Impact of bipolar plate flow channel cross-section shape on PEMFC mass transfer and performance

-

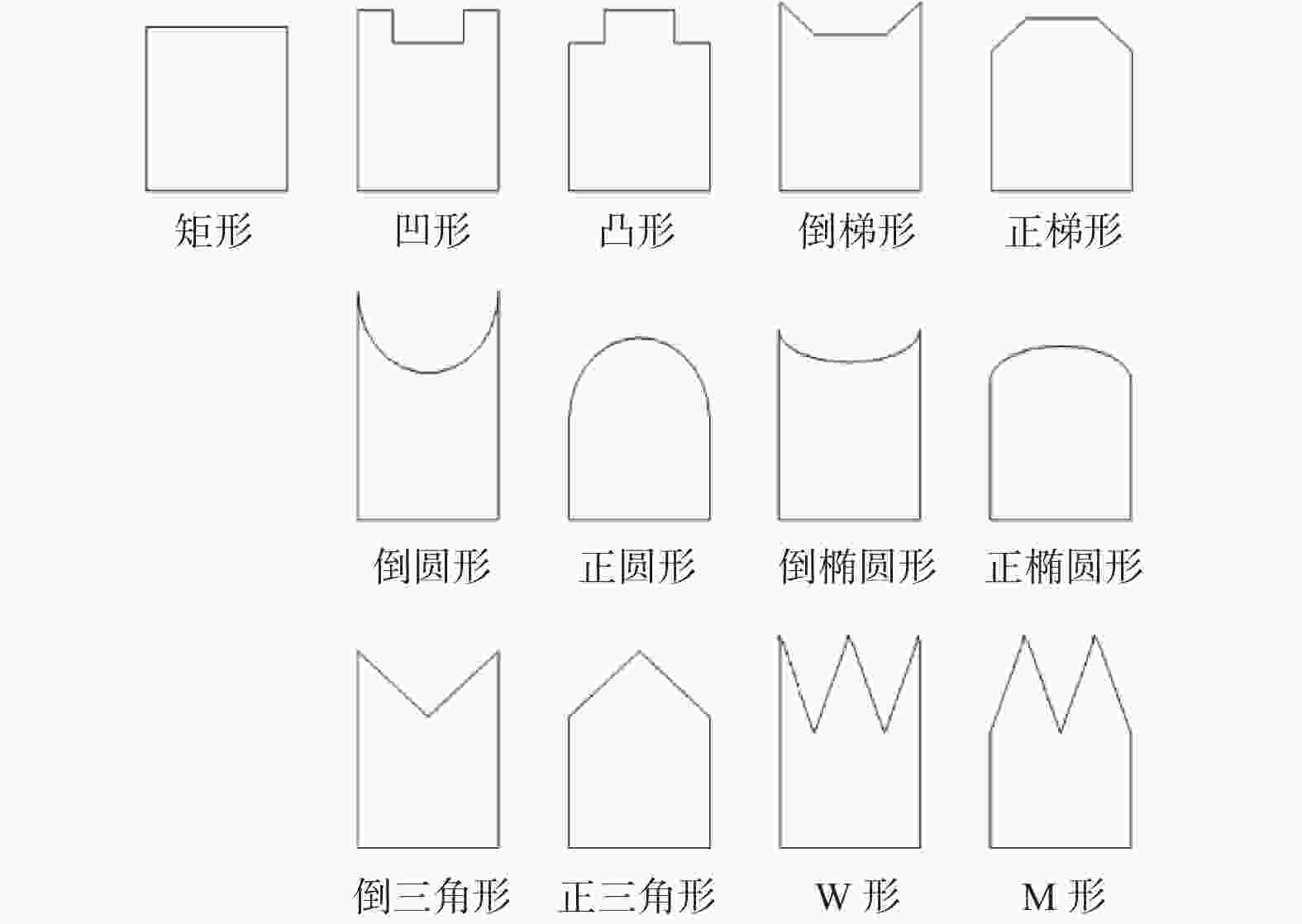

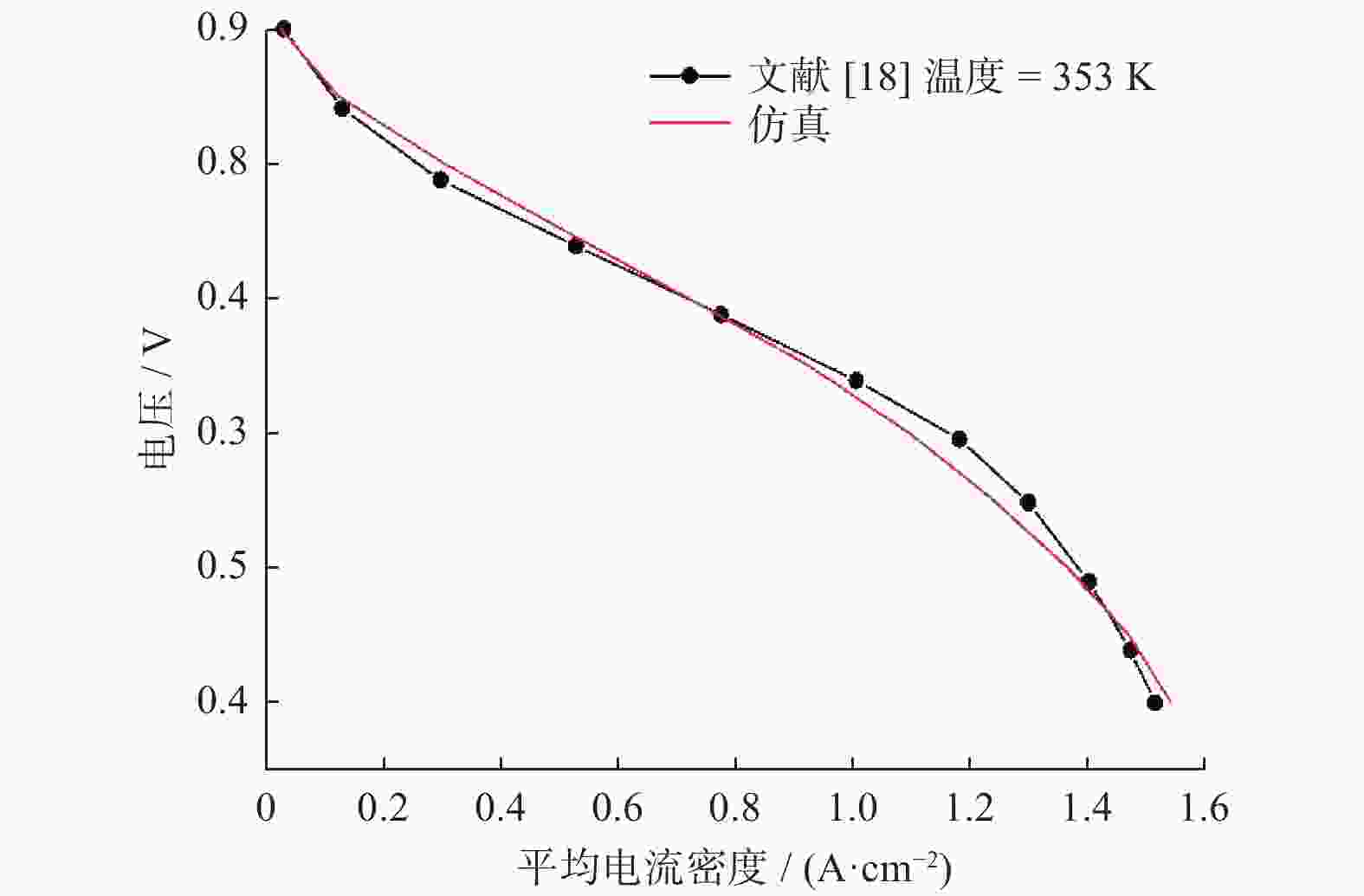

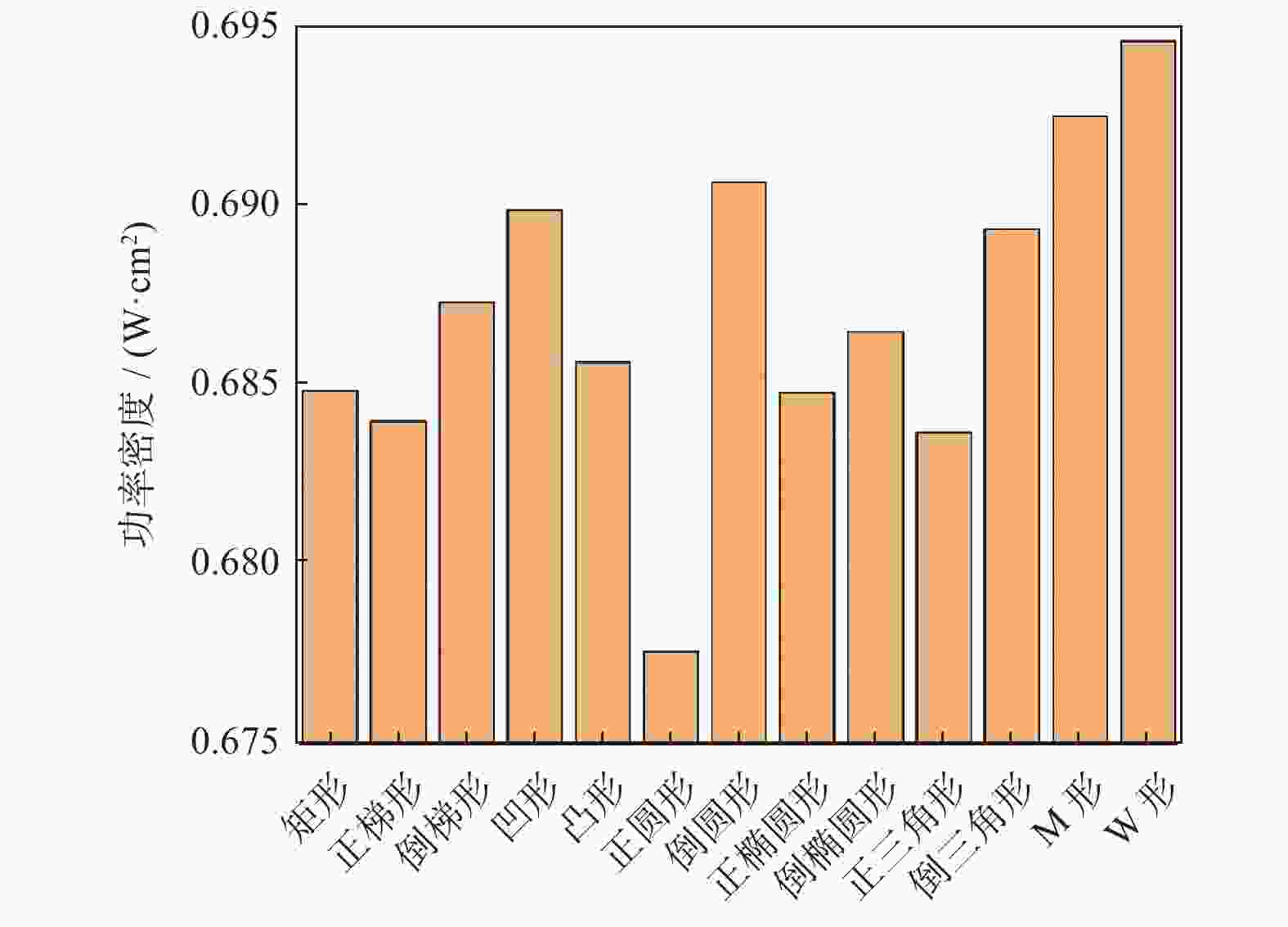

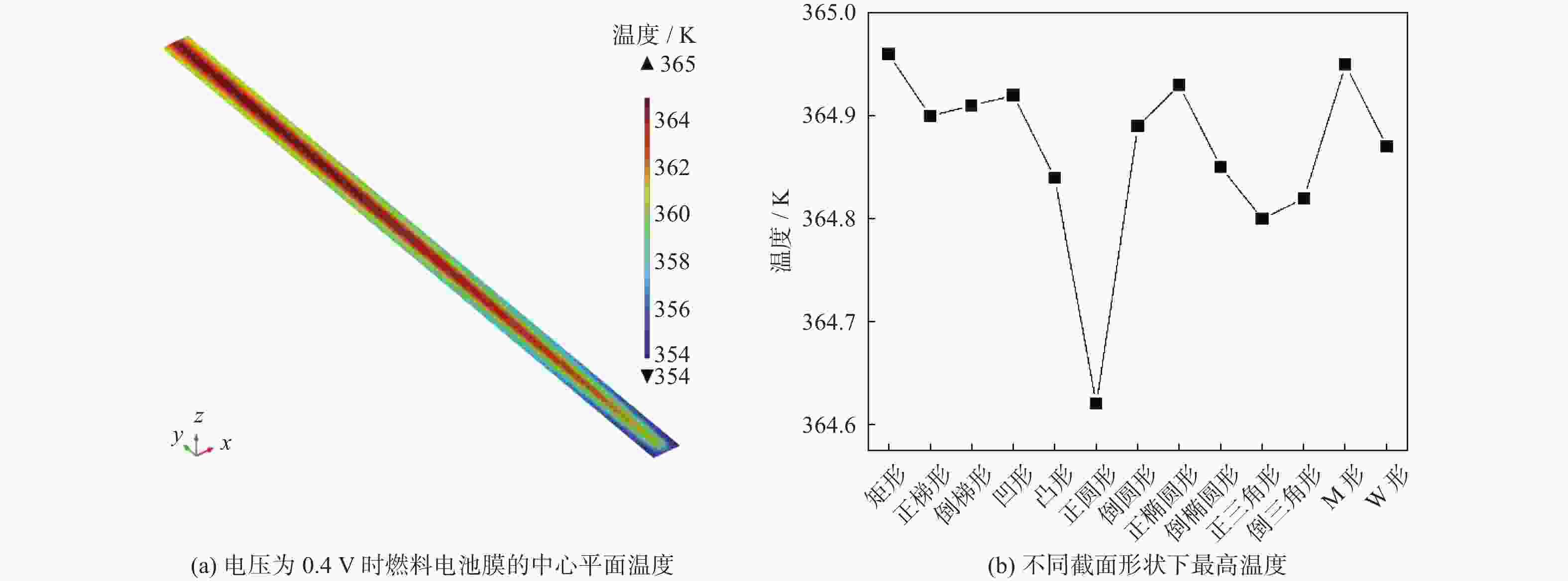

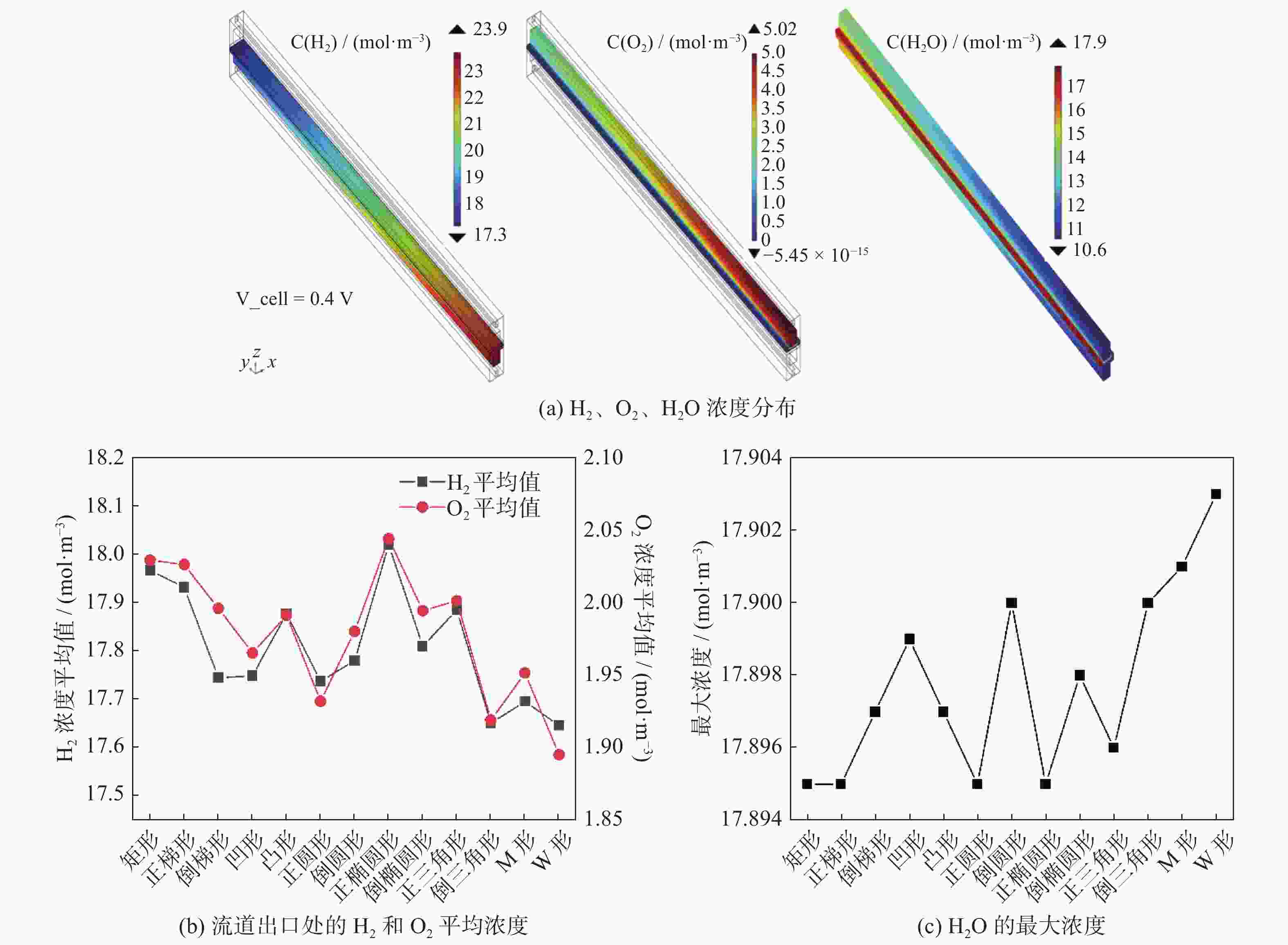

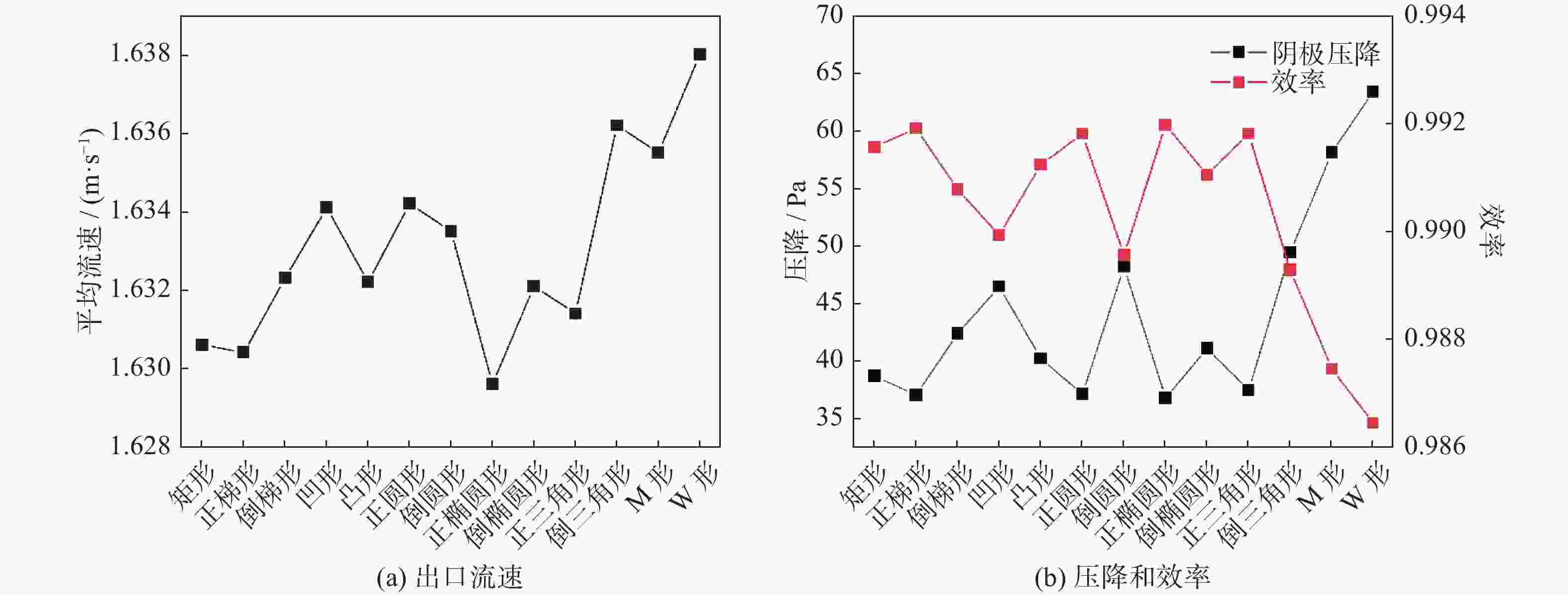

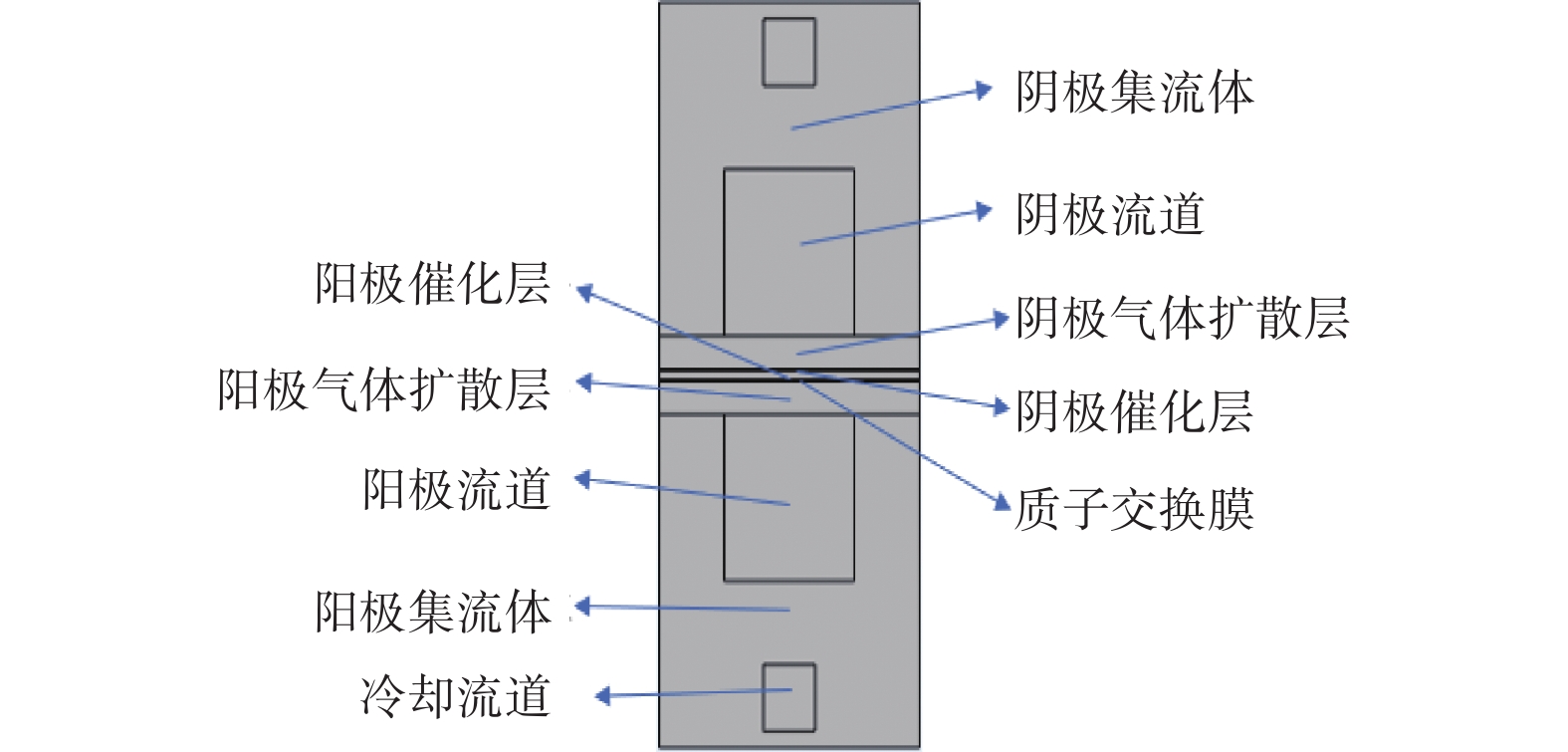

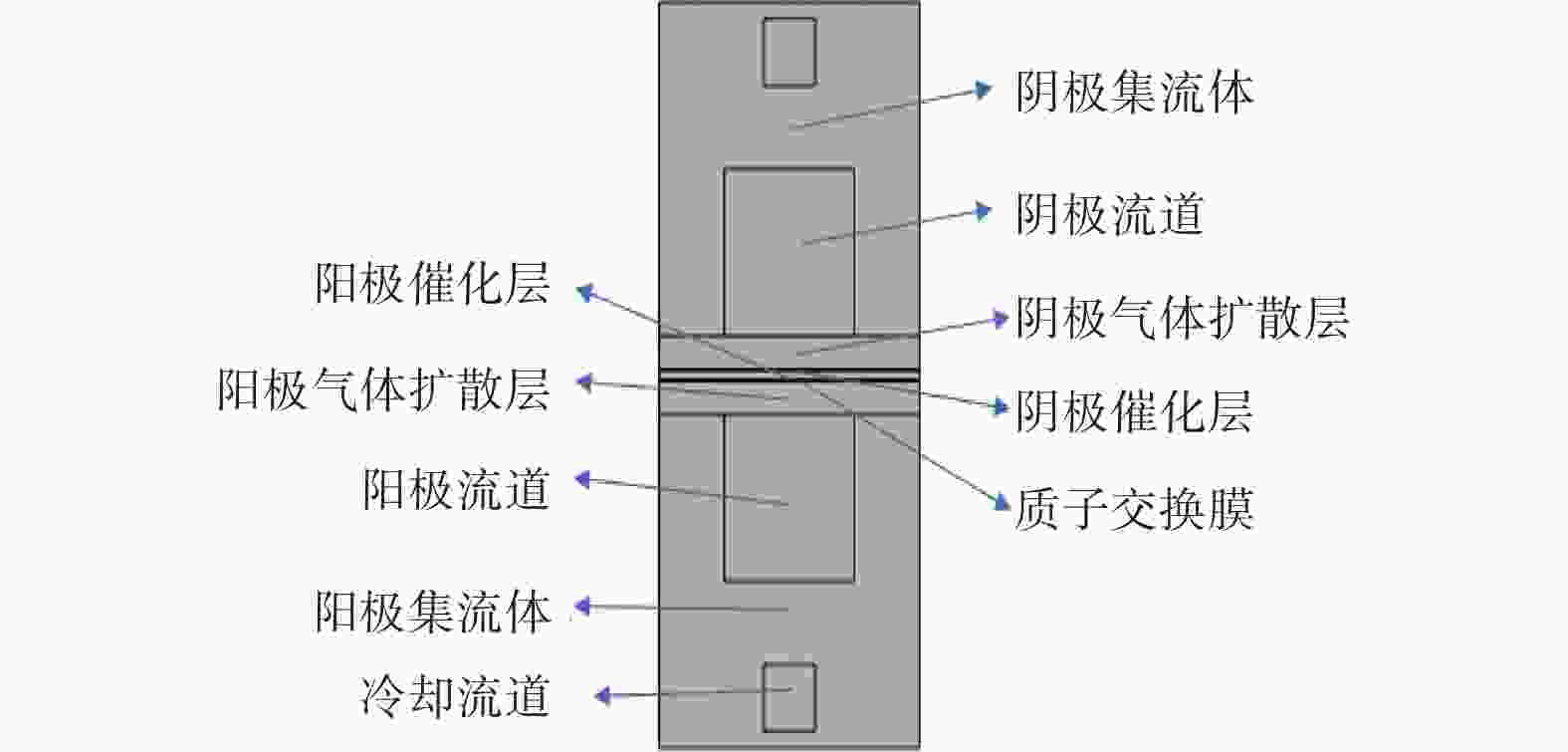

摘要: 以矩形截面为基础,采用COMSOL软件研究截面形状对平行单流道燃料电池性能的影响,建立性能仿真模型并验证模型的可行性。在此基础上,研究不同截面形状的流道对平行单流道燃料电池功率密度、质量传输、温度、速度、压降、净输出效率的影响。结果表明,在低电压和高电流密度的情况下,流道的截面形状对燃料电池性能影响明显。三角形截面模型普遍具有较高的最大功率密度,其中W形截面比矩形截面有更高的流速和更小的温度变化,其氢气消耗提高1.8%,氧气消耗提高6.6%,在净输出效率相差不大的情况下,具有更高的功率密度,研究结果为双极板的设计提供了支撑。Abstract: The performance of parallel single-flow channel fuel cells with a rectangular cross-section was investigated using COMSOL software. A performance simulation model was established and its feasibility was verified. On this basis, the impacts of different cross-sectional shapes on the power density, mass transfer, temperature, velocity, pressure drop, and net output efficiency of parallel single channel fuel cells were examined. The result shows that the cross-sectional shape of the flow channel significantly affects the fuel cell performance under low voltage and high current density conditions. The triangular cross-section model generally exhibits a higher maximum power density. The W-shaped cross-section has a higher flow velocity and smaller temperature change compared to the rectangular cross-section, with an increase of 1.8% in hydrogen consumption and a 6.6% in oxygen consumption respectively. It demonstrates a higher power density with a similar net output efficiency, providing support for the design of bipolar plates.

-

Key words:

- hydrogen fuel cell /

- cross-section /

- mass transfer /

- power density /

- net output efficiency

-

表 1 模型几何参数

Table 1. Model geometric parameters

名称 值 单位 电池长度 0.05 m 电池宽度 2 × 10−3 m 电池高度 4.47 × 10−4 m 流道宽度 1 × 10−3 m 流道高度 1 × 10−3 m 集流体高度 2 × 10−3 m 肋宽 5 × 10−4 m 气体扩散层厚度 2 × 10−4 m 催化层厚度 1 × 10−5 m 膜的厚度 5 × 10−5 m 横截面积 1 mm2 表 2 控制方程

Table 2. Control equations

名称 控制方程 质量守恒方程 $\nabla \cdot \left( {\varepsilon \rho {u}} \right) = {S_{\text{m}}}$ 动量守恒方程 $\nabla \cdot \left( {\varepsilon \rho {uu}} \right){\text{ = }} - \varepsilon \nabla p + \nabla \cdot \left( {\varepsilon {\mu _{eff}}\nabla {u}} \right) + {s_u}$ 能量守恒方程 $\nabla \cdot \left( {\varepsilon \kappa \nabla T} \right) + {S_e} = \nabla \cdot \left( {\varepsilon \rho {u}{c_p}T} \right)$ brinkman方程 $ \dfrac{\partial }{\partial t}\left({\varepsilon }_{p}\rho \right) + \nabla \cdot \left(\rho \text{u}\right)={Q}_{br} $ 传热方程 ${C_{st}}{M_{st}}\Delta T + {Q_{gas,in}} = {Q_{chem}} - {P_{st}} - {Q_{gas,out}} - {Q_{water}} - {Q_{rad}}$ 浓物质传递方程 $\dfrac{\partial }{{\partial t}}\left( {\rho {c_i}} \right) + \nabla \cdot \left( {\rho {c_i}{u}} \right) = - \nabla \cdot \left( {D_i^{eff}\nabla {c_i}} \right) + {S_i}$ 表 3 材料特性和关键物理参数

Table 3. Material properties and key physical parameters

名称 值 单位 开路电压 0.9 V GDL孔隙率 0.6 — CL孔隙率 0.3 — GDL渗透率 1.18 × 10−11 m2 CL渗透率 1 × 10−13 m2 GDL电导率 5000 S/m CL电导率 2000 S/m 阳极传递系数 0.5 — 阴极传递系数 1 — 入口温度(Tin) 353 K 压力 1 atm 阳极化学计量比 1 — 阴极化学计量比 1 — GDL 导热率 1.7 W/(m·K) CL导热率 0.3 W/(m·K) 膜的导热率 0.25 W/(m·K) CC导热率 40 W/(m·K) H2_H2O扩散系数 9.15 × 10−5×(Tin/307.1) 1.75 m2/s N2_H2O扩散系数 2.56 × 10−5×(Tin/307.15) 1.75 m2/s O2_N2扩散系数 2.2 × 10−5×(Tin/293.2) 1.75 m2/s O2_H2O扩散系数 2.82 × 10−5×(Tin/308.1) 1.75 m2/s 阳极参考交换电流密度 100 A/m2 阴极参考交换电流密度 $ 10^{(0.037\;41\times T_{\mathrm{in}}-16.96)} $ A/m2 -

[1] SINGLA MK, NIJHAWAN P, OBEROI AS. Hydrogen fuel and fuel cell technology for cleaner future: a review[J] . Environ Sci Pollut Res Int,2021,28(13):15607 − 15626. [2] MANOHARAN Y, HOSSEINI SE, BUTLER B, et al. Hydrogen fuel cell vehicles; current status and future prospect[J] . Applied Sciences-Basel,2019,9(11):2296 − 2313. [3] AHLUWALIA RK, WANG X. Fuel cell systems for transportation: status and trends[J] . Journal of Power Sources,2008,177(1):167 − 176. [4] BOCK R, KAROLIUSSEN H, POLLET BG, et al. The influence of graphitization on the thermal conductivity of catalyst layers and temperature gradients in proton exchange membrane fuel cells[J] . International Journal of Hydrogen Energy,2020,45(2):1335 − 1342. [5] WANG Y, CHEN KS, MISHLER J,et al. A review of polymer electrolyte membrane fuel cells: technology, applications, and needs on fundamental research[J] . Applied Energy,2011,88(4):981 − 1007. [6] 颜敬昊, 孙宾宾, 高松. 流道截面形状对质子交换膜燃料电池性能的影响[J] . 山东理工大学学报(自然科学版),2021,35(6):11 − 17. [7] WANG XD, YAN WM, DUAN YY, et al. Numerical study on channel size effect for proton exchange membrane fuel cell with serpentine flow field[J] . Energy Conversion and Management,2010,51(5):959 − 968. [8] VARADHA RAJAN L, PAVANAN V, PALANISWAMY K. Interdigitated flow channel on a proton exchange membrane fuel cell investigated using the response surface methodology[J] . Transactions of FAMENA,2019,43(2):61 − 72. [9] MOHAMMEDIA, SAHLI Y, BEN MOUSSA H. 3D investigation of the channel cross-section configuration effect on the power delivered by PEMFCs with straight channels[J] . Fuel,2020,263(3):116713 − 116741. [10] MANSO AP, MARZO FF, BARRANCO J, et al. Influence of geometric parameters of the flow fields on the performance of a PEM fuel cell. A review[J] . International Journal of Hydrogen Energy,2012,37(20):15256 − 15287. [11] PAULINO ALR, CUNHA EF, ROBALINHO E, et al. CFD analysis of PEMFC flow channel cross sections[J] . Fuel Cells,2017,17(1):27 − 36. [12] LIN L, ZHANG XX, FENG HT, WANG XD. Optimization of a serpentine flow field with variable channel heights and widths for PEM fuel cells[J] . Science China-Technological Sciences,2010,53(2):453 − 460. [13] MAHMOUDIMEHR J, DARYADEL A. Influences of feeding conditions and objective function on the optimal design of gas flow channel of a PEM fuel cell[J] . International Journal of Hydrogen Energy,2017,42(36):23141 − 23159. [14] NGUYEN PT, BERNING T, DJILALI N. Computational model of a PEM fuel cell with serpentine gas flow channels[J] . Journal of Power Sources,2004,130(1-2):149 − 157. [15] ANDERSSON M, BEALE SB, ESPINOZA M, et al. A review of cell-scale multiphase flow modeling, including water management, in polymer electrolyte fuel cells[J] . Applied Energy,2016,180:757 − 778. [16] LI WK, ZHANG QL, WANG C, et al. Experimental and numerical analysis of a three-dimensional flow field for PEMFCs[J] . Applied Energy,2017,195:278 − 288. [17] KUMAR A, G,REDDY R. Effect of channel dimensions and shape in the flow-field distributor on the performance of polymer electrolyte membrane fuel cells[J] . Journal Power Sources,2003,113:11 − 18. [18] WANG L. A parametric study of PEM fuel cell performances[J] . International Journal of Hydrogen Energy,2003,28(11):1263 − 1272. [19] YANG C, WAN ZM, CHEN X, et al. Geometry optimization of a novel M-like flow field in a proton exchange membrane fuel cell[J] . Energy Conversion and Management,2021,228:113651 − 113661. [20] CAI YH, FANG Z, CHEN B, et al. Numerical study on a novel 3D cathode flow field and evaluation criteria for the PEM fuel cell design[J] . Energy,2018,161:28 − 37. -

下载:

下载: