Design and control of a complementary dual voice coil motor push-pull two-dimensional translational motion parallel precision motion platform

-

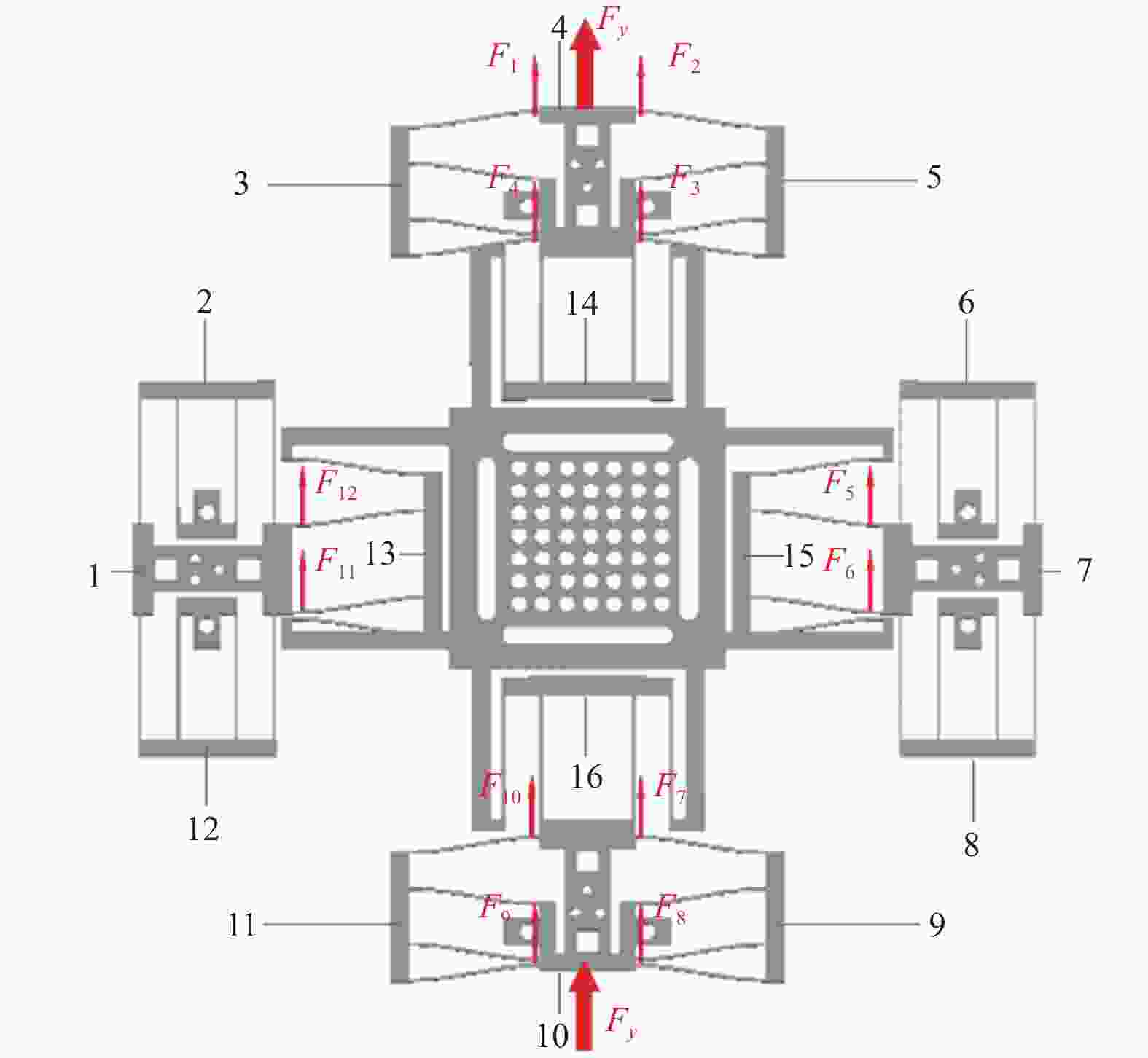

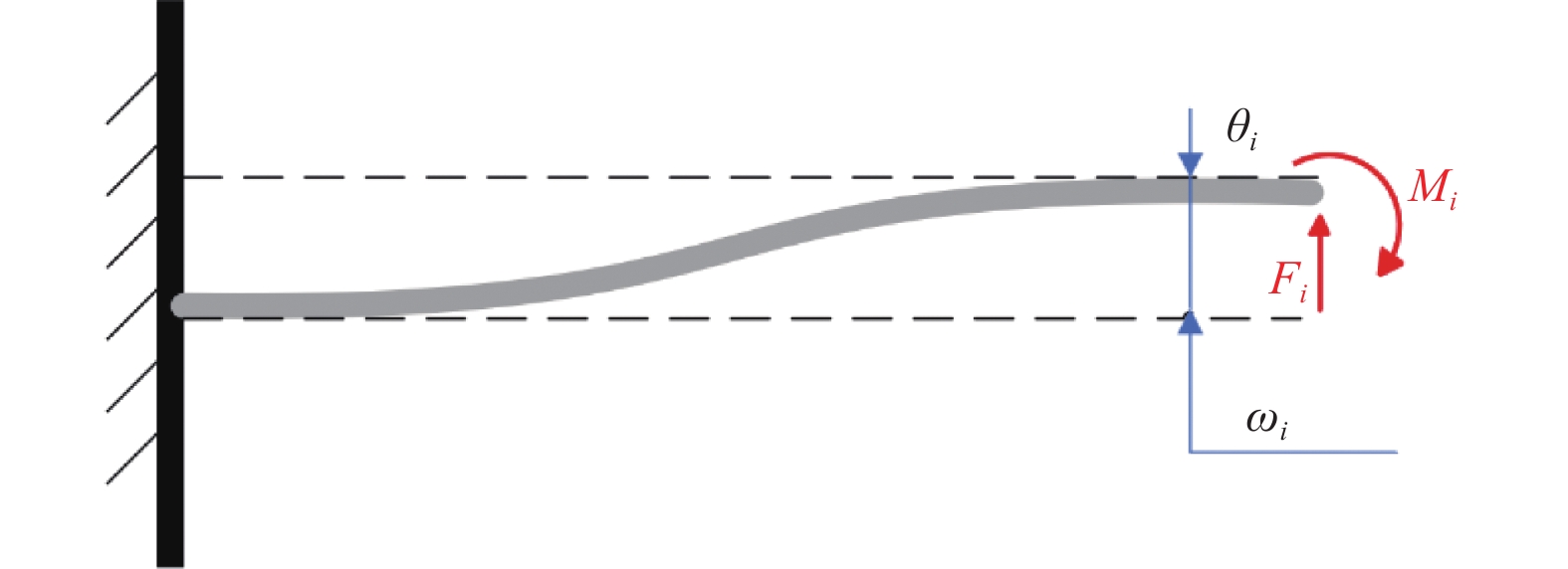

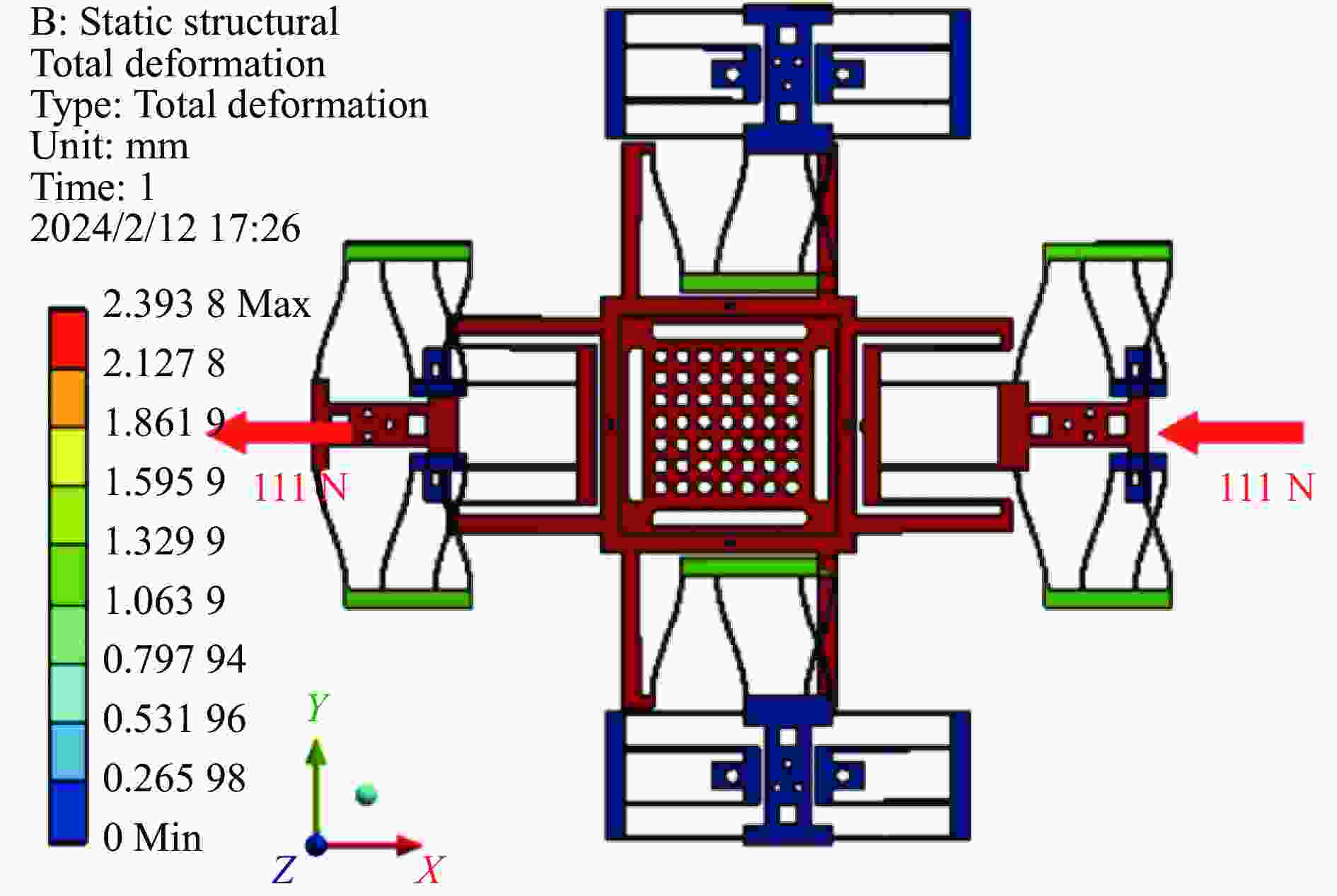

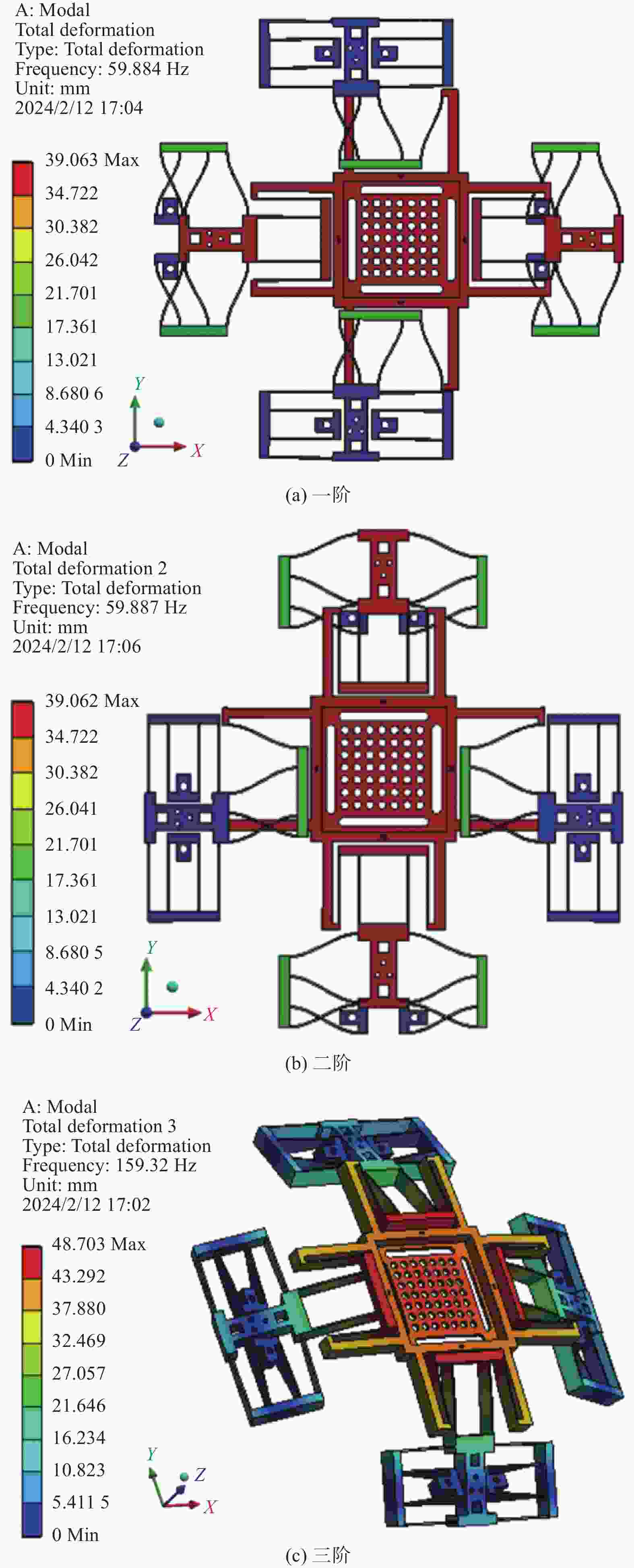

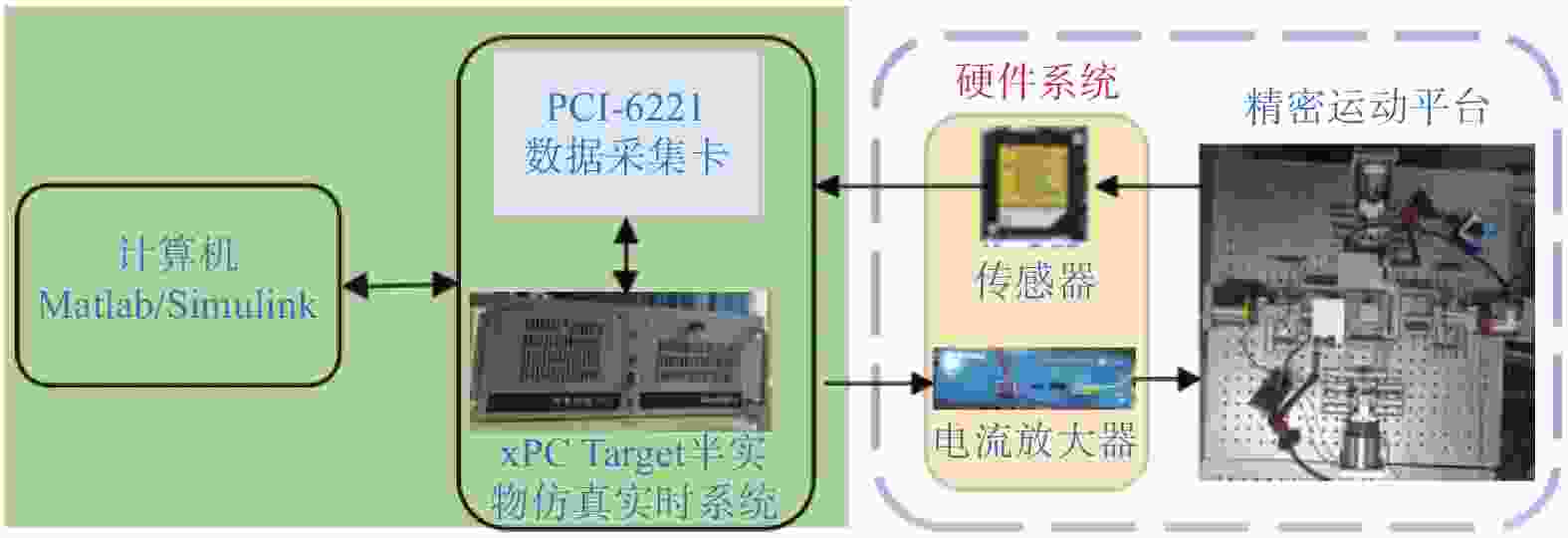

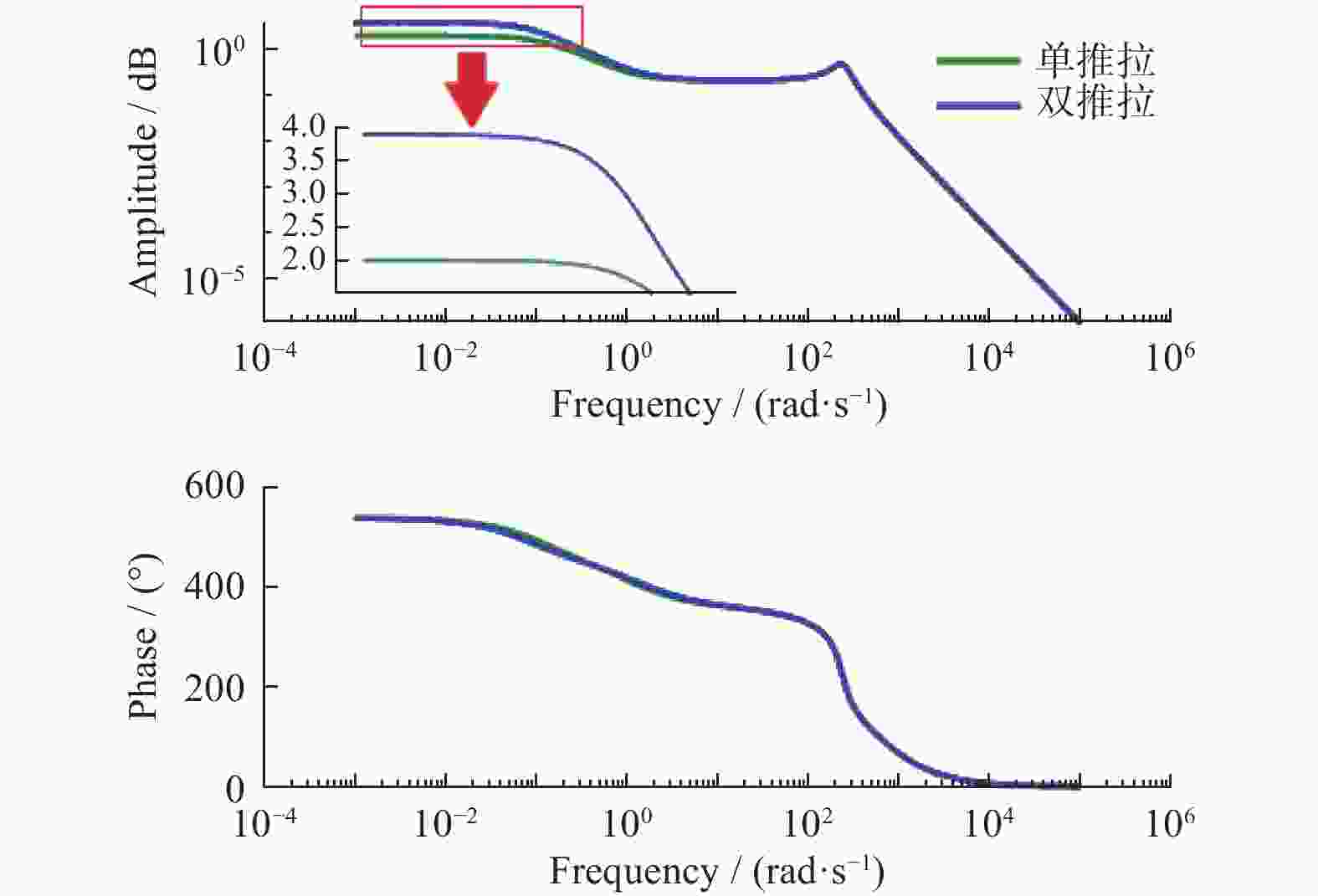

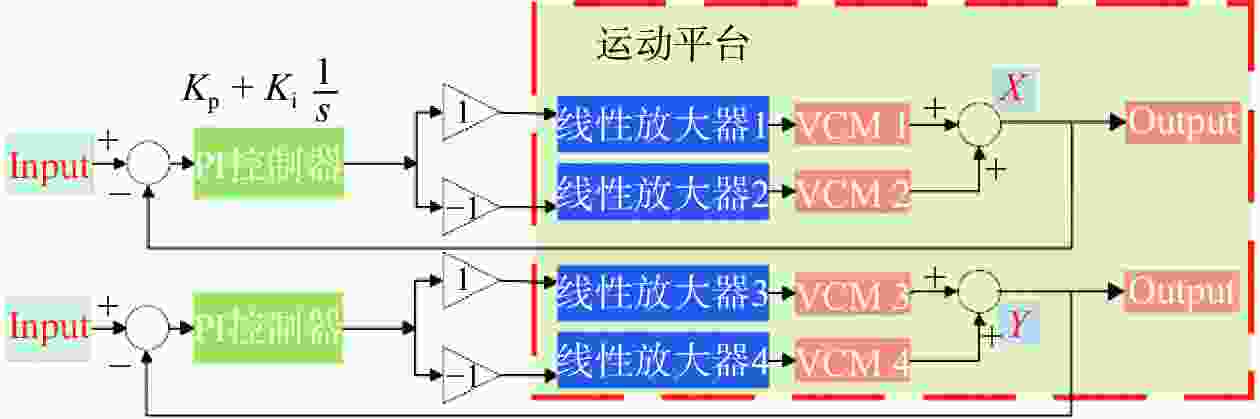

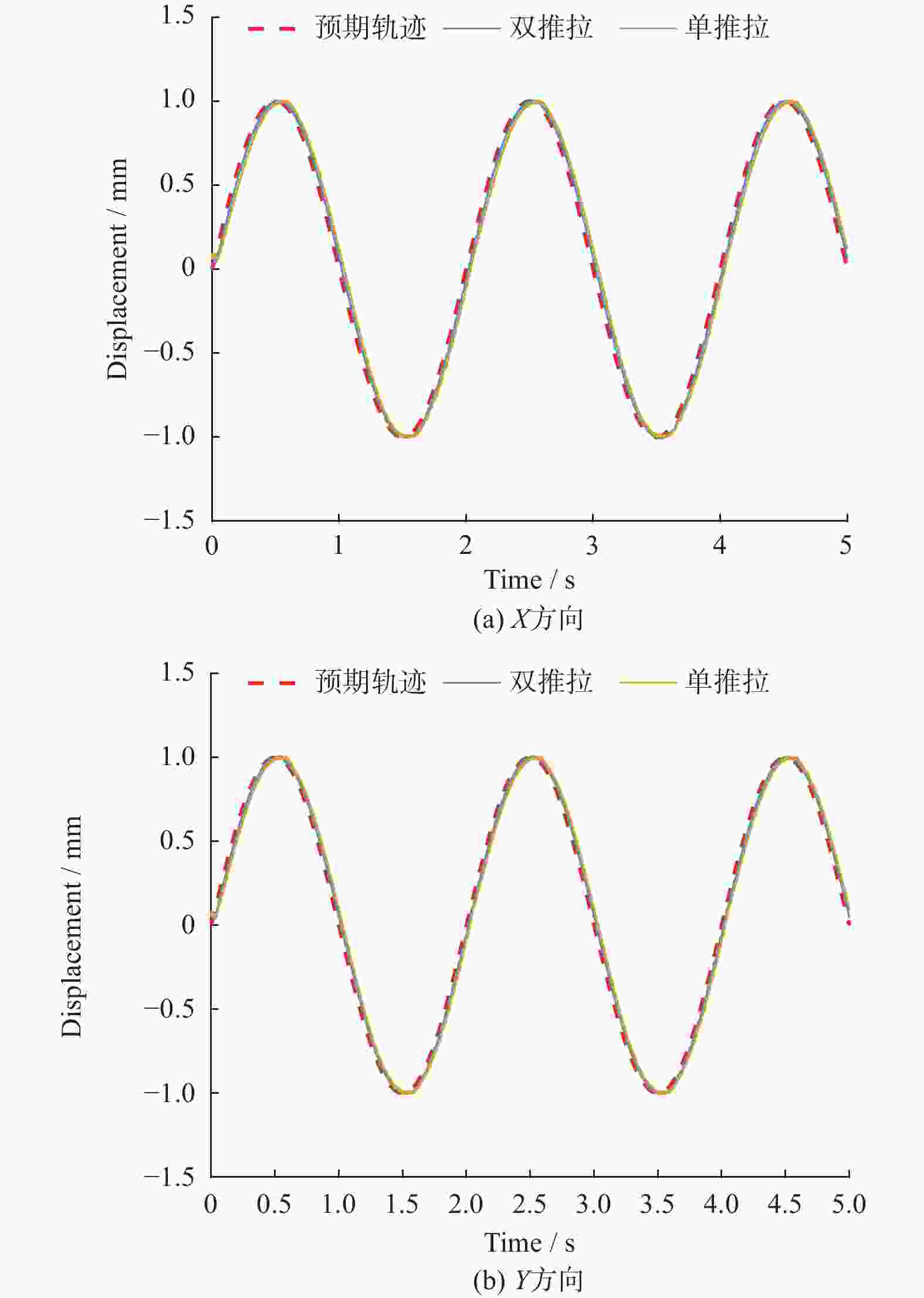

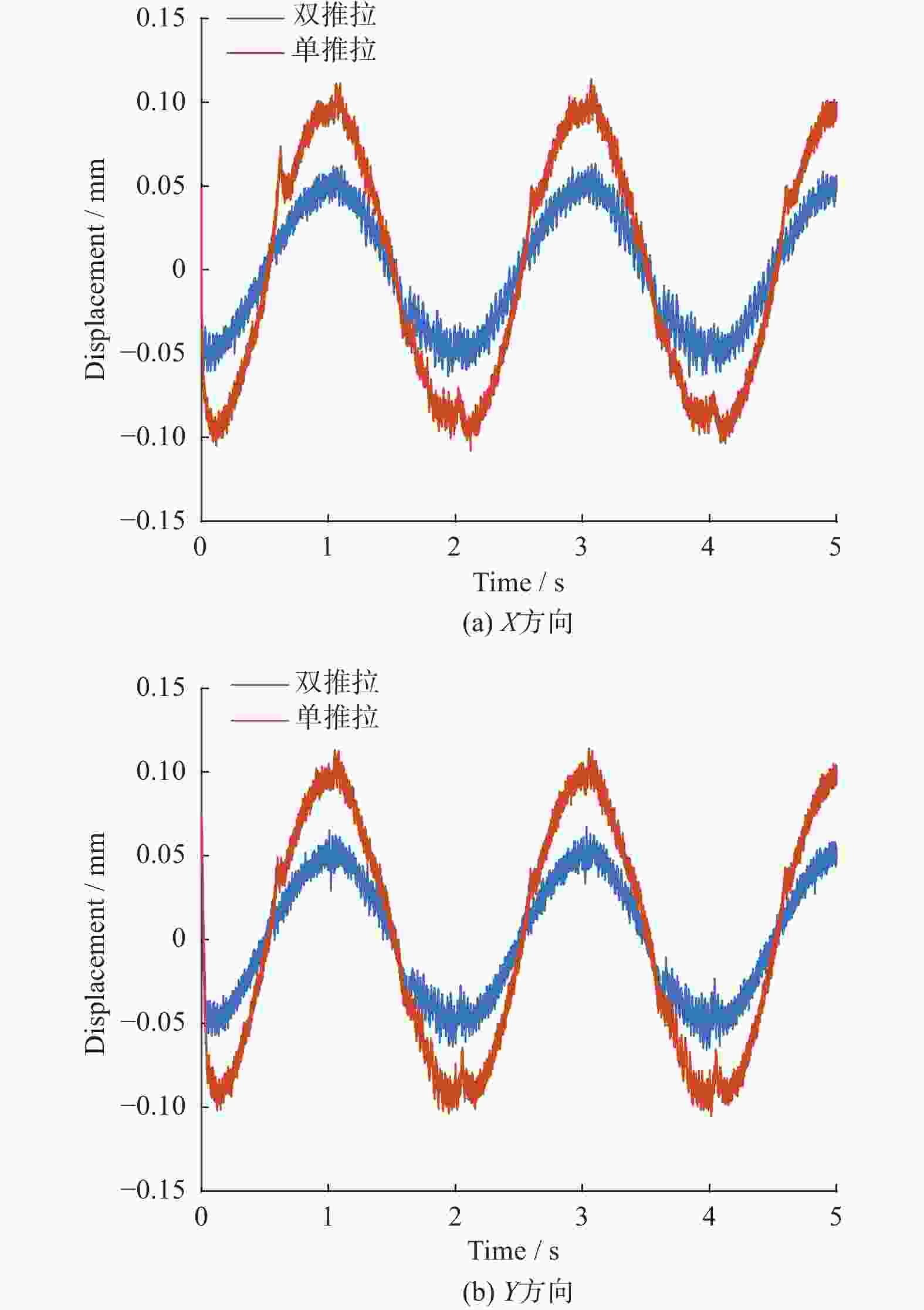

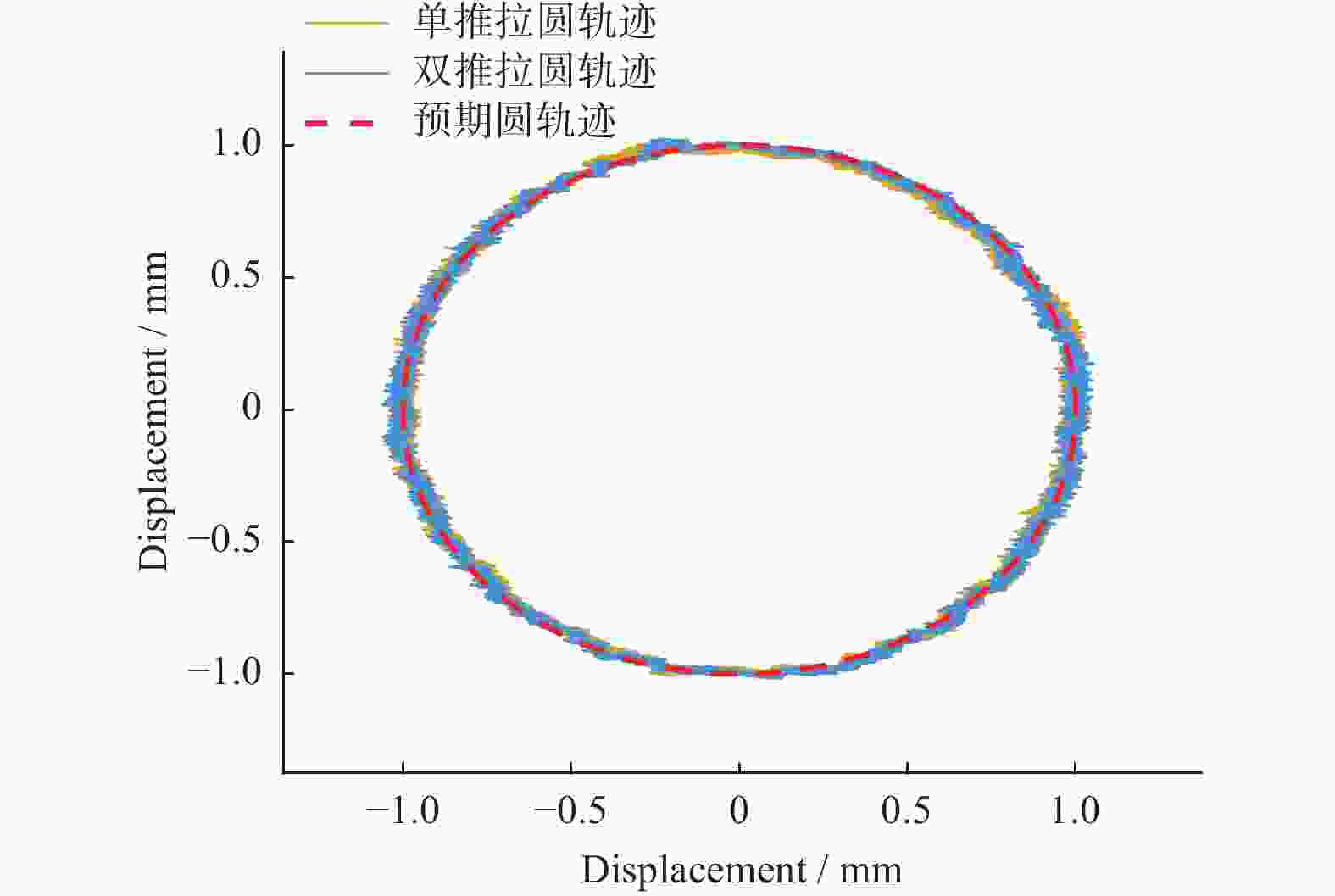

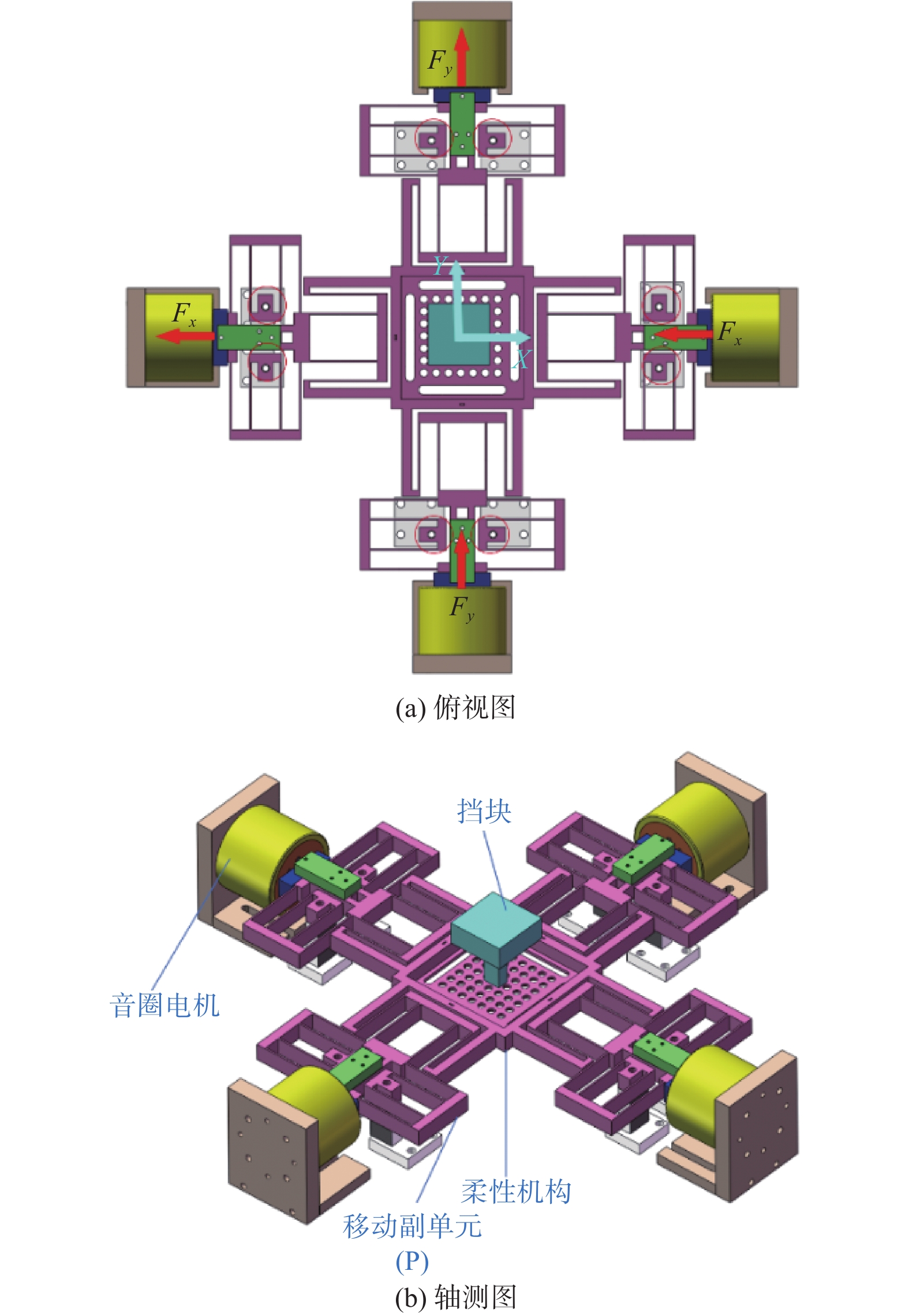

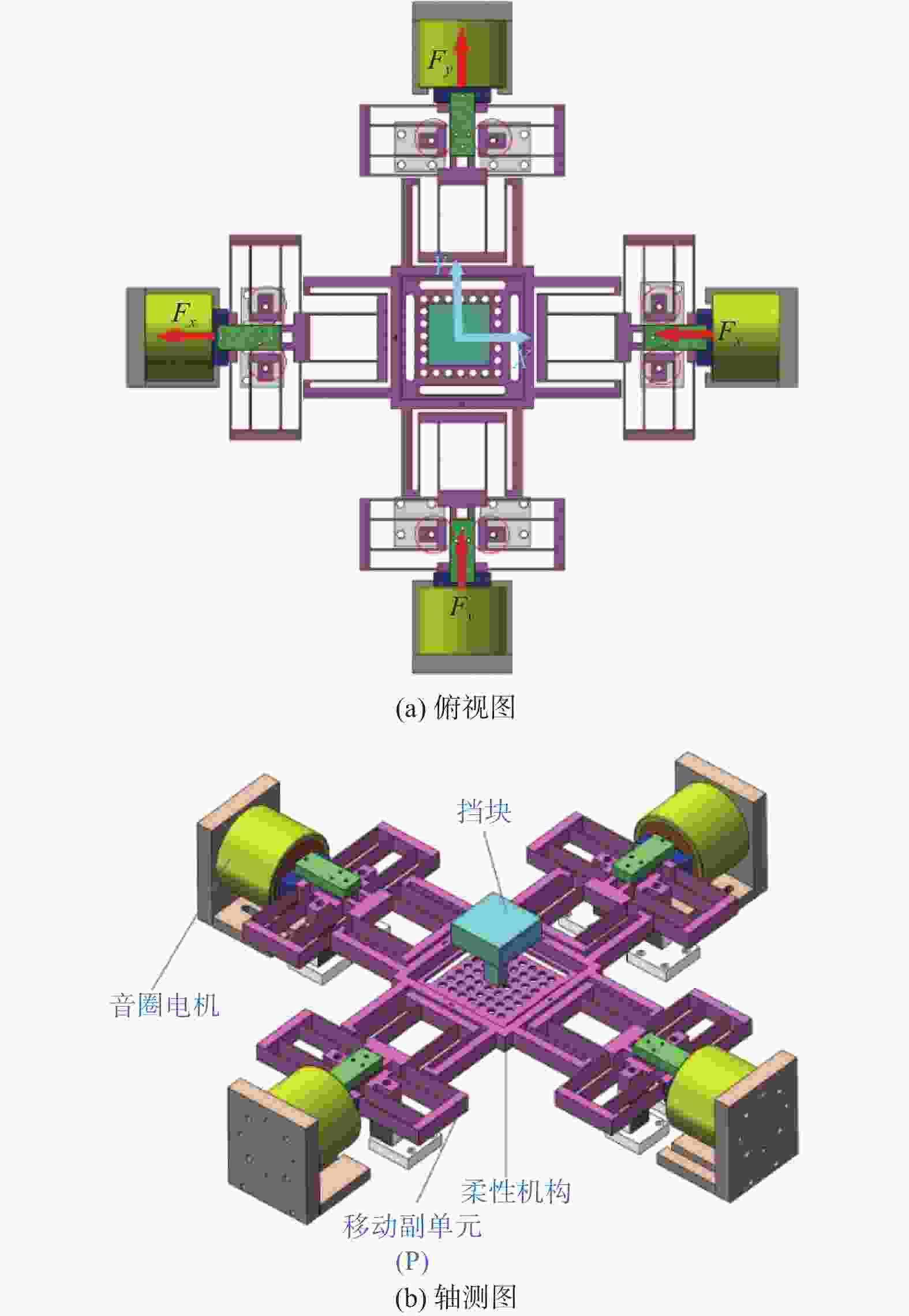

摘要: 提出一种音圈电机驱动二自由度平动大行程解耦微动工作台,采用直板柔性簧片梁和复合双平行四杆机构耦合的并联双推拉机构。基于音圈电机的双推拉驱动原理及二自由度柔性机构的构型设计,利用簧片梁的受力与变形特征以及拉格朗日方程对平台的静力学和动力学特性进行建模,得到用于计算平台静刚度和固定频率的解析模型。进行有限元分析验证所建模型的合理性和准确性,并搭建平台的控制试验系统,对比单、双推拉模式的轨迹跟踪效果。结果表明,双推拉模式比单推拉模式具有更好的跟踪效果、更高的精度和更好的稳定性。所提出的互补音圈电机驱动的大行程柔性并联精密运动平台具有行程大、精度高和稳定性好的特点,适用于大行程高速精密运动场景。Abstract: A voice coil motor-driven two-degree-of-freedom translational large-stroke decoupled micro-motion stage was proposed, which adopts a parallel dual-push-pull structure coupling straight flexible reed beams with a compound double parallelogram mechanism. Based on the push-pull driving principle of the voice coil motor and the configuration design of the dual-degree-of-freedom flexible mechanism, the static and dynamic characteristics of the platform were modeled using the force and deformation characteristics of the spring beam and the Lagrange equation, and an analytical model for calculating the static stiffness and natural frequency of the platform was obtained. Finite element analysis was conducted to validate the rationality and accuracy of the proposed models, and a control experimental system for the platform was constructed to compare trajectory tracking performance between single-push-pull and dual-push-pull modes. The experimental results show that the dual-push-pull mode has better tracking performance, higher precision, and better stability compared to the single-push-pull mode. The proposed complementary voice coil motor-driven large stroke flexible parallel precision motion platform features large stroke, high precision, and high stability characteristics, making it particularly suitable for large-stroke high-speed precision motion scenarios.

-

表 1 理论建模与有限元分析结果对比

Table 1. Results comparison between theoretical modeling and finite element analysis

模型 X/Y方向模态/Hz 静态刚度/(N·m−1) 最大应力/MPa 解析模型 62.77 94496.15 115.2 有限元模型 59.88 92739.58 108.6 误差/% 4.83 1.89 6.08 -

[1] ITO S, CIGARINI F, UNGER S, et al. Flexure design for precision positioning using low-stiffness actuators[J] . IFAC-PapersOnLine, 2016, 49(21): 200 − 205. doi: 10.1016/j.ifacol.2016.10.548 [2] ITO S, TROPPMAIR S, LINDNER B, et al. Long-range fast nanopositioner using nonlinearities of hybrid reluctance actuator for energy efficiency[J] . IEEE Transactions on Industrial Electronics, 2019, 66(4): 3051 − 3059. doi: 10.1109/TIE.2018.2842735 [3] LI Y M, XU Q S. A totally decoupled piezo-driven XYZ flexure parallel micropositioning stage for micro/nanomanipulation[J] . IEEE Transactions on Automation Science and Engineering, 2011, 8(2): 265 − 279. doi: 10.1109/TASE.2010.2077675 [4] PINSKIER J, SHIRINZADEH B, CLARK L, et al. Development of a 4-DOF haptic micromanipulator utilizing a hybrid parallel-serial flexure mechanism[J] . Mechatronics, 2018, 50: 55 − 68. doi: 10.1016/j.mechatronics.2018.01.007 [5] WANG T W, LI Y Z, ZHANG Y X, et al. Design of a flexure-based parallel XY micropositioning stage with millimeter workspace and high bandwidth[J] . Sensors and Actuators A: Physical, 2021, 331(7): 112899. [6] LYU Z, XU Q S. Design and testing of a large-workspace XY compliant manipulator based on triple-stage parallelogram flexure[J] . Mechanism and Machine Theory, 2023, 184: 105287. doi: 10.1016/j.mechmachtheory.2023.105287 [7] CAI K H, TIAN Y L, LIU X P, et al. Development and control methodologies for 2-DOF micro/nano positioning stage with high out-of-plane payload capacity[J] . Robotics and Computer-Integrated Manufacturing, 2019, 56: 95 − 105. doi: 10.1016/j.rcim.2018.08.007 [8] OKYAY A, ERKORKMAZ K, KHAMESEE M B. Mechatronic design, actuator optimization, and control of a long stroke linear nano-positioner[J] . Precision Engineering, 2018, 52: 308 − 322. doi: 10.1016/j.precisioneng.2018.01.007 [9] LIU H, LAI L J, FANG Y, et al. Push–pull large stroke flexure-based micropositioning stage driven by electromagnetic actuators with complementary double configuration[J] . Review of Scientific Instruments, 2023, 94(3): 035012. doi: 10.1063/5.0133906 [10] XI S Z, LAI L J. Paired double parallelogram flexure mechanism clamped by corrugated beam for underconstraint elimination[J] . Review of Scientific Instruments, 2020, 91(8): 086102. doi: 10.1063/5.0003176 [11] 陈云壮, 赖磊捷, 李朋志, 等. 全簧片式空间大行程并联柔性微定位平台及其轨迹控制[J] . 光学精密工程, 2023, 31(18): 2675 − 2686. -

下载:

下载: