Experimental study on shear strength of geopolymer stabilized soft soil

-

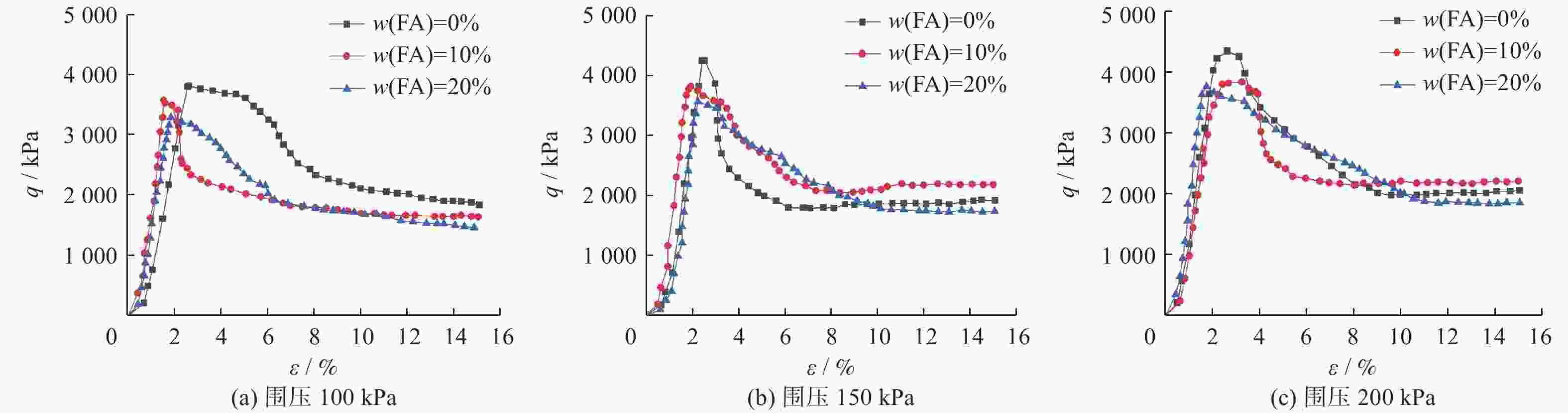

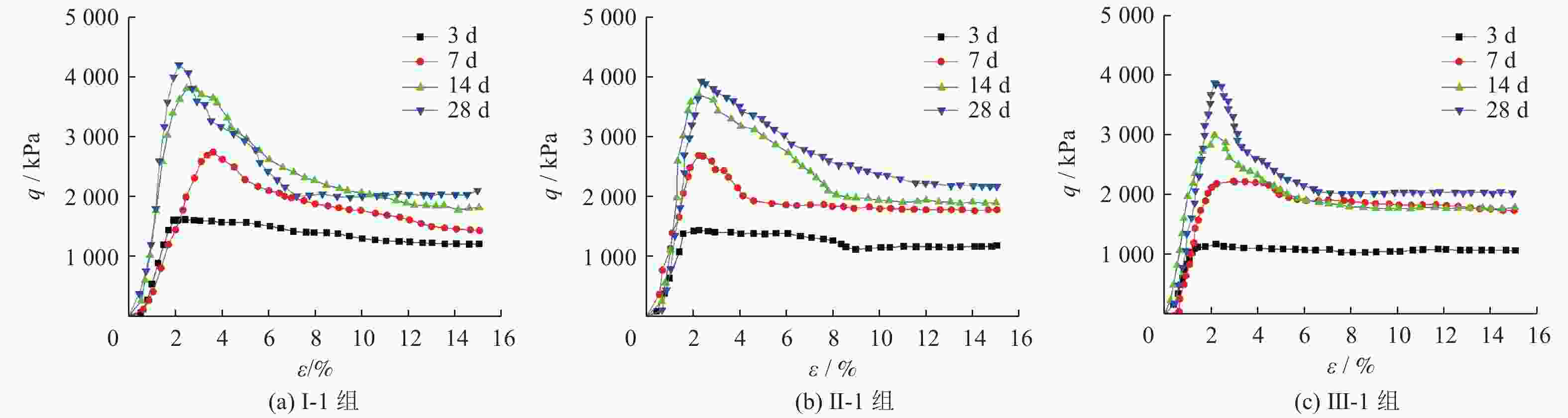

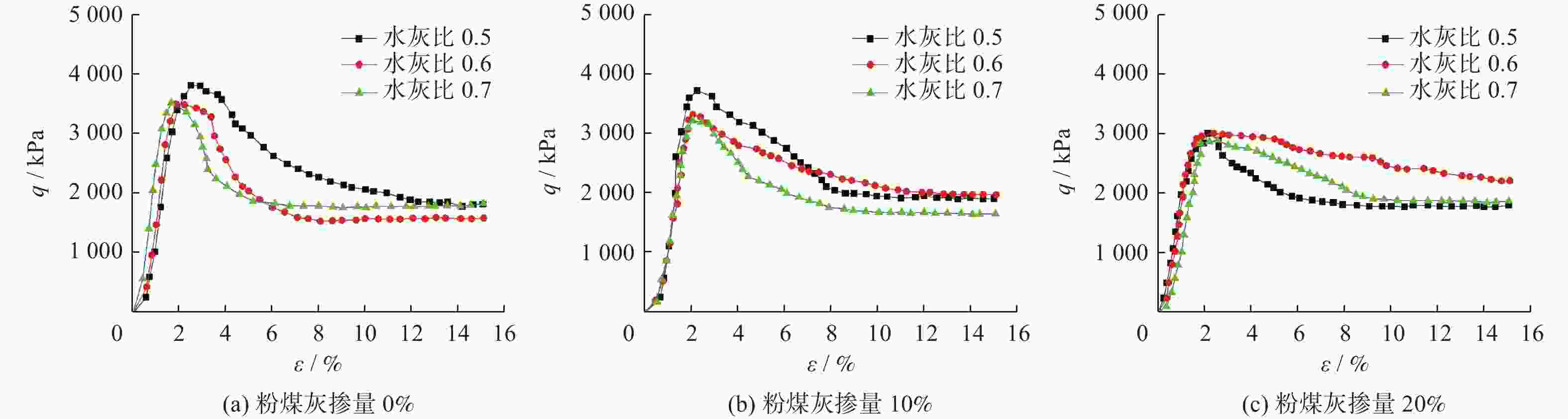

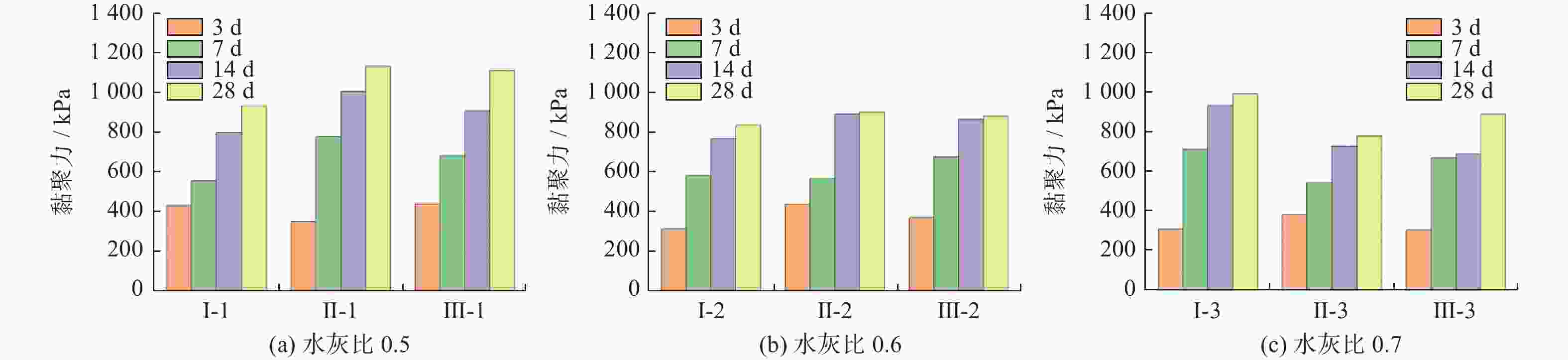

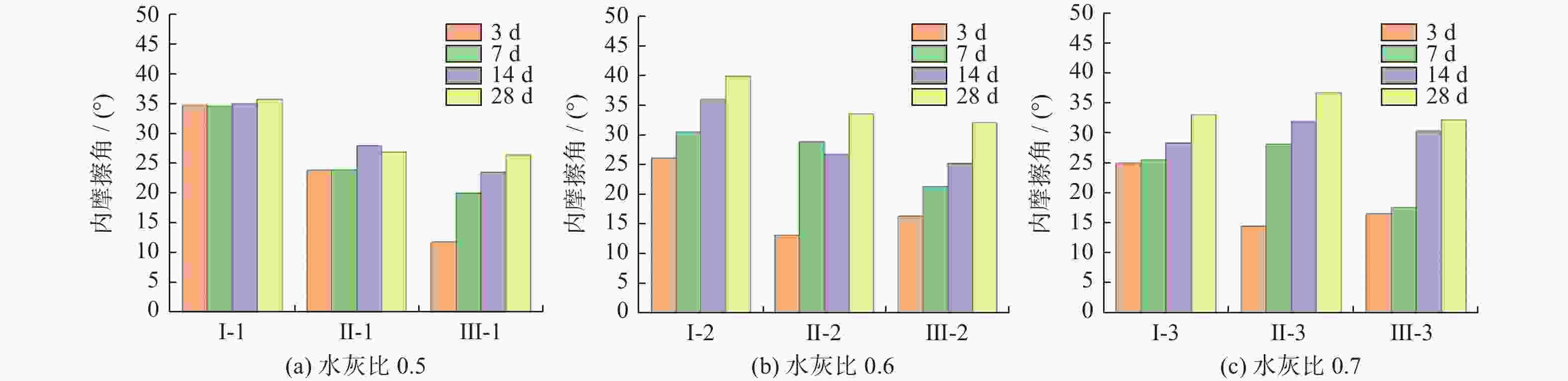

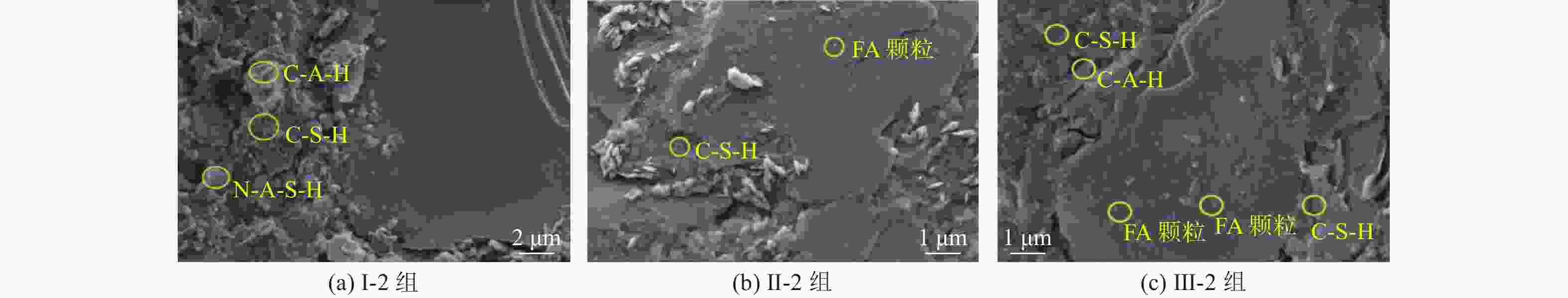

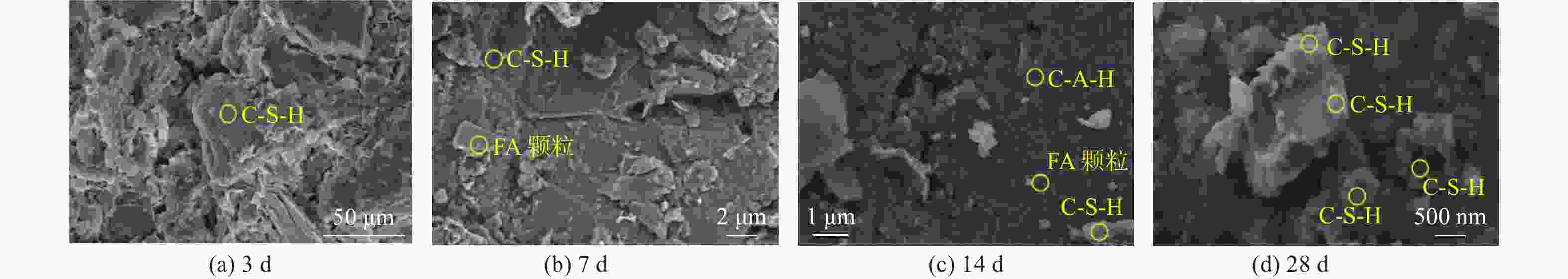

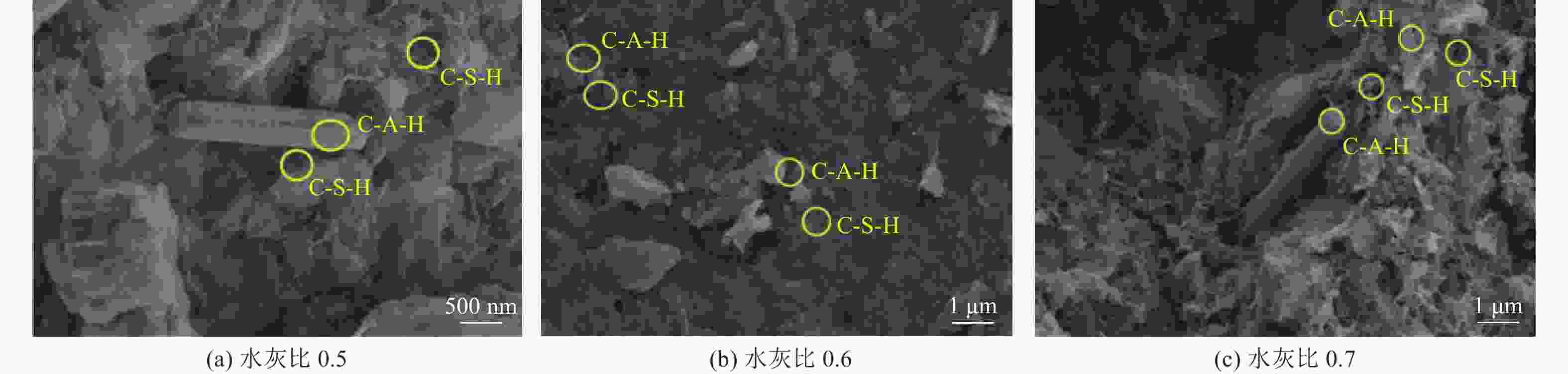

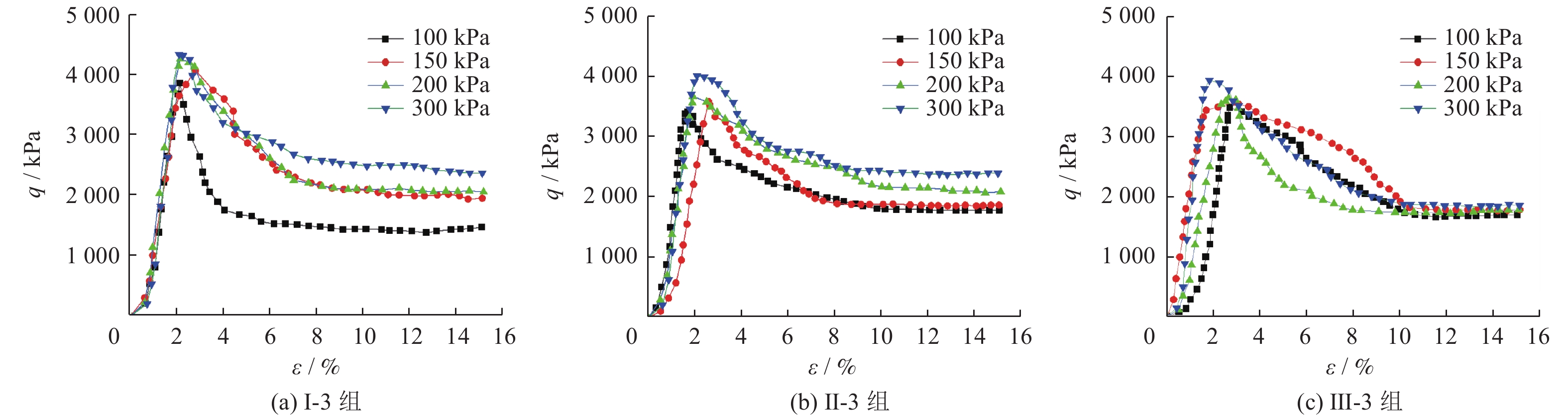

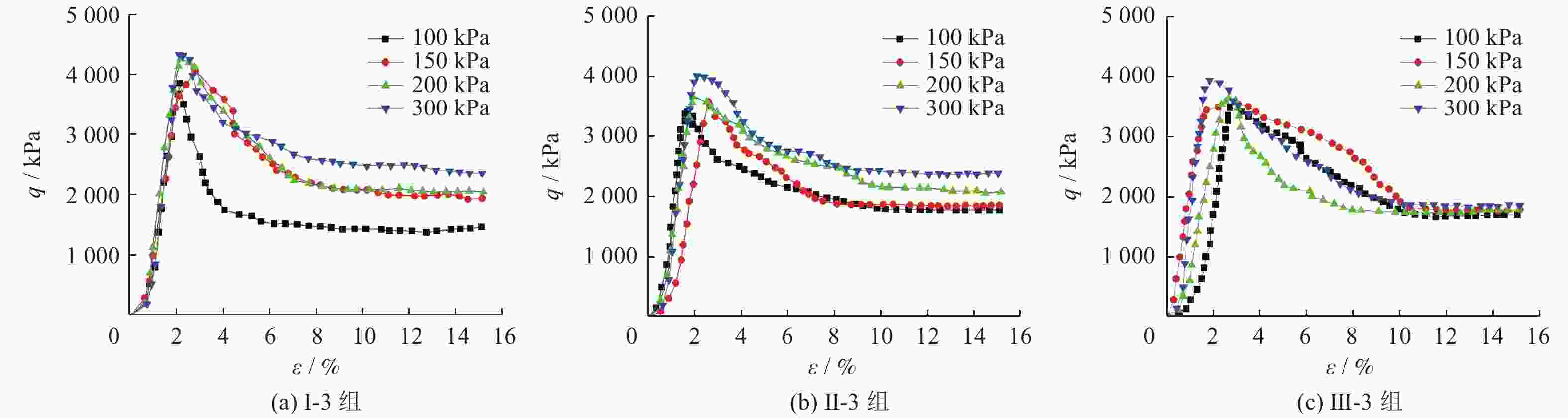

摘要: 以固体氢氧化钠为碱性激发剂,矿渣和粉煤灰为前驱体,采用“一步法”制备粉煤灰−矿渣基地质聚合物。通过开展不固结不排水(UU)三轴剪切试验,测试粉煤灰−矿渣基地质聚合物固化软土的力学性能,揭示粉煤灰掺量、水灰比及养护时间等因素对固化软土抗剪强度的影响机制。同时计算固化软土的黏聚力和内摩擦角,并通过微观试验分析地质聚合物固化软土的作用机理。结果表明:粉煤灰掺量的增加导致地质聚合物固化软土的抗剪强度和内摩擦角减小;水灰比的增加使固化软土的抗剪强度降低;增大围压会使应变软化逐渐减弱,强度逐渐提高;养护时间增加,抗剪强度增加,黏聚力和内摩擦角同步呈现上升趋势。Abstract: Using solid sodium hydroxide as the alkaline exciter and slag and fly ash as the precursors, the fly ash-slag based geopolymer was prepared by "one-step" method. Through the unconsolidated and undrained (UU) triaxial shear test, the mechanical properties of soft soil stabilized with fly ash-slag based geopolymer were tested, and the influence mechanism of such as fly ash content, water to biner ratio, and curing time on the shear strength of the stabilized soft soil were investigated. The cohesion and internal friction angle of the stabilized soft soil were calculated, and the mechanisms of geopolymer stabilizing soft soil were also analyzed through microscopic tests. The results show that the increase of fly ash doping leads to the decrease of shear strength and internal friction angle of geopolymer stabilized soft soil; the increase of water to binder ratio reduces the shear strength of stabilized soft soil; the increase of cofining pressure makes the strain softening gradually weakened, and the strength gradually improved; the increase of curing time increases the shear strength, and the cohesion and the internal friction angle show a rising trend at the same time.

-

Key words:

- geopolymer /

- stabilized soft soil /

- fly ash content /

- confining pressure /

- shear strength

-

表 1 土样物理性质指标

Table 1. Soil physical properties

天然含水率/% 天然重度γ/(N·cm−3) 相对密度G 孔隙比e 液限wL/% 塑限wP/% 塑性指数IP 50 17.2 2.74 1.24 42.5 23.6 18.8 表 2 矿渣和粉煤灰的化学成分

Table 2. Chemical compositions of GGBFS and FA

单位:% 原材料 w(CaO) w(SiO2) w(Al2O3) w(SO3) w(TiO2) w(K2O) w(Fe2O3) GGBFS 40.303 30.638 15.721 2.039 0.779 0.521 0.416 FA 2.299 54.700 35.571 0.740 1.368 1.358 3.303 表 3 地质聚合物固化软土的配比

Table 3. Proportioning of geopolymer stabilized soft soil

组号 地质聚合物固化软土配比 地质聚合物总掺量(m(硅铝

原材料) + m NaOH))/m(干土)重塑土含水率

m(水)/m(干土)养护

时间/dm(矿渣)/m(粉煤灰) m(水)/(m(硅铝原材料) + m(NaOH)) m(NaOH)/m(硅铝原材料) Ⅰ-1 100∶0 0.5 0.15 3/7/14/

28Ⅰ-2 0.6 Ⅰ-3 0.7 Ⅱ-1 90∶10 0.5 0.15 0.2 0.5 3/7/14/

28Ⅱ-2 0.6 Ⅱ-3 0.7 Ⅲ-1 80∶20 0.5 0.15 3/7/14/

28Ⅲ-2 0.6 Ⅲ-3 0.7 -

[1] BELL F G. Cement stabilization and clay soils, with examples[J] . Environmental & Engineering Geoscience, 1995, 1(2): 139 − 151. [2] 张冰雪. 矿渣−粉煤灰/偏高岭土地聚物再生混凝土轴压性能试验研究[D] . 广州: 广东工业大学, 2018. [3] BONG S H, NEMATOLLAHI B, NAZARI A, et al. Efficiency of different superplasticizers and retarders on properties of ‘one-part’ fly ash-slag blended geopolymers with different activators[J] . Materials, 2019, 12(20): 3410. doi: 10.3390/ma12203410 [4] 何华. 地聚合物处理软土地基性能与应用研究[D] . 长沙: 长沙理工大学, 2017. [5] 高铭洁, 户国, 吴俊, 等. 固体硅酸钠激发粉煤灰−矿渣基地质聚合物抗压强度的试验研究[J] . 特种结构, 2023, 40(2): 100 − 105. [6] LUUKKONEN T, SARKKINEN M, KEMPPAINEN K, et al. Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate[J] . Applied Clay Science, 2016, 119: 266 − 276. doi: 10.1016/j.clay.2015.10.027 [7] 王军, 丁光亚, 潘林有, 等. 静三轴试验中水泥土力学特性及本构模型研究[J] . 岩土力学, 2010, 31(5): 1407 − 1412. doi: 10.3969/j.issn.1000-7598.2010.05.010 [8] 武欣慧, 王海龙, 申向东, 等. 基于静三轴试验的水泥改善粉质黏土工程特征的试验研究[J] . 中国科技论文, 2015, 10(13): 1583 − 1587. doi: 10.3969/j.issn.2095-2783.2015.13.022 [9] OH S, JEON J, KIM D, et al. Shear strength and erosion resistance characteristics of stabilized green soils[J] . Journal of the Korean Geo-Environmental Society, 2015, 16(12): 45 − 52. doi: 10.14481/jkges.2015.16.12.45 [10] AZHAR A T S, FAZLINA M I S, NIZAM Z M, et al. Shear strength of stabilized kaolin soil using liquid polymer[J] . IOP Conference Series: Materials Science and Engineering, 2017, 226: 012063. doi: 10.1088/1757-899X/226/1/012063 [11] 侯云芬. 粉煤灰基地质聚合物[M] . 北京: 化学工业出版社, 2014. [12] 征西遥. 地质聚合物在软土加固中的应用研究[D] . 上海: 上海工程技术大学, 2020. [13] 王甲春, 许金鼓, 夏丹丹. 固化软土的抗剪强度测试与分析[J] . 低温建筑技术, 2011, 33(1): 8 − 10. doi: 10.3969/j.issn.1001-6864.2011.01.003 [14] KITAZUME M, GRISOLIA M, LEDER E, et al. Applicability of molding procedures in laboratory mix tests for quality control and assurance of the deep mixing method[J] . Soils and Foundations, 2015, 55(4): 761 − 777. doi: 10.1016/j.sandf.2015.06.009 [15] ZHENG X Y, WU J. Early strength development of soft clay stabilized by one-part ground granulated blast furnace slag and fly ash-based geopolymer[J] . Frontiers in Materials, 2021, 8: 616430. doi: 10.3389/fmats.2021.616430 [16] 殷维. 淤泥质土室内水泥固化三轴试验研究[J] . 福建建材, 2022(3): 6 − 9, 25. [17] 杨敬斌, 方媛, 李东旭. 碱胶凝材料水化产物C-A-S-H与N-A-S-H的研究进展[J] . 硅酸盐通报, 2017, 36(10): 3292 − 3297, 3310. [18] 牛恒, 孙德安, 阮坤林. 掺粉煤灰和二灰上海软土的力学特性[J] . 防灾减灾工程学报, 2020, 40(6): 992 − 1000. [19] 杨爱武, 周金, 孔令伟. 固化吹填软土力学特性试验[J] . 吉林大学学报(工学版), 2014, 44(3): 661 − 667. -

下载:

下载: