Mechanism study on ultrasonic vibration assisted drilling of Al7075-T6/Ti6Al4V laminated materials

-

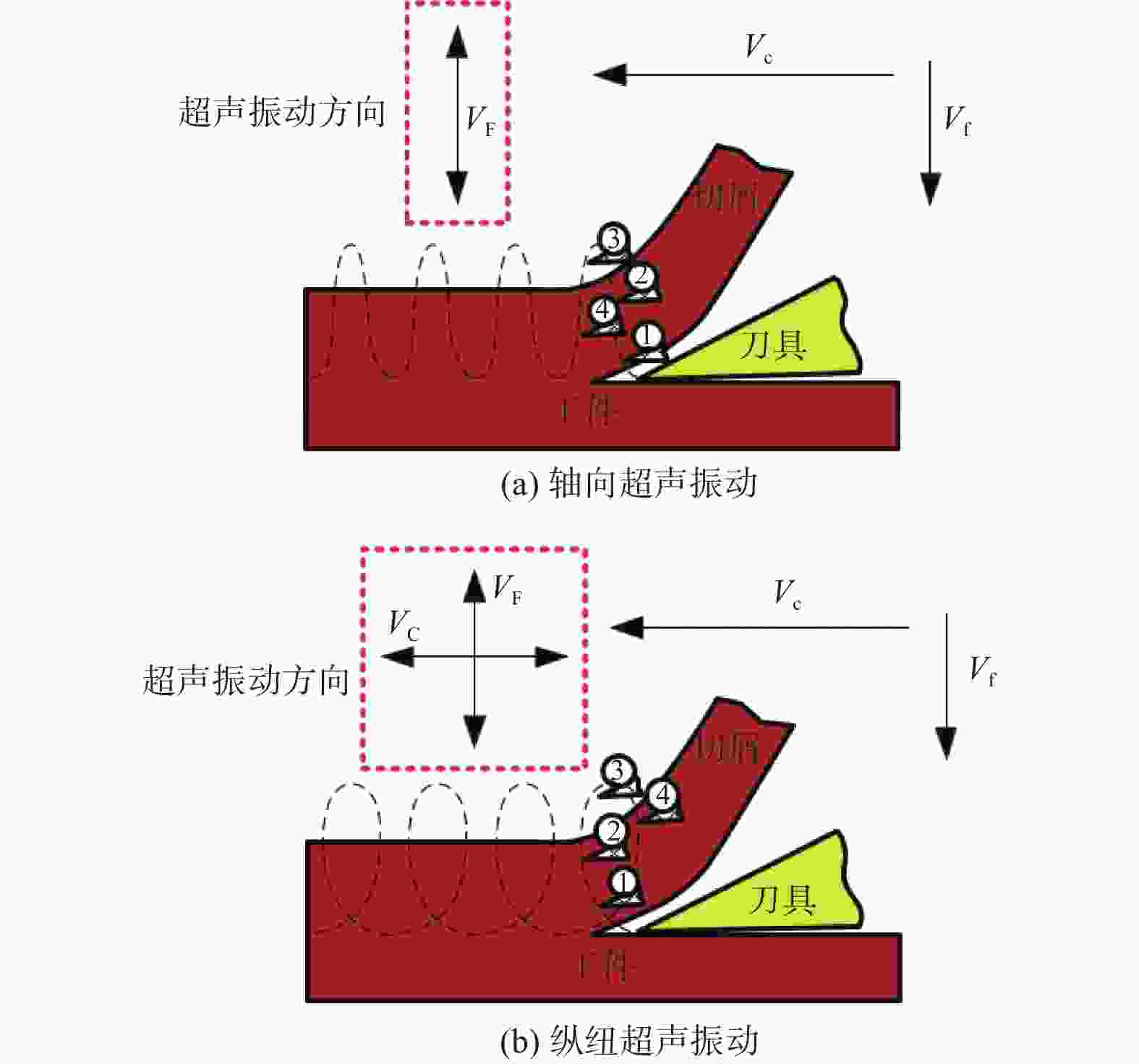

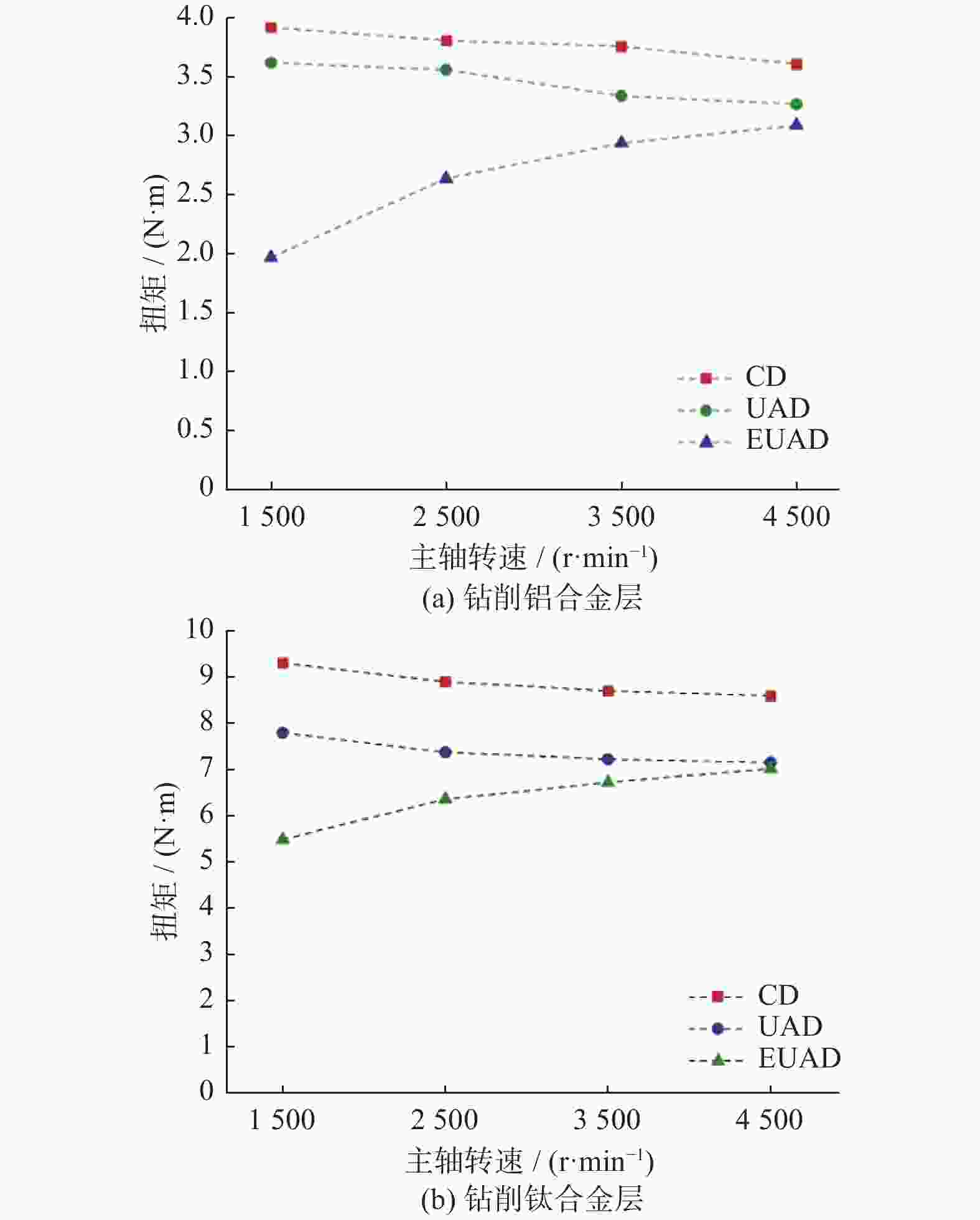

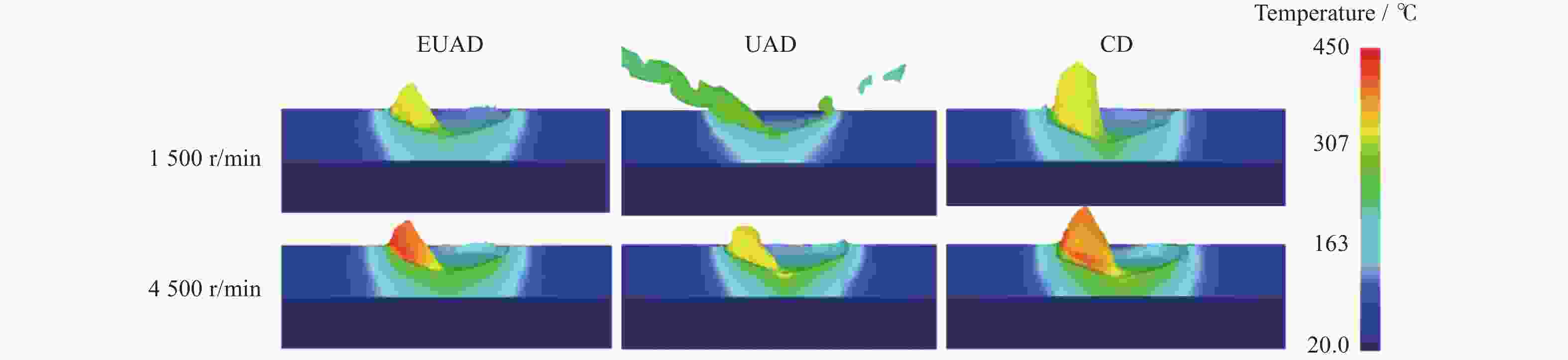

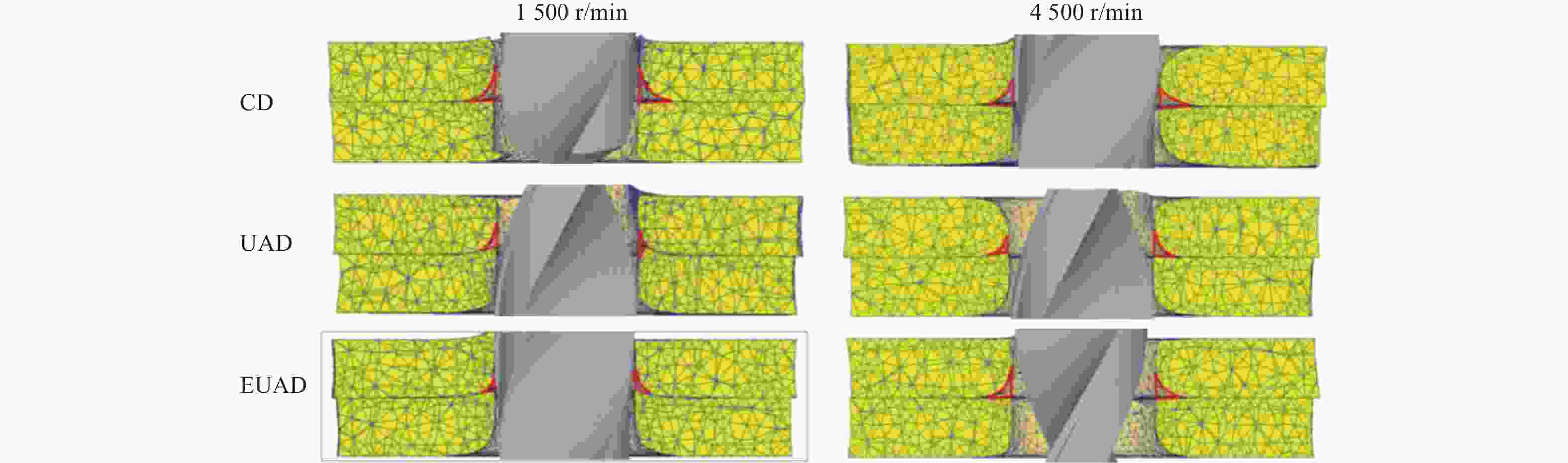

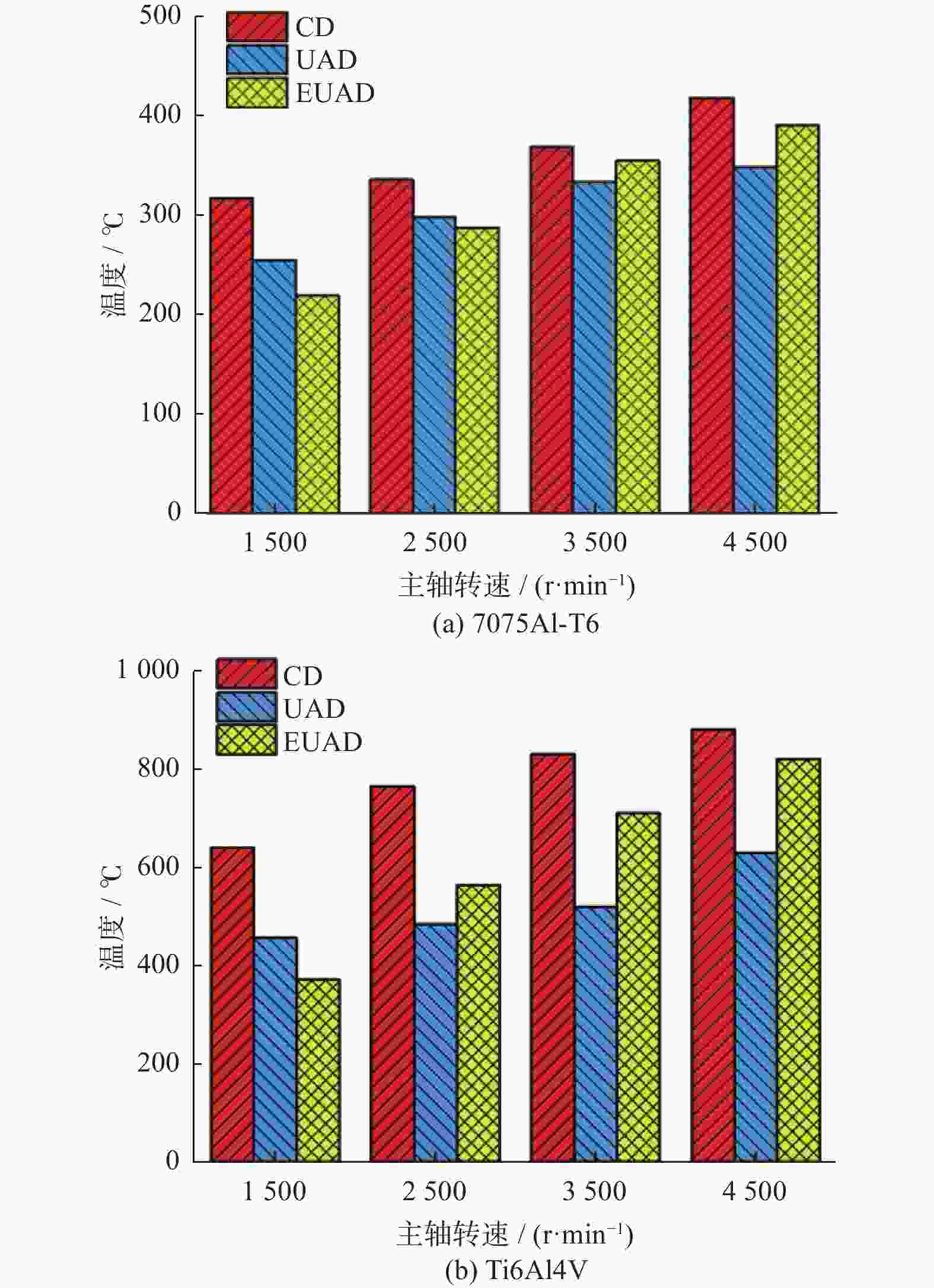

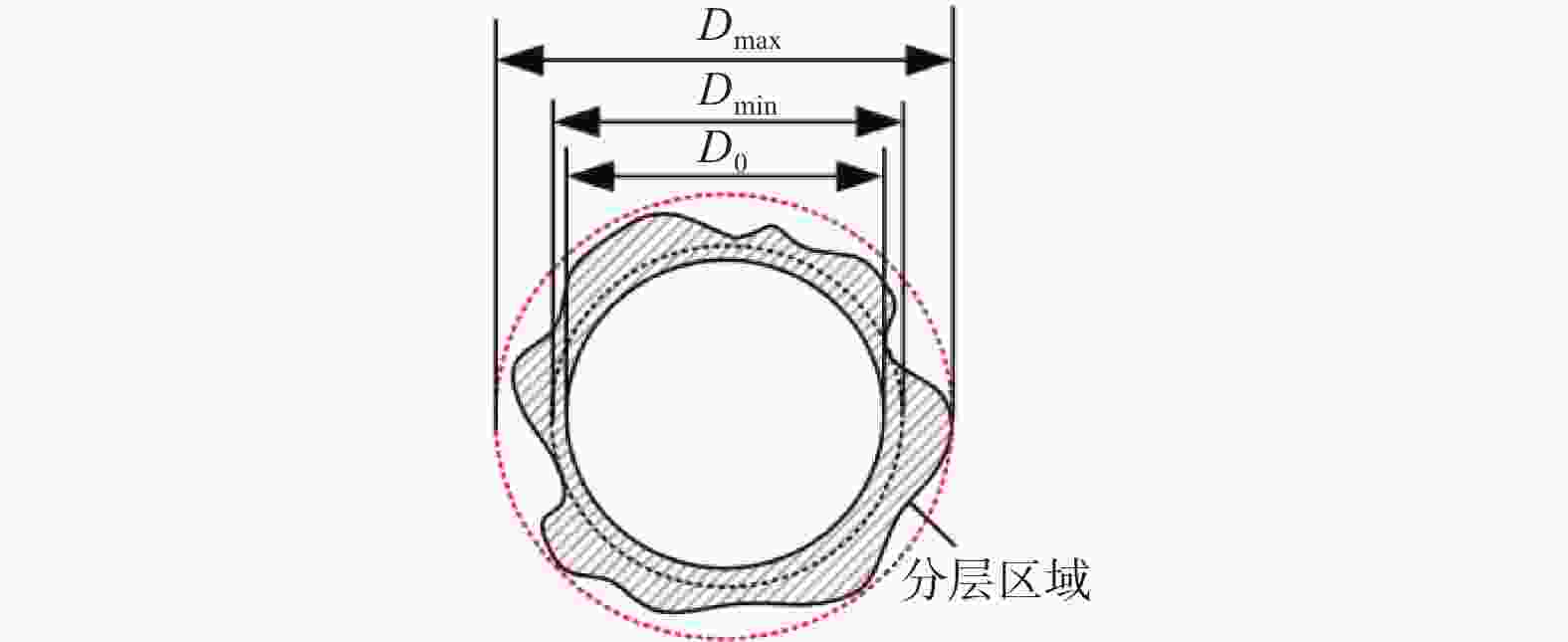

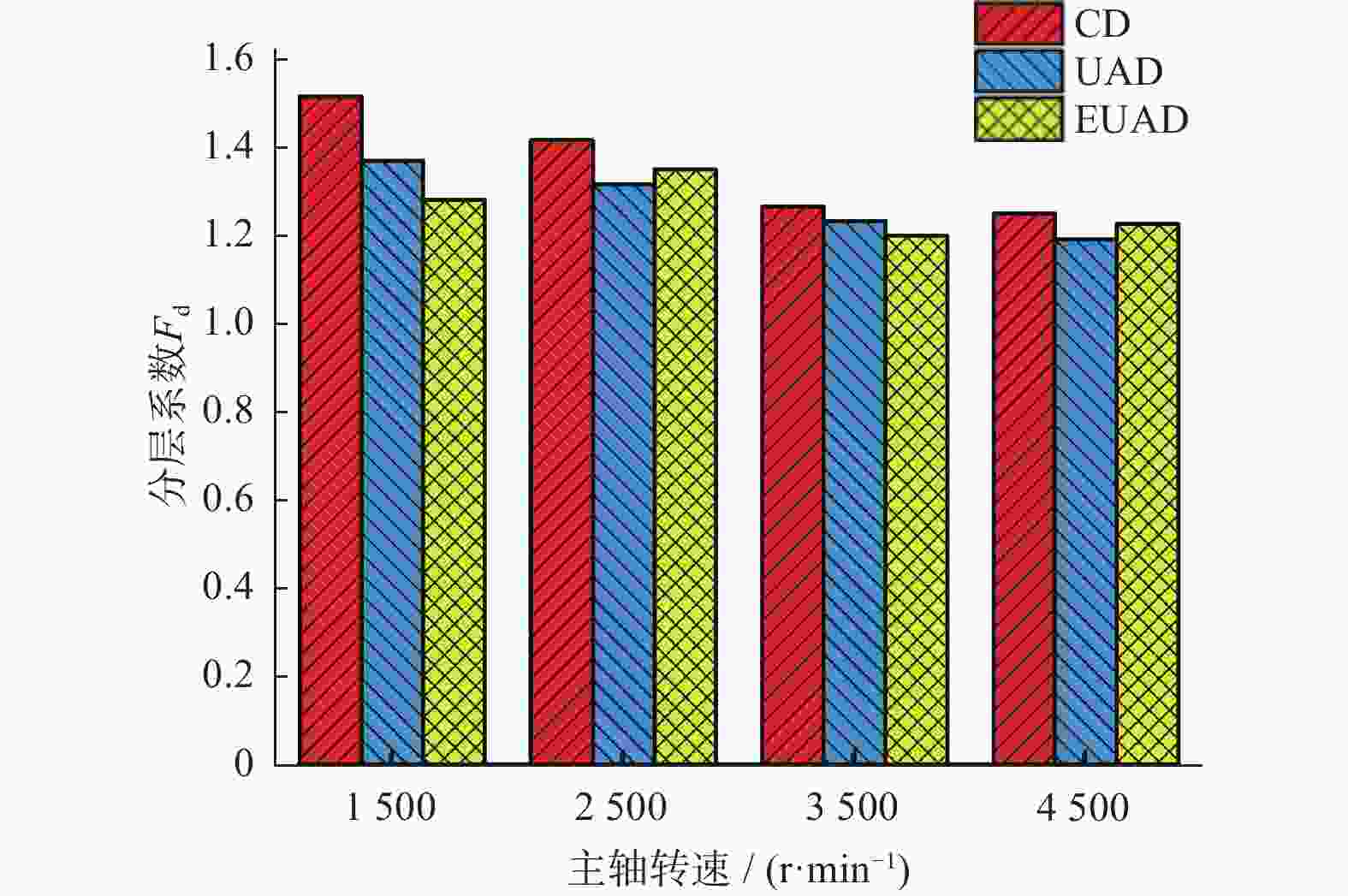

摘要: 分析不同转速和振动轨迹下Al7075-T6/Ti6Al4V叠层材料的超声振动辅助钻削加工过程。采用有限元软件开展钻削过程数值模拟,在振动辅助钻削Al7075-T6/Ti6Al4V条件下对钻削力、热量及分层等进行分析。结果表明,采用传统钻削(CD)、轴向振动辅助钻削(UAD)、纵扭振动辅助钻削(EUAD)不同切削方式,钻削力与温度均有明显改变。分层方面,铝合金比钛合金更容易受热软化效应的影响,发生抬升分层的可能性更大。钛合金底部失去支撑,发生推离分层可能性较大。采用超声振动改变各层受力,降低了钻削过程中钻削力、温度与分层缺陷。研究发现,低转速下EUAD有优越的钻削性能,对轴向力、扭矩与温度的降低分别达到30%以上,而高转速下其效果分别下降20%以上。

-

关键词:

- 超声振动 /

- 钻削 /

- Al7075-T6 /Ti6Al4V叠层材料 /

- 有限元法

Abstract: The ultrasonic vibration assisted drilling process of Al7075-T6/Ti6Al4V under varying rotational speeds and vibration trajectories was analyzed. The drilling process was simulated using the finite element software Deform, with detailed analysis conducted on the workpiece's drilling force, heat and delamination under vibration assisted conditions. The simulation results show that in the thermo-mechanical coupling model of titanium alloy and aluminum alloy drilling, the most significant changes in drilling force and temperature occur when comparing conventional drilling (CD), axial vibration assisted drilling (UAD), and longitudinal torsional vibration assisted drilling (EUAD) model. In terms of delamination, aluminum alloy is more prone to the thermal softening effect than titanium alloy, and the possibility of uplift delamination is greater. The bottom of titanium alloy loses support, and the possibility of pushing away delamination is also high. Ultrasonic vibration changes the force distribution of each layer, reducing the drilling force, temperature and delamination defects during the drilling process. It reveals that EUAD exhibits performance at low rotational speeds, achieving over 30% reduction in axial force, torque and temperature exceeds , whereas its effectiveness decreases by more than 20% at high speed. -

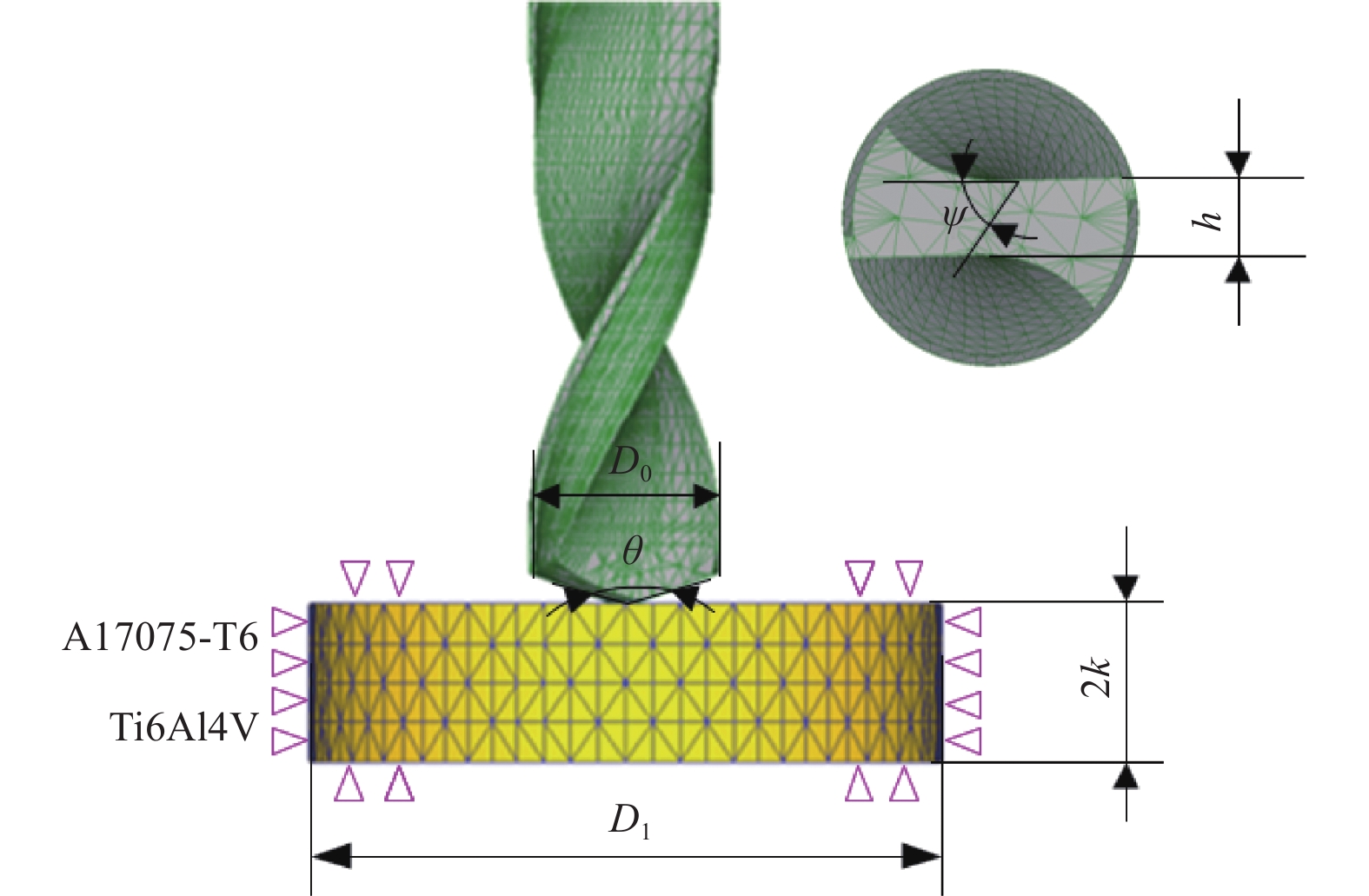

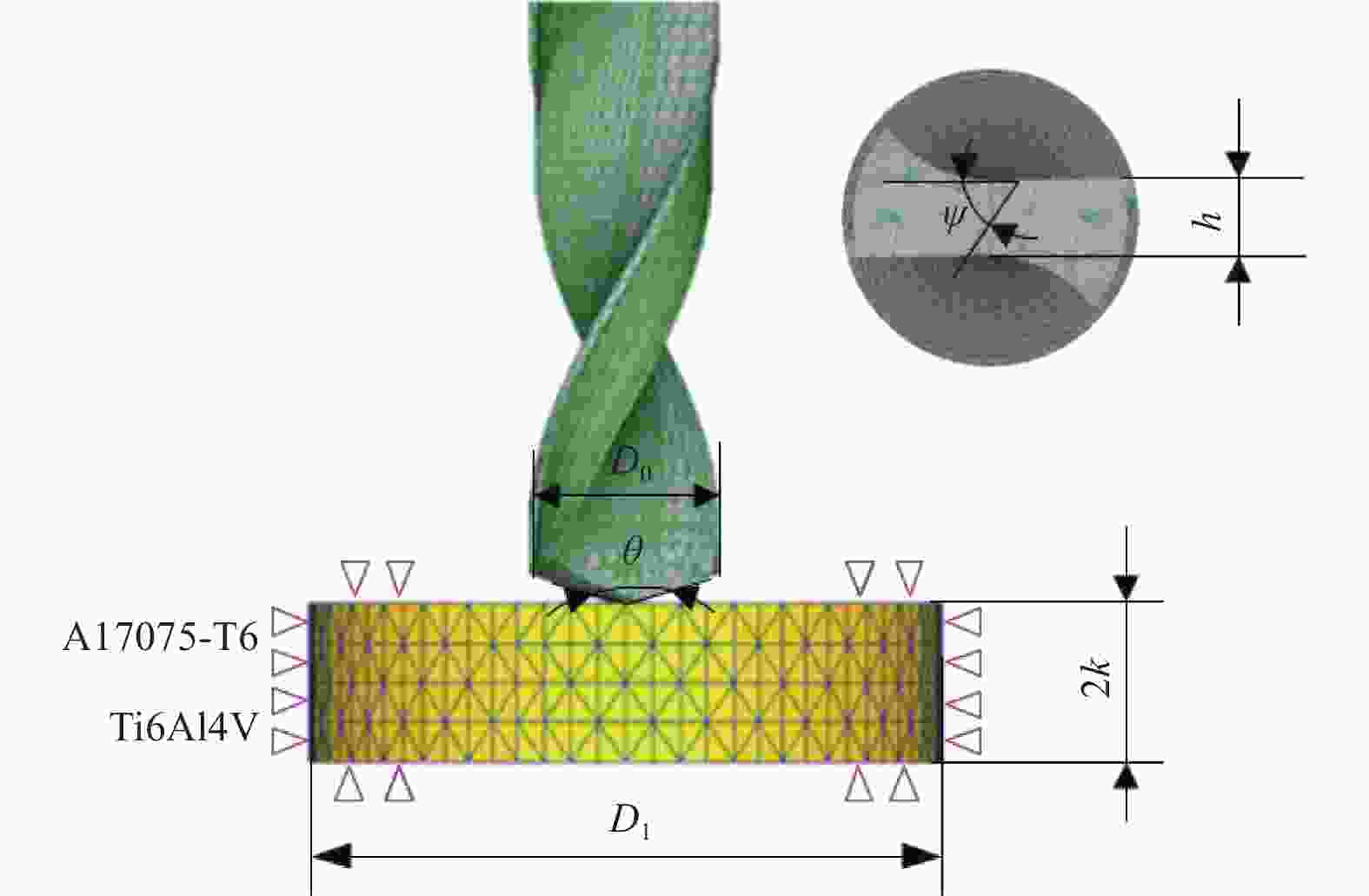

表 1 刀具参数

Table 1. Tool parameters

顶角θ/(°) 直径D0/mm 凿边厚度h/mm 螺旋角β/(°) 棱角α/(°) 140 6 1.5 30 60 表 2 工件材料物理属性

Table 2. Workpiece material property

属性 Ti6Al4V Al7075-T6 密度/(kg·m−3) 4430 2810 热膨胀系数/(μm·(m℃)−1) 1×10−5 2.2×10−5 杨氏模量/GPa 105 71.7 泊松比 0.3 0.25 导热系数/(W·(m·K)−1) 6.7 130 -

[1] CHEN Y, ZHANG J, LI Z, et al. Manufacturing technology of lightweight fiber-reinforced composite structures in aerospace: current situation and toward intellectualization[J] . Aerospace,2023,10(3):206. doi: 10.3390/aerospace10030206 [2] ZHU L, LI N, CHILDS P R N. Light-weighting in aerospace component and system design[J] . Propulsion and Power Research,2018,7(2):103 − 119. doi: 10.1016/j.jppr.2018.04.001 [3] SINMA ZÇELIK T, AVCU E, BORA M Ö, et al. A review: fibre metal laminates, background, bonding types and applied test methods[J] . Materials & Design,2011,32(7):3671 − 3685. [4] WU S J , WEI L, GUO G Q, et al. Study on the mechanism of AL2024-T351/Ti6Al4V laminated materials by ultrasonic vibration drilling[J] . Archives of Civil and Mechanical Engineering,2022,22:161. doi: 10.1007/s43452-022-00482-w [5] AAMIR M, GIASIN K, TOLOUEI-RAD M, et al. A review: drilling performance and hole quality of aluminium alloys for aerospace applications[J] . Journal of Materials Research and Technology,2020,9(6):12484 − 12500. doi: 10.1016/j.jmrt.2020.09.003 [6] Wilk M S, Śliwa R E. The influence of features of aluminium alloys 2024, 6061 and 7075 on the properties of glare-type composites[J] . Archives of Metallurgy and Materials, 2015, 60(4):3101 − 3108. [7] WEI L, WANG D Z. Effect of ultrasound-assisted vibration on Ti6Al4V/Al2024-T351 laminated material processing with geometric tools[J] . The International Journal of Advanced Manufacturing Technology,2020,106:219 − 232. doi: 10.1007/s00170-019-04637-7 [8] 刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展[J] . 航空材料学报,2020,40(3):77 − 94. doi: 10.11868/j.issn.1005-5053.2020.000061 [9] ZHANG L B, WANG L J, LIU X Y. A mechanical model for predicting critical thrust forces in drilling composite laminates[J] . Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2001,215(2):135 − 146. doi: 10.1243/0954405011515235 [10] 台春雷, 单丹丹. 钛合金与铝合金叠层结构铰孔精加工工艺研究[J] . 沈阳航空航天大学学报,2015,32(5):63 − 67. doi: 10.3969/j.issn.2095-1248.2015.05.009 [11] FLEISCHER J, TETI R, LANZA G, et al. Composite materials parts manufacturing[J] . CIRP Annals - Manufacturing Technology,2018,67:603 − 626. doi: 10.1016/j.cirp.2018.05.005 [12] RUBIO J C, ABRAO A M, FARIA P E, et al. Effects of high speed in the drilling of glass fibre reinforced plastic: evaluation of the delamination factor[J] . International Journal of Machine Tools and Manufacture,2008,48(6):715 − 720. doi: 10.1016/j.ijmachtools.2007.10.015 [13] SONIA P, JAIN J K, SAXENA K K. Influence of ultrasonic vibration assistance in manufacturing processes: a review[J] . Materials and Manufacturing Processes,2021,36(13):1451 − 1475. doi: 10.1080/10426914.2021.1914843 [14] HUSSEIN R, SADEK A, ELBESTAWI M A, et al. Elimination of delamination and burr formation using high-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material[J] . The International Journal of Advanced Manufacturing Technology,2019,105:859 − 873. doi: 10.1007/s00170-019-04248-2 [15] JIAO F, LI Y, NIU Y, et al. A review on the drilling of CFRP/Ti stacks: machining characteristics, damage mechanisms and suppression strategies at stack interface[J] . Composite Structures,2023,305:116489. doi: 10.1016/j.compstruct.2022.116489 [16] MA G, KANG R, YAN C, et al. Mechanical model of thrust force and torque in longitudinal-torsional coupled ultrasonic-assisted drilling of CFRP[J] . The International Journal of Advanced Manufacturing Technology, 2021, 119: 189–202. [17] MA G, KANG R, DONG Z, et al. Hole quality in longitudinal torsional coupled ultrasonic vibration assisted drilling of carbon fiber reinforced plastics[J] . Frontiers of Mechanical Engineering,2020,15:538 − 546. doi: 10.1007/s11465-020-0598-y [18] LIU Y, LI Q, QI Z, et al. Defect suppression mechanism and experimental study on longitudinal torsional coupled rotary ultrasonic assisted drilling of CFRPs[J] . Journal of Manufacturing Processes,2021,70:177 − 192. doi: 10.1016/j.jmapro.2021.08.042 [19] WANG J J, FENG P F, ZHANG J F, et al. Reducing cutting force in rotary ultrasonic drilling of ceramic matrix composites with longitudinal-torsional coupled vibration[J] . Manufacturing Letters,2018,18:1 − 5. doi: 10.1016/j.mfglet.2018.08.002 [20] CELAYA A, De LOPEZ LACALLE L N, CAMPA F J, et al. Ultrasonic assisted turning of mild steels[J] . International Journal of Materials and Product Technology,2010,37(1/2):60 − 70. [21] TIAN Y, ZOU P, WANG X, et al. Study on chip shapes in longitudinal-torsional composite ultrasonic vibration–assisted drilling of Ti-6Al-4V[J] . The International Journal of Advanced Manufacturing Technology,2023,128(11-12):5561 − 5571. doi: 10.1007/s00170-023-12242-y [22] UCUN İ. 3D finite element modelling of drilling process of Al7075-T6 alloy and experimental validation[J] . Journal of Mechanical Science and Technology,2016,30:1843 − 1850. doi: 10.1007/s12206-016-0341-0 [23] PARIDA A K. Simulation and experimental investigation of drilling of Ti-6Al-4V alloy[J] . International Journal of Lightweight Materials and Manufacture,2018,1(3):197 − 205. doi: 10.1016/j.ijlmm.2018.07.001 -

下载:

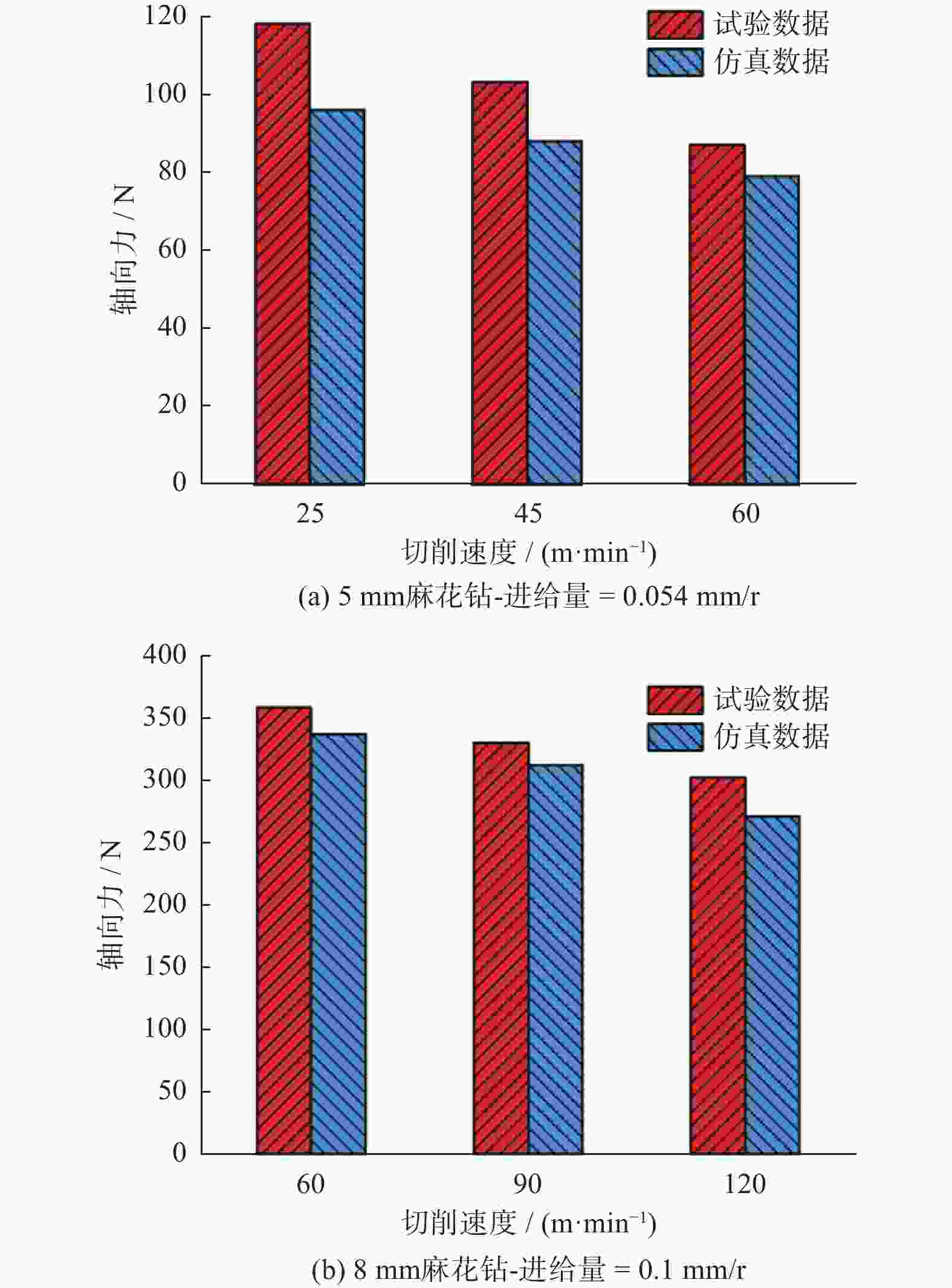

下载: