Analysis of impact of manufacturing defects on bearing capacity of carbon fiber aluminum honeycomb sandwich structures

-

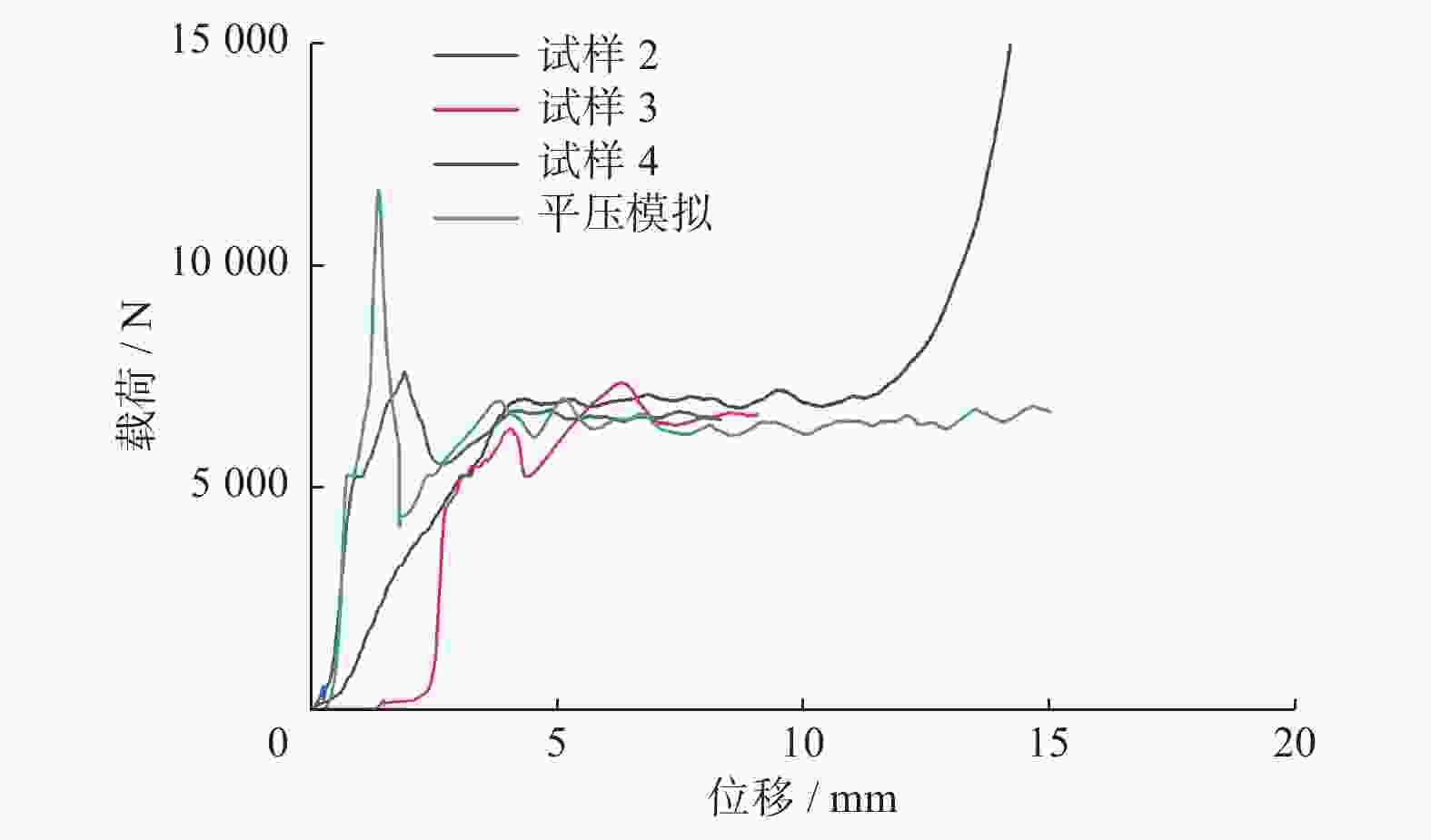

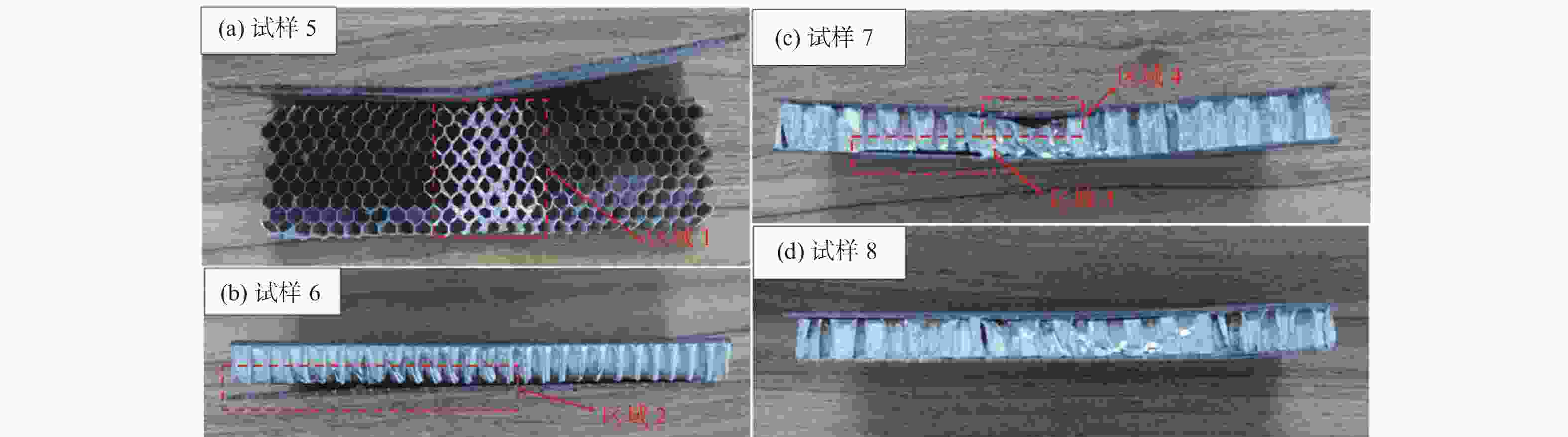

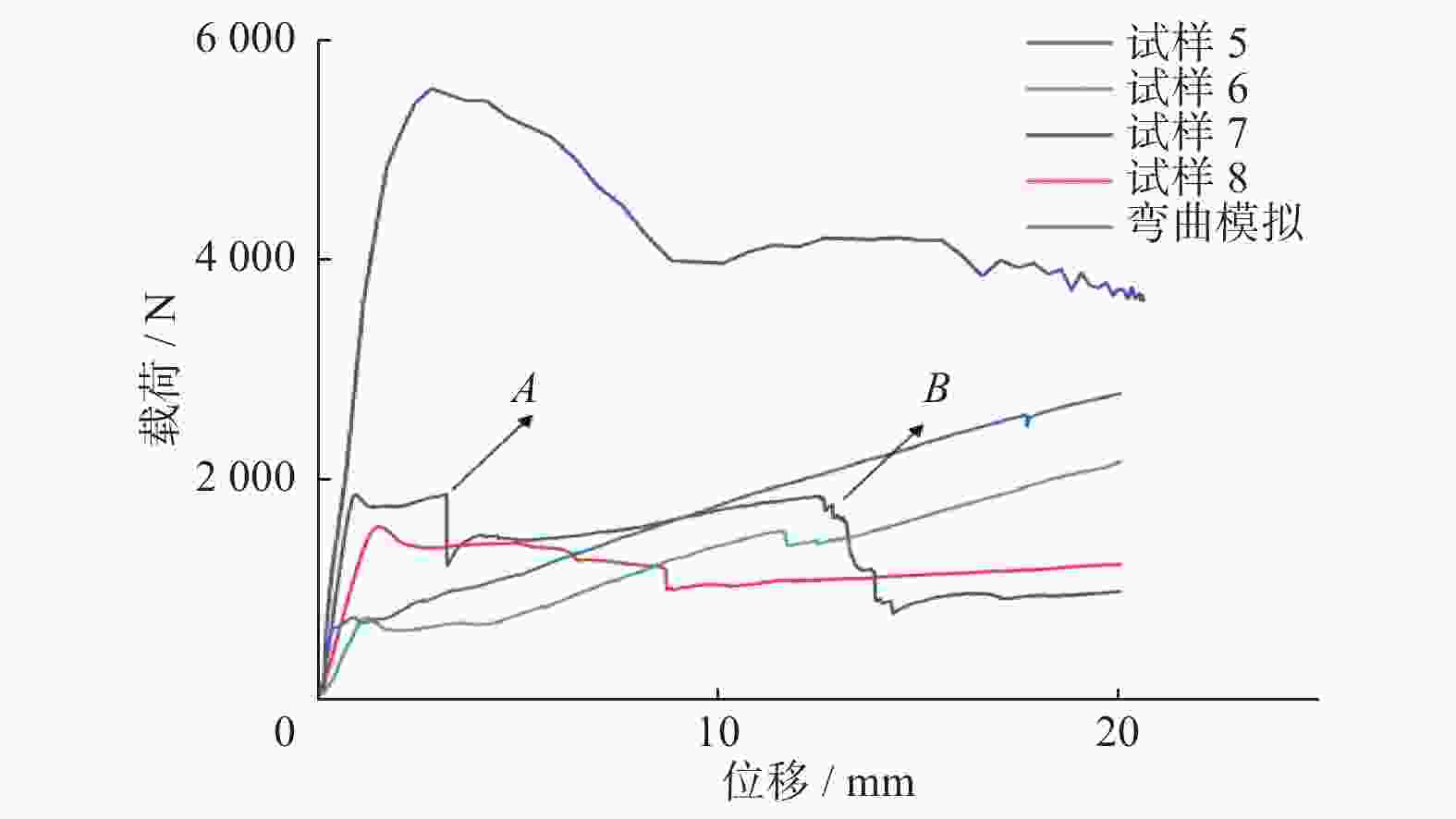

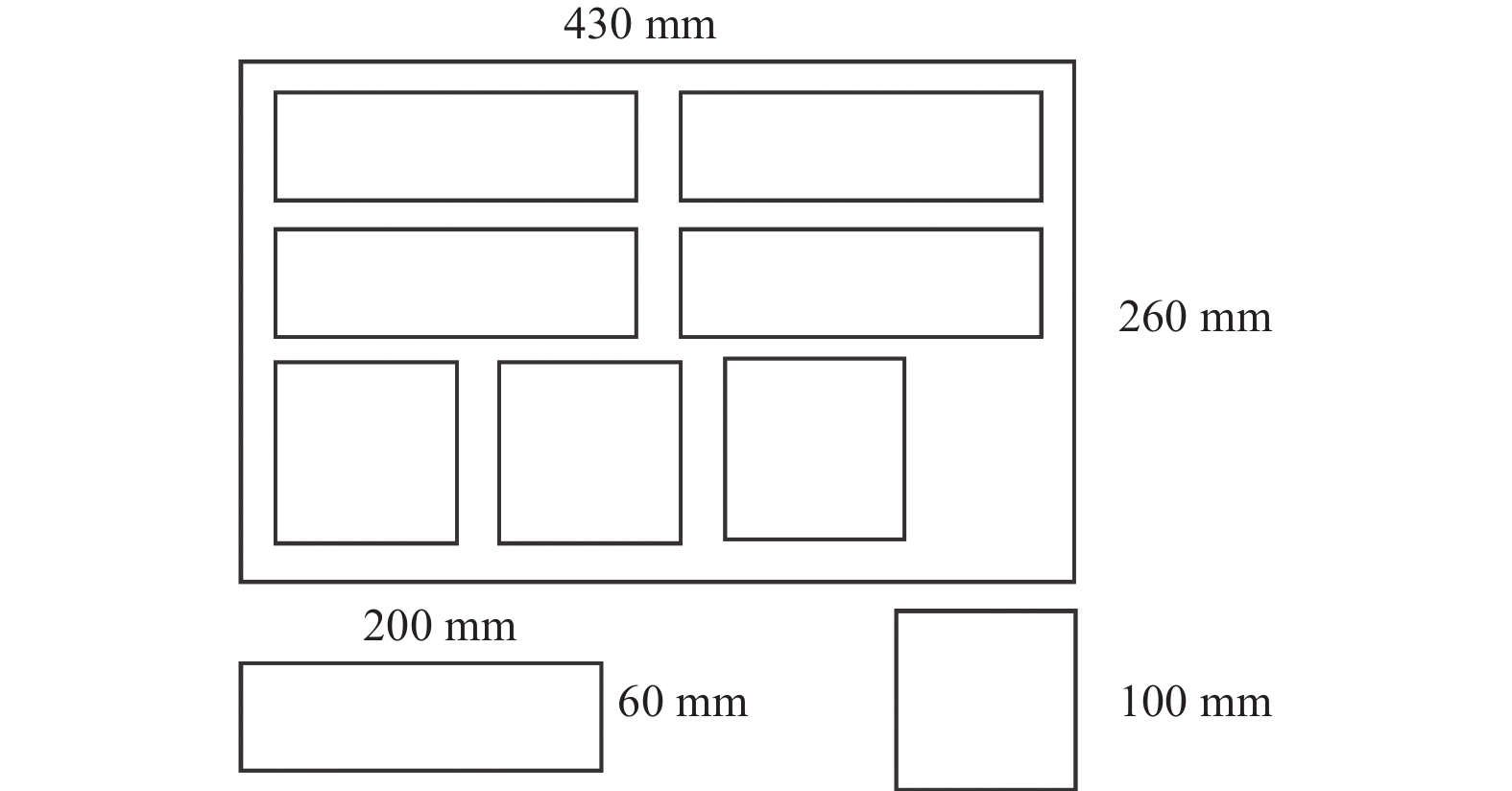

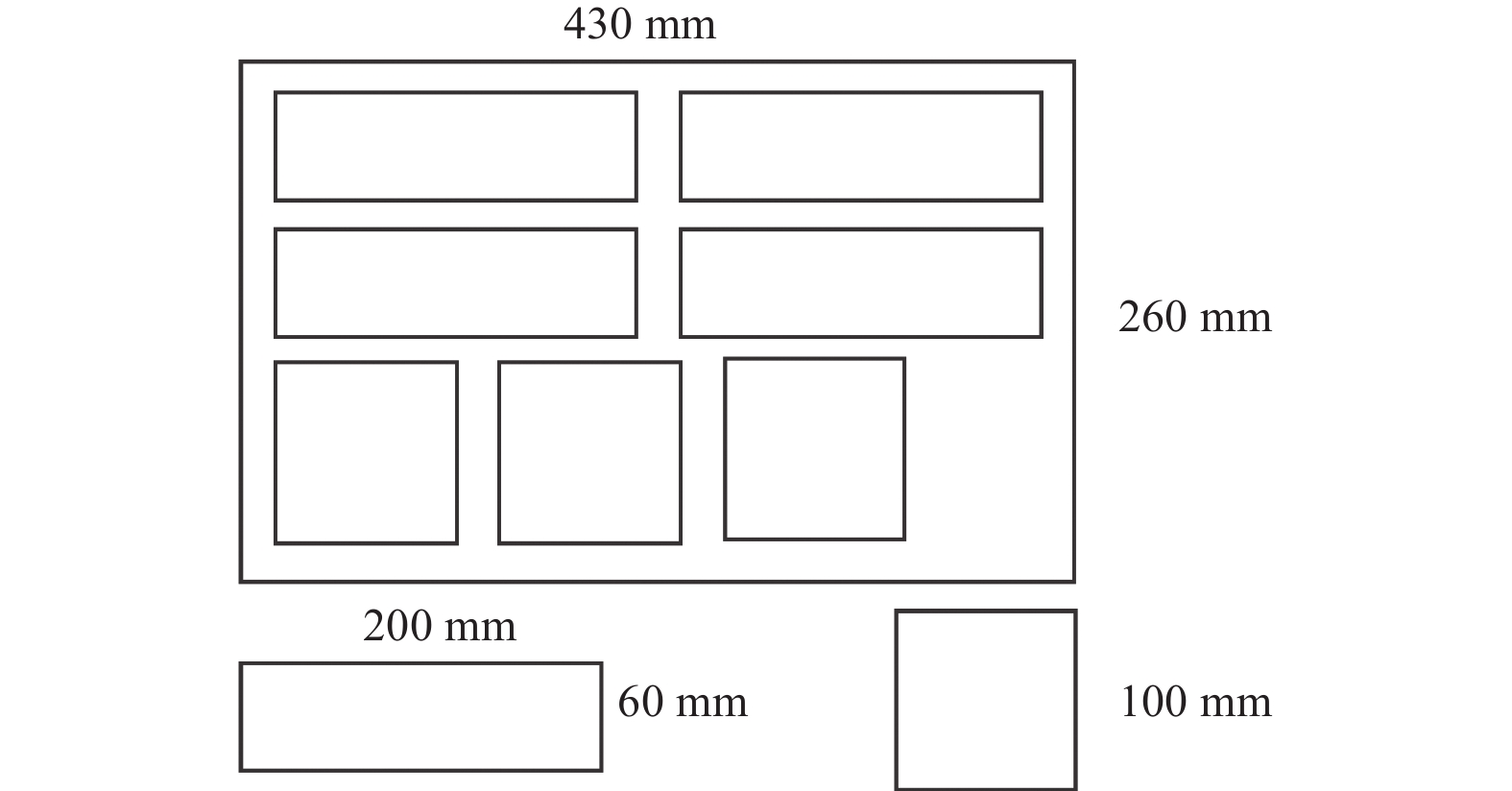

摘要: 为研究制造缺陷对碳纤维铝蜂窝夹层结构承载性能影响的原因,对胶接碳纤维铝蜂窝夹层结构进行准静态下的平压试验和三点弯曲试验,分析同批相同结构、尺寸下夹层结构的不同脱胶失效形式。得到夹层结构的峰值载荷与平均载荷的变化趋势,与Abaqus CAE软件仿真的不脱胶试样的载荷位移曲线对比,研究承载能力的变化。结果表明,含有制造缺陷的夹层结构会产生不同形式的脱胶,且其承载能力低于不脱胶试样。研究结果可为碳纤维铝蜂窝夹层结构的加工工艺改进提供依据,对拓宽其应用领域有重要意义。

-

关键词:

- 碳纤维铝蜂窝夹层结构 /

- 胶接缺陷 /

- 仿真模拟

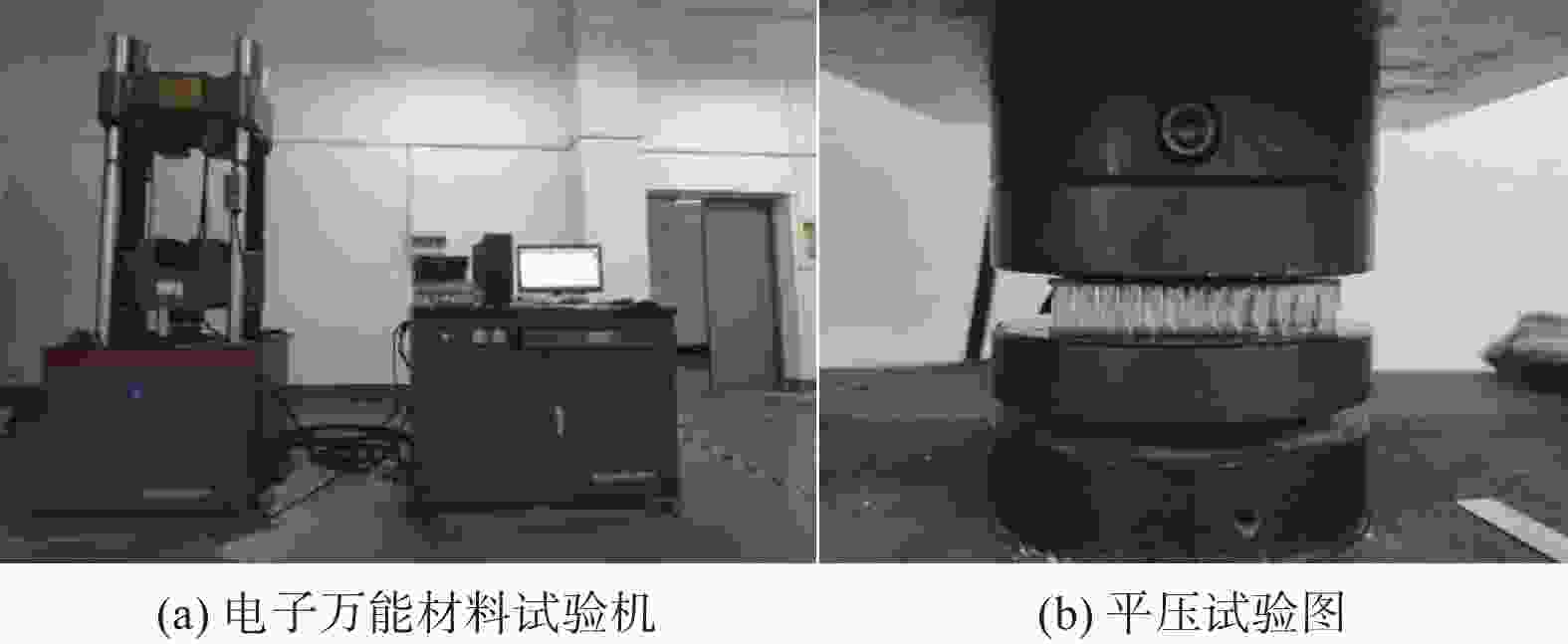

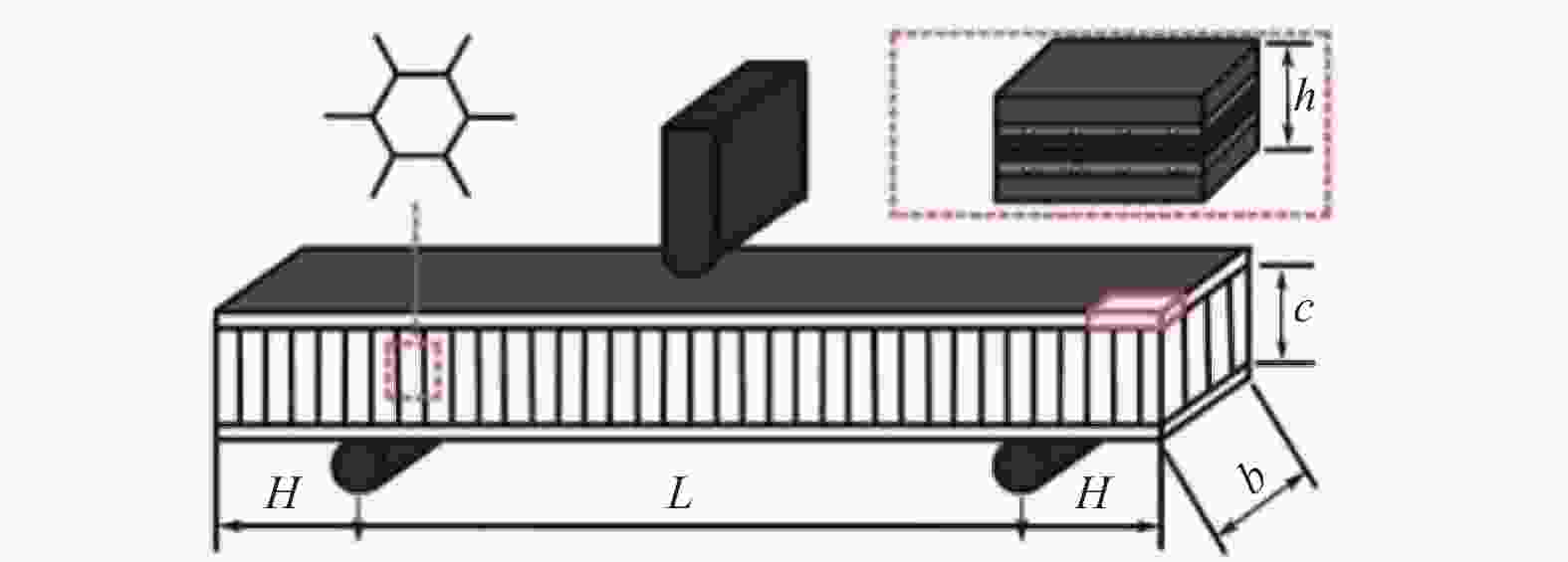

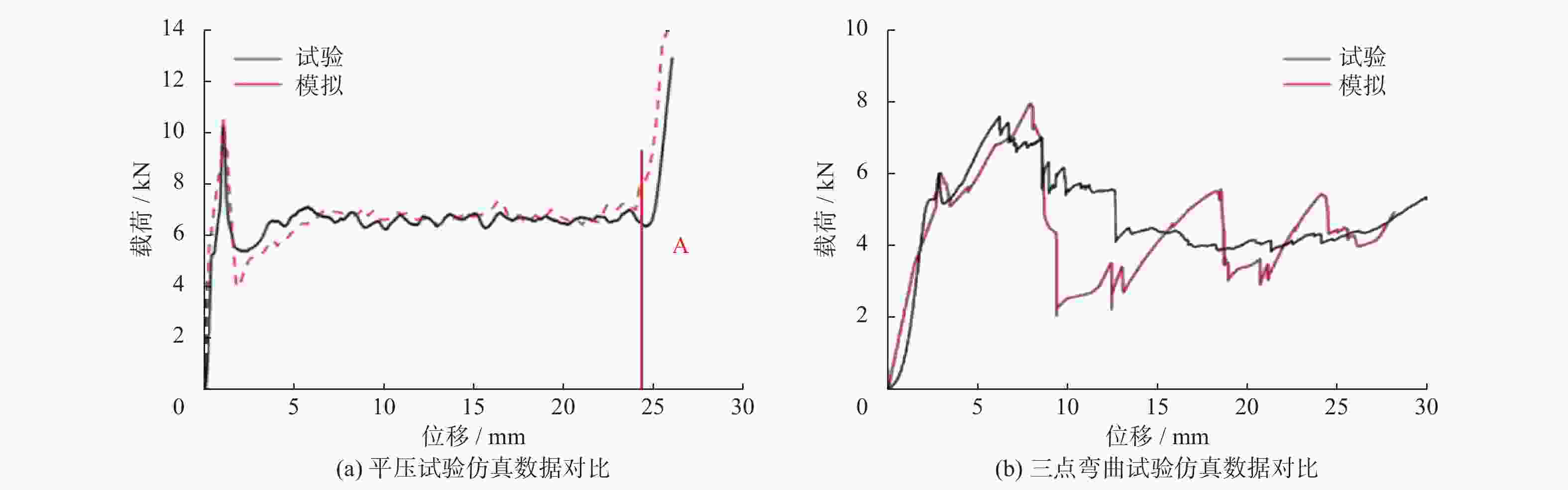

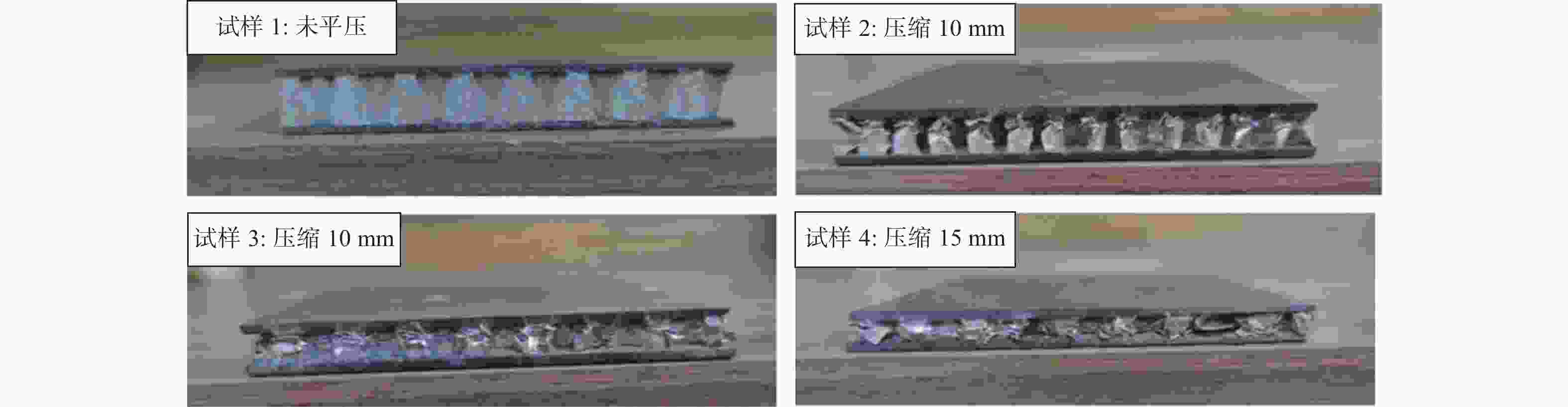

Abstract: To investigate reasons for the impact of manufacturing defects on bearing performance of carbon fiber aluminum honeycomb sandwich structures, flat compression tests and three-point bending tests under quasi-static conditions were conducted on these structures with glued joints, the different forms of debonding failure existing in the same batch and size were analyzed. The trends of peak load and average load generated by the sandwich structure were observed and compared with the load-displacement curves of non-debonded specimens simulated using Abaqus CAE software, to study the changes in its bearing capacity. The results show that sandwich structures with manufacturing defects exhibit different forms of debonding and have lower bearing capacity than non-debonded specimens, which can provide a basis for improving the fabrication process and have great significance for broadening its application ares. -

表 1 碳纤维单向预浸料参数

Table 1. Carbon fiber unidirectional prepreg parameters

纤维密度/(kg·m−3) 树脂质量百分比/% 厚度/mm 290 31 0.2 表 2 T300/7901材料属性

Table 2. Material properties of T300/7901

符号 值 符号 值 E1/MPa 125000 Xc/MPa 1000 E2,E3/MPa 11300 Yt/MPa 80 G12,G13/MPa 5430 Yc/MPa 280 G23/MPa 3979 Zt/MPa 100 V12,V13 0.3 S12,S13/MPa 120 V23 0.42 S23/MPa 120 Xt/MPa 2000 表 3 BHC3003铝合金材料性能

Table 3. Material properties of BHC3003 aluminum alloy

密度/(kg·m−3) 杨氏模量/GPa 泊松比 屈服强度/MPa 2680 69 0.3 116 -

[1] 台雪琰, 朱利媛, 牛忠荣. 蜂窝材料的工程应用及发展[J] . 工程与建设,2012,26(4):518 − 520. doi: 10.3969/j.issn.1673-5781.2012.04.035 [2] 杨桂英, 赵睿, 肖冰, 等. 碳纤维复合材料在汽车轻量化中的应用[J] . 当代石油石化,2020,28(10):24 − 28. doi: 10.3969/j.issn.1009-6809.2020.10.005 [3] 陈静. 蜂窝夹层结构在飞机上的应用及发展[J] . 新材料产业,2018(7):63 − 67. [4] 齐佳旗, 段玥晨, 铁瑛, 等. 结构参数对CFRP蒙皮-铝蜂窝夹层板低速冲击性能的影响[J] . 复合材料学报,2020,37(6):1352 − 1363. [5] BORIA S, OBRADOVIC J, BELINGARDI G. Experimental and numerical investigations of the impact behaviour of composite frontal crash structures[J] . Composites Part B: Engineering,2015,79:20 − 27. doi: 10.1016/j.compositesb.2015.04.016 [6] XIE W, ZHANG W, KUANG N, et al. Experimental investigation of normal and oblique impacts on CFRPs by high velocity steel sphere[J] . Composites Part B Engineering,2016,99:483 − 493. doi: 10.1016/j.compositesb.2016.06.020 [7] PERNAS-SÁNCHEZ J, ARTERO -GUERRERO J A, VARAS D, et al. Experimental analysis of normal and oblique high velocity impacts on carbon/epoxy tape laminates[J] . Composites Part A: Applied Science and Manufacturing,2014,60:24 − 31. doi: 10.1016/j.compositesa.2014.01.006 [8] 周祝林, 吴妙生. 复合材料胶接(上)[J] . 纤维复合材料,1997(1):51 − 55. [9] 卢子兴, 黄纪翔. 两种典型缺陷对六边形蜂窝压缩性能的影响[J] . 宇航材料工艺,2017,47(6):73 − 78. doi: 10.12044/j.issn.1007-2330.2017.06.015 [10] CHENG M, LIU F J. Research progress in processing technology of honeycomb materials[J] . Aeronautical Manufacturing Technology,2016(3):48 − 54. [11] LANGDON G S, NURICK G N, YAHYA M Y, et al. The response of honeycomb core sandwich panels with aluminum and composite face sheets to blast loading[J] . Journal of Sandwich Structures and Materials,2010,12(6):733 − 754. [12] DHARMASENA K P, WADLEY H N G, XUE Z, et al. Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading[J] . International Journal of Impact Engineering,2008,35(9):1063 − 1074. doi: 10.1016/j.ijimpeng.2007.06.008 [13] CÔTÉ F, DESHPANDE V S, FLECK N A, et al.The out-of-plane compressive behavior of metallic honeycombs[J] . Materials Science and Engineering: A,2004,380(1):272 − 280. [14] SHAHDIN A, MEZEIX L, BOUVET C, et al. Fabrication and mechanical testing of glass fiber entangled sandwich beams[J] . Composite Structures, 2009, 90(4): 404−412. doi: 10.1016/j.compstruct.2009.04.003 [15] TORIBIO M G, SPEARING S M. Compressive response of notched glass-fiber epoxy/honeycomb sandwich panels[J] . Composites Part A: Applied Science and Manufacturing,2001,32(6):859 − 870. [16] IVAÑEZ I, SANCHEZ-SAEZ S. Numerical modelling of the low-velocity impact response of composite sandwich beams with honeycomb core[J] . Composite Structures, 2013, 106: 716–723. [17] CRUPI V, EPASTO G, GUGLIELMINO E. Collapse modes in aluminium honeycomb sandwich panels under bending and impact loading[J] . International Journal of Impact Engineering,2012,43:6 − 15. doi: 10.1016/j.ijimpeng.2011.12.002 [18] AI S G, MAO YQ, PEI Y M. et al. Study on aluminum honeycomb sandwich panels with random skin/core weld defects[J] . Journal of Sandwith Structures and Marerials,2023,15(6):704 − 717. [19] 张天星, 段春争, 常宾宾, 等. 铝蜂窝芯加工缺陷对蜂窝平压性能的影响[J] . 组合机床与自动化加工技术,2022(2):133 − 136. [20] 孔祥皓. 含缺陷金属蜂窝夹层结构的力学性能分析与失效评估研究[D] . 哈尔滨: 哈尔滨工业大学, 2010. -

下载:

下载: