Acoustic-structural coupling analysis of wiper-windshield friction noise

-

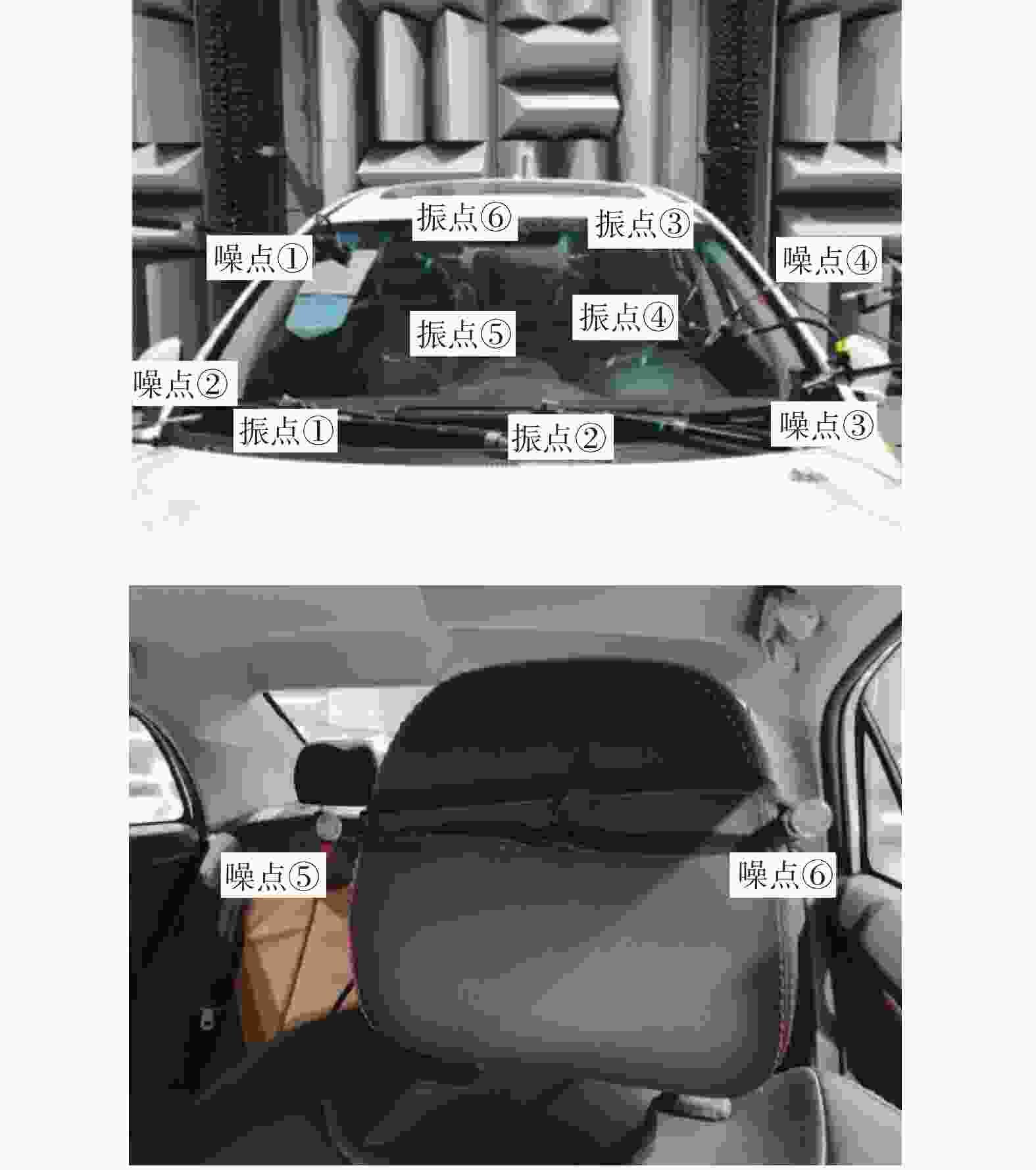

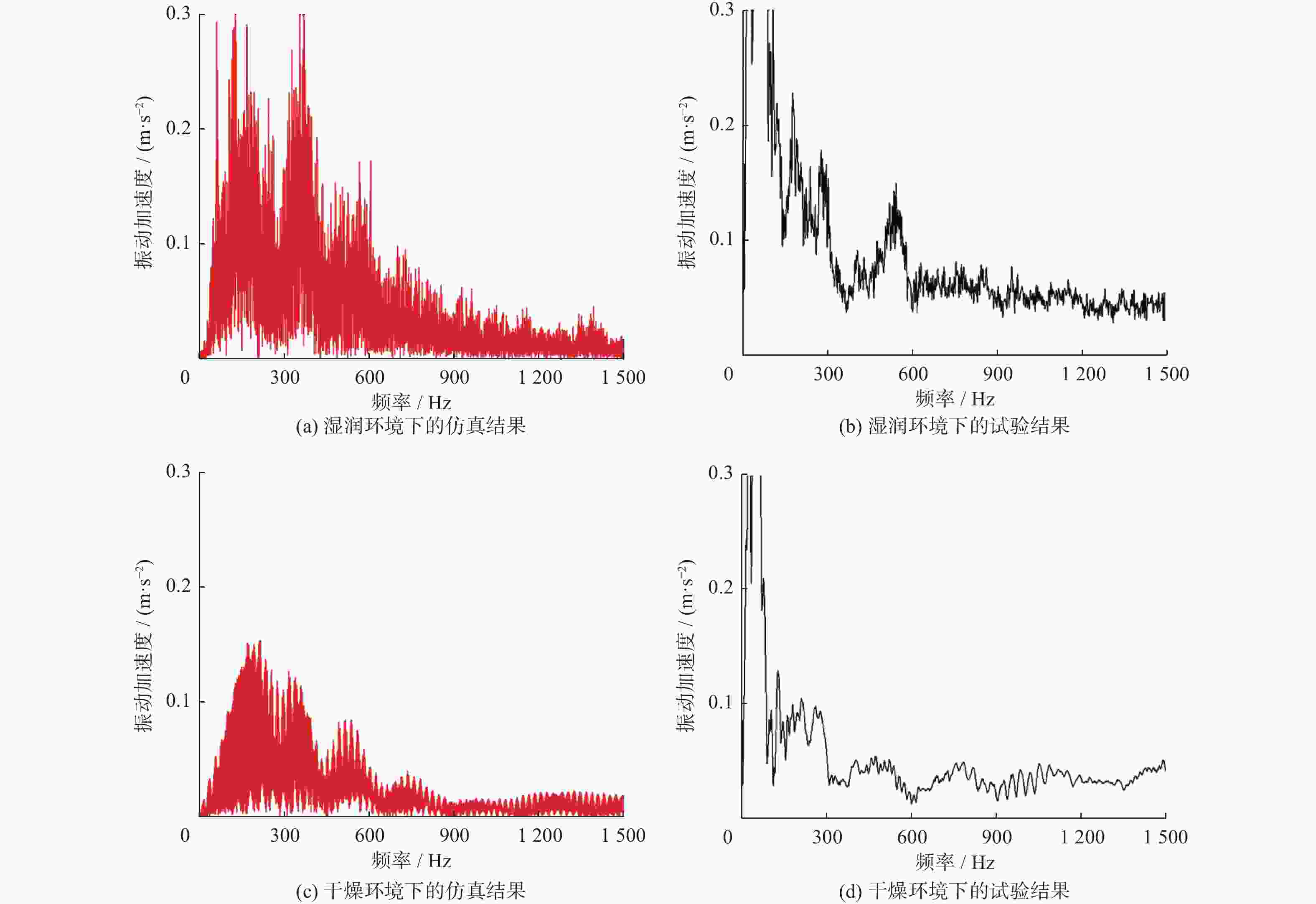

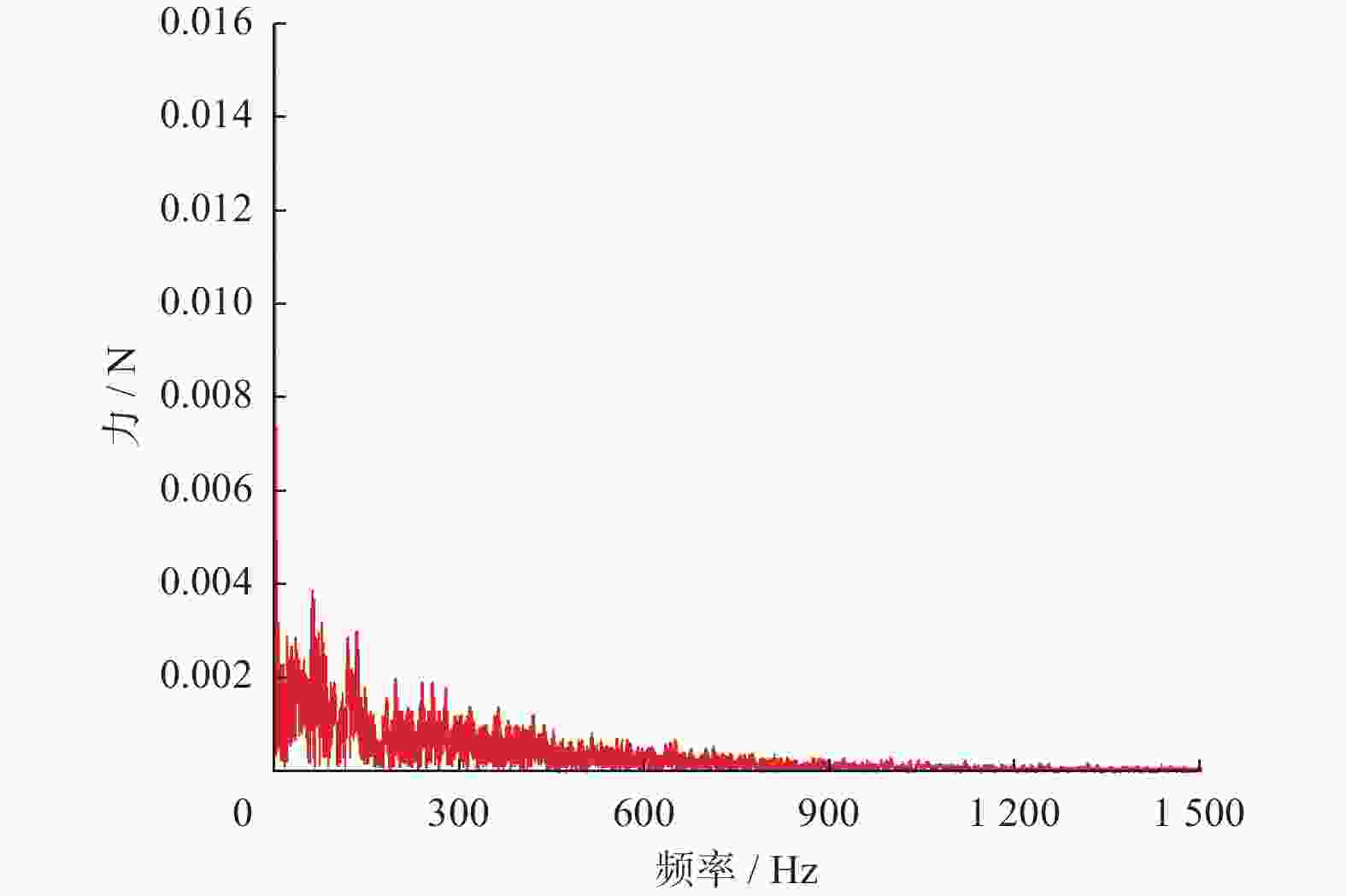

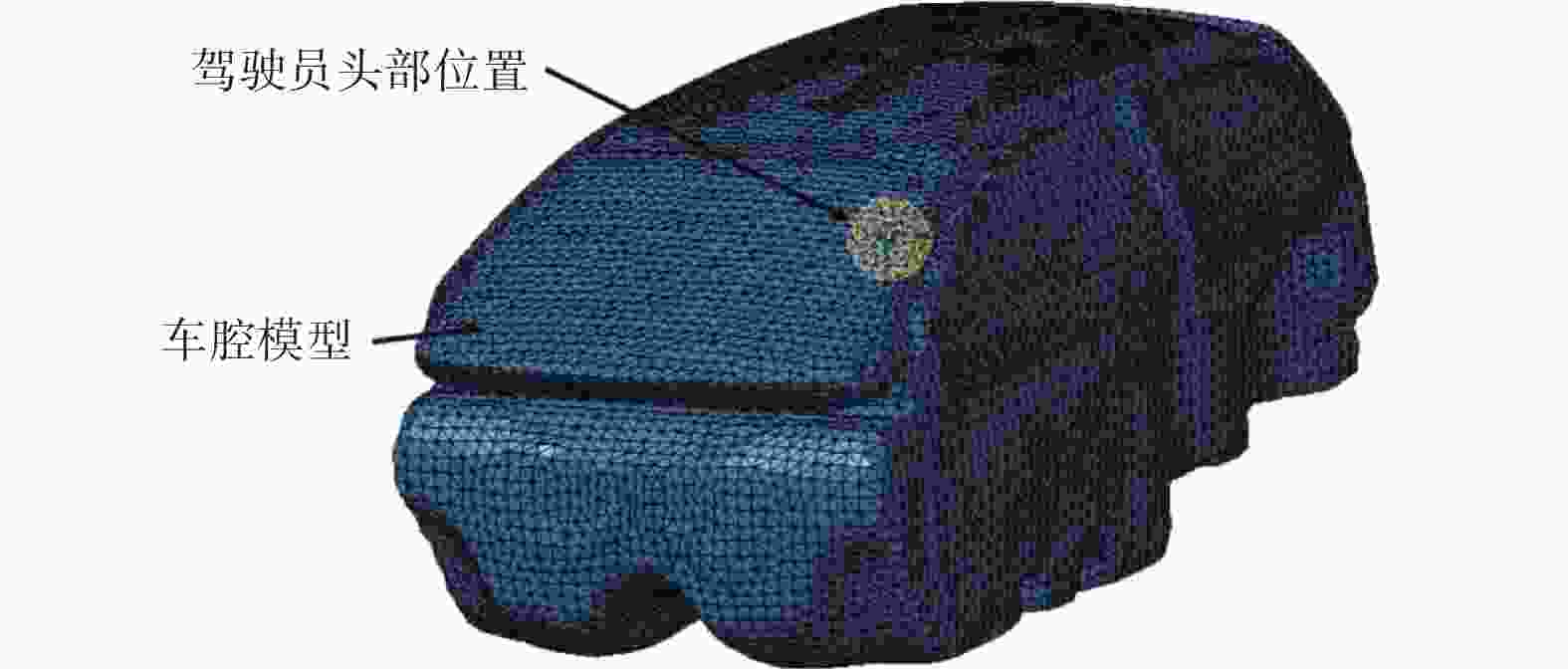

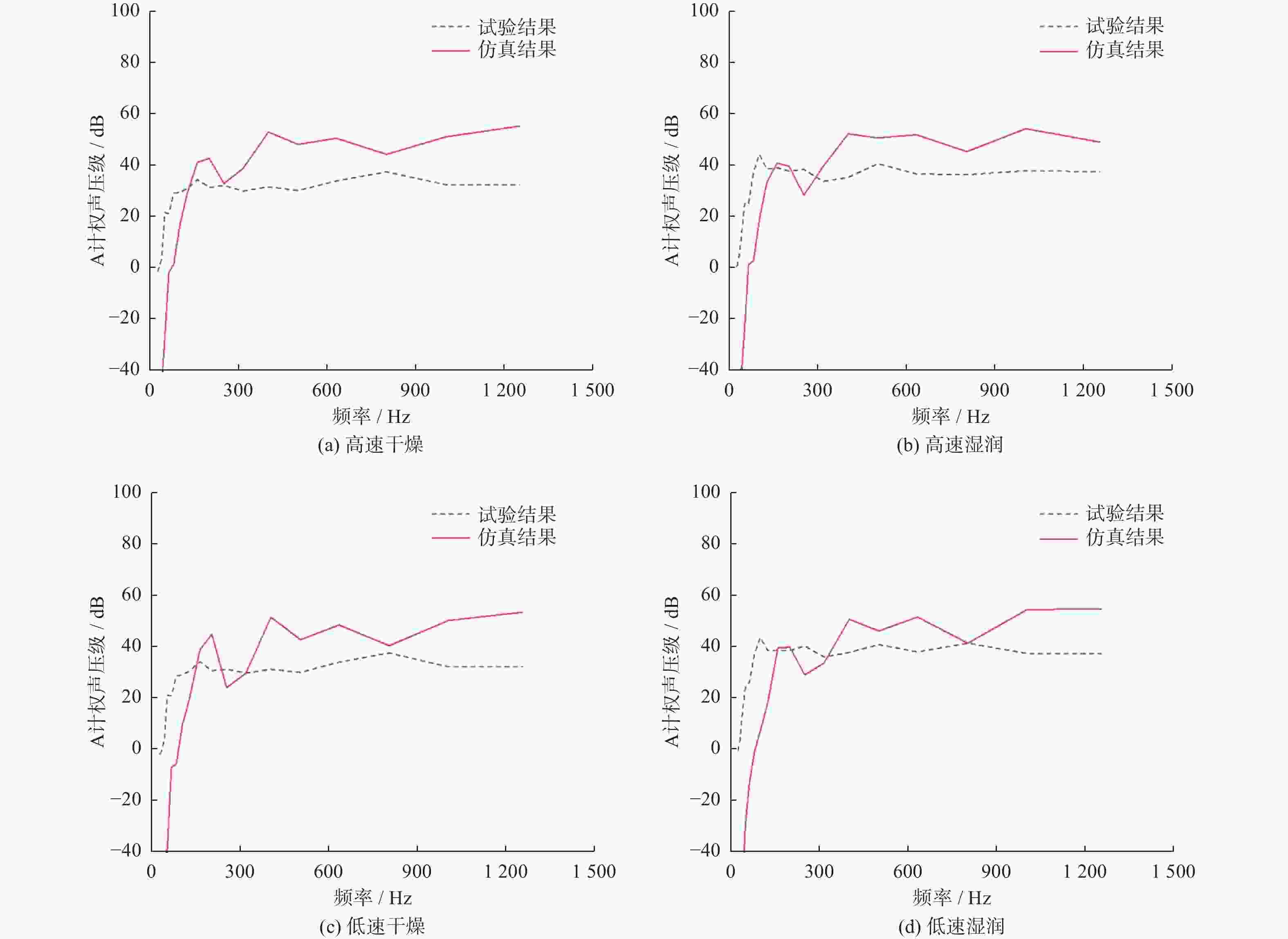

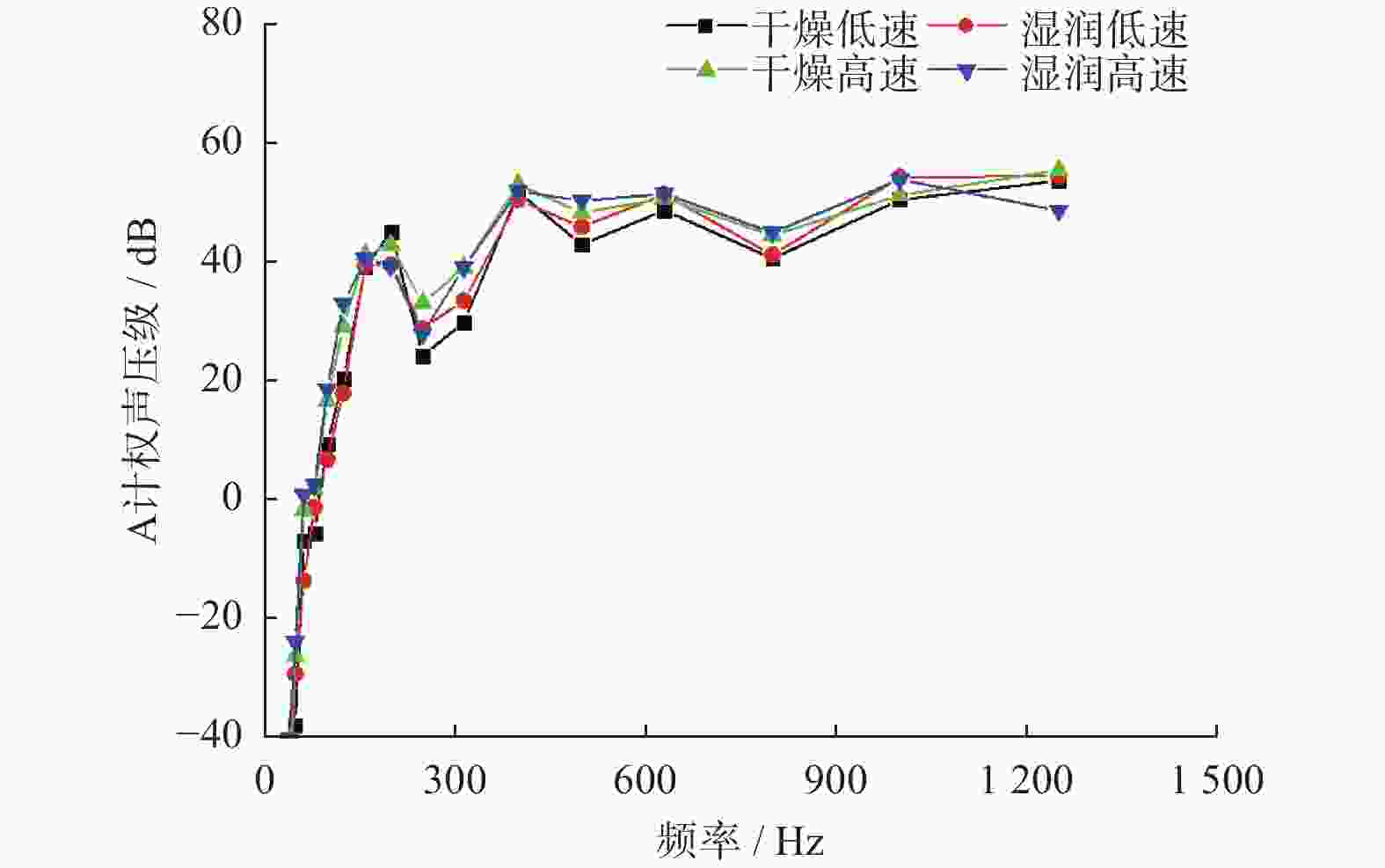

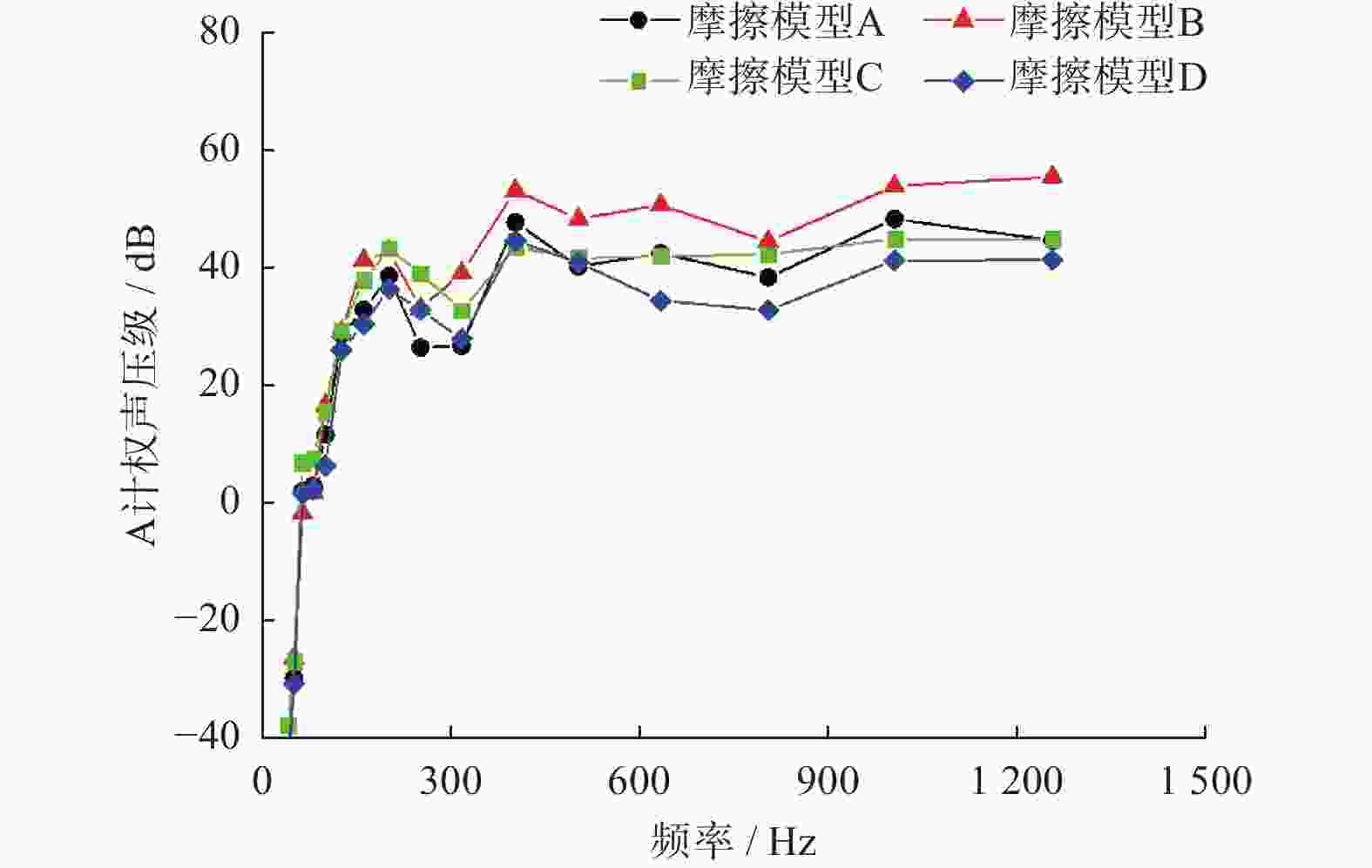

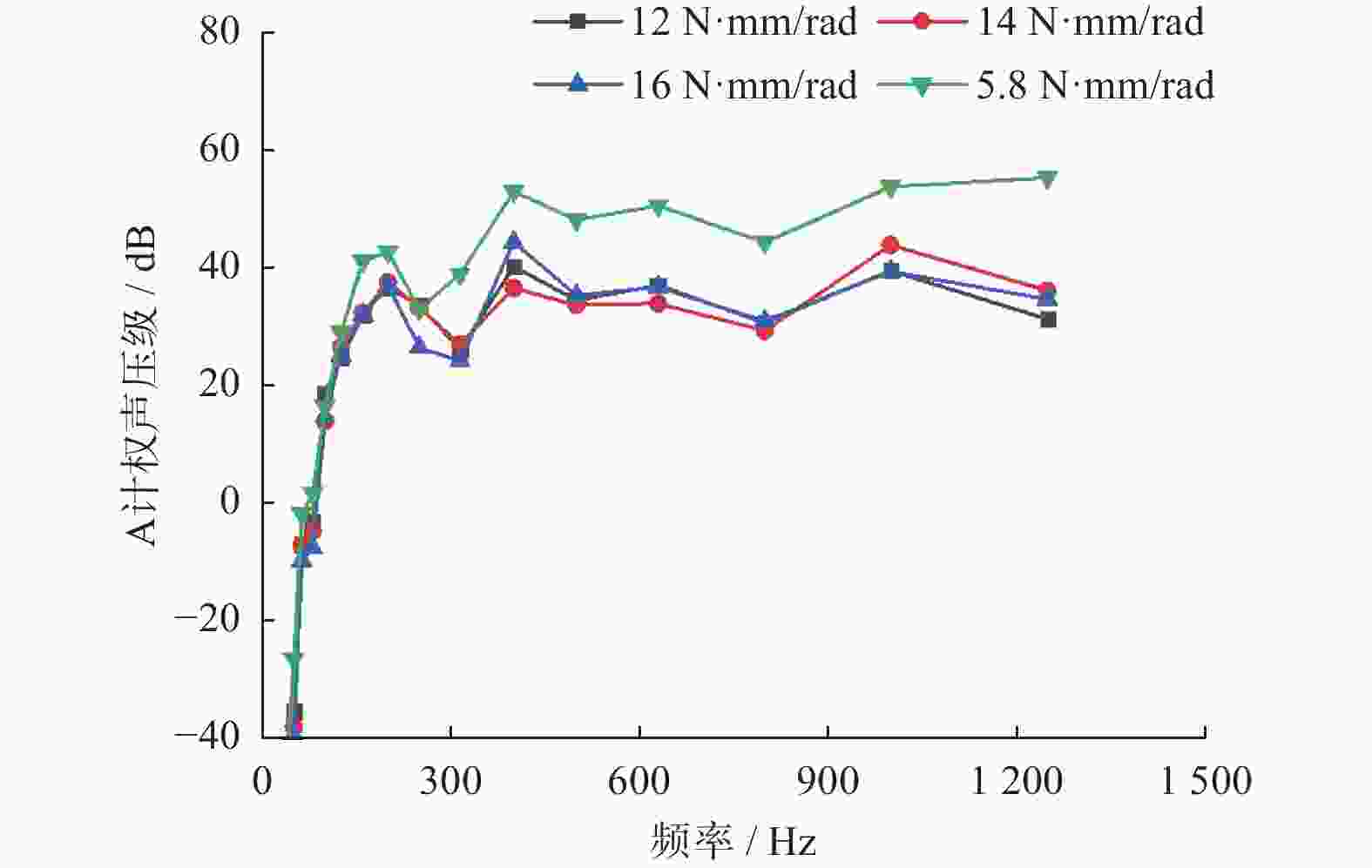

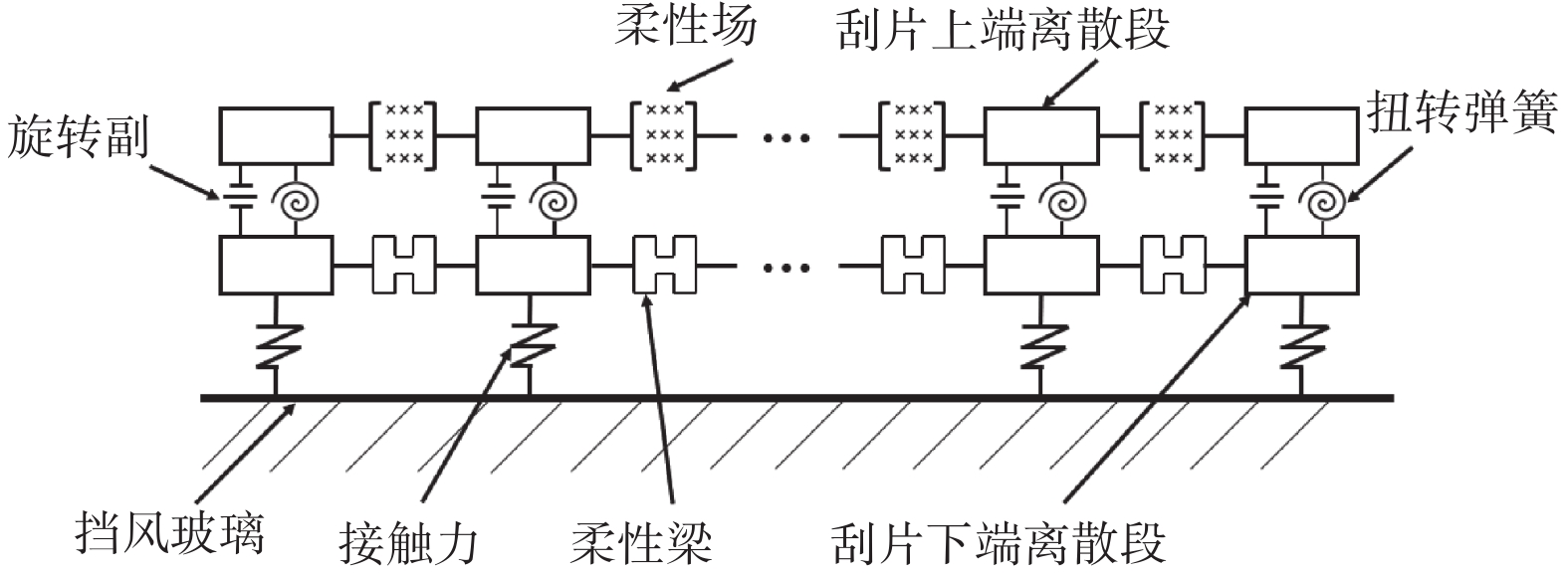

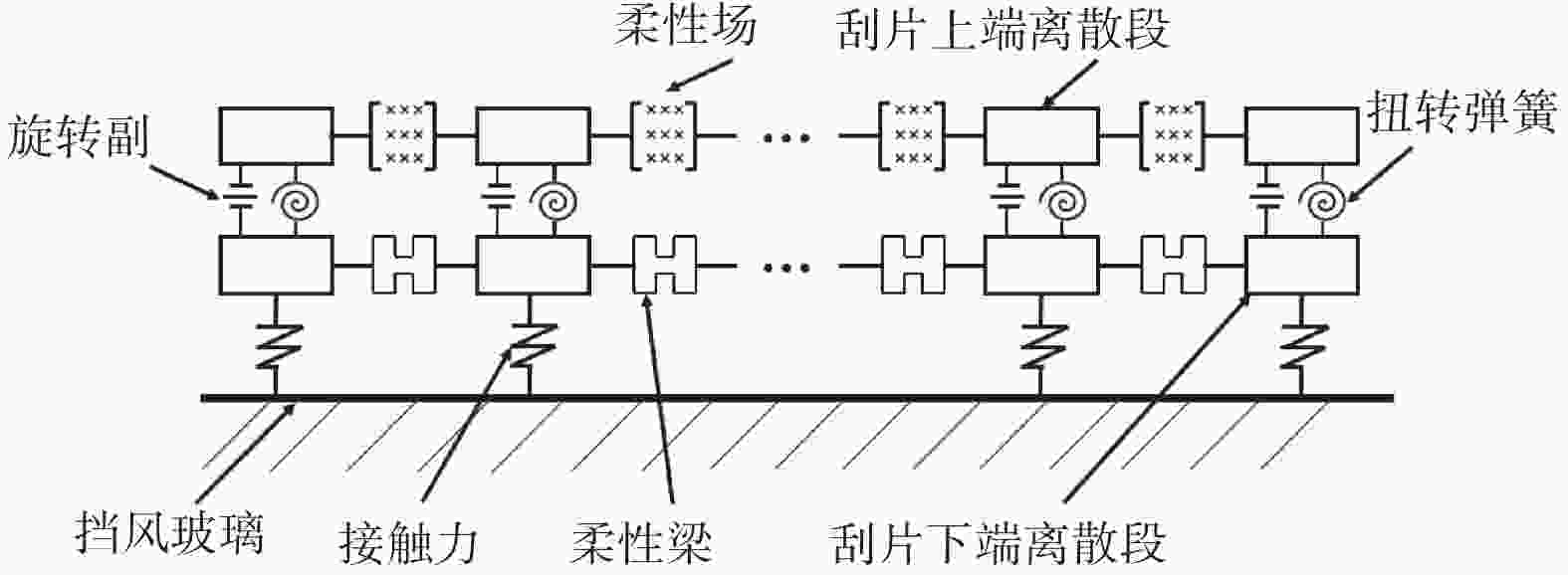

摘要: 基于ADAMS建立雨刮片细化模型,分析雨刷片振动特性;利用Virtual.Lab建立前挡风玻璃与车厢腔体声−固耦合有限元模型,分析雨刮−风窗系统摩擦噪声传递至驾驶员位置的声压级,研究转速、摩擦模型及雨刮片扭转刚度对系统摩擦噪声特性的影响;通过实车雨刮−风窗系统试验验证仿真模型有效性。结果表明,建立的雨刮片细化模型和声−固耦合有限元模型与试验结果吻合,针对系统的3种摩擦噪声,转速、摩擦模型及雨刮片扭转刚度分别产生不同影响。Abstract: Based on ADAMS, a detailed model of the wiper blade was established to analyze the vibration characteristics of the wiper blade. Using Virtual.Lab, a finite element model of the acoustic-structural coupling between the windshield and the vehicle cabin was constructed to analyze the sound pressure level of friction noise transmitted to the driver’s position from the wiper-windshield system. The effects of different rotational speeds, friction models, and torsional stiffness of the wiper blade on the friction noise characteristics of the system were investigated. Through experimental testing of the wiper-windshield system on a real vehicle, the validity of the simulation models was verified. The results indicate that the detailed wiper blade model and the acoustic-structural coupling finite element model agree well with the experimental results. For the three types of friction noise in the system, rotational speeds, friction models, and torsional stiffness of the wiper blade each have different impacts.

-

表 1 雨刮片结构参数

Table 1. Structural parameters of wiper blade

参数 值 无质量梁拉伸模量/MPa 7.1 无质量梁剪切模量/MPa 2.38 无质量梁截面积/mm2 6.79 无质量梁的X轴惯性矩/mm4 3.06 无质量梁的Y轴惯性矩/mm4 5.42 无质量梁的Z轴惯性矩/mm4 8.48 颈部扭转弹簧扭转刚度/(N·mm·rad−1) 5.8 颈部扭转弹簧扭转阻尼/(N·mm·s·rad−1) 0.024 刮片与挡风玻璃间接触刚度/(N·mm−1) 2.5 刮片与挡风玻璃间接触阻尼/(N·s·mm−1) 0.9 表 2 声−固耦合仿真材料参数

Table 2. Material parameters for acoustic-structural coupling simulation

参数 空气 玻璃 多孔材料 密度(kg·m−3) 1.225 2750 64 传播速度(m·s−1) 340 — — 杨氏模量(N·m−2) — 7e+10 — 泊松比 — 0.2 — 体积模量(N·m−2) — — 28500 结构损耗因子 — — 0.01 静态流阻率(Pa·m−2) — — 5000 曲率 — — 1.08 -

[1] 张立军, 徐飞, 王小博. 汽车刮水器摩擦引起的噪声特性试验分析[J] . 同济大学学报(自然科学版), 2010, 38(7): 1062 − 1068. doi: 10.3969/j.issn.0253-374x.2010.07.022 [2] MUSCA I, MUSCA G, VULTUR D C, et al. About the friction of the wiper windscreen contact[J] . Applied Mechanics and Materials, 2014, 658: 335 − 338. doi: 10.4028/www.scientific.net/AMM.658.335 [3] 陈清泉, 董大伟, 闫兵, 等. 前雨刮器振动噪声的试验研究[J] . 机械科学与技术, 2010, 29(12): 1628 − 1632. [4] MIN D, JEONG S, YOO H H, et al. Experimental investigation of vehicle wiper blade’s squeal noise generation due to windscreen waviness[J] . Tribology International, 2014, 80: 191 − 197. doi: 10.1016/j.triboint.2014.06.024 [5] 毛之安, 王岩松, 孙裴, 等. 雨刮反转过程振动冲击特性实验研究[J] . 噪声与振动控制, 2024, 44(1): 288 − 295. doi: 10.3969/j.issn.1006-1355.2024.01.044 [6] MOHAMAD S M, OTHMAN N, SHARIF I, et al. Dynamic behaviour and characteristics of rubber blade car performance[J] . International Journal of Automotive and Mechanical, 2019, 16(1): 6437 − 6452. [7] LEE C E, KIM H Y. Analysis of the cross-sectional shape and wiping angle of a wiper blade[J] . SAE International Journal of Materials and Manufacturing, 2020, 13(2): 183 − 194. [8] HUANG M. Analysis of friction induced stability, bifurcation, chaos, stick-slip vibration and their impacts on wiping effect of automotive wiper system[J] . SAE International Journal of Passenger Cars-Mechanical Systems, 2014, 7(1): 21 − 31. doi: 10.4271/2014-01-0021 [9] LANCIONI G, LENCI S, GALVANETTO U. Dynamics of windscreen wiper blades: squeal noise, reversal noise and chattering[J] . International Journal of Non-Linear Mechanics, 2016, 80: 132 − 143. doi: 10.1016/j.ijnonlinmec.2015.10.003 [10] LANCIONI G, LENCI S, GALVANETTO U. Non-linear dynamics of a mechanical system with a frictional unilateral constraint[J] . International Journal of Non-Linear Mechanics, 2009, 44(6): 658 − 674. doi: 10.1016/j.ijnonlinmec.2009.02.012 [11] BÓDAI G, GODA T J. Sliding friction of wiper blade: measurement, FE modeling and mixed friction simulation[J] . Tribology International, 2014, 70: 63 − 74. doi: 10.1016/j.triboint.2013.07.013 [12] ZHAO Z H, YABUNO H, KAMIYAMA K. Dynamic analysis of a wiper blade in consideration of attack angle and clarification of the jumping phenomenon[J] . Applied Sciences, 2022, 12(9): 4112. doi: 10.3390/app12094112 [13] YANG X, WANG Y S, ZHANG Z Y, et al. Simulation and experimental analysis on frictional vibration in the reversal process of a wiper-windscreen system[J] . Applied Acoustics, 2023, 203: 109211. doi: 10.1016/j.apacoust.2023.109211 [14] YANG X, WANG Y S, GUO H, et al. A theoretical analysis of friction and vibration characteristics of wiper reversal process[J] . Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2023, 237(6): 1327 − 1337. doi: 10.1177/09544070221091021 [15] AWANG I M, ABUBAKAR A R, GHANI B A, et al. Complex eigenvalue analysis of windscreen wiper chatter noise and its suppression by structural Modifications[J] . International Journal of Vehicle Structures & Systems, 2009, 1(1/3): 24 − 29. [16] CHEN T, HONG Y. Geometric analysis of the vibration of rubber wiper blade[J] . Taiwanese Journal of Mathematics, 2021, 25(3): 491 − 516. [17] GRAHAM B, KNOWLES J, MAVROS G. The influence of contact distribution shaping on the dynamic response of a wiper blade[J] . Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2024, 238(8): 2302 − 2311. doi: 10.1177/09544070231164792 [18] LI Y Y, XU J J. Dynamic characteristics and generation mechanism of windscreen frameless wiper blade oscillations[J] . Nonlinear Dynamics, 2023, 111(4): 3053 − 3079. doi: 10.1007/s11071-022-08030-0 [19] LE ROUZIC J, LE BOT A, PERRET-LIAUDET J, et al. Friction-induced vibration by stribeck’s law: application to wiper blade squeal noise[J] . Tribology Letters, 2013, 49(3): 563 − 572. doi: 10.1007/s11249-012-0100-z [20] WANG Y S, HUANG Z C, GUO H, et al. Vibration response analysis of boneless wiper-windshield system based on multi-body dynamics model[J] . Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2024: 1−16. DOI: 10.1177/09544070241248049 -

下载:

下载: