Optimization of preventive maintenance for airbag type cylinders of electric locomotives based on reliability

-

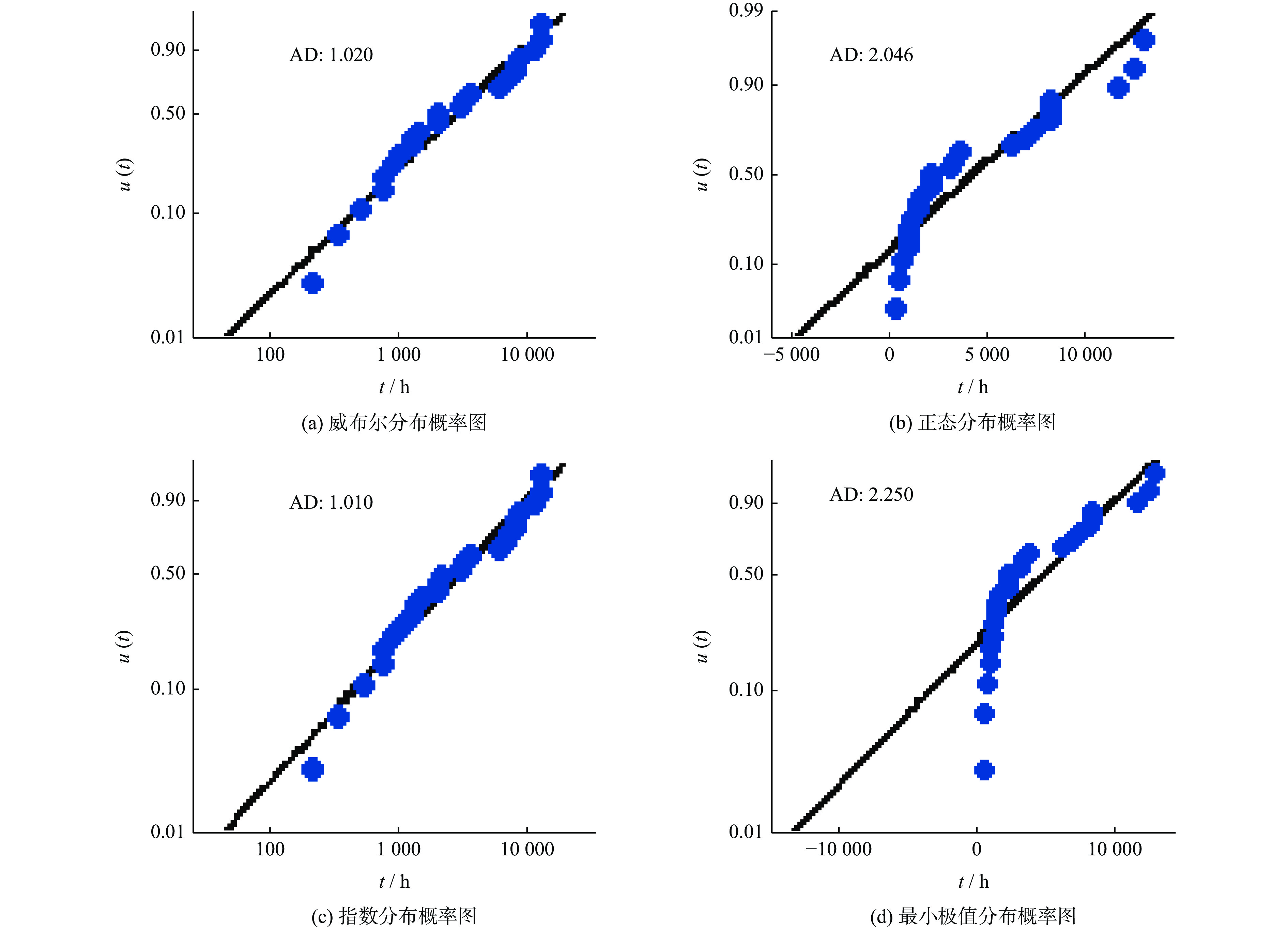

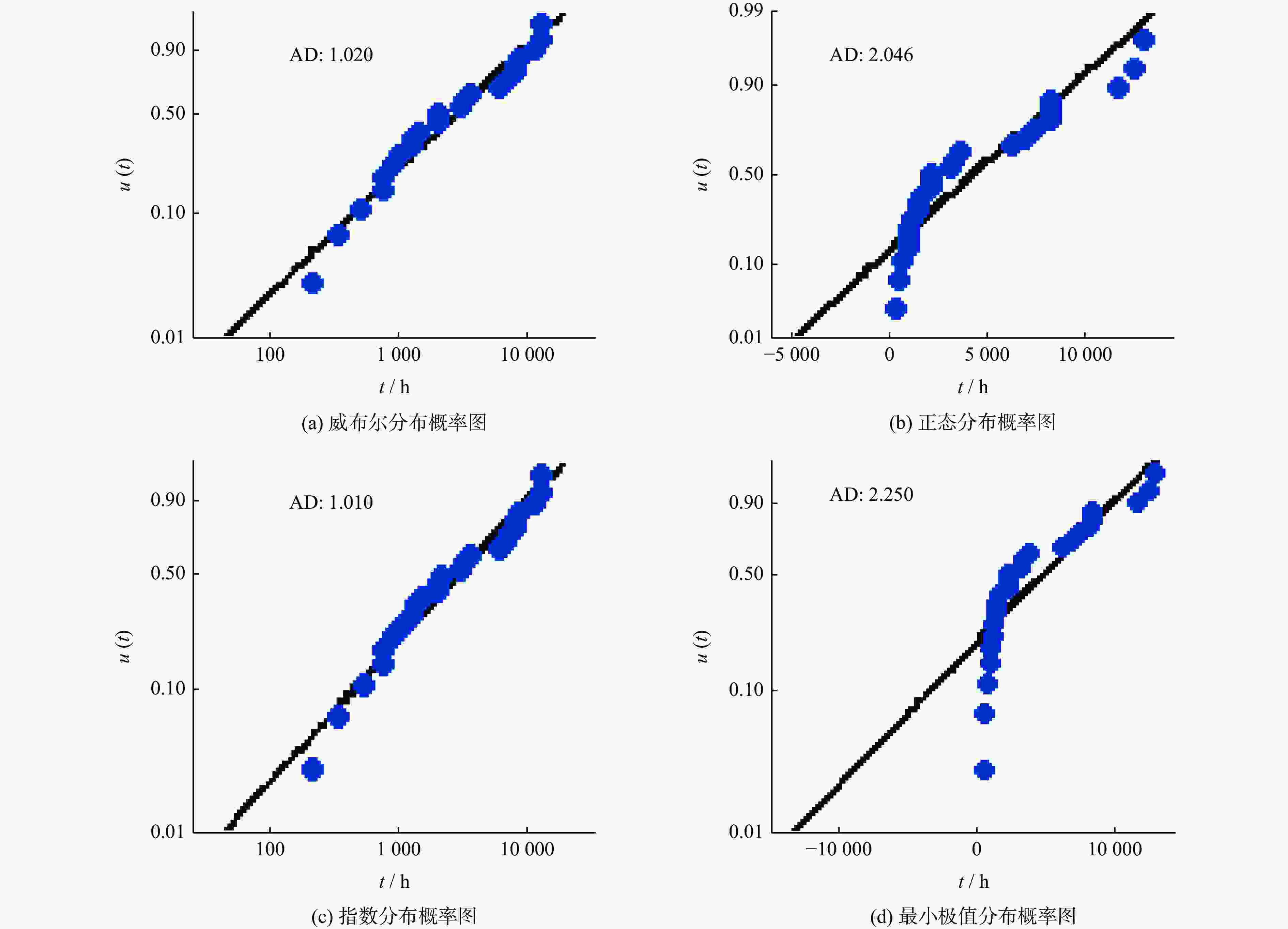

摘要: 针对电力机车受电弓气囊式气缸预防性维修存在欠维修或过维修问题,提出一种利用气囊式气缸失效数来优化检查维修参数的方法。首先,在传统预防性维修策略基础上,利用图参数法分析气囊式气缸失效数服从指数分布,进一步采用Bartlett值法,验证失效数服从指数分布的有效性。其次,基于气囊式气缸具有恒定失效率的特征,建立可靠性模型得出其失效数、瞬时可用度、稳态可用度等可靠性指标,为制定最佳预防性维修策略提供依据。再次,建立气囊式气缸预防性维修和更换的最小费用模型,得到其最优预防性维修的间隔时间和最优维修费用。该优化方法可为检修人员提升维修水平和降低维修成本提供科学参考。Abstract: To address the problem of under-maintenance and over-maintenance in the preventive maintenance of electric locomotive pantograph airbag cylinder, a method for optimizing inspection and maintenance parameters using failure data of the airbag cylinders was proposed. Firstly, based on the traditional preventive maintenance strategy, the graph parameter method was used to analyze whether the failure data of the airbag cylinders followed an exponential distribution. Subsequently, the Bartlett test was employed to verify the validity of this distribution assumption. Secondly, based on the characteristic constant failure rate of the airbag cylinders, a reliability model was established. Key reliability indicators, such as the instantaneous availability and steady-state availability, then derived, providing a basis for formulating the optimal preventive maintenance strategy. Thirdly, a minimum cost model for the preventive maintenance and replacement of the airbag cylinder was established, and the optimal preventive maintenance interval and maintenance cost were obtained. The optimized inspection and maintenance parameters for the airbag cylinders can provide scientific basis for maintenance personnel to improve quality and reduce maintenance costs.

-

Key words:

- airbag cylinder /

- index distribution /

- availability /

- maintenance cycle /

- maintenance cost

-

表 1 气囊式气缸失效时间统计

Table 1. Statistics of failure time of airbag type cylinders

序号 失效时间/h 序号 失效时间/h 序号 失效时间/h 1 1 980 10 8 023 19 12 815 2 1 014 11 6 037 20 3 071 3 12 420 12 889 21 3 520 4 754 13 1 440 22 1 291 5 2 921 14 11 460 23 1 243 6 7 224 15 743 24 8 106 7 510 16 336 25 8 144 8 2 043 17 1 985 9 210 18 6 700 -

[1] 左洪福, 蔡景, 王华伟, 等. 维修决策理论与方法[M] . 北京: 航空工业出版社, 2008: 41 − 50. [2] 李勤, 周立新. 轨道车辆部件运用可靠性分析方法研究[J] . 城市轨道交通研究, 2010, 13(1): 63 − 65, 69. doi: 10.3969/j.issn.1007-869X.2010.01.017 [3] 李琴, 王硕, 王智勇, 等. 热-机耦合作用下压缩机气缸形变效应评价[J] . 流体机械, 2023, 51(7): 39 − 45. doi: 10.3969/j.issn.1005-0329.2023.07.006 [4] 刘静, 朱志松, 陈凯聪. 气缸低速爬行特性影响因素及补偿[J] . 机械设计与制造, 2018(5): 86 − 88, 92. doi: 10.3969/j.issn.1001-3997.2018.05.026 [5] 赵春娟, 杨平, 王洁, 等. 基于疲劳试验的气缸气缓冲性能研究[J] . 机床与液压, 2017, 45(1): 43 − 46, 62. doi: 10.3969/j.issn.1001-3881.2017.01.010 [6] 王翔, 齐恩兵, 房振勇. 基于预测控制的垂直轴卸荷气缸压力调节[J] . 机床与液压, 2023, 51(14): 101 − 105. doi: 10.3969/j.issn.1001-3881.2023.14.017 [7] 罗辉, 汪达军, 舒春辉, 等. 基于STM32的比例阀控气缸位置伺服控制器[J] . 机电工程, 2023, 40(2): 218 − 224. doi: 10.3969/j.issn.1001-4551.2023.02.008 [8] 郝博, 杨斯涵. 打壳机气缸内孔加工装置设计[J] . 中国工程机械学报, 2016, 14(5): 421 − 425. [9] 柳忠彬, 肖守讷, 王欢. 非爆破柔性气缸弹射器研究[J] . 兵工学报, 2017, 38(2): 389 − 395. doi: 10.3969/j.issn.1000-1093.2017.02.025 [10] 李锋, 苑志凯, 何祯鑫, 等. 退化数据驱动的气缸剩余寿命在线预测[J] . 振动、测试与诊断, 2019, 39(3): 577 − 581. [11] 赵宇. 可靠性数据分析[M] . 北京: 国防工业出版社, 2011: 56 − 70. [12] ELSAYED E A. 可靠性工程[M] . 杨舟, 译. 2版. 北京: 电子工业出版社, 2013: 339 − 357. -

基于可靠性的电力机车气囊式气缸预防性维修优化研究_附加材料.pdf

基于可靠性的电力机车气囊式气缸预防性维修优化研究_附加材料.pdf

-

下载:

下载: