Simulation study of cutting Inconel 718 alloy with micro textured tools

-

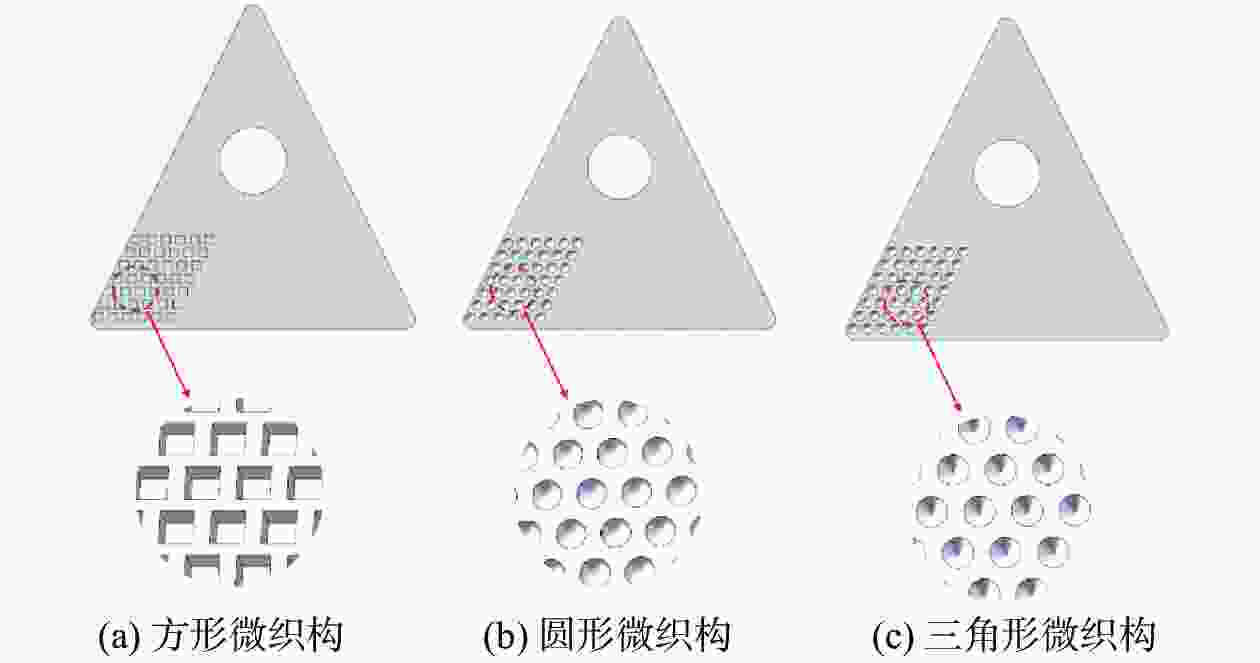

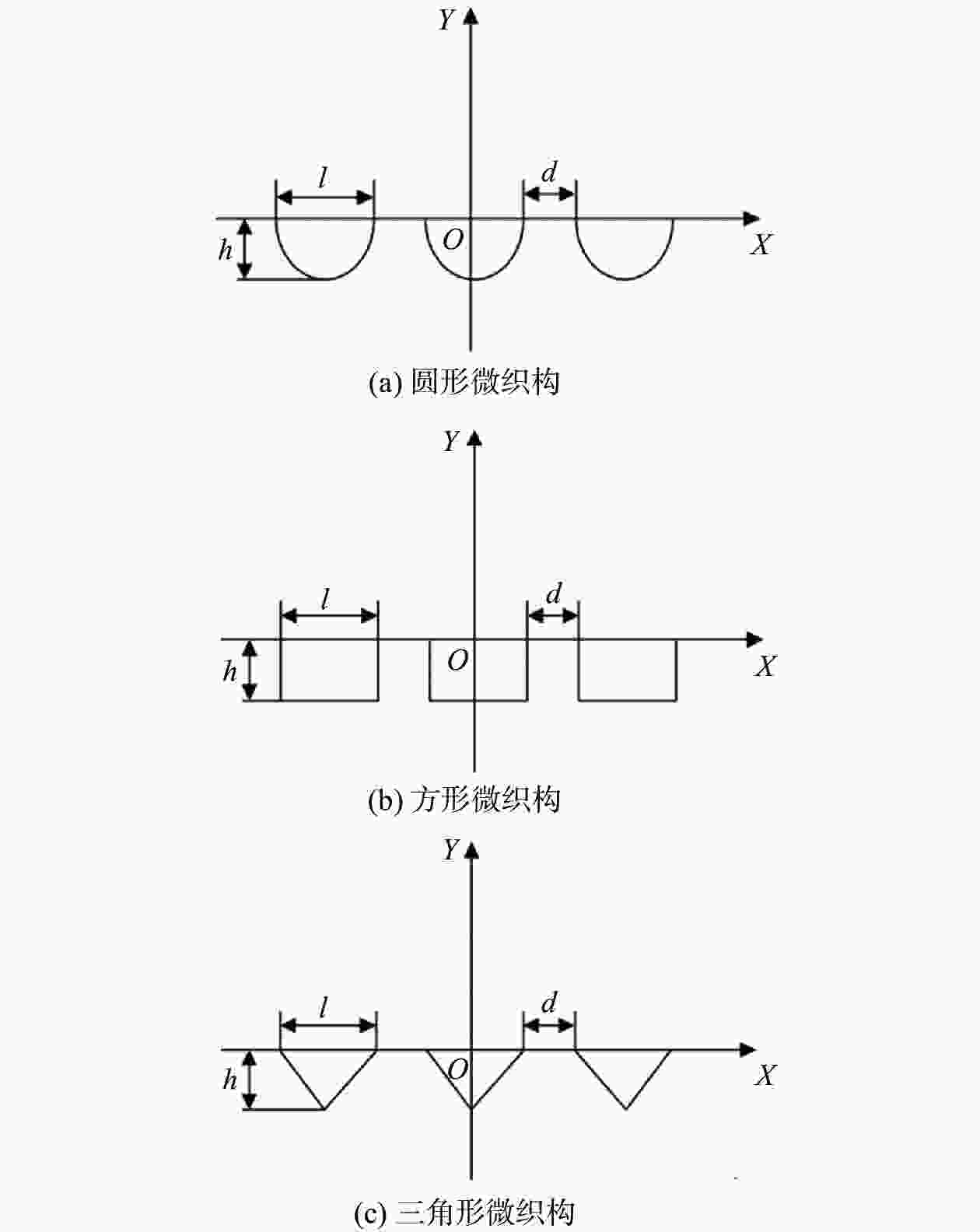

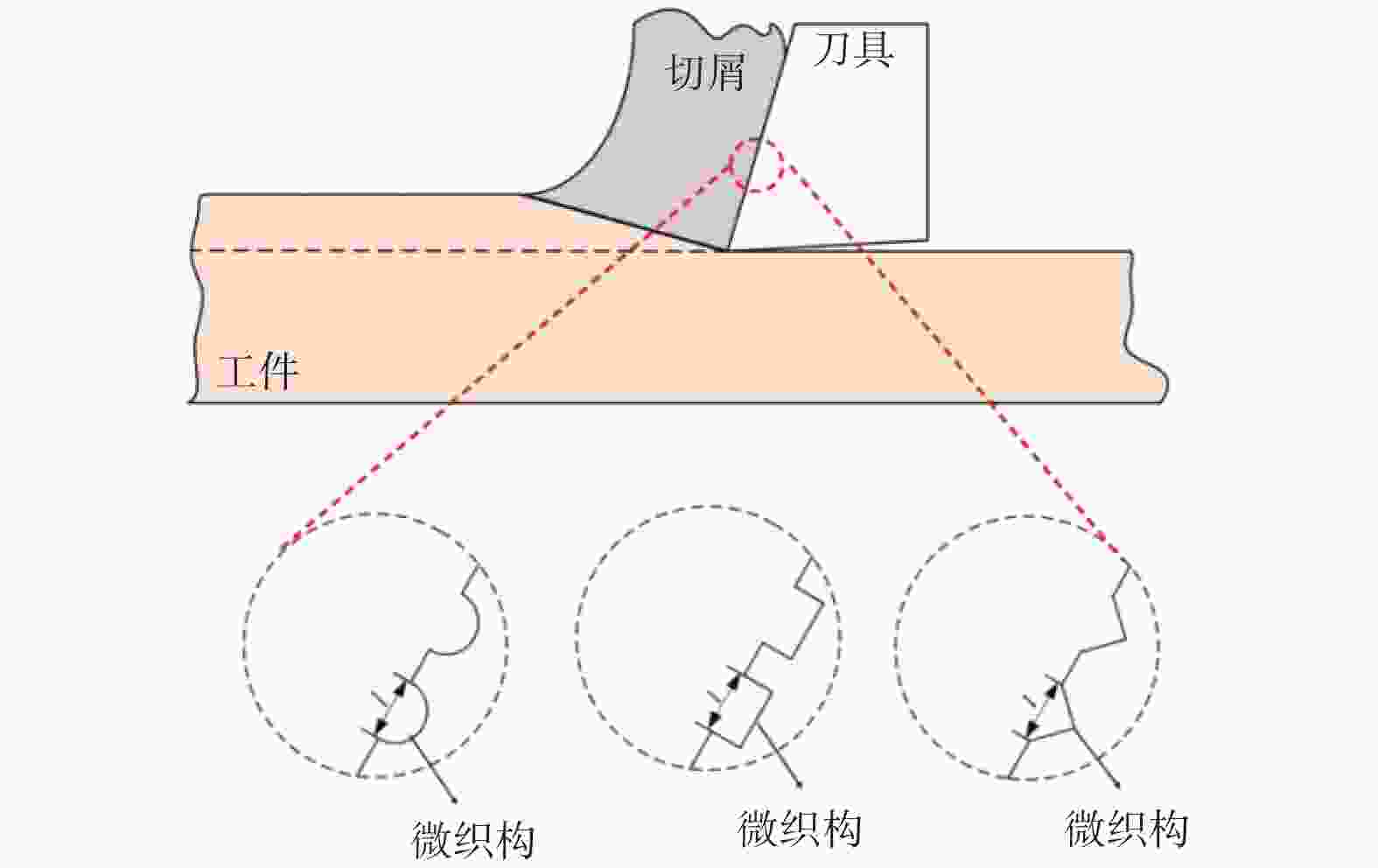

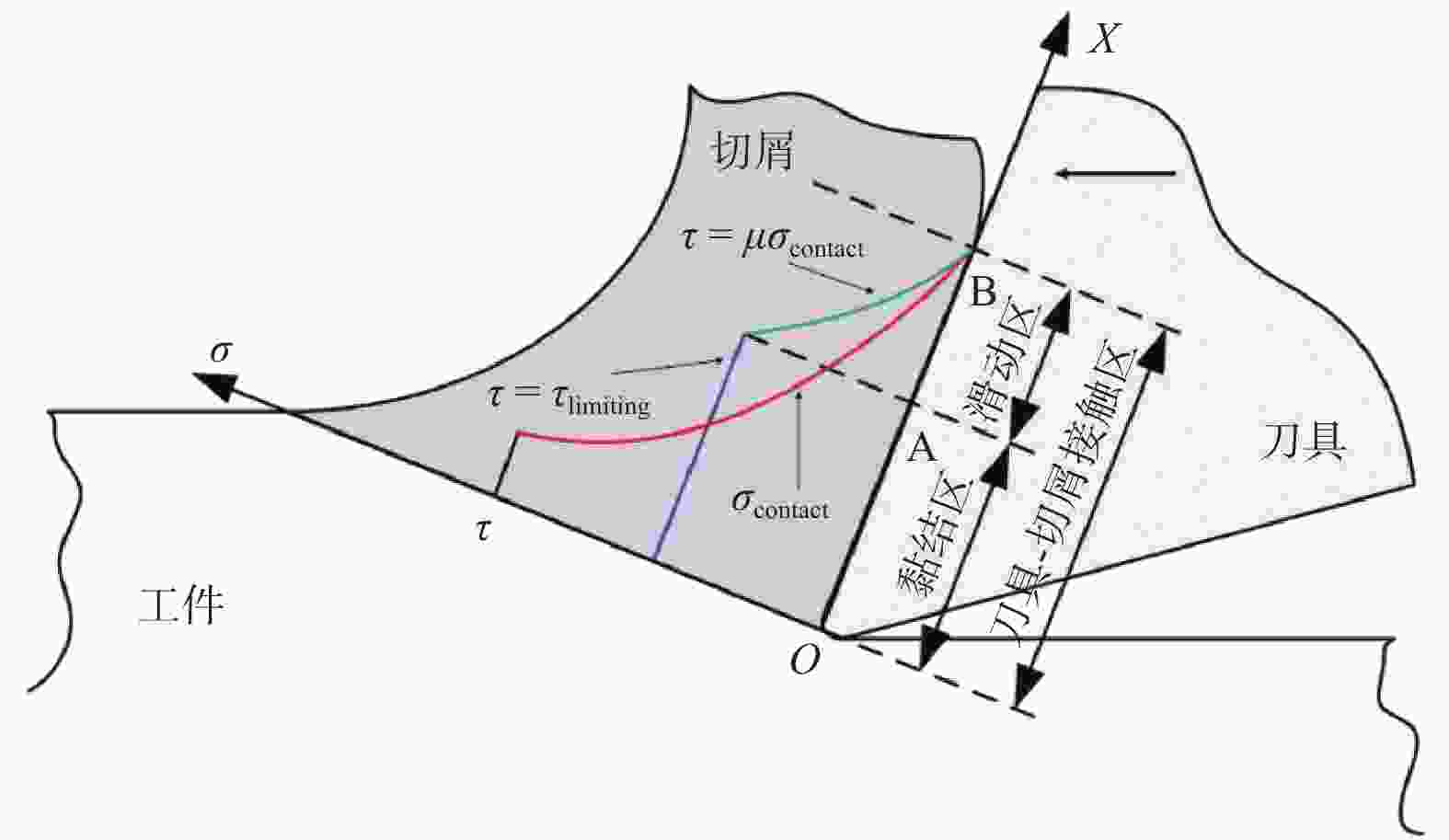

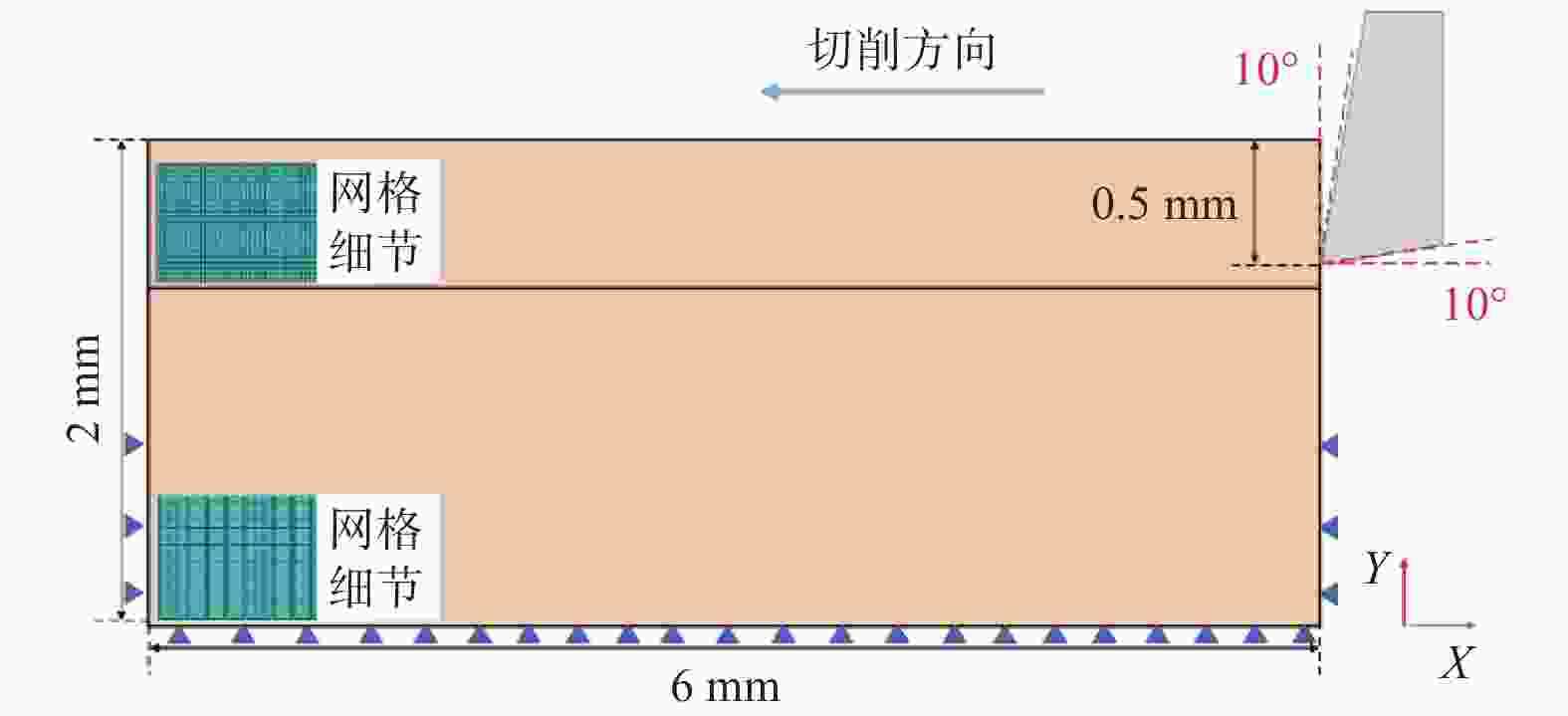

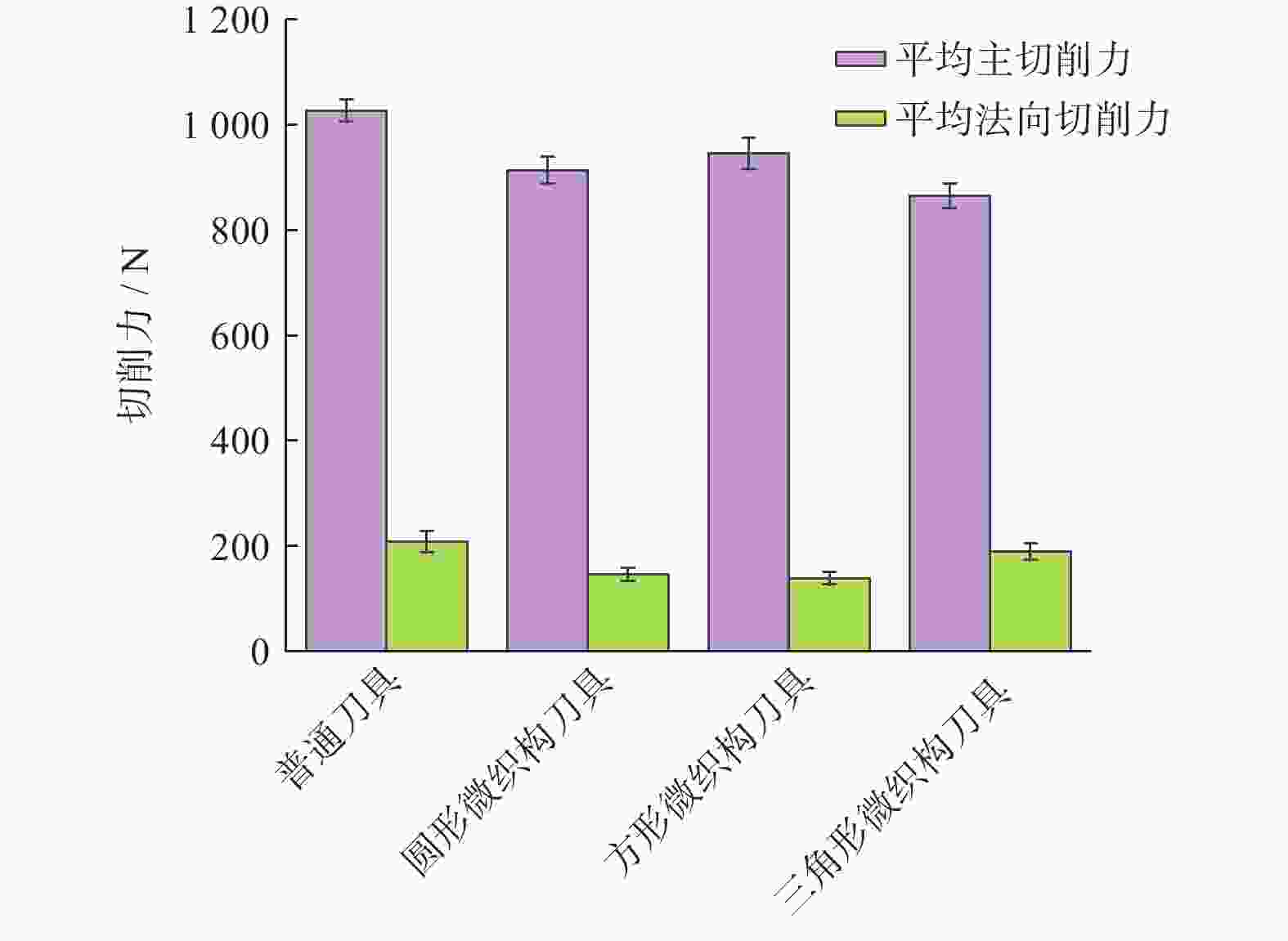

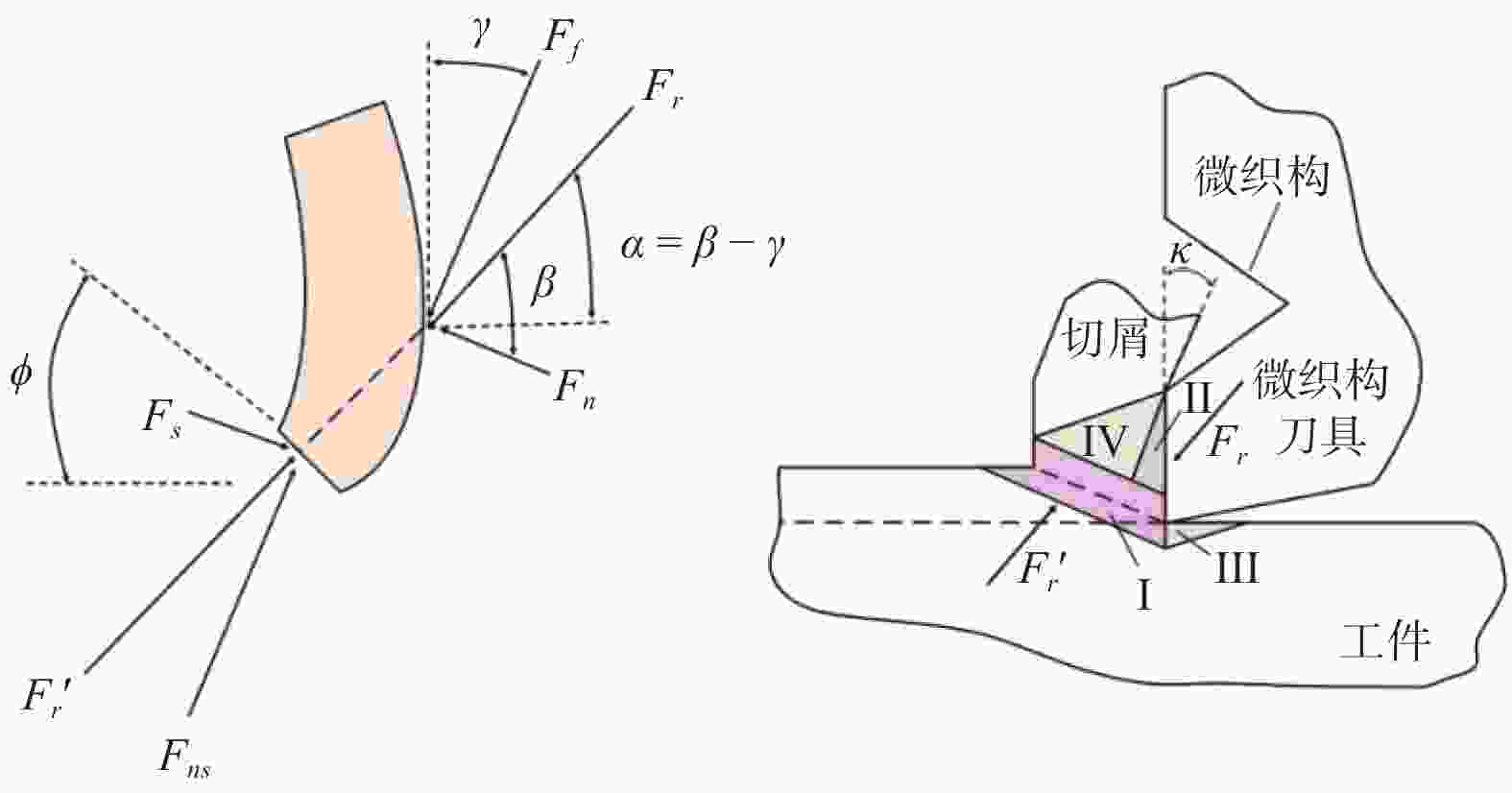

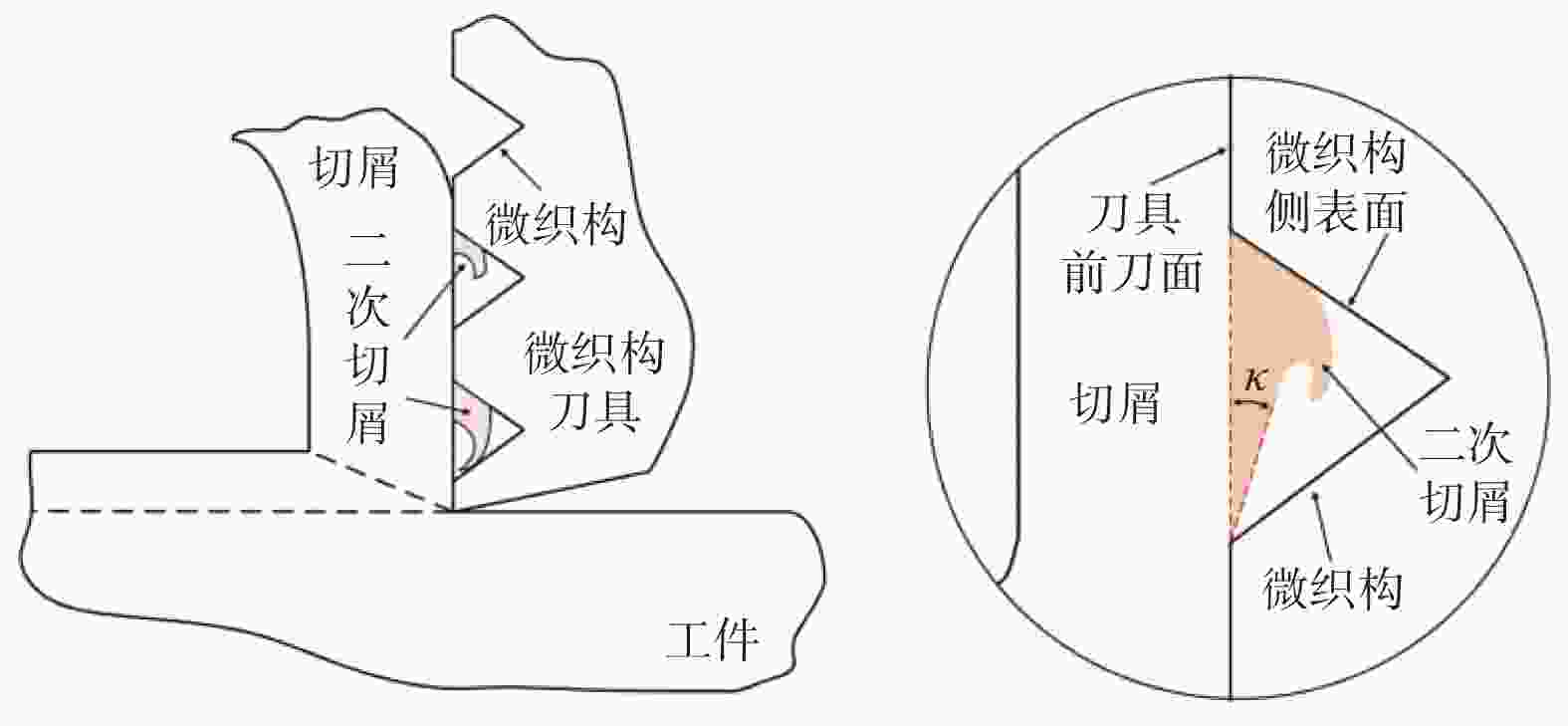

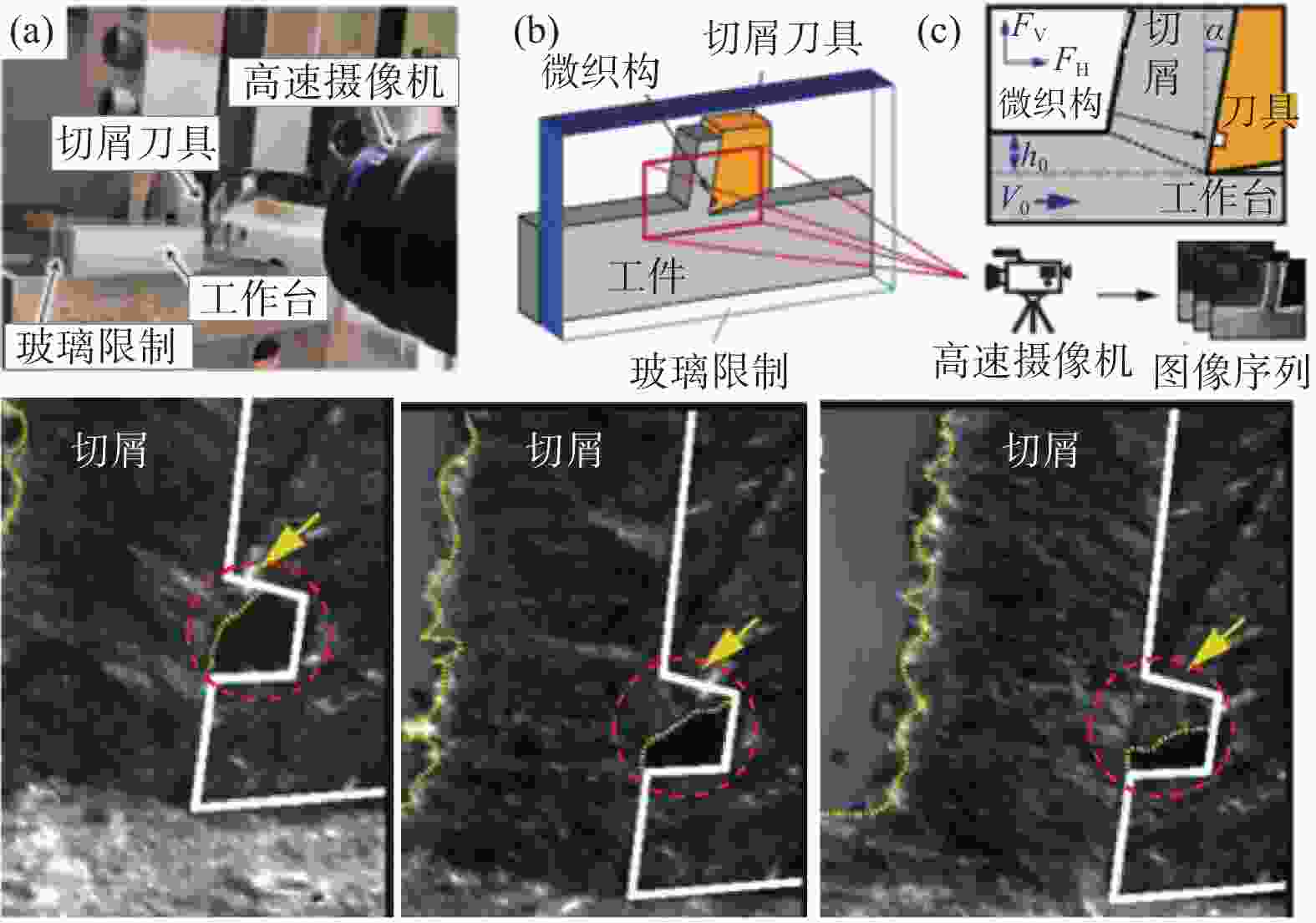

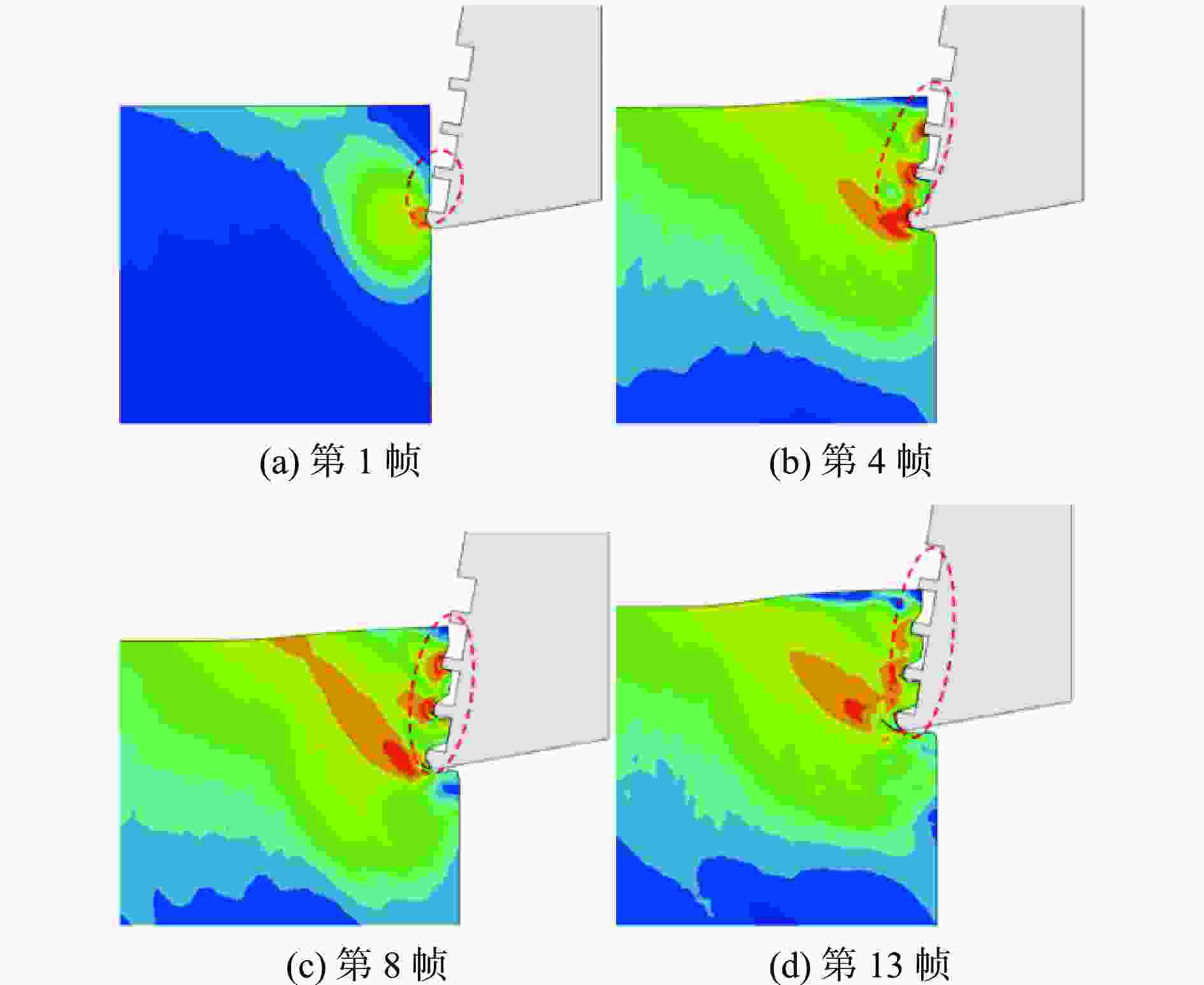

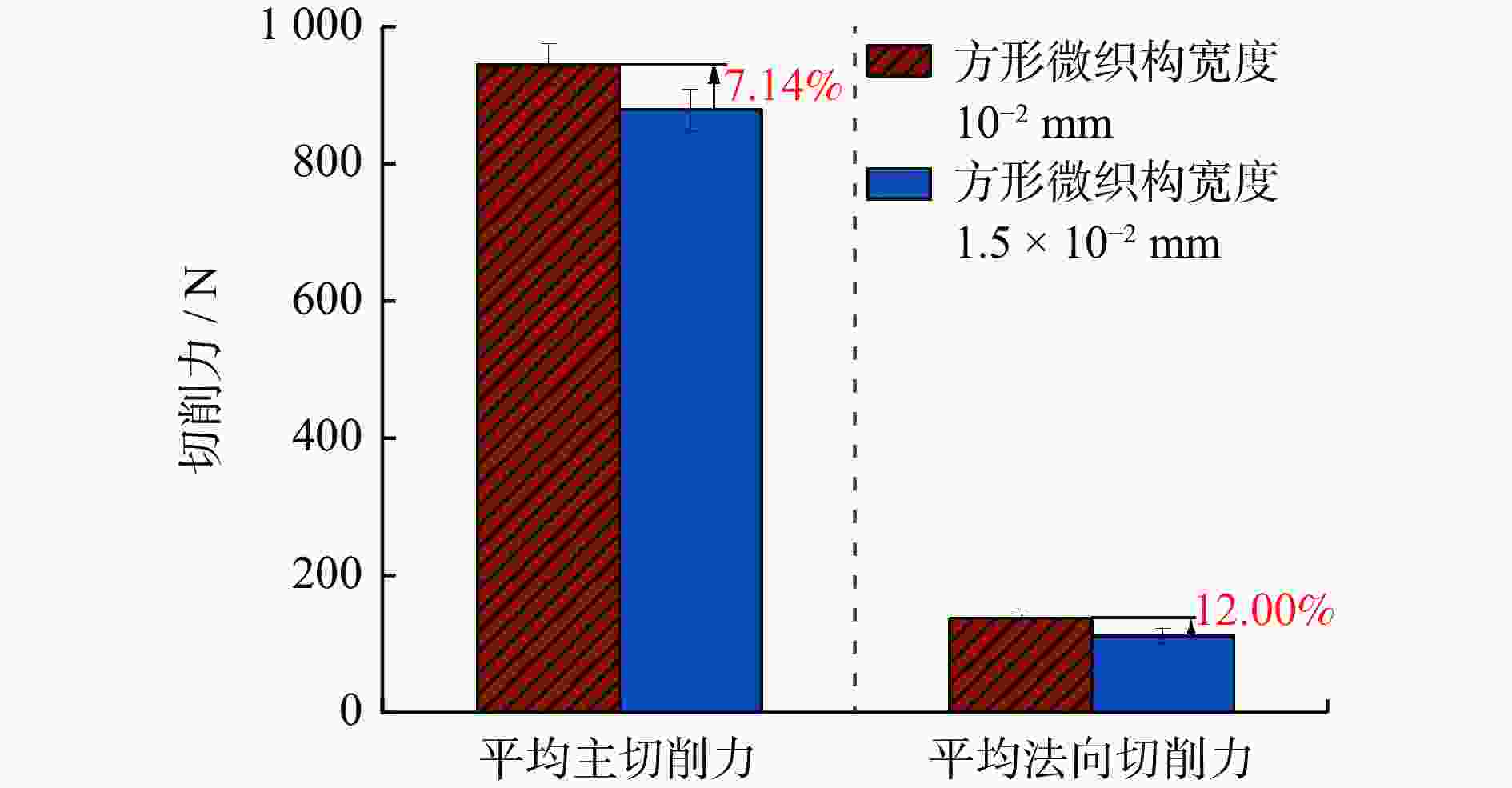

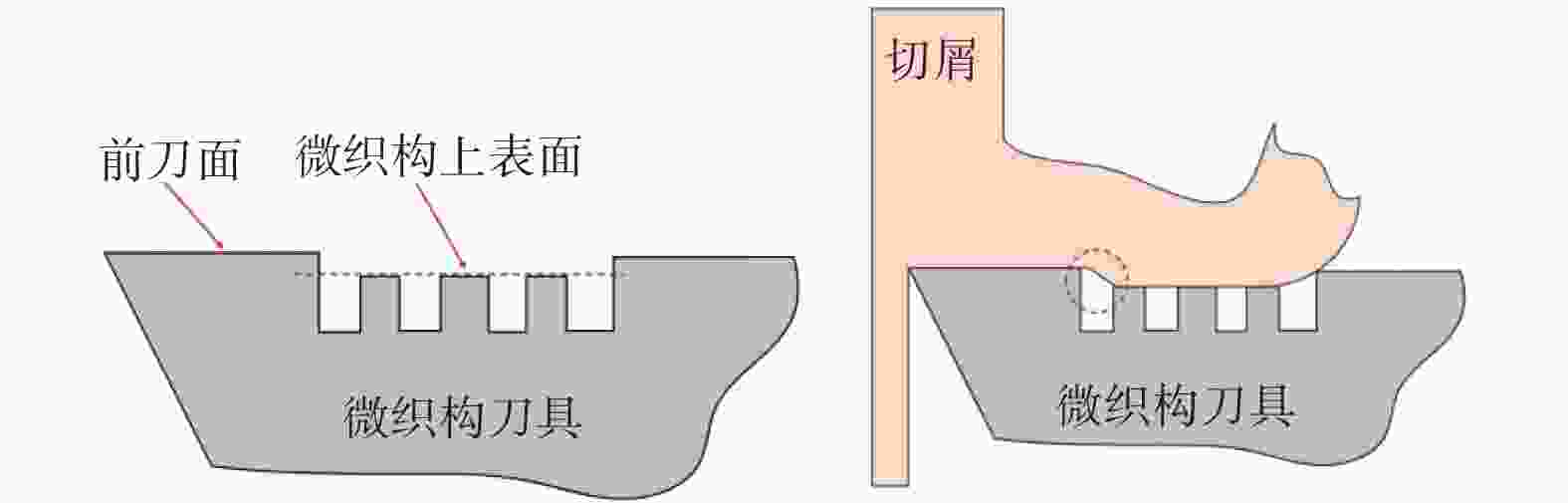

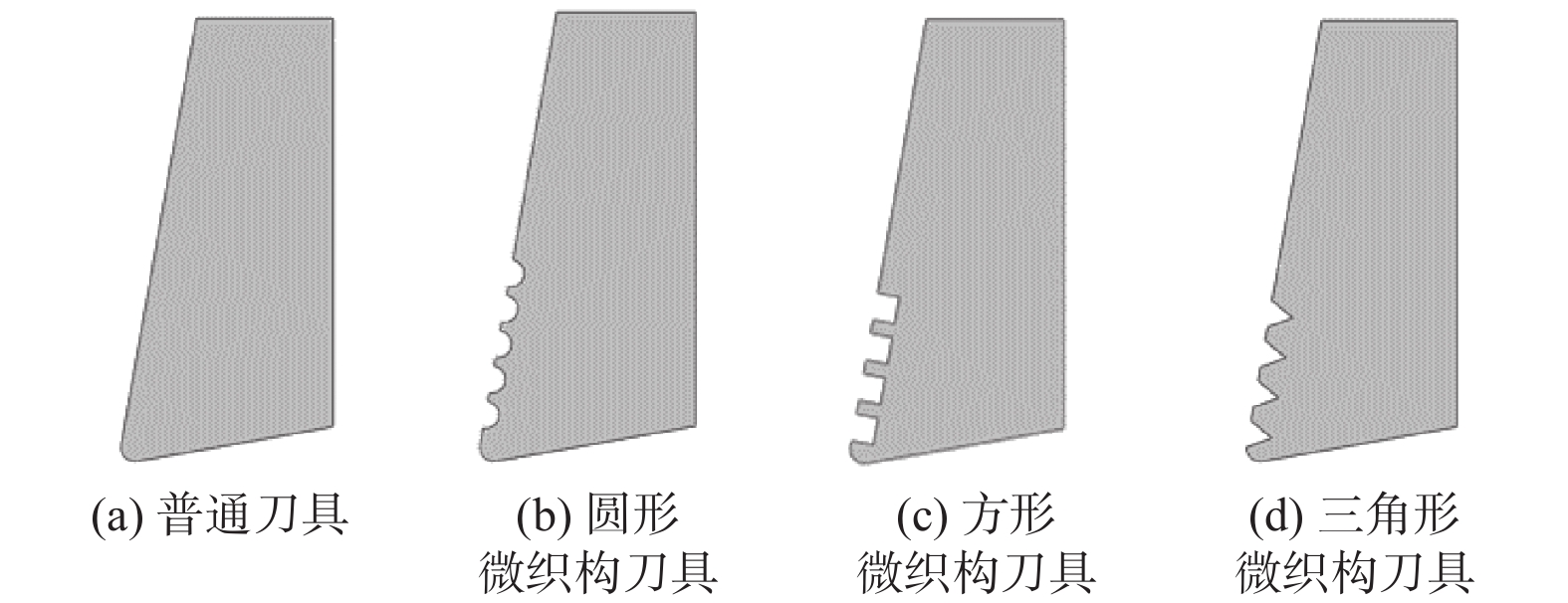

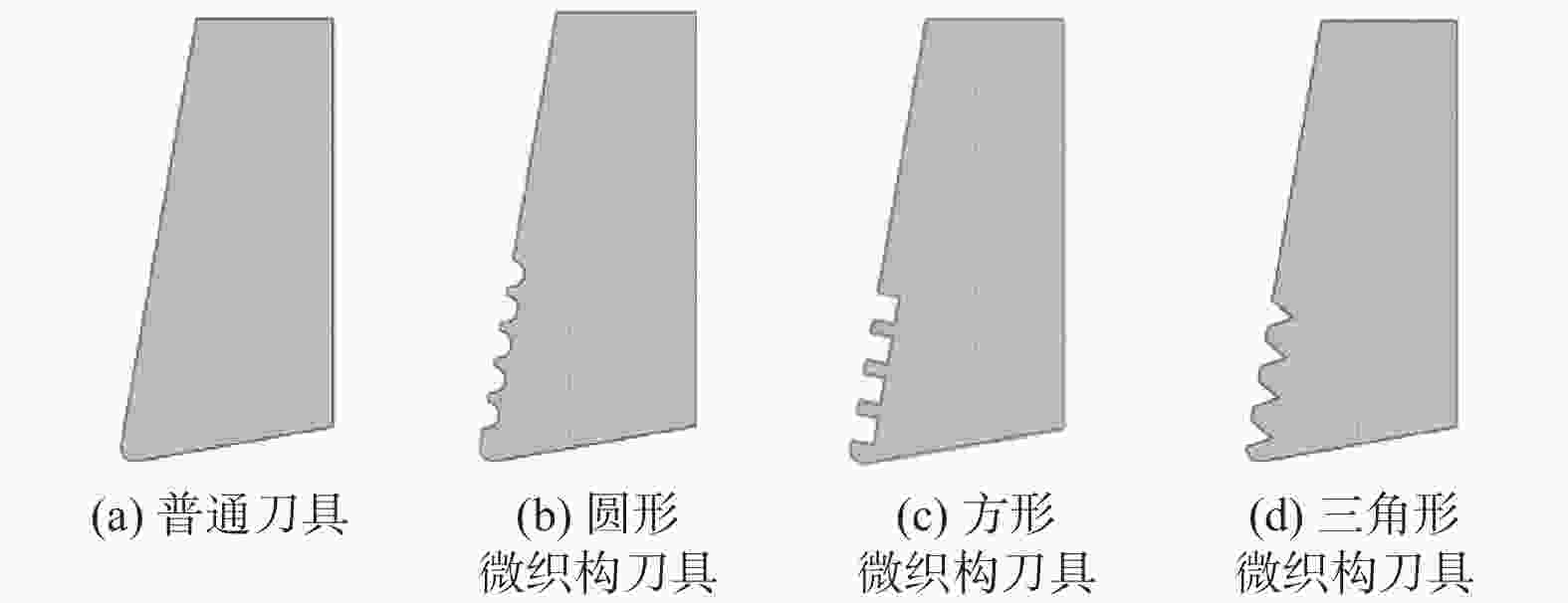

摘要: Inconel 718合金是一种典型的难加工材料,在刀具前刀面设计方形、圆形和三角形等不同形状的微织构,分别对Inconel 718合金进行切削仿真和实验研究,探讨微织构形状对Inconel 718合金加工性能的影响,分析切削过程中的材料去除、应力分布、切屑形态以及切削力的变化规律。结果表明,相比普通刀具,微织构刀具可有效降低切削力、减小刀具−切屑接触长度以及改善刀具的摩擦情况。对切削过程中产生二次切削现象进行讨论,分析二次切削的产生机理,通过受力分析提出抑制二次切削的方法,并采用实验和有限元仿真验证了方法的可靠性。Abstract: Inconel 718 alloy is considered a typical difficult-to-machine material. The cutting simulation and experimental research of Inconel 718 alloy were conducted through the design of three different shapes of micro-weave on the front face of the tool: square, round, and triangular. The influence of the shape of the micro-weave on the machining performance of Inconel 718 was explored, and the material removal process, stress distribution, chip morphology, and cutting force during the cutting process were analyzed. The change rule of these aspects was passively observed and documented. The results show that compared with ordinary tools, microtextured tools can effectively reduce the cutting force, reduce the tool-chip contact length and improve the friction of the tool. In addition, the phenomenon of secondary cutting in the cutting process was discussed, the mechanism of secondary cutting was analyzed, a method to inhibit secondary cutting through force analysis was propose, and the reliability of the method was verified by using experiments and finite element simulation.

-

Key words:

- micro-texture tool /

- secondary cutting /

- finite element simulation /

- cutting force

-

表 1 微织构刀具设计参数

Table 1. Micro-textured tool design parameters

微织构类型 前角/

(°)后角/

(°)圆角半径/

μm深度/

μm宽度/

μm间距/

μm圆形 10 10 5 10 20 10 方形 10 10 5 10 20 10 三角形 10 10 5 10 20 10 表 2 Inconel 718 J-C本构模型参数

Table 2. Inconel 718 J-C intrinsic model parameters

本构参数 A/MPa B/MPa C m n T0 /℃ Tm/℃ 参数值 440 1600 0.016 1.2 0.64 20 1320 表 3 镍基高温合金合金 Inconel 718 的化学成分

Table 3. Chemical composition of the nickel-based high-temperature alloy Inconel 718

元素 Ni Cr Fe Nb Mo Ti Co Cu Si Mn C 质量分数/% 53.66 18.41 17.90 4.92 2.87 0.96 0.35 0.13 0.09 0.08 0.03 -

[1] 冀寒松, 宋清华, 杜宜聪, 等. Inconel-718微构件晶粒尺度伪随机建模与仿真[J] . 机械工程学报, 2023, 59(17): 232 − 240. [2] AI Y W, YAN Y C, DONG G Y, et al. Investigation of microstructure evolution process in circular shaped oscillating laser welding of Inconel 718 superalloy[J] . International Journal of Heat and Mass Transfer, 2023, 216: 124522. doi: 10.1016/j.ijheatmasstransfer.2023.124522 [3] FERNANDES G H N, BARBOSA L M Q, FRANÇA P H P, et al. Enhancing sustainability in Inconel 718 machining: temperature control with internally cooled tools[J] . The International Journal of Advanced Manufacturing Technology, 2024, 131(5): 2771 − 2789. [4] M'SAOUBI R, AXINTE D, SOO S L, et al. High performance cutting of advanced aerospace alloys and composite materials[J] . CIRP Annals, 2015, 64(2): 557 − 580. doi: 10.1016/j.cirp.2015.05.002 [5] WANG R, YANG D Y, WANG W, et al. Tool wear in nickel-based superalloy machining: an overview[J] . Processes, 2022, 10(11): 2380. doi: 10.3390/pr10112380 [6] ALAGAN N T, ZEMAN P, HOIER P, et al. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling[J] . Journal of Manufacturing Processes, 2019, 37: 606 − 616. doi: 10.1016/j.jmapro.2018.12.023 [7] PANG K, WANG D Z. Study on the performances of the drilling process of nickel-based superalloy Inconel 718 with differently micro-textured drilling tools[J] . International Journal of Mechanical Sciences, 2020, 180: 105658. doi: 10.1016/j.ijmecsci.2020.105658 [8] DUAN Z F, CHEN L, LI B B. Effect of micro-textured morphology with different wettabilities on tool cutting performance[J] . The International Journal of Advanced Manufacturing Technology, 2022, 123(5): 1745 − 1754. [9] DUAN R, DENG J X, LEI S T, et al. Effect of derivative cutting on machining performance of micro textured tools[J] . Journal of Manufacturing Processes, 2019, 45: 544 − 556. doi: 10.1016/j.jmapro.2019.07.037 [10] GUPTA M K, SONG Q H, LIU Z Q, et al. Tribological behavior of textured tools in sustainable turning of nickel based super alloy[J] . Tribology International, 2021, 155: 106775. doi: 10.1016/j.triboint.2020.106775 [11] GAO Z J, ZHANG H, JI M, et al. Influence of various cooling and lubrication conditions on tool wear and machining quality in milling Inconel 718[J] . International Journal of Precision Engineering and Manufacturing-Green Technology, 2024, 11(2): 391 − 406. doi: 10.1007/s40684-023-00558-9 [12] ERDOGAN C, VURAL H, KARAKAŞ A, et al. Ductile failure of Inconel 718 during flow forming process and its numerical investigation[J] . Engineering Failure Analysis, 2023, 152: 107424. doi: 10.1016/j.engfailanal.2023.107424 [13] LIU C, WAN M, YANG Y. Simulation of the chip morphology together with its evolution in machining of Inconel 718 by considering widely spread cutting speed[J] . The International Journal of Advanced Manufacturing Technology, 2021, 116(1/2): 175 − 195. [14] UÇAK N, ÇIÇEK A. The effects of cutting conditions on cutting temperature and hole quality in drilling of Inconel 718 using solid carbide drills[J] . Journal of Manufacturing Processes, 2018, 31: 662 − 673. doi: 10.1016/j.jmapro.2018.01.003 [15] CIPRIANO FARIAS F W, REBELO DUARTE V, DA CRUZ PAYÃO FILHO J, et al. Arc-based directed energy deposited Inconel 718: role of heat treatments on high-temperature tensile behavior[J] . Materials Research Letters, 2024, 12(2): 97 − 107. doi: 10.1080/21663831.2023.2297734 [16] 郭江, 王兴宇, 赵勇, 等. 微织构刀具制备技术及加工性能研究新进展[J] . 机械工程学报, 2021, 57(13): 172 − 200. -

下载:

下载: