Modeling, trajectory planning, and rhythm analysis of a six-axis stacking robot

-

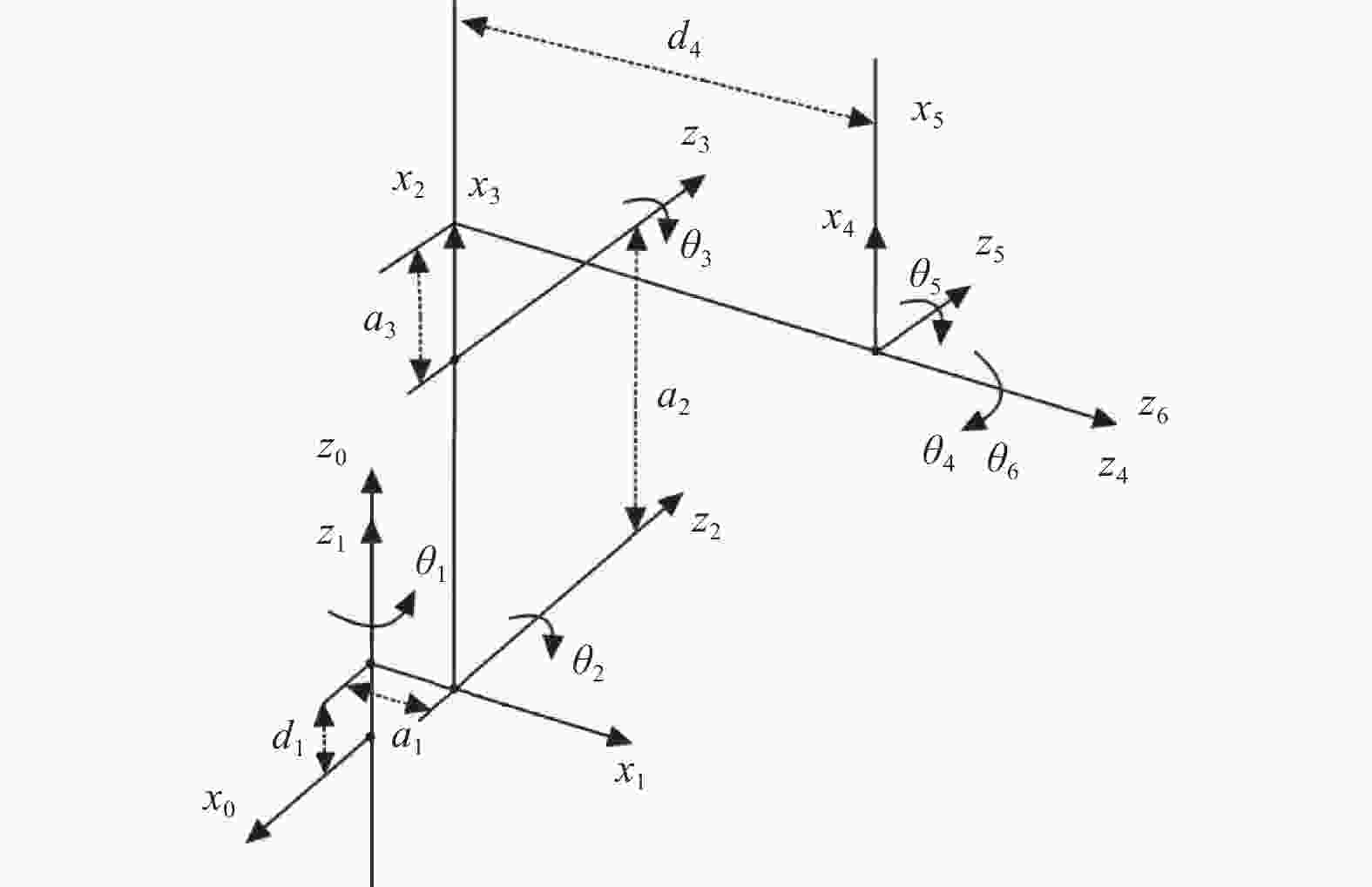

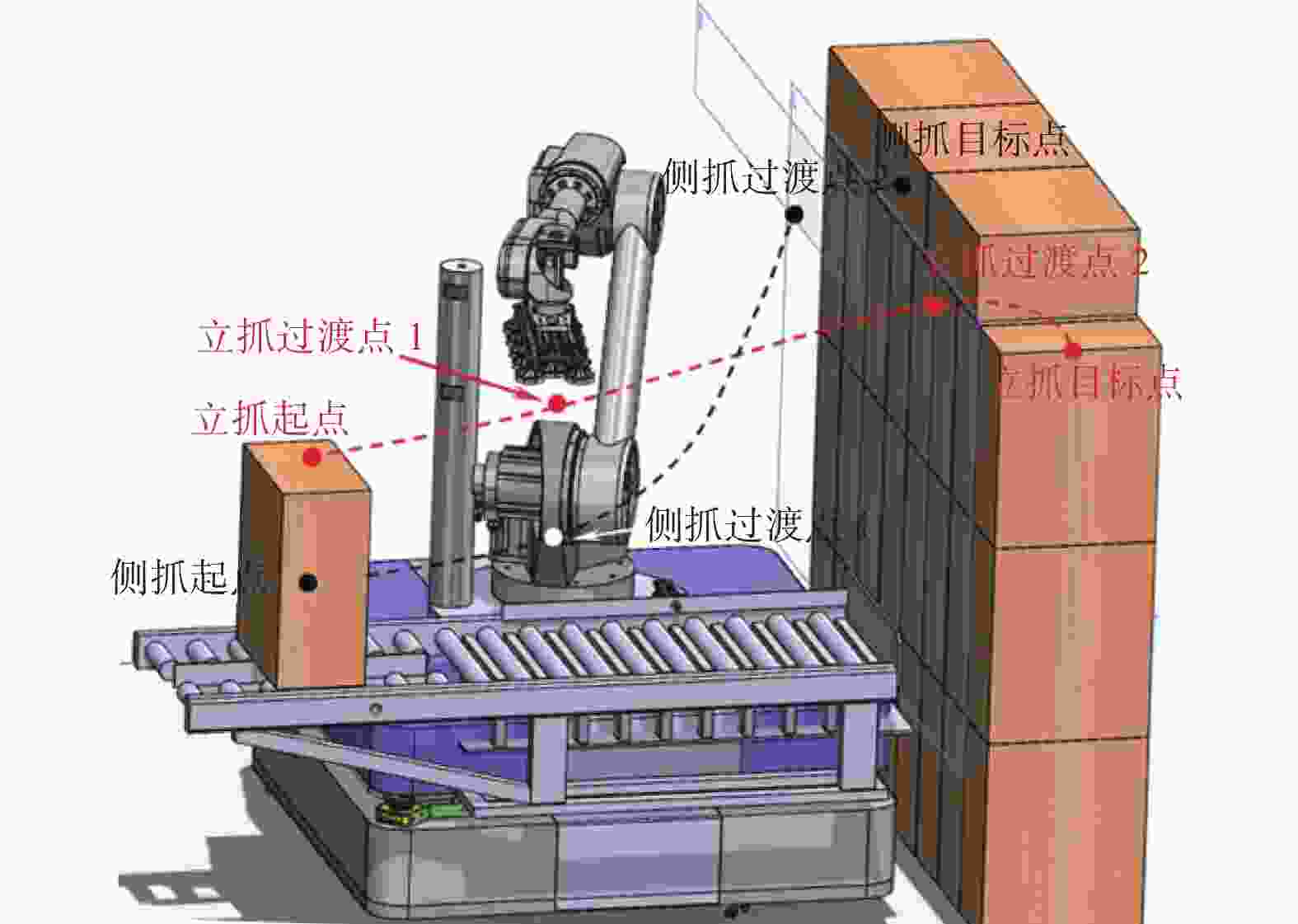

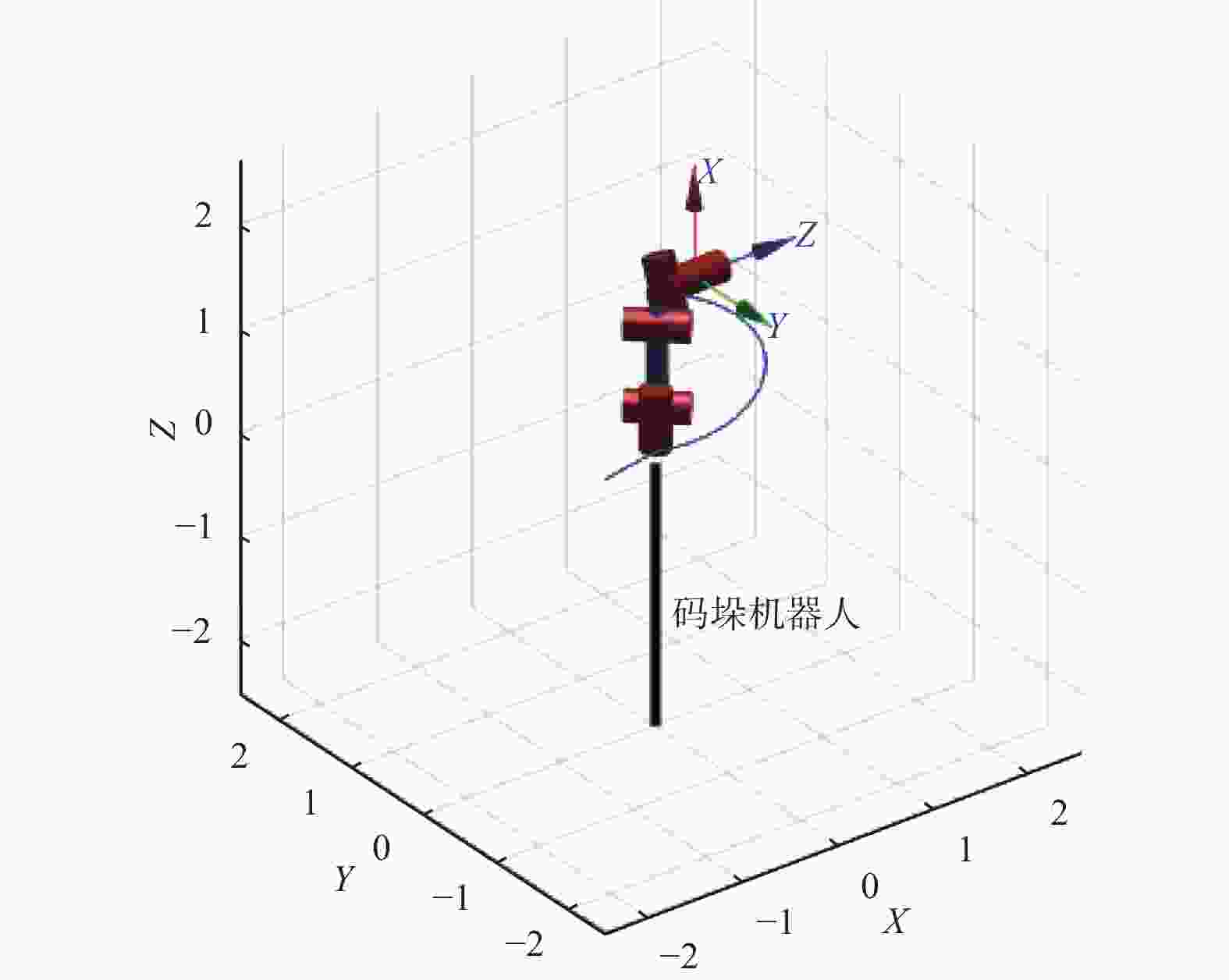

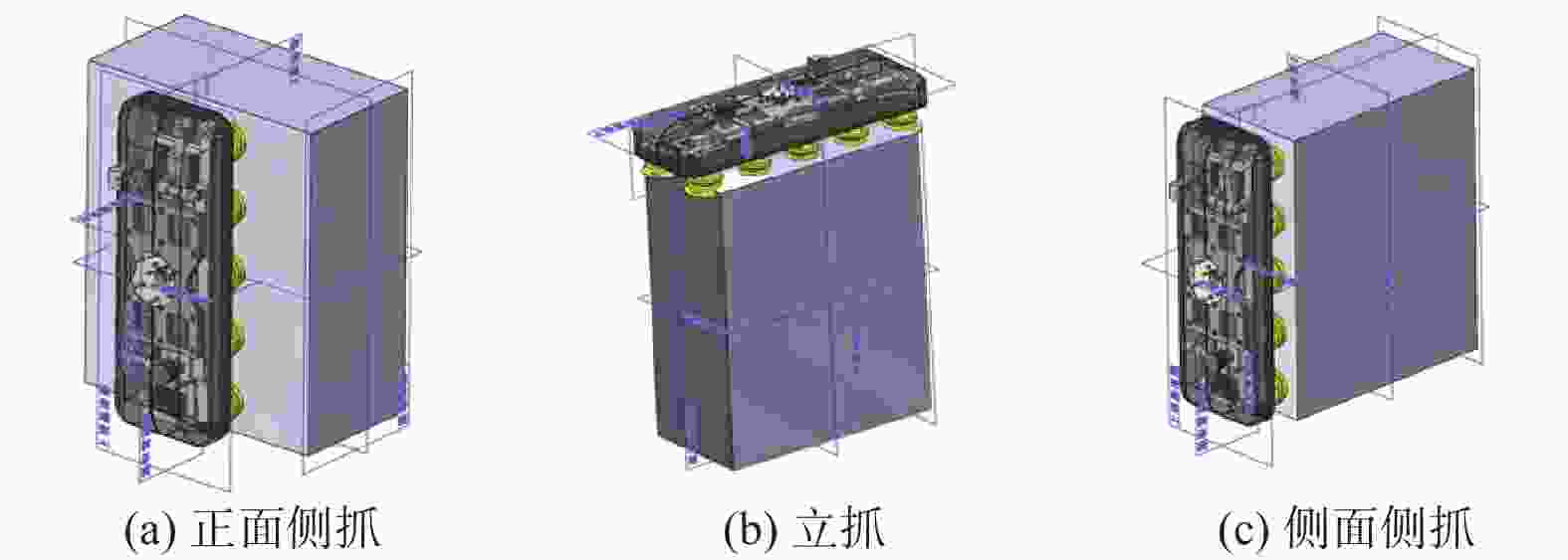

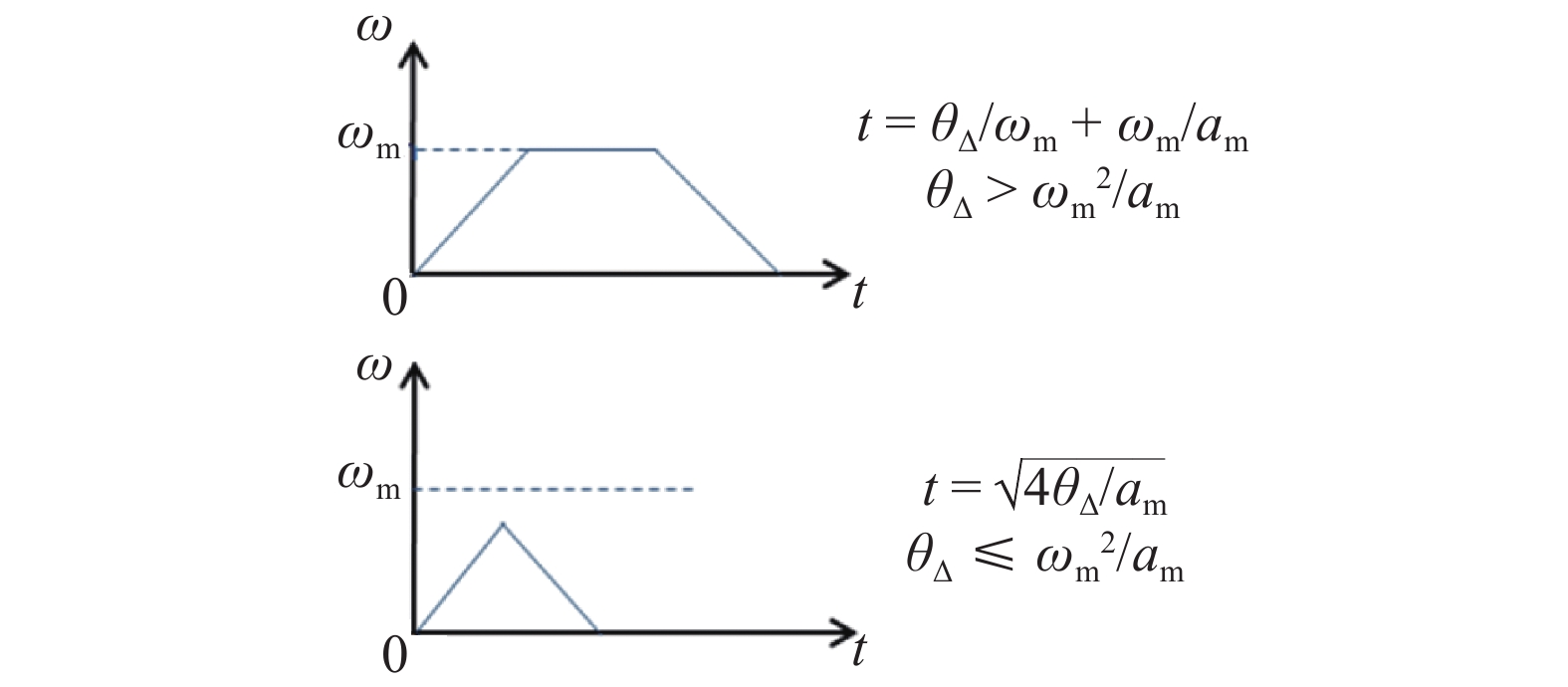

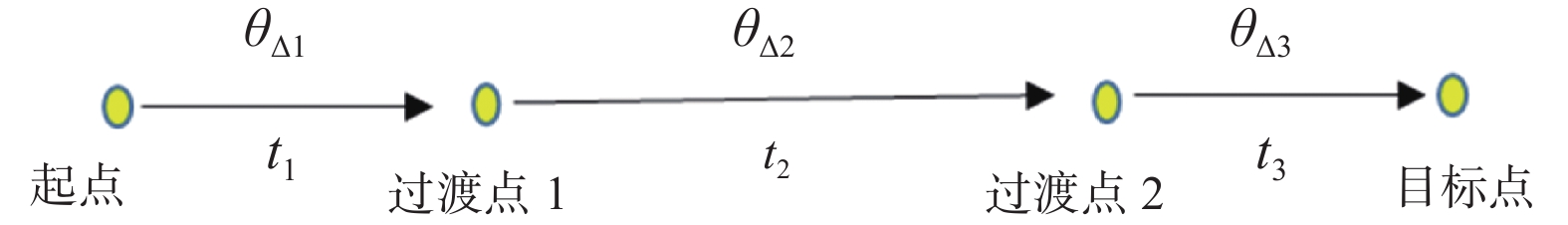

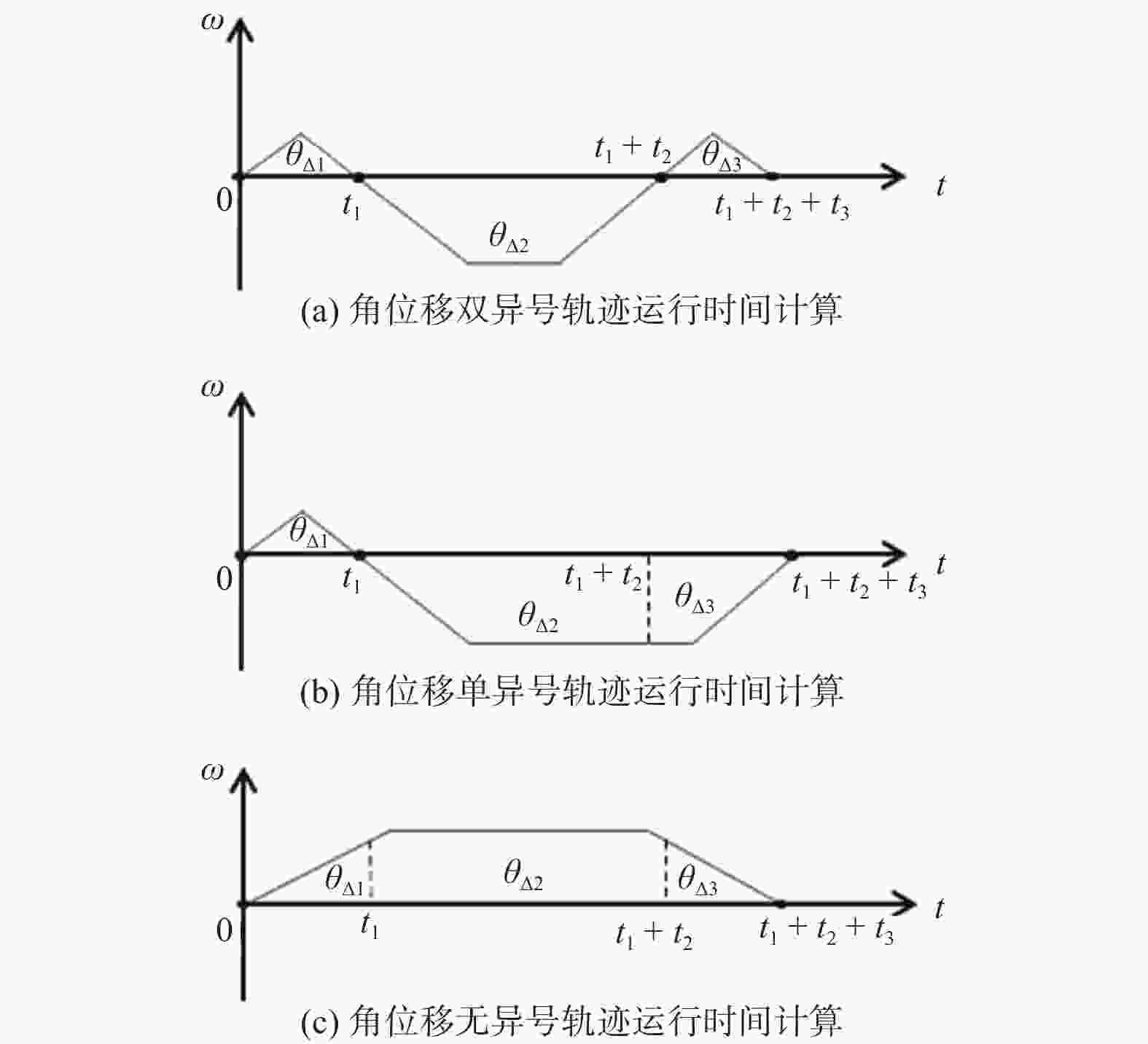

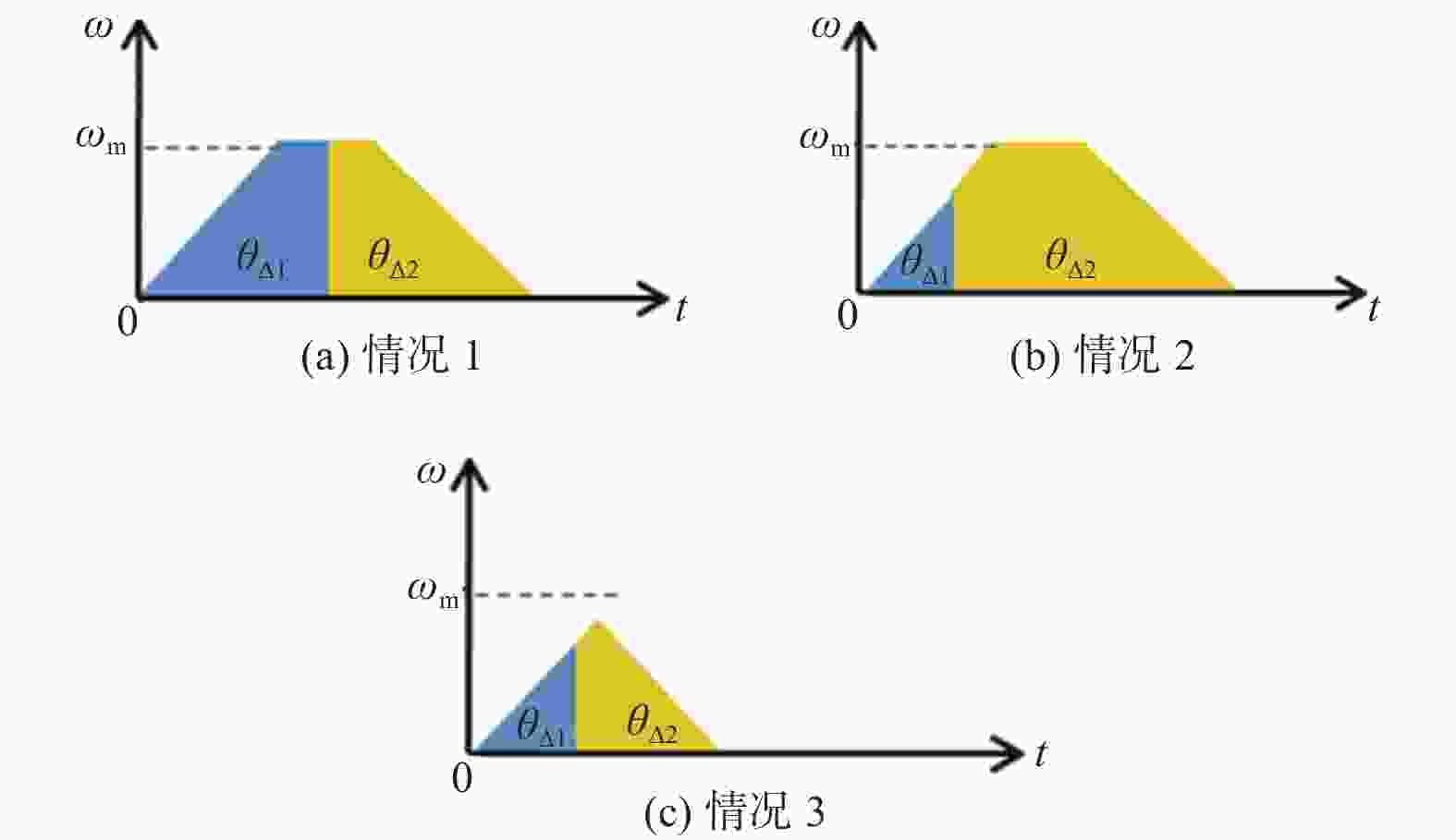

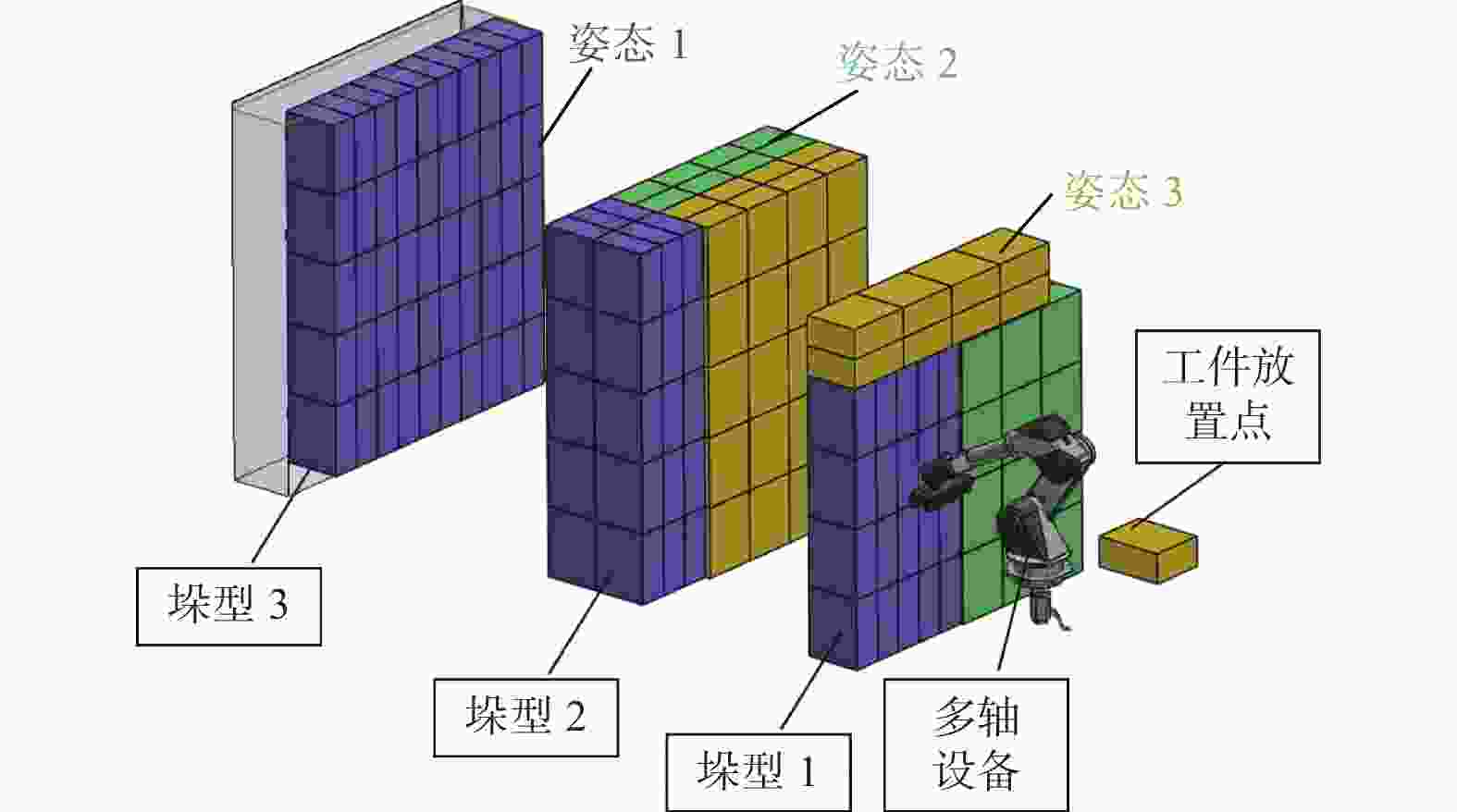

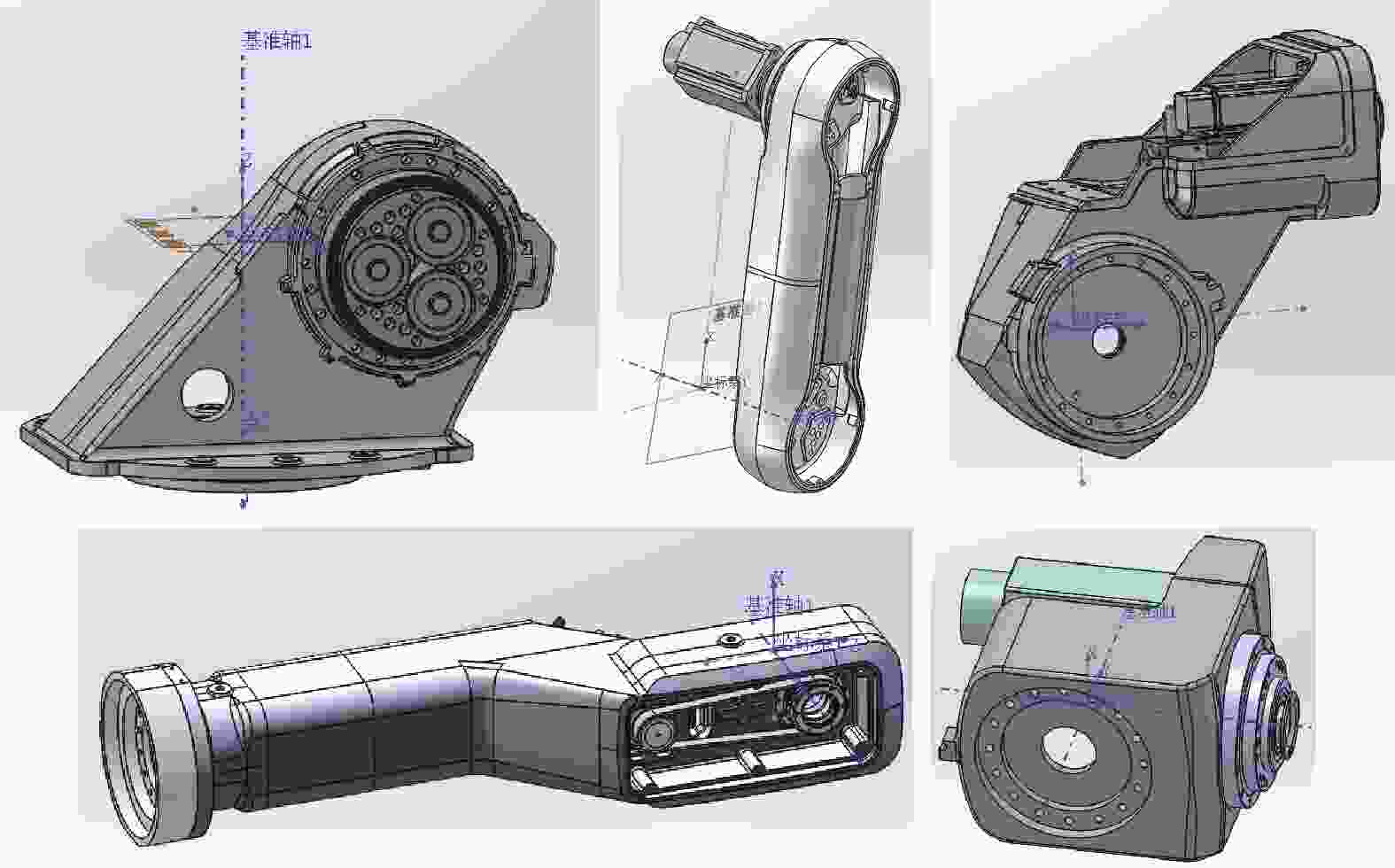

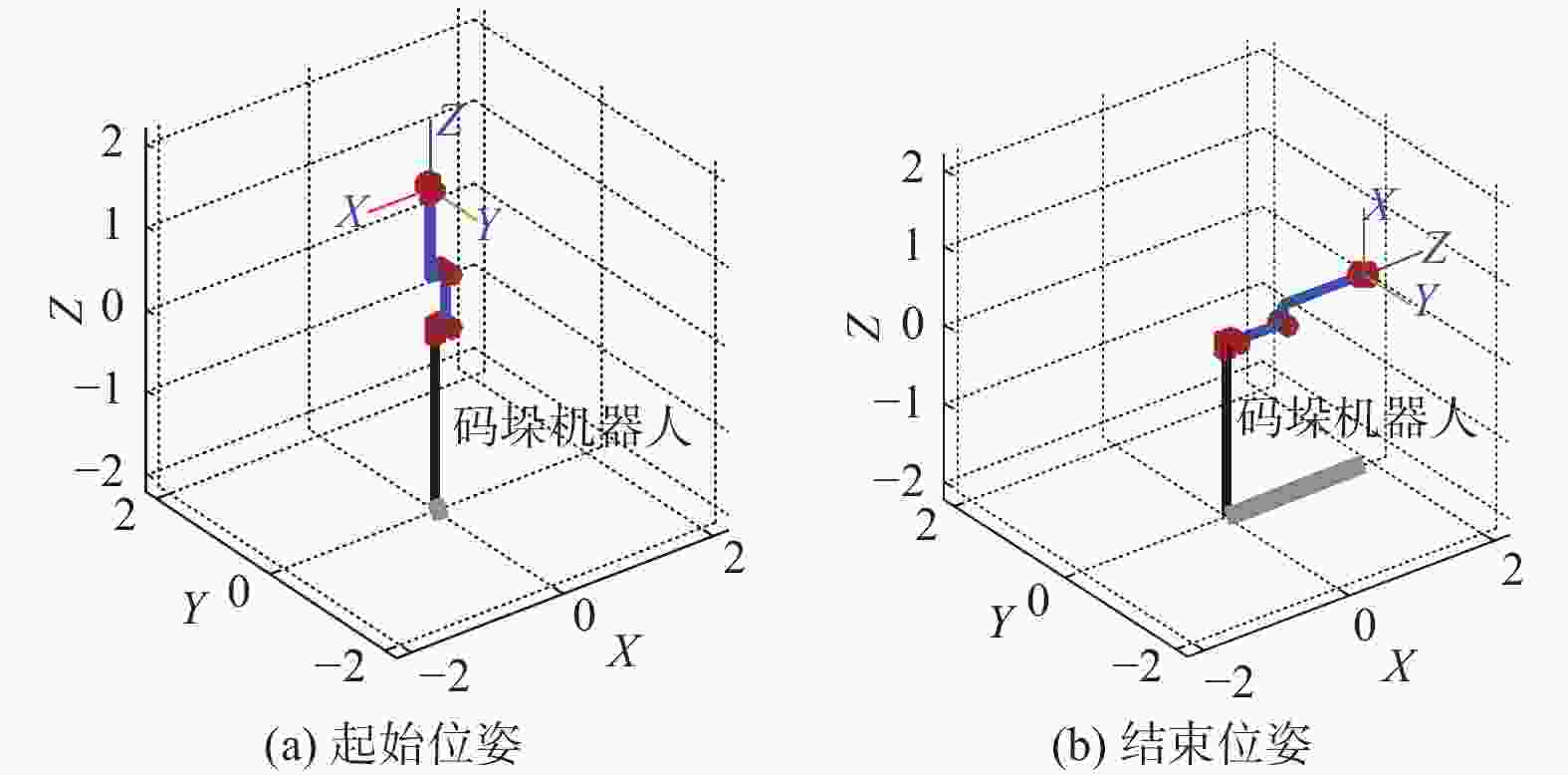

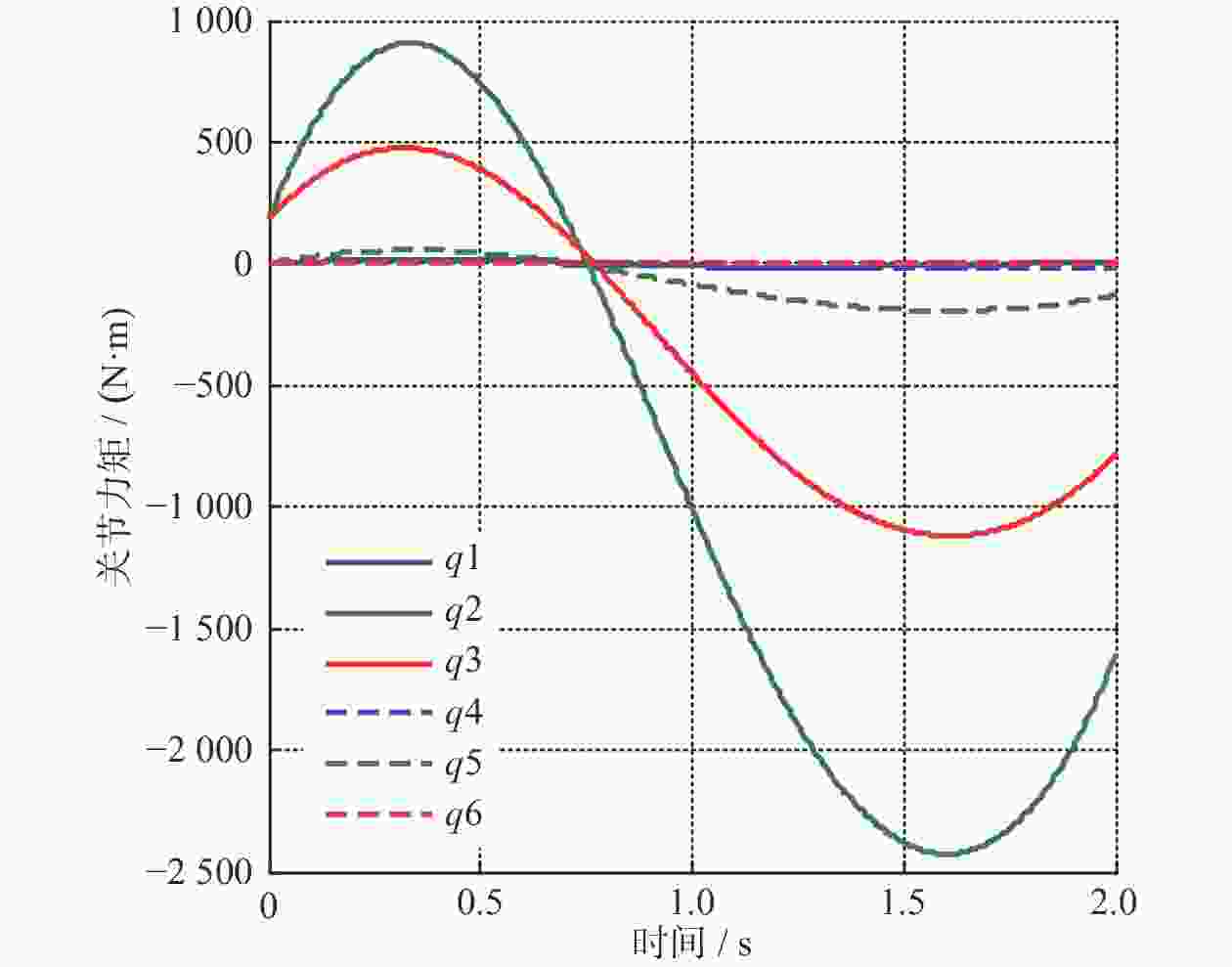

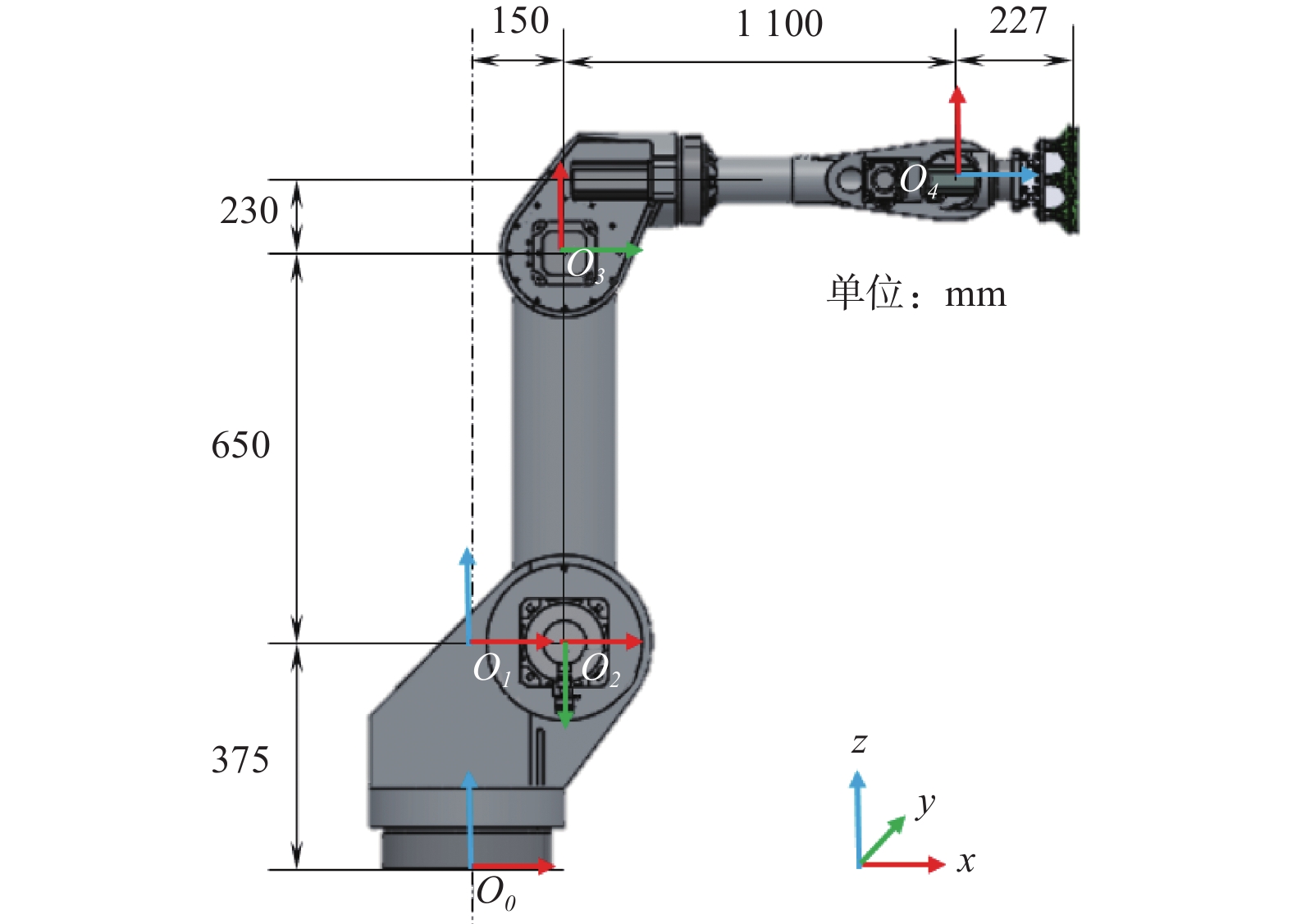

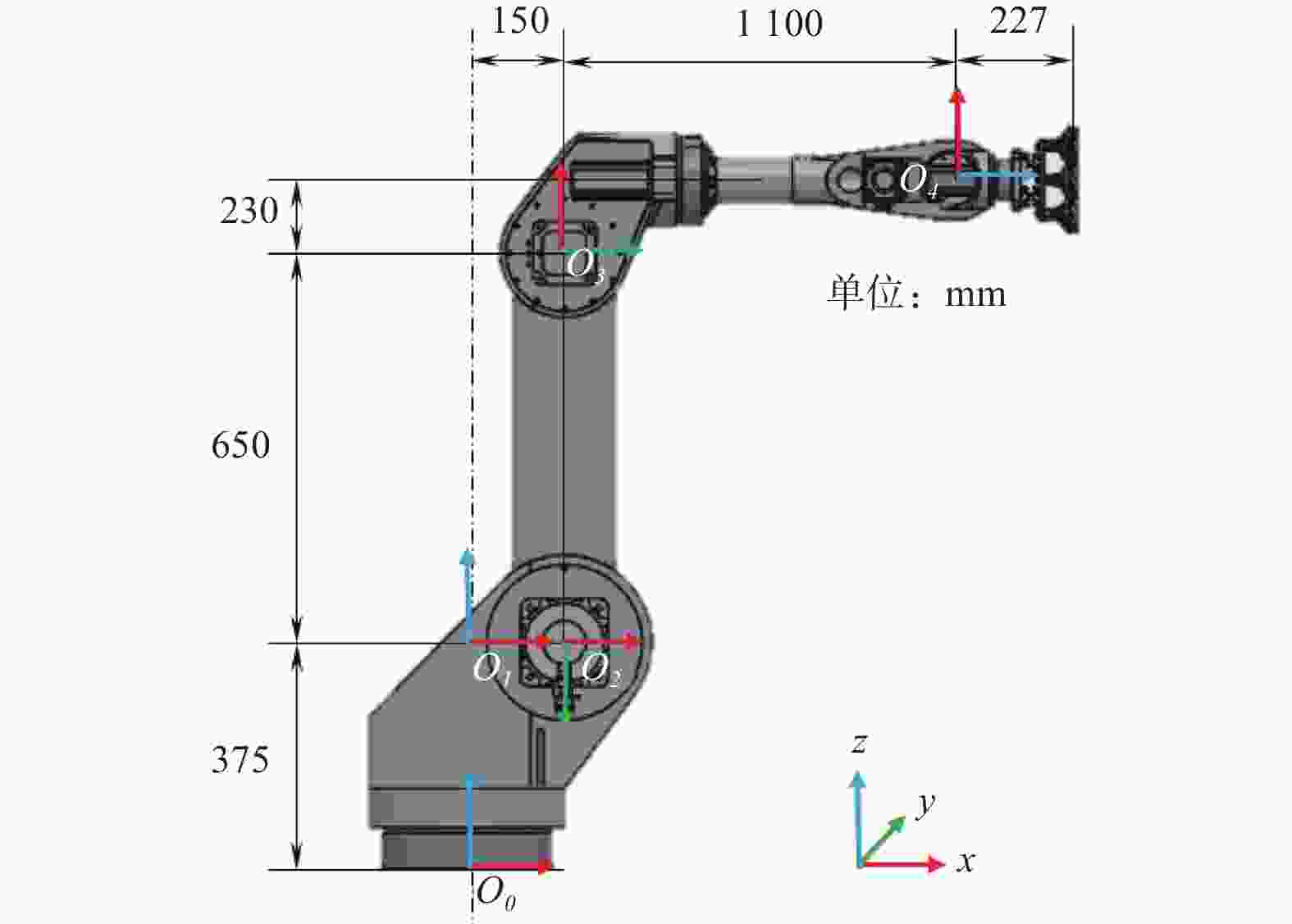

摘要: 提出一种基于Matlab的六自由度码垛机器人运动学和动力学建模方法,进行码垛轨迹规划与节拍分析。首先根据改进D-H法建立六自由度码垛机器人连杆坐标系及其变换关系,利用Matla软件中机器人工具箱建立仿真模型。针对不同的工件垛型和堆叠姿态要求,面向码垛任务需求进行搬运轨迹规划和节拍分析,对机器人码垛的轨迹、节拍、时间、效率等参数分析与计算。根据所设计机器人各连杆的质量、惯性矩和质心等参数,建立机器人动力学模型,数值分析获得各关节力矩曲线。通过仿真分析机器人码垛过程中运动情况,可为机器人结构设计和关键零部件选型提供必要依据。Abstract: The kinematics and dynamics modeling method for a six-degree-of-freedom stacking robot using Matlab was proposed, as well as stacking trajectory planning and rhythm analysis methods. The improved D-H method was employed to establish coordinate systems and transformation matrices for robot links, followed by the contruction of a simulation model through robot toolbox in Matlab. Trajectory planning and operational rhythm analysis were conducted according to different pallet patterns and stacking postures, which enabled a comprehensive evaluation of trajectory parameters, rhythm time, efficiency and other parameters. Based on the parameters of the mass, moment of inertia, and center of mass of each link of the designed robot, a dynamics model of the robot was established in Matlab for numerical analysis to obtain the torque curves of each joint. Simulation results demonstrate that the motion characteristics of the robot during palletizing operations can provide critical references for mechanical structure design and key component selection.

-

Key words:

- stacking robot /

- Matlab software /

- kinematics /

- trajectory planning /

- rhythm analysis /

- dynamics

-

表 1 码垛机器人的D-H参数

Table 1. D-H parameters of stacking robot

关节 θi αi-1 ai-1 di 范围 1 θ1 0° 0 d1 −185° ~ 185° 2 θ2 −90° a1 0 −165° ~ −15° 3 θ3 0° a2 0 −90° ~ 110° 4 θ4 −90° a3 d4 −180° ~ 180° 5 θ5 90° 0 0 −120° ~ 120° 6 θ6 −90° 0 0 −180° ~ 180° 表 2 搬运轨迹中4个节点位姿坐标

Table 2. Pose coordinates of four nodes in transportation trajectory

节点 X/mm Y/mm Z/mm Wx/(°) Py/(°) Rz/(°) 起点 −960.0 −540 415.0 180 180 180 过渡点1 −360.0 −540 500.0 −180 −180 180 过渡点2 502.5 729 1128.5 0 −90 180 目标点 967.5 729 1128.5 0 −90 180 表 3 对应关节坐标空间中各关节角度

Table 3. Angles of each joint in corresponding joint coordinate space

节点 J1/(°) J2/(°) J3/(°) J4/(°) J5/(°) J6/(°) 起点 −150.6 17.4 28.7 0 43.8 29.4 过渡点1 −123.7 −19.9 58.1 0 51.8 56.3 过渡点2 36.0 −61.0 48.8 −73.7 37.7 69.8 目标点 12.4 −24.4 36.8 −134.3 17.5 135.6 表 4 各关节每段轨迹的角位移

Table 4. Angular displacement of joint trajectory segment

角位移 J1/(°) J2/(°) J3/(°) J4/(°) J5/(°) J6/(°) θΔ1 27.0 −37.3 29.4 0 7.9 27.0 θΔ2 159.7 −41.1 −9.3 −73.7 −14.0 13.4 θΔ3 −23.6 36.7 −12.0 −60.5 −20.3 65.9 表 5 轨迹节拍时间

Table 5. Trajectory beat time

轨迹 轨迹段1 轨迹段2 轨迹段3 总时间 节拍时间/s 1.5164 1.7874 0.4939 3.7977 表 6 各垛型搬运时间

Table 6. Handling time for each stack type

参数 垛型1 垛型2 垛型3 数量/箱 52 55 50 时间/s 189.54 184.98 92.46 节拍/(箱·h−1) 987 1070 1946 -

[1] 孙阳, 杨先海, 代瑞恒, 等. 六自由度机器人的运动学分析及码垛轨迹规划[J] . 机床与液压,2021,49(21):33 − 37. [2] 刘鹏, 宋涛, 贠超, 等. 焊接机器人运动学分析及轨迹规划研究[J] . 机电工程,2013,30(4):390 − 394. [3] 陈守欢, 周婷婷, 胡天亮. 六自由度铣削加工机器人刚度建模及误差补偿[J] . 计算机集成制造系统,2023,29(2):404 − 418. [4] CHEN C Y, DAI J, YANG G, et al. Sensor-based force decouple controller design of macro–mini manipulator[J] . Robotics and Computer-Integrated Manufacturing,2023,79:102415. doi: 10.1016/j.rcim.2022.102415 [5] 魏雅君, 邱国梁, 丁广和, 等. 一种重载码垛机器人结构优化设计方法[J] . 工程设计学报, 2020, 27(3): 332−339. [6] 黄冰鹏, 林义忠, 杨中华, 等. 码垛机器人的研究与应用现状[J] . 包装工程,2017,38(5):82 − 87. [7] 贺莹, 梅江平, 方志炜, 等. 一种高速重载码垛机器人机座的多目标优化设计[J] . 机械设计,2017,34(7):1 − 9. [8] 梁邻鉴. 重载码垛机器人设计及结构优化研究[D] . 上海: 上海交通大学, 2021. [9] 王殿君, 关似玉, 陈亚, 等. 六自由度搬运机器人动力学分析及仿真[J] . 机械设计与制造,2017(1):25 − 29. [10] 张程, 张卓. 码垛机器人运动学分析及关节空间轨迹规划研究[J] . 组合机床与自动化加工技术,2020(2):19 − 21, 25. [11] 熊有伦, 李文龙, 陈文斌, 等. 机器人学: 建模、控制与视觉[M] . 2版. 武汉:华中科技大学出版社, 2020. [12] 任军, 吴正虎, 曹秋玉. 基于MATLAB Robotics工具箱的ER50机器人轨迹规划与仿真[J] . 机械设计与制造,2022(8):33 − 36. -

下载:

下载: