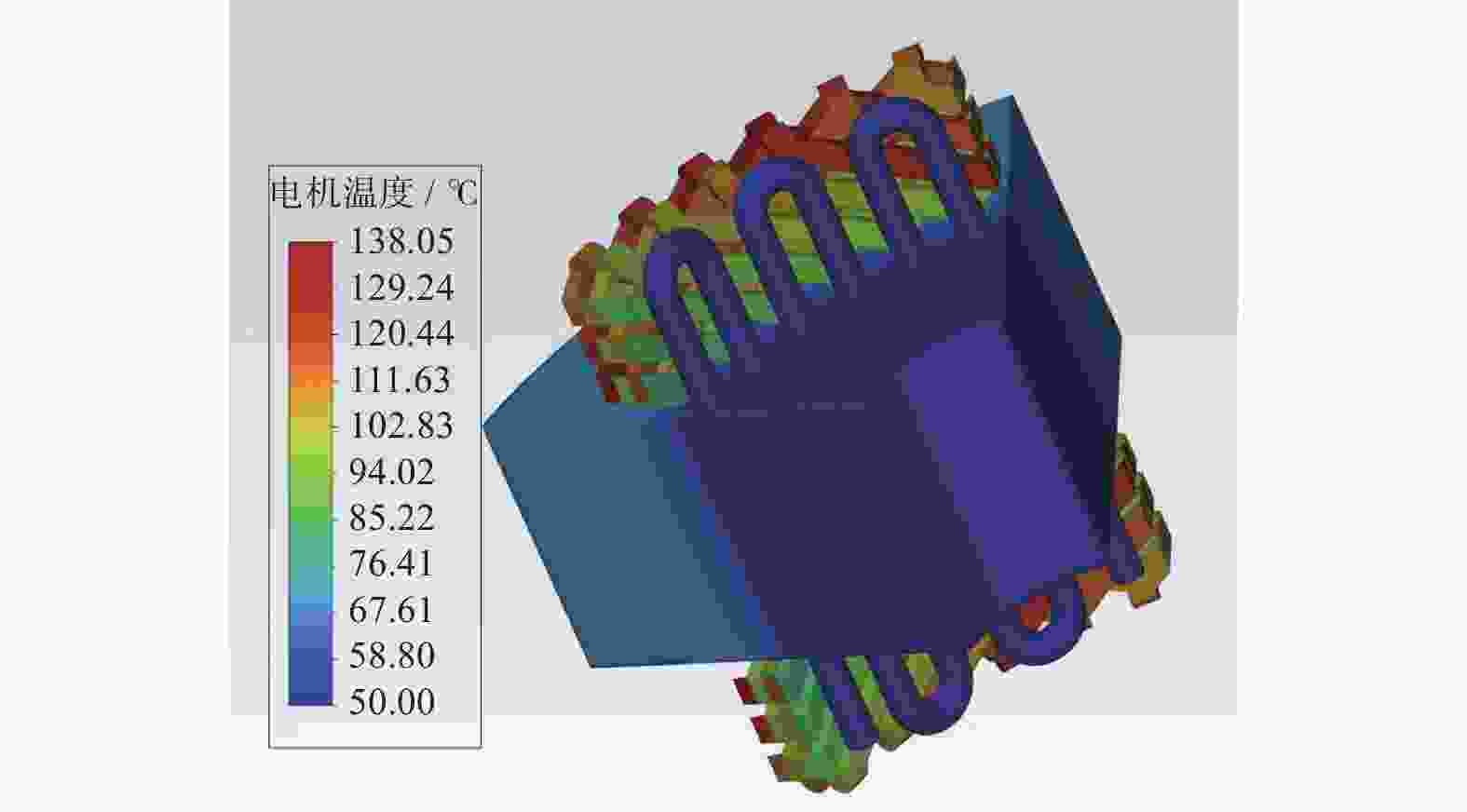

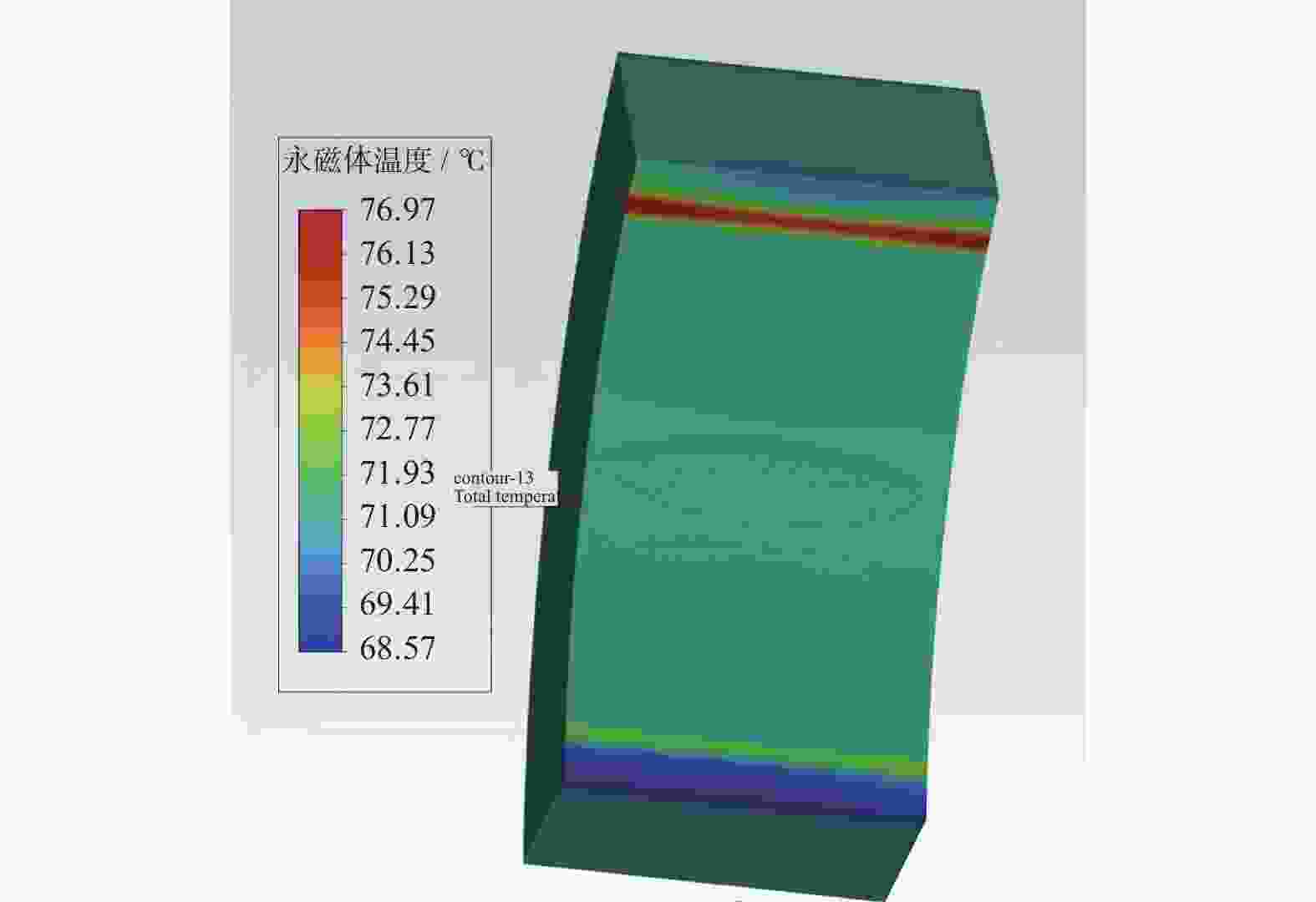

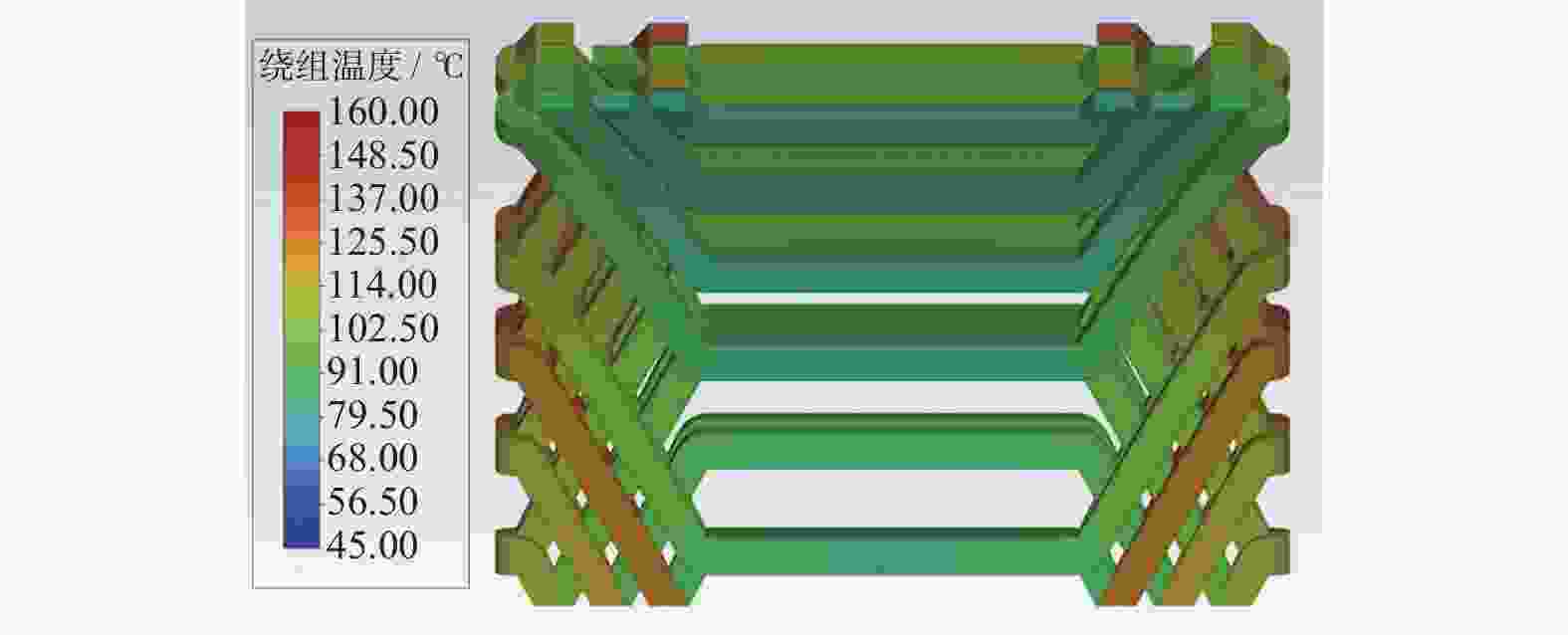

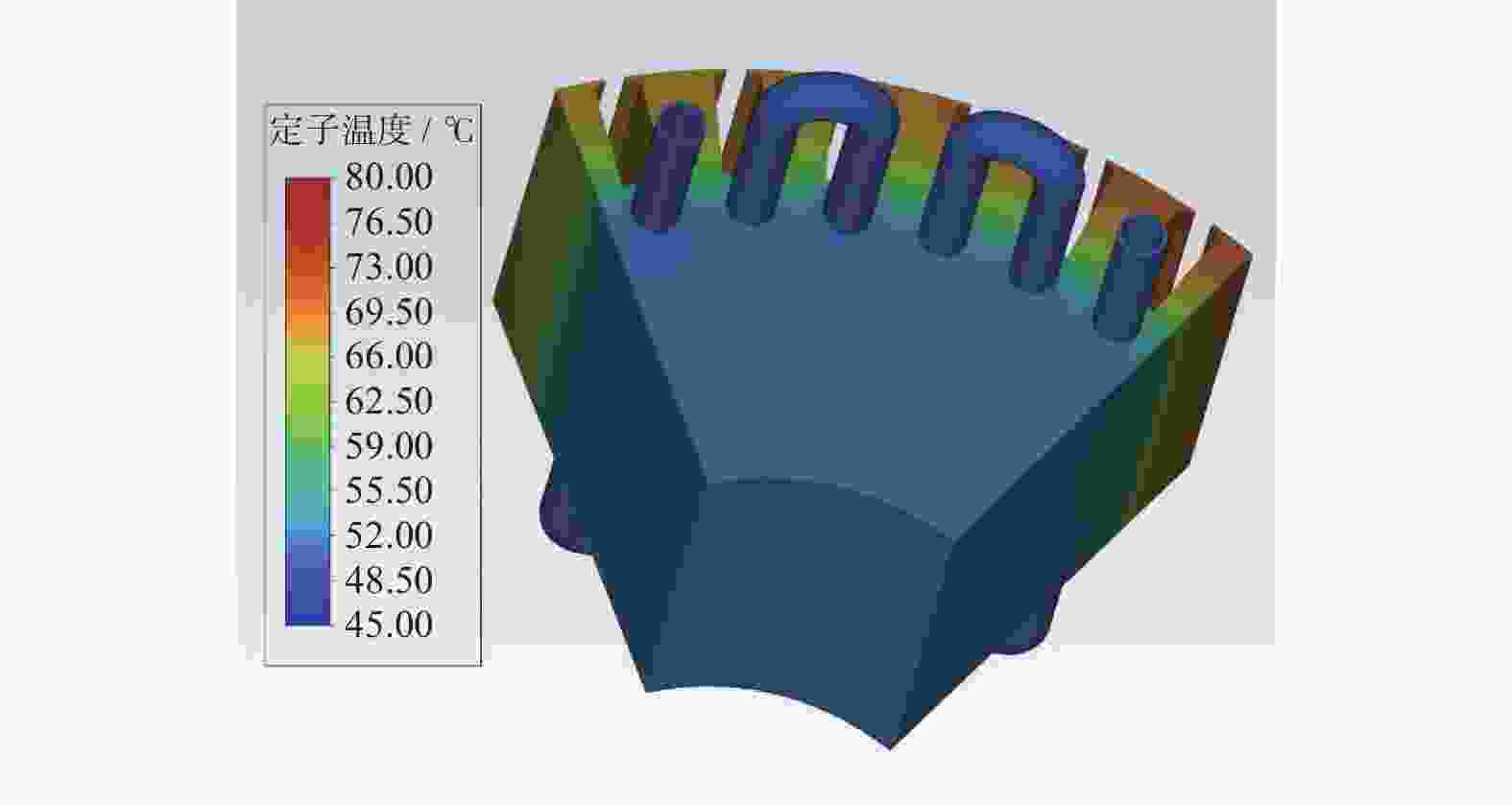

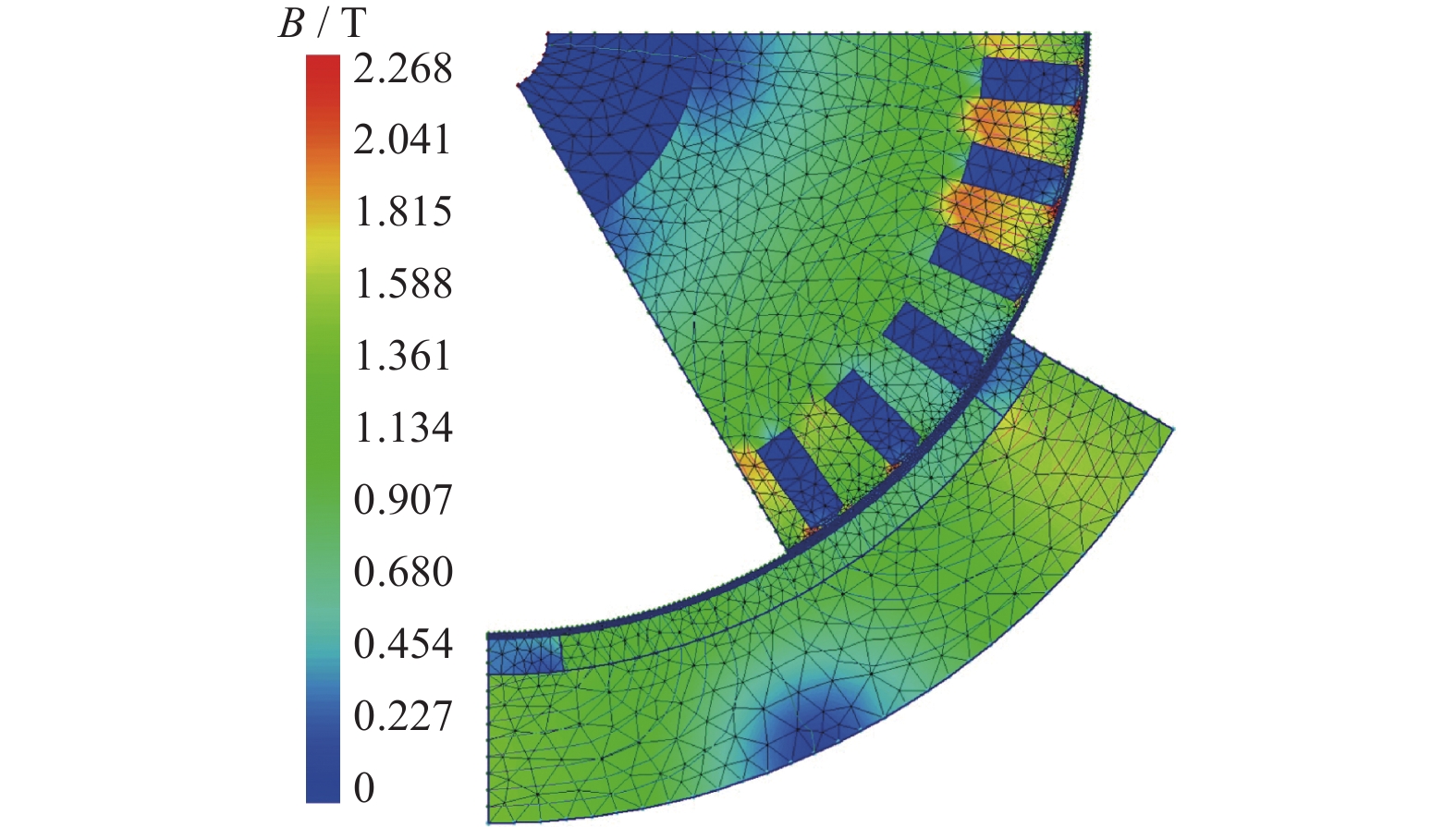

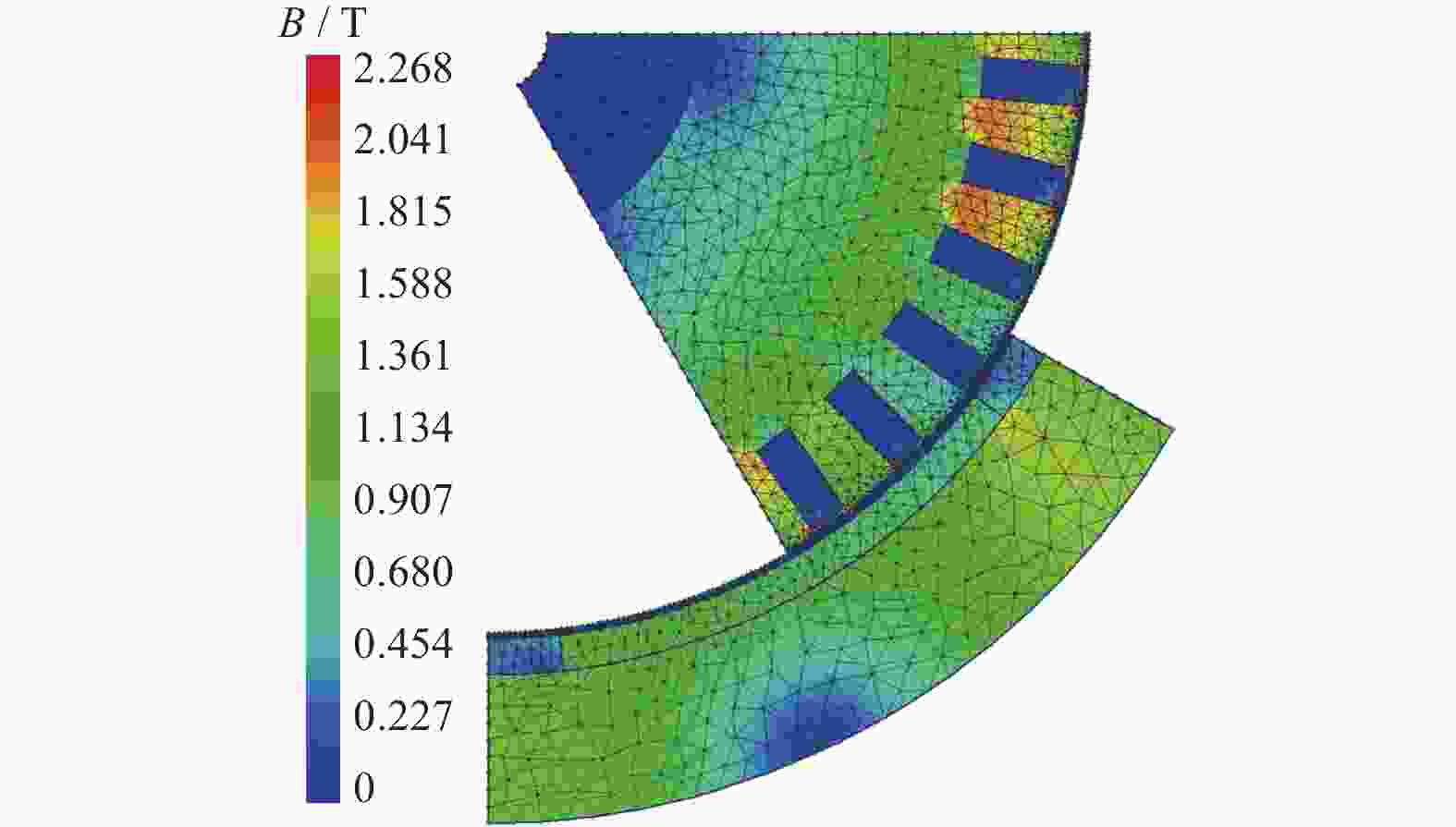

摘要: 为解决电动汽车运行中轮毂电机散热困难及端部绕组高温的问题,以一款电动汽车外转子轮毂电机为研究对象,提出一种新型的轴向U型水道冷却结构设计. 建立轮毂电机磁热耦合仿真模型,通过对电机损耗分析获得电机温度场分布,进行轴向U型水道的设计与流热耦合分析. 结果表明,采用U型冷却流道后,电机内部的高温,特别是端部绕组的高温问题得到有效改善,温升降低了28.7%.Abstract: In order to solve the problems of heat dissipation difficulty and high temperature of end windings in the operation of electric vehicles, a new type of axial U-shaped water channel cooling structure design was proposed by taking an external rotor hub motor of electric vehicles as the research object. Firstly, the magnetothermal coupling simulation model of the hub motor was established, the temperature field distribution of the motor was obtained through the motor loss analysis, and the design and fluid-thermal coupling analysis of the axial U-shaped waterway were carried out. The results show that the use of U-shaped cooling channel could effectively improved the high temperature inside the motor, especially the high temperature problem of the end winding, and the temperature rise was reduced by 28.7%.

-

Key words:

- hub motor /

- magnetothermal coupling /

- loss analysis /

- fluid-thermal coupling /

- cooling

-

表 1 电机主要参数

Table 1. Main parameters of motor

参数名称 参数值 额定功率/kW 25 额定转速/(r·min−1) 1000 定子直径/mm 200 永磁体长度/mm 120 气隙厚度/mm 1.5 铁心长度/mm 120 绕组层数 4 槽/极数 36,6 表 2 额定工况下轮毂电机主要损耗

Table 2. Main losses of hub-motor under rated conditions

部件 损耗功率/W 定子 66.54 转子 1.21 槽内绕组 1482.49 永磁体 8.04 表 3 各部位的损耗功率

Table 3. Power lost in each part

部件 损耗功率/W 绕组 1431.56 定子 66.57 转子 1.29 永磁体 7.80 表 4 冷却前后的温度

Table 4. Temperature before and after cooling

部位 冷却前温度/℃ 冷却后温度/℃ 温度降低百分比/% 定子 157.3 66.0 58.0 转子 88.7 55.0 38.0 磁铁 92.4 71.9 22.2 端部绕组 160.8 114.0 29.1 槽内绕组 163.0 102.0 37.4 -

[1] LI L, LI W L, LI D, et al. Influence of sleeve thickness and various structures on eddy current losses of rotor parts and temperature field in surface mounted permanent magnet synchronous motor[J] . IET E-lectric Power Applications,2018,12(8):1183 − 1191. doi: 10.1049/iet-epa.2018.0083 [2] 余中军, 陈祖涛, 杨君坦. 电机端部绕组表面对流换热系数的研究[J] . 大电机技术,2023(3):8 − 12. doi: 10.3969/j.issn.1000-3983.2023.03.002 [3] 杨学威, 张小发. 电机壳体Z字型冷却水道设计[J] . 电机与控制应用,2016,43(9):62 − 65. [4] 王晓远, 杜静娟. CFD分析车用电机螺旋水路的散热特性[J]. 电工技术学报, 2018, 33(4): 955-963. [5] WANG X. Heat dissipation of three permanent magnet synchronous motors integrated with heat pipes[J]. International Journal of Thermophysics, 2021, 42(5): 1−20. [6] 吴柏禧, 万珍平, 张昆, 等. 考虑温度场和流场的永磁同步电机折返型冷却水道设计[J]. 电工技术学报, 2019, 34(11): 2306−2314. [7] 孟大伟, 刘兆江, 孙兵成. 采煤机用防爆型水冷电机的设计[J] . 哈尔滨理工大学学报,2009,14(2):55 − 58. doi: 10.15938/j.jhust.2009.02.016 [8] 李翠萍, 柴凤, 程树康. 冷却水流速对汽车水冷电机温升影响研究[J]. 电机与控制学报, 2012, 16(9): 1−8. [9] 王钰琦. 永磁同步电机温度场分析与冷却结构设计[D]. 杭州: 浙江大学, 2020. [10] 陈浈斐, 邢宁, 马宏忠, 等. 分数槽永磁电机永磁体谐波涡流损耗建模与分析[J]. 电工技术学报, 2022, 37(14): 3514−3527. [11] 王光辉, 田德文, 刘华源. 车用轮毂电机多物理场耦合分析[J]. 车辆与动力技术, 2016(3): 27−32. [12] 王晓远, 高鹏. 电动汽车用油内冷永磁轮毂电机三维温度场分析[J]. 电机与控制学报, 2016, 20(3): 36−42. [13] 刘细平, 曾剑, 徐晨. 电动汽车用开关磁阻电机温度场分析研究[J] . 微特电机,2017,45(1):23 − 25 , 43. -

下载:

下载: