Numerical simulation and experimental study of ultrasonic machining of aluminum honeycomb core

-

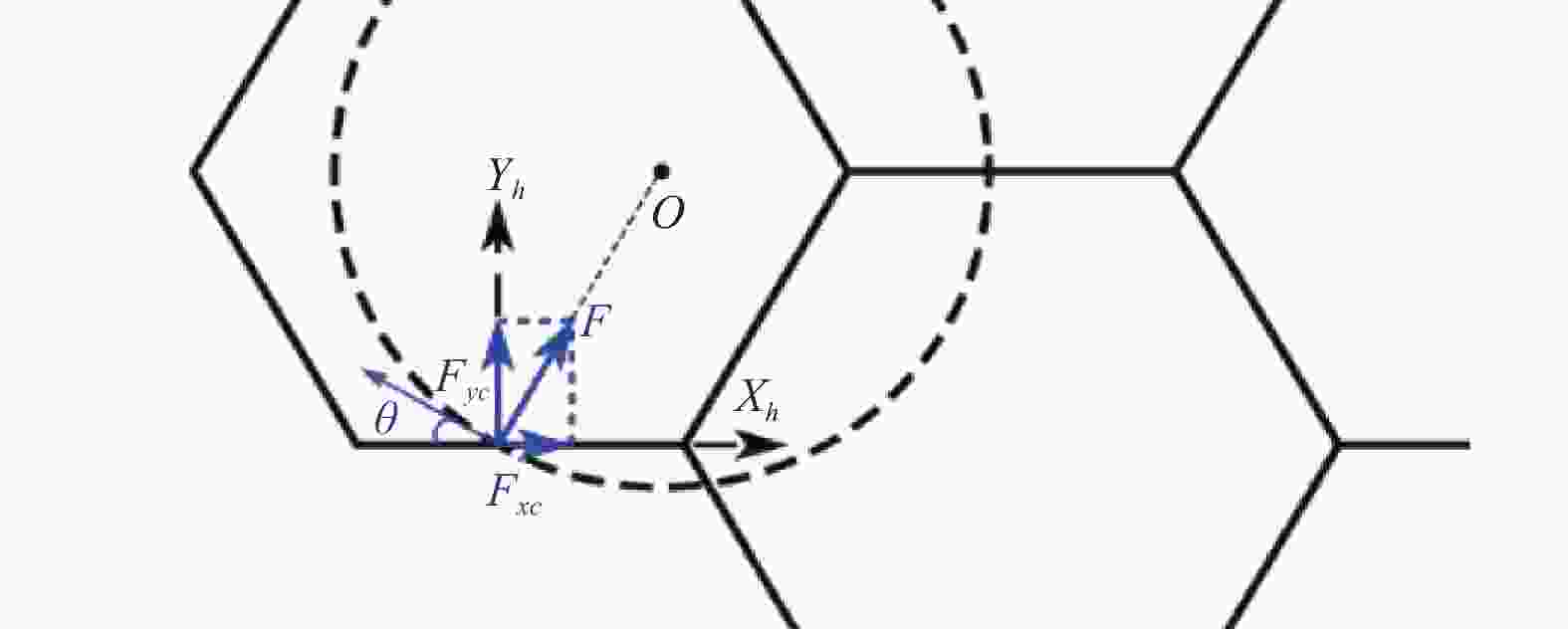

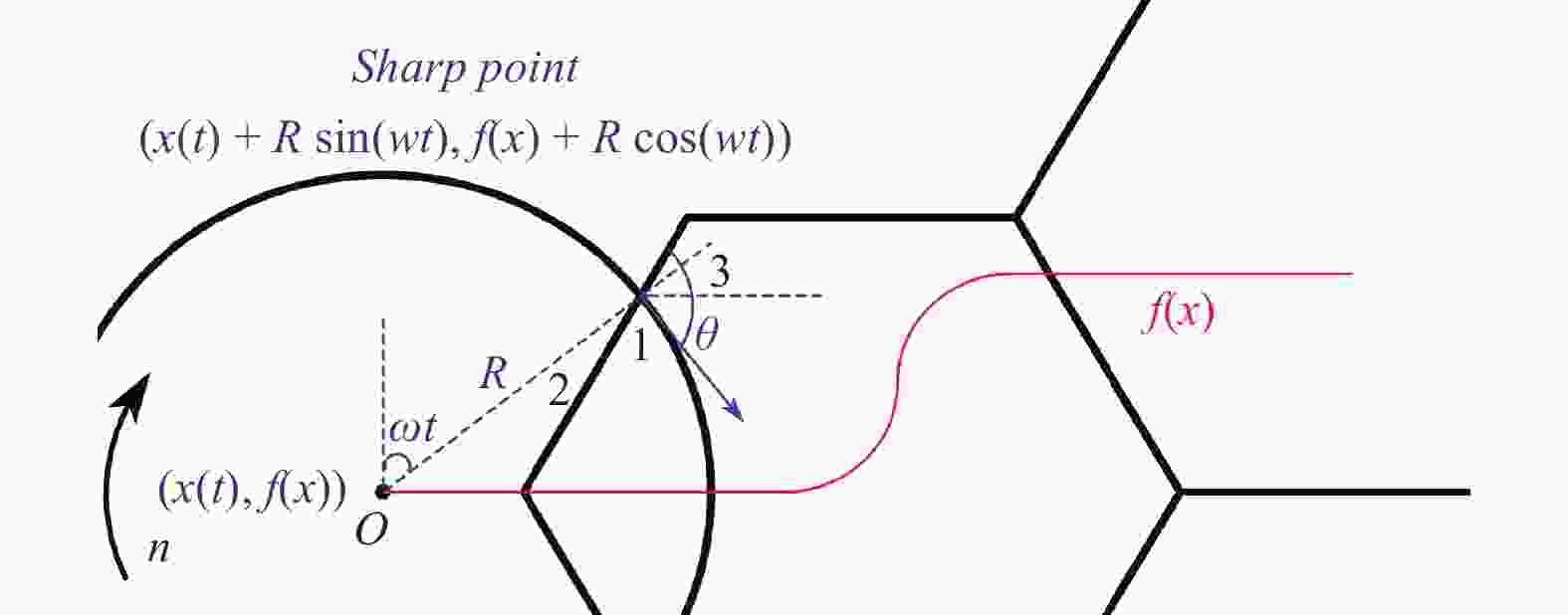

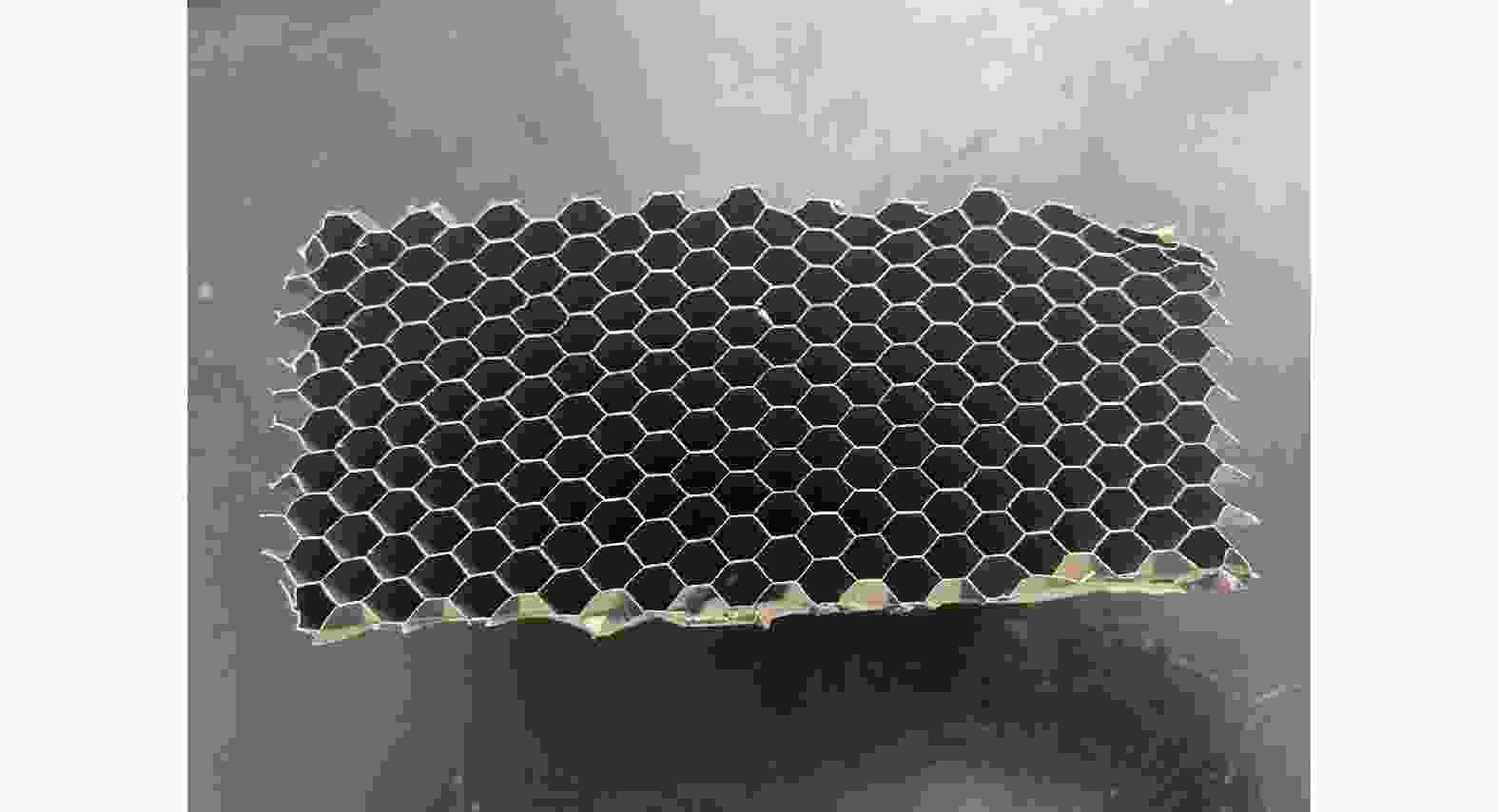

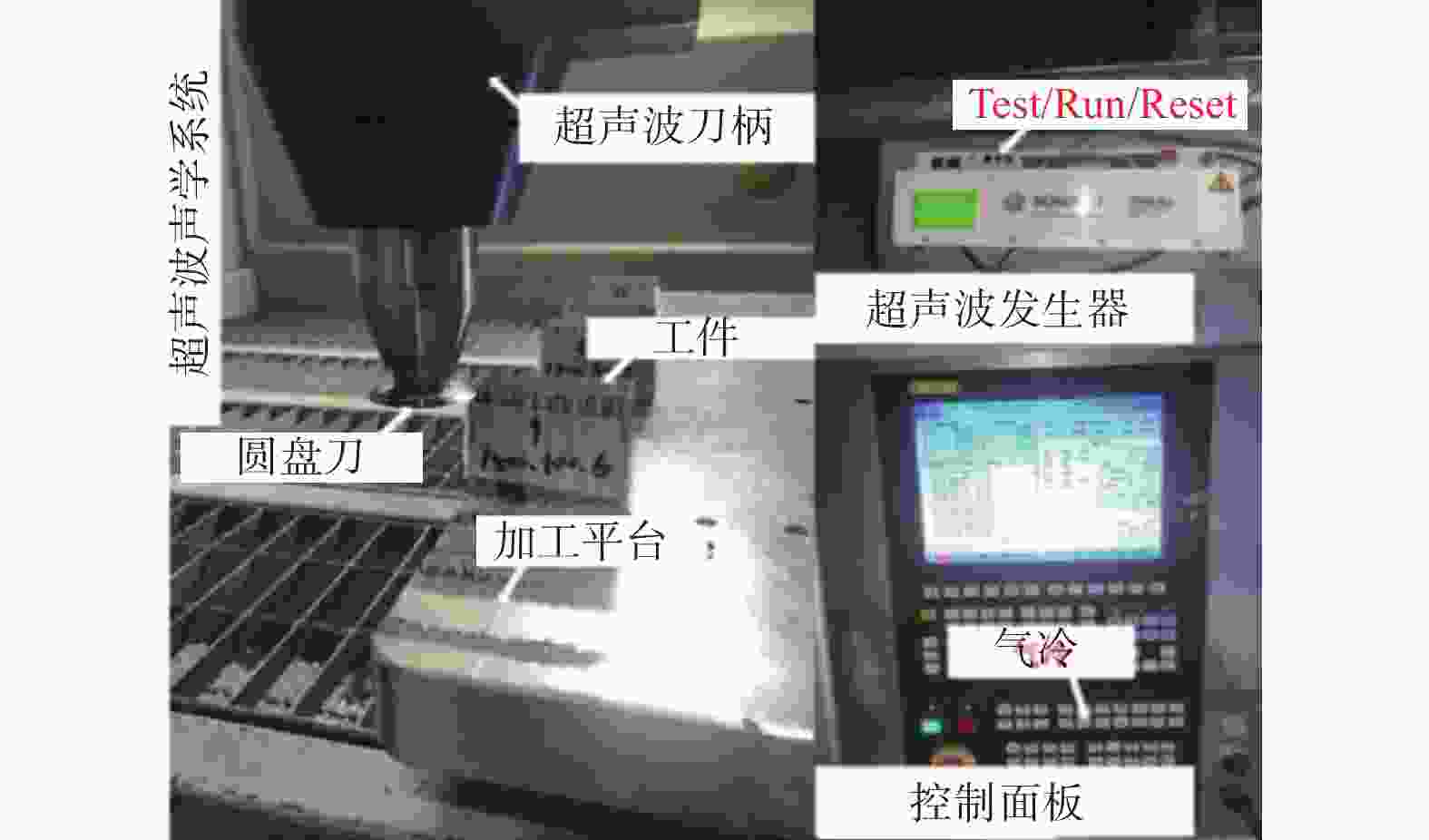

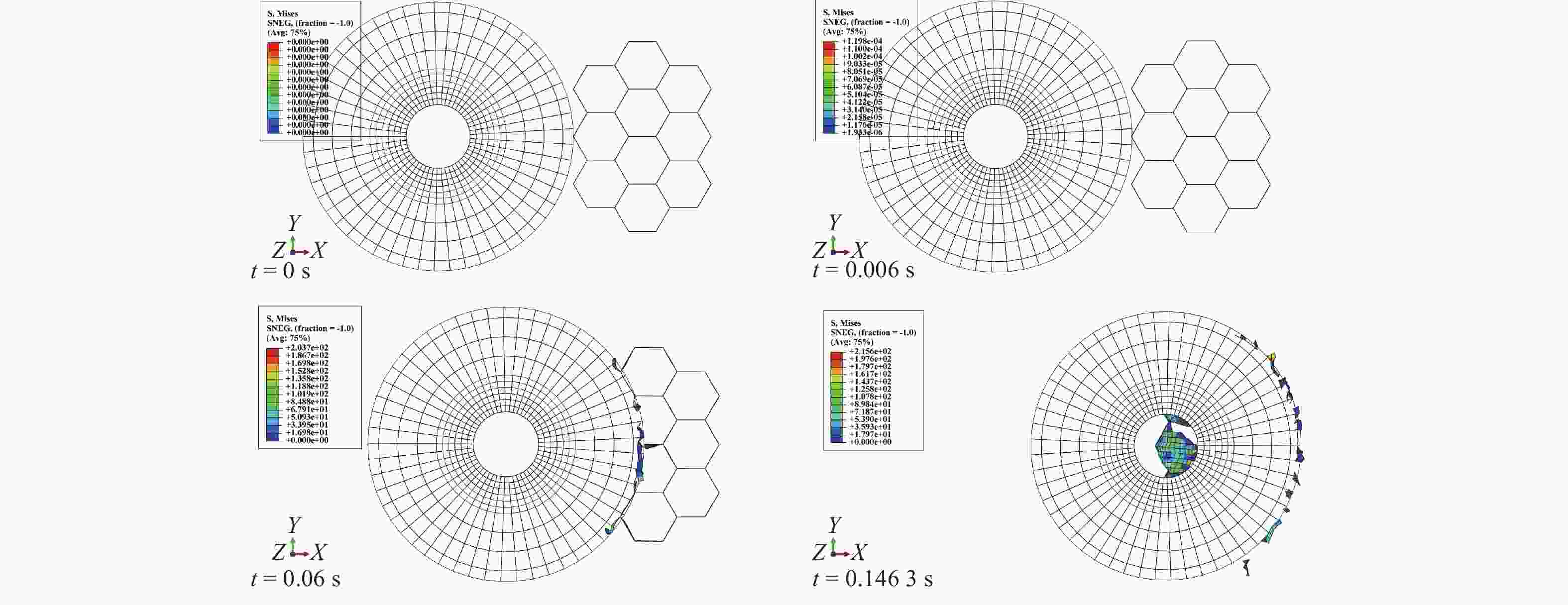

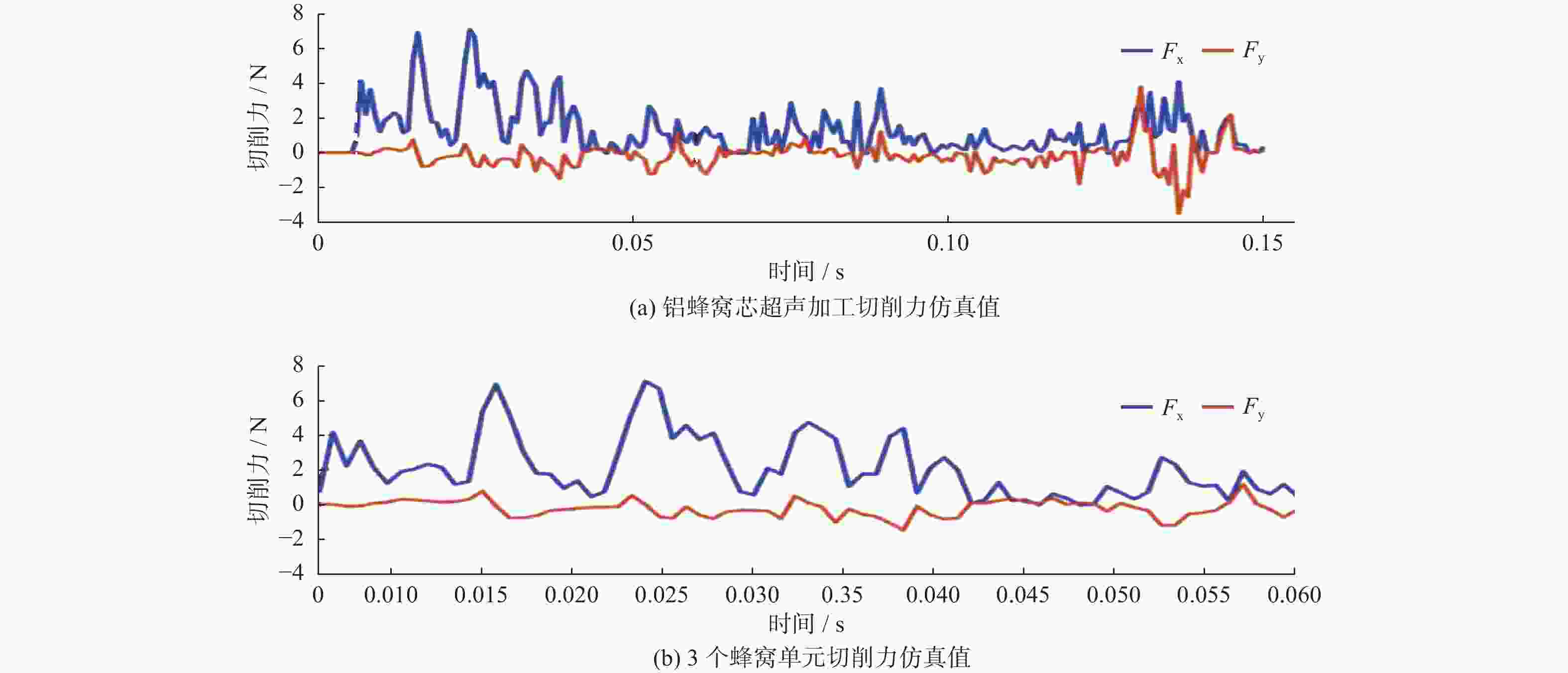

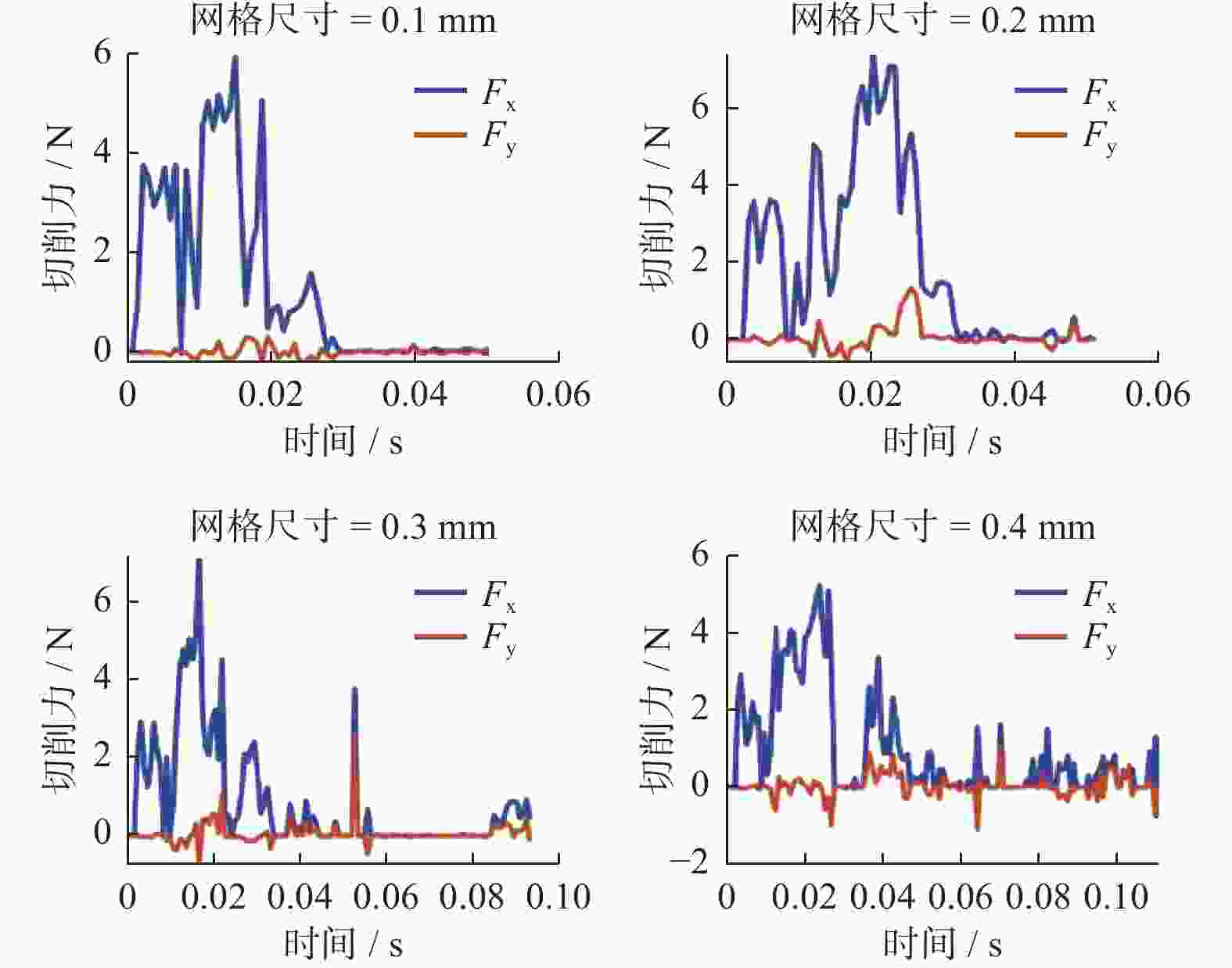

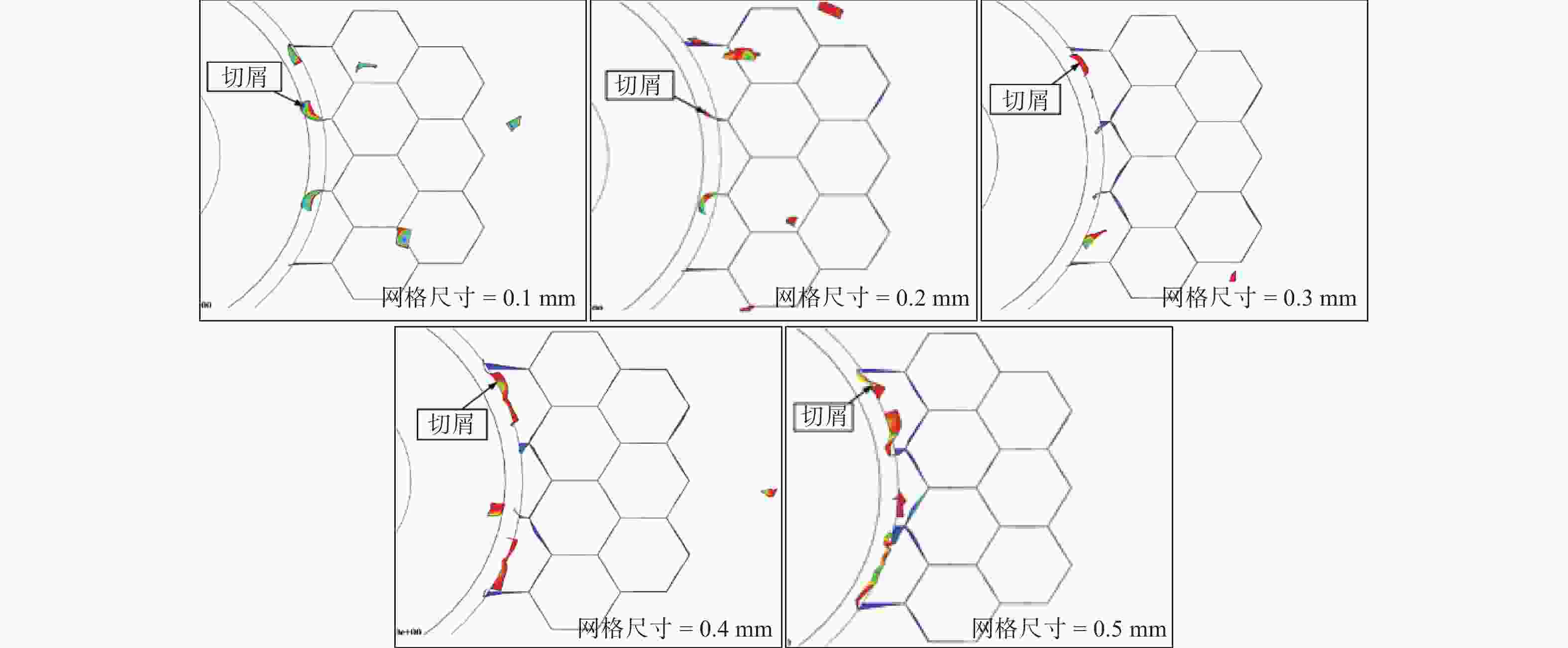

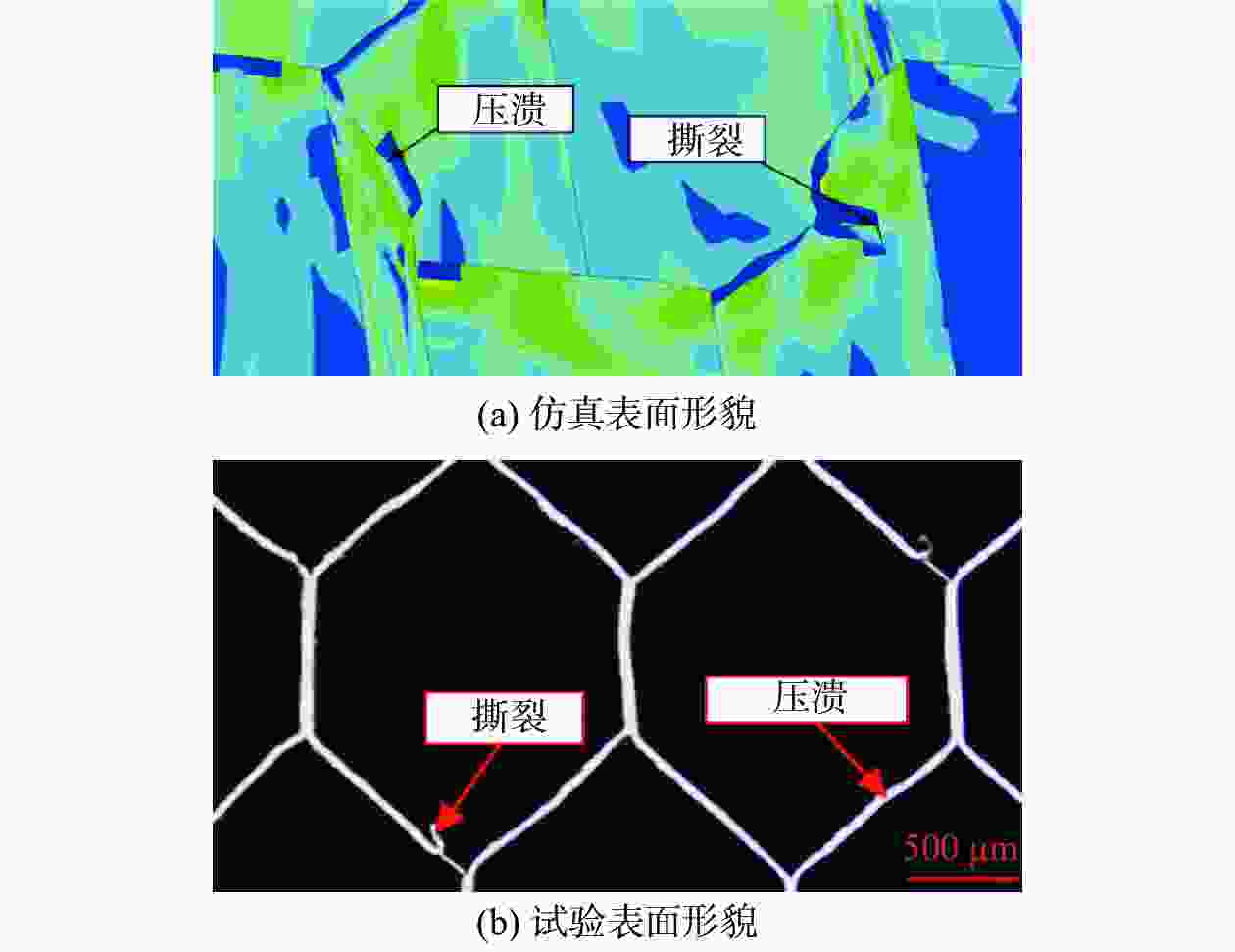

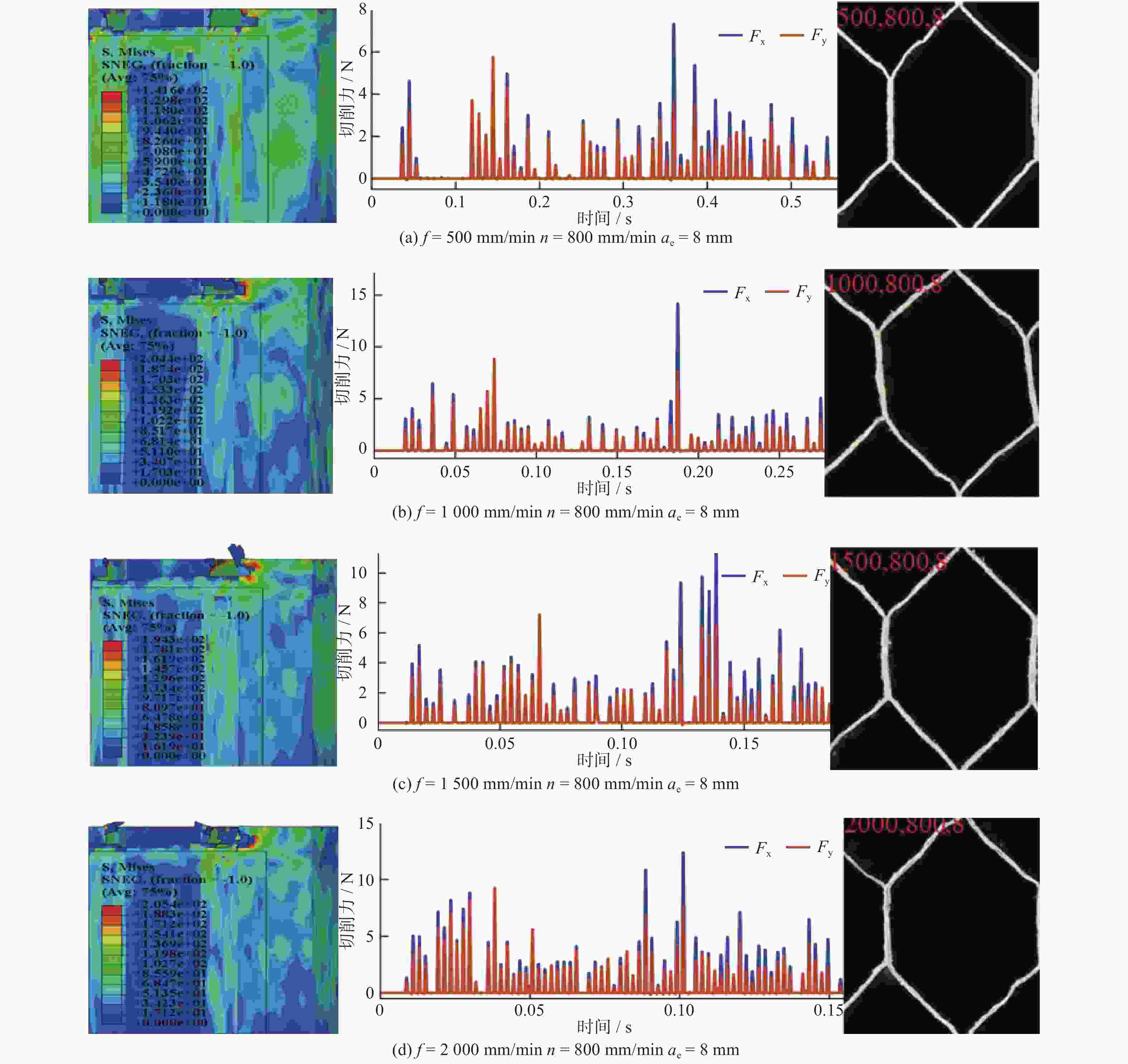

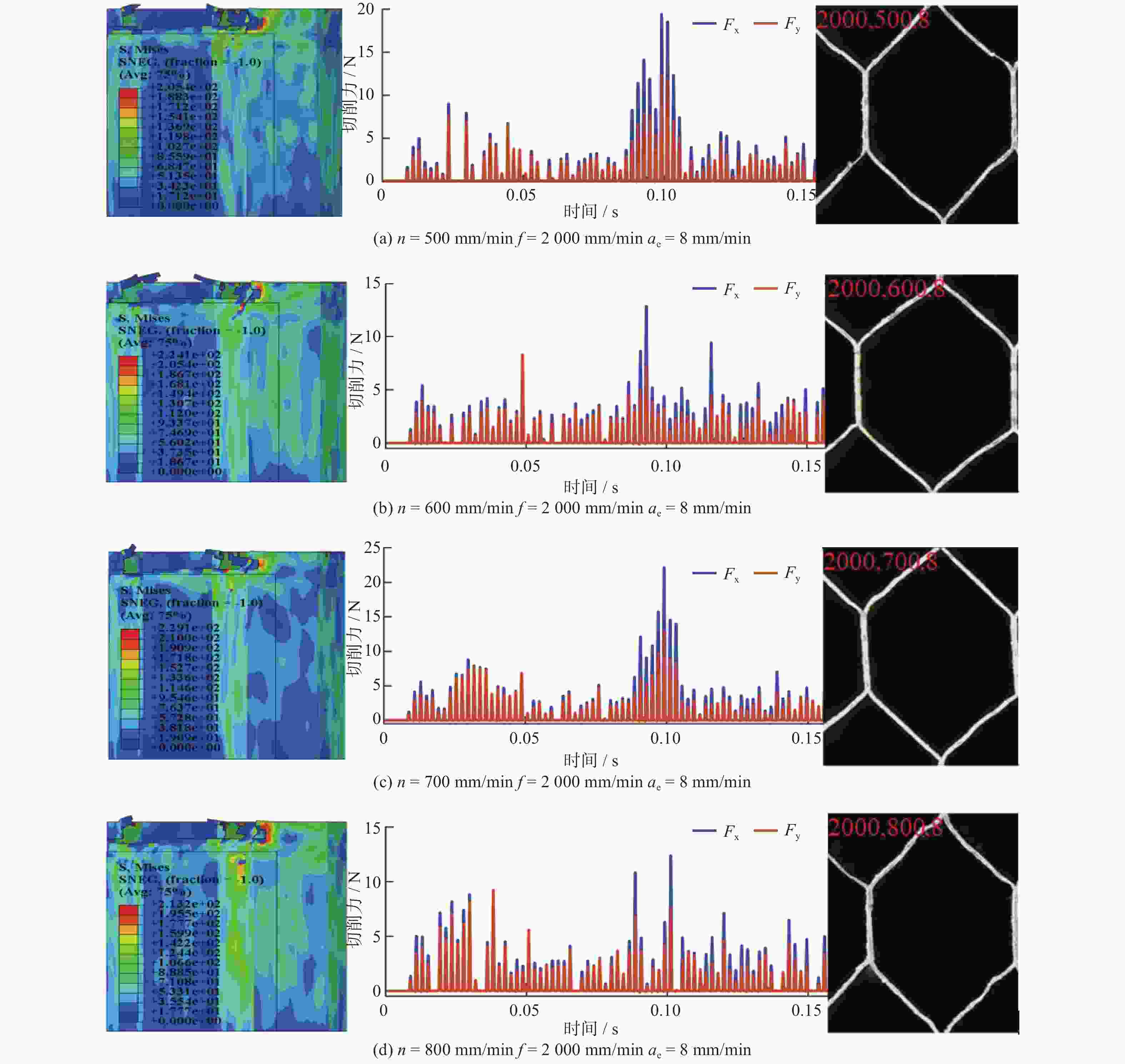

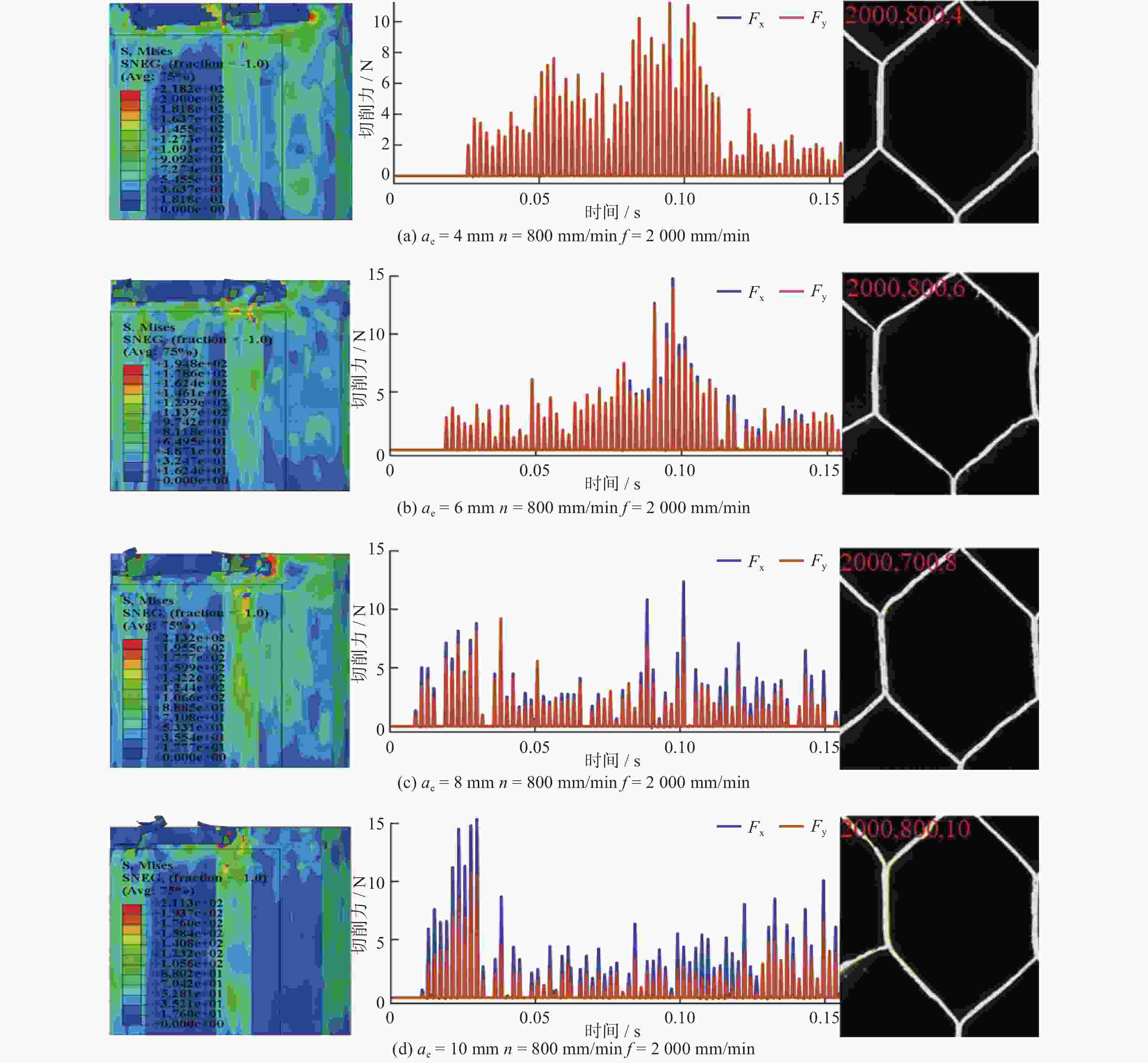

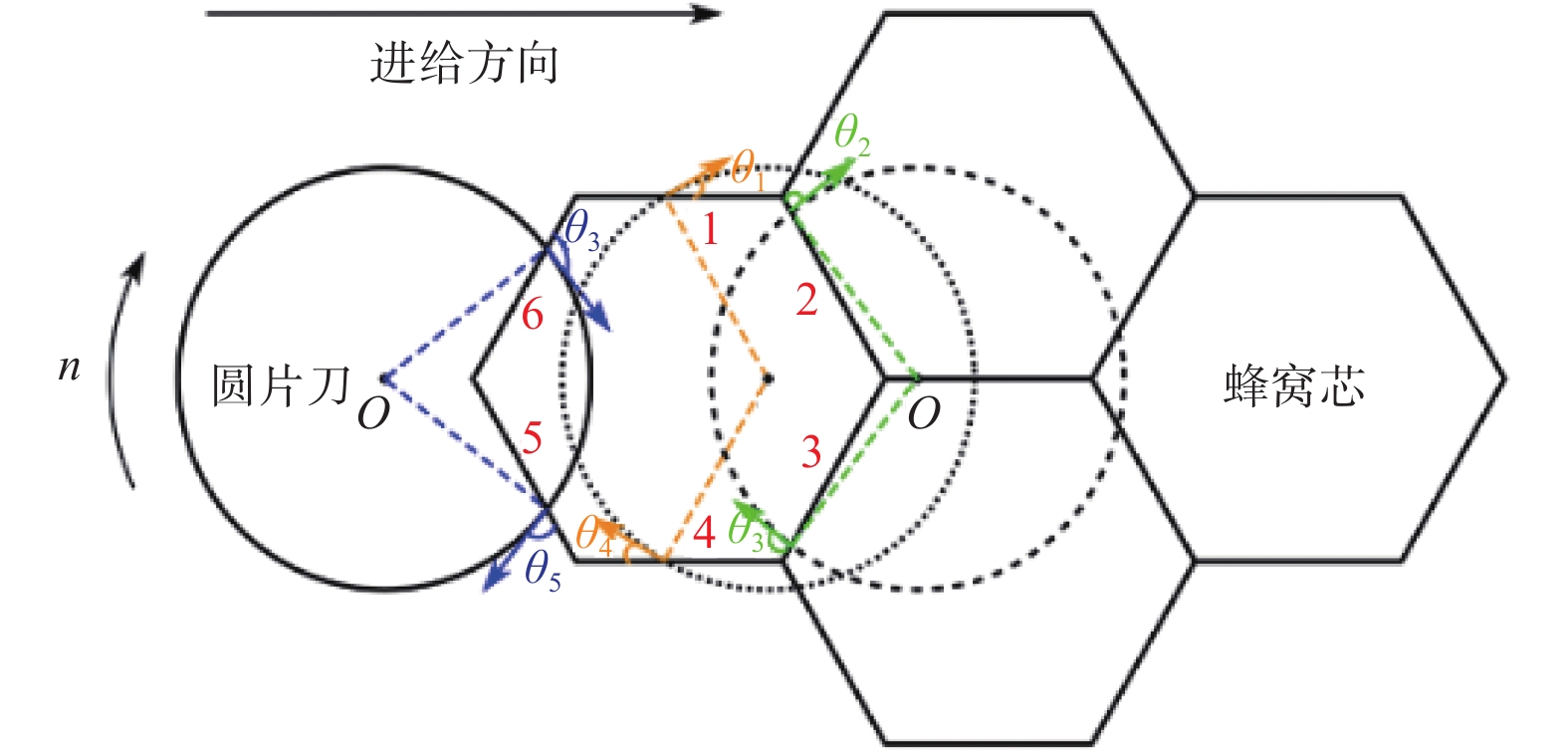

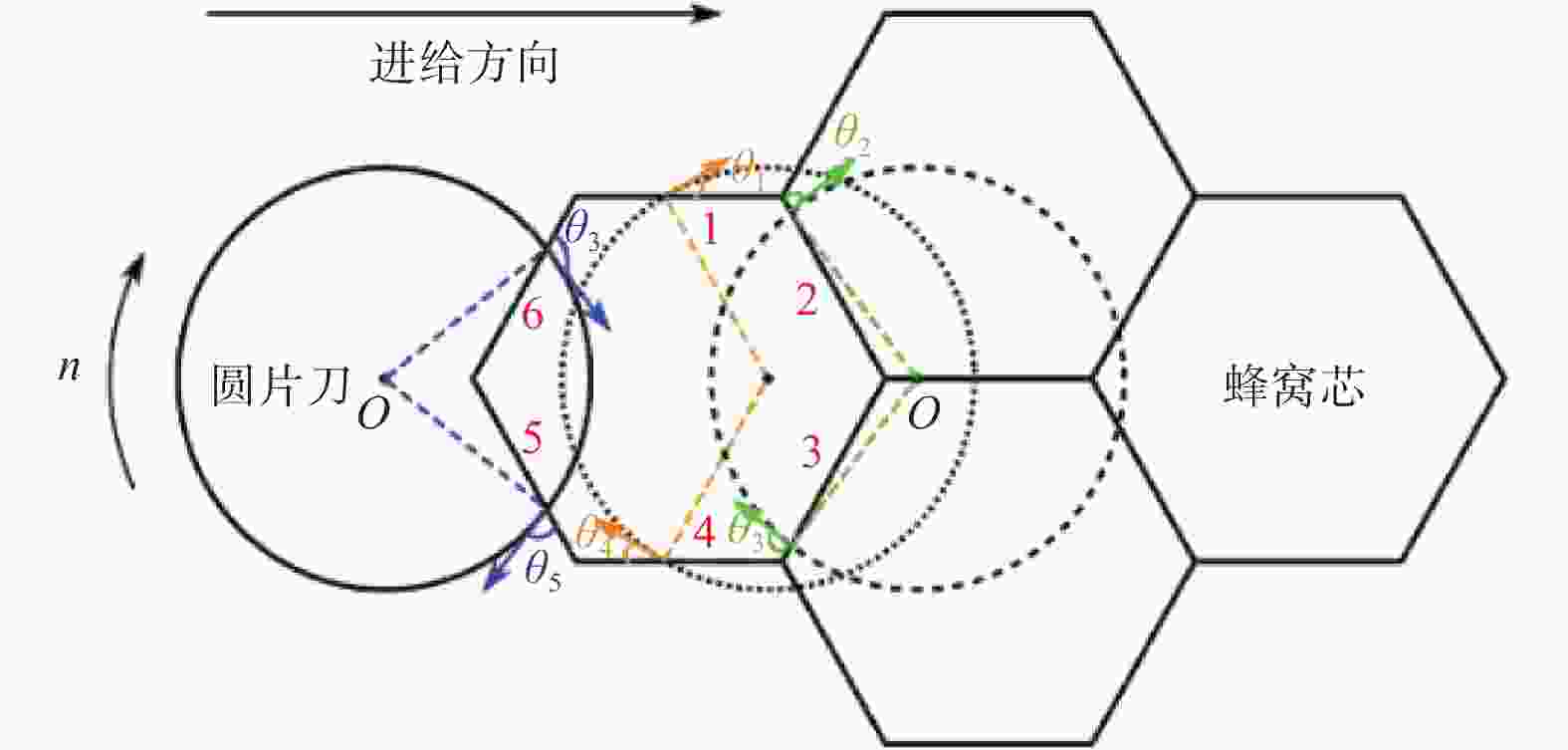

摘要: 铝蜂窝在使用传统加工技术加工时容易受损。为提高铝蜂窝加工表面质量,建立铝蜂窝超声加工切削力数学模型和仿真计算模型,研究网格尺寸对仿真结果的影响,确定合适的网格尺寸,并分析不同加工参数下的切削力和表面形貌。综合评价后选用0.2 mm的网格进行仿真模拟,结果表明随着进给量、主轴转速和切削宽度数值分别增大,加工损伤明显呈下降趋势。研究结果为铝蜂窝超声辅助加工的数值模型、仿真和试验提供了基础。Abstract: Traditional machining techniques often result in damage to the aluminum honeycomb. In order to improve the surface quality of aluminum honeycomb machining, the numerical and simulation models of cutting force in ultrasonic-assisted machining of aluminum honeycomb were established. The influence of mesh size on simulation results was investigated to determine an appropriate mesh size. Furthermore the cutting forces and surface morphology were analyzed for different machining parameters. After a thorough evaluation, a mesh of 0.2 mm was chosen for the simulation. The results show that there is a clear reduction in machining damage with increasing the feed rate, spindle speed, and cutting width values. This conclusion can provide reference for mathematical model, simulation and experiment of ultrasonic-assisted machining of aluminum honeycomb.

-

Key words:

- aluminum honeycomb /

- ultrasonic machining /

- surface quality /

- machining parameters

-

表 1 蜂窝细胞结构参数

Table 1. Structure parameters of aluminum honeycomb core

蜂窝细胞结构参数 数值 细胞尺寸c/mm 4.7 单层细胞厚度t/mm 0.0 细胞边长a/mm 1.37 细胞边长b/mm 1.37 胞壁角度$ \mathrm{\phi } $/(°) 120 表 2 Al5052的力学性能

Table 2. Mechanical properties of Al5052

属性 符号 单位 数值 密度 $ \rho $ ${\rm{kg}}/{{\rm{m}}}^{3}$ 2680 弹性模量 — ${\rm{GPa}}$ 70.3 泊松比 — — 0.33 比热 — J/(kg·℃ ) 930 参考温度 ${T}_{{\rm{r}}}$ ${\rm{K}}$ 293 熔化温度 ${T}_{{\rm{m}}}$ ${\rm{K}}$ 903 屈服应力 $ A $ ${\rm{MPa}}$ 92.4 硬化模量 $ B $ ${\rm{MPa}}$ 132 应变率敏感常数 $ C $ — 0.02511 参考应变率 $ {\dot{\stackrel{-}{\varepsilon }}}_{0} $ ${{\rm{s}}}^{-1}$ 1 硬化指数 $ n $ — 0.25 热软化指数 $ m $ — 1 表 3 Al5052的损伤参数

Table 3. Damage parameters of Al5052

参数 $ {D}_{1} $ $ {D}_{2} $ $ {D}_{3} $ $ {D}_{4} $ $ {D}_{5} $ 数值 0.306 0.0446 −1.72 0.0056 0.0 表 4 单因素试验参数

Table 4. Machining parameters for single-factor experiments

变量 水平 进给速度f/(mm·min−1) 500, 1000 ,1500 ,2000 主轴转速n/(r·min−1) 500,600,700,800 切削宽度ae/mm 4,6,8,10 表 5 不同网格尺寸的仿真耗时

Table 5. Simulation time consumption of different mesh sizes

网格尺寸/mm 耗时/h 0.1 23.50 0.2 2.50 0.3 2.01 0.4 1.09 0.5 0.85 -

[1] COGNARD P. Collage des composites[M]. France Ed. [S.l.]: Techniques Ingénieur, 2003. [2] REYNE M. Les composites dans les sports et les loisirs[M]. France Ed. [S.l.]: Techniques Ingénieur, 1998. [3] WANG Z, TIAN H, LU Z, et al. High-speed axial impact of aluminum honeycomb-experiments and simulations[J] . Composites Part B: Engineering,2014,56:1 − 8. [4] QIU K, MING W, SHEN L, et al. Study on the cutting force in machining of aluminum honeycomb core material[J] . Composite Structures,2017,164:58 − 67. doi: 10.1016/j.compstruct.2016.12.060 [5] JANSONS J, KILAKOV V, ANISKEVICH A, et al. Structural composites-from aerospace to civil engineering applications[J] . Innovations and Technologies News,2012,4(17):3 − 12. [6] MENDOZA M M, EMAN K F, WU S M. Development of a new milling cutter for aluminium honeycomb[J] . International Journal of Machine Tool Design and Research,1983,23(2/3):81 − 91. doi: 10.1016/0020-7357(83)90009-4 [7] AN Q, DANG J, MING W, et al. Experimental and numerical studies on defect characteristics during milling of aluminum honeycomb core[J] . Journal of Manufacturing Science and Engineering,2019,141(3):031006. doi: 10.1115/1.4041834 [8] AHMAD S, ZHANG J, FENG P, et al. Experimental study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by circular knife cutting tools[J] . Journal of Manufacturing Processes,2020,58:524 − 535. doi: 10.1016/j.jmapro.2020.08.023 [9] LIU G, YANG J, ZHANG L, et al. Surface quality experimental study on rotary ultrasonic machining of honeycomb composites with a circular knife cutting tool[J] . Crystals,2022,12(5):725. doi: 10.3390/cryst12050725 [10] 孟倩, 王毅丹, 董志刚, 等. 圆片刀超声切削Nomex蜂窝芯的切削力和表面质量研究[J] . 航空制造技术,2021,64(6):88 − 95. [11] AHMAD S, ZHANG J, FENG P, et al. Research on design and FE simulations of novel ultrasonic circular saw blade (UCSB) cutting tools for rotary ultrasonic machining of nomex honeycomb composites[C]//Proceedings of the 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST). Islamabad: IEEE, 2019: 113−119. [12] 袁信满, 曹文军, 张桂, 等. 匕首刀超声切削Nomex蜂窝芯复合材料切削力预测模型构建[J] . 制造技术与机床,2021(9):79 − 85. [13] 袁信满, 赵清泉, 鄢旭东, 等. 圆盘锯齿刀超声切削Nomex蜂窝芯力热分析[J] . 组合机床与自动化加工技术,2021(8):27 − 30, 35. [14] 孙健淞, 康仁科, 周平, 等. 蜂窝芯超声切削技术研究进展[J] . 机械工程学报,2023,59(9):298 − 319. [15] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures[J] . Engineering Fracture Mechanics,1985,21(1):31 − 48. doi: 10.1016/0013-7944(85)90052-9 [16] ZENG R, MA F, HUANG L, et al. Investigation on spinnability of profiled power spinning of aluminum alloy[J] . The International Journal of Advanced Manufacturing Technology,2015,80:535 − 548. doi: 10.1007/s00170-015-7025-2 -

下载:

下载: