Aperture compensation method based on projection error

-

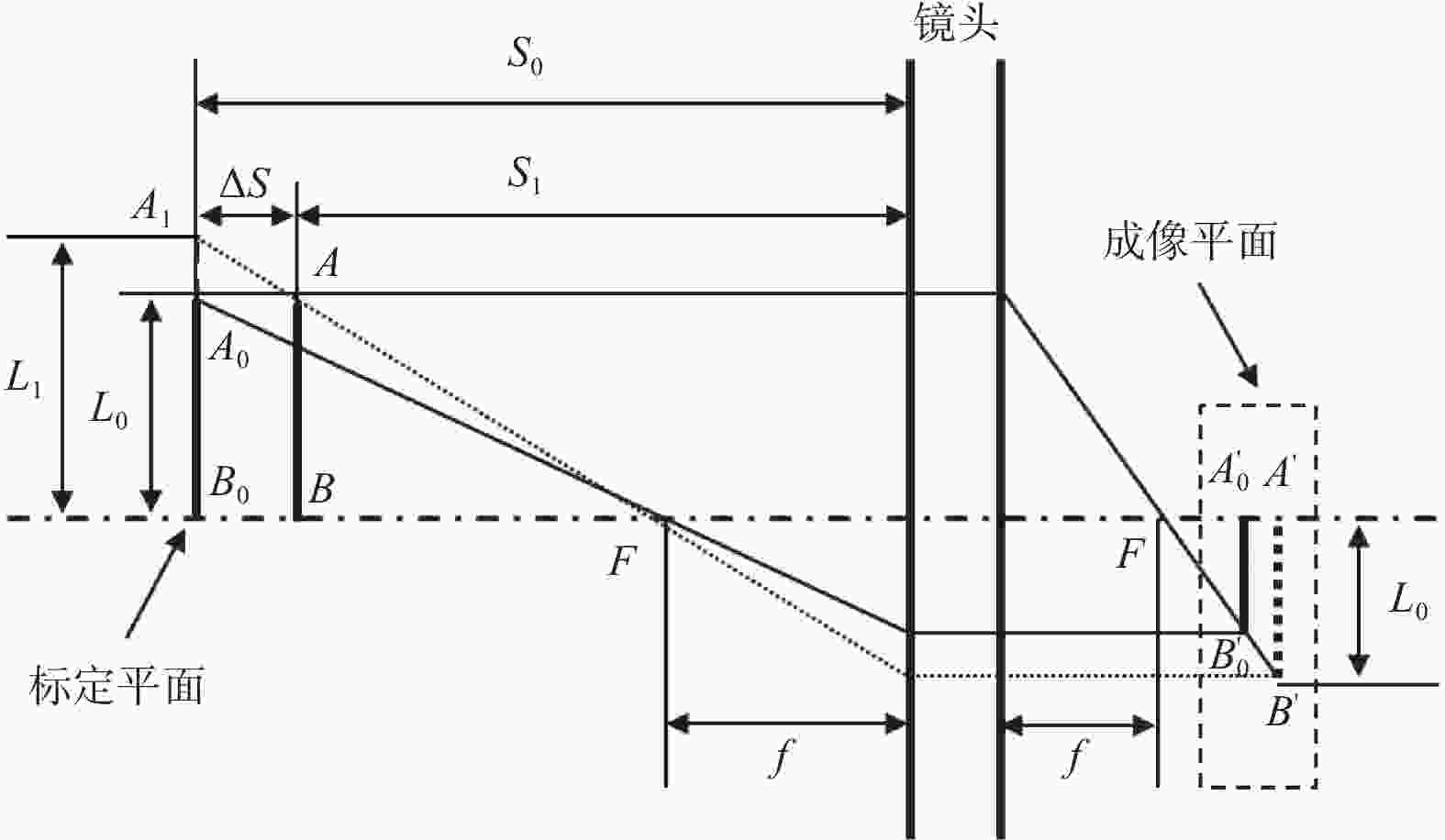

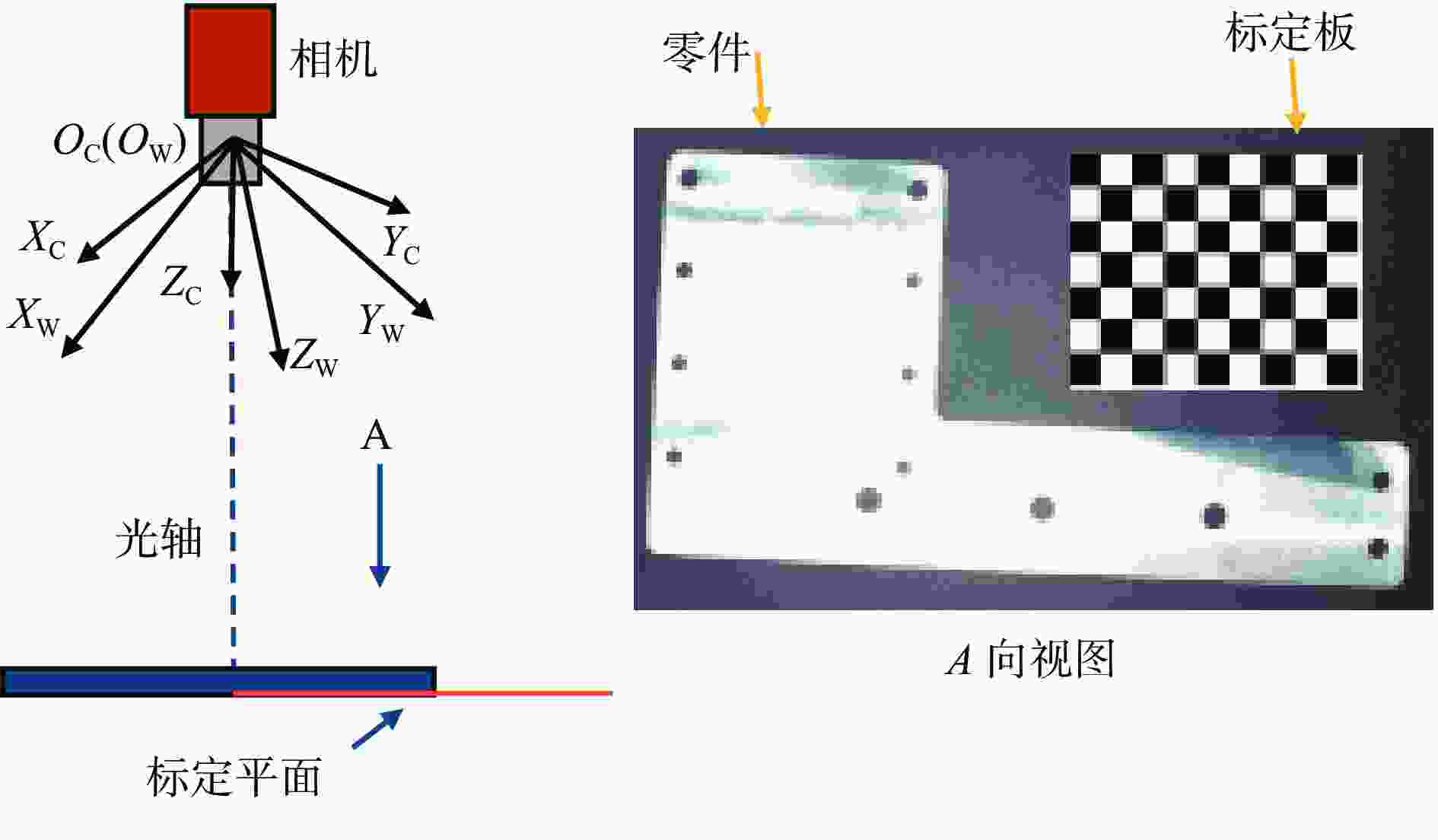

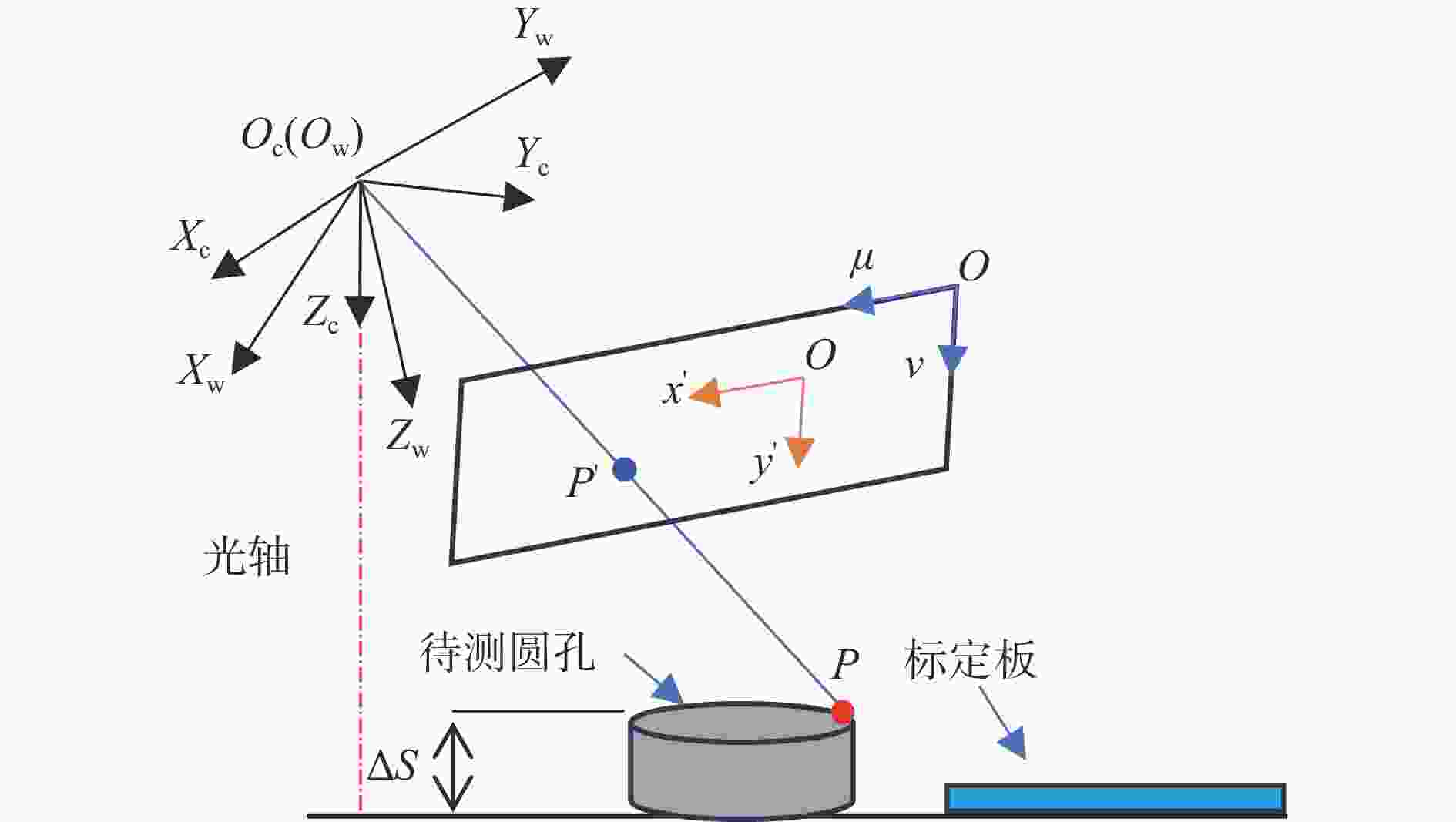

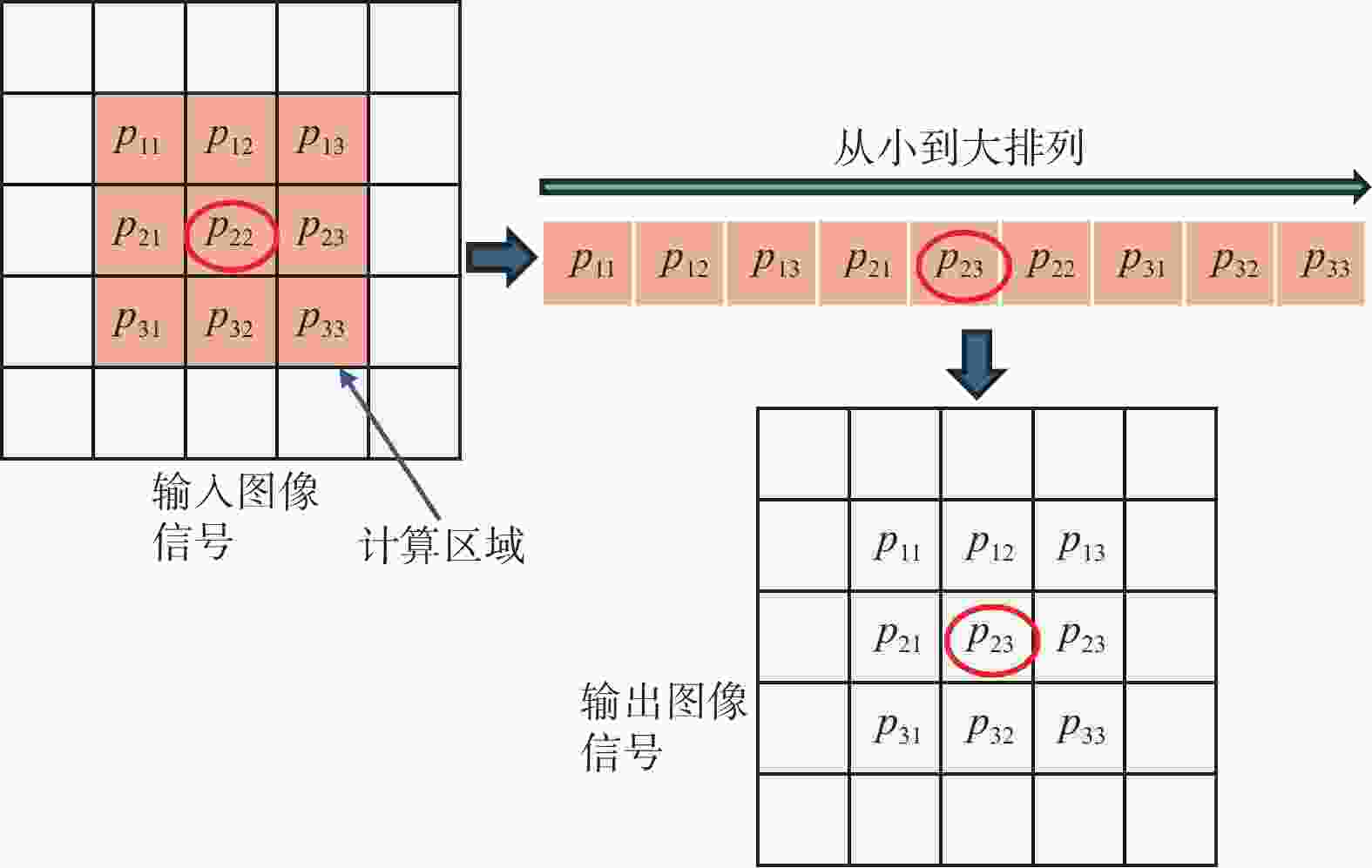

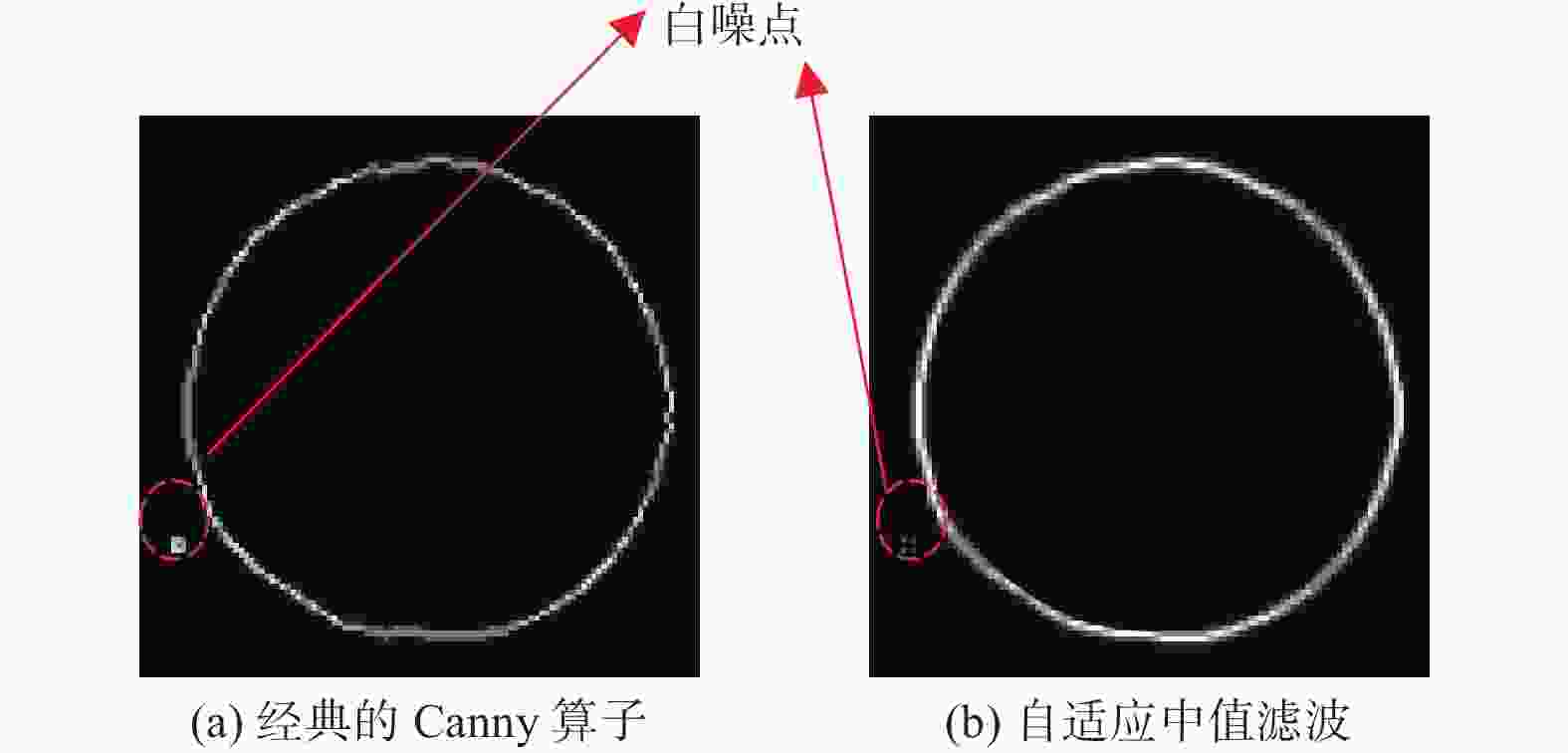

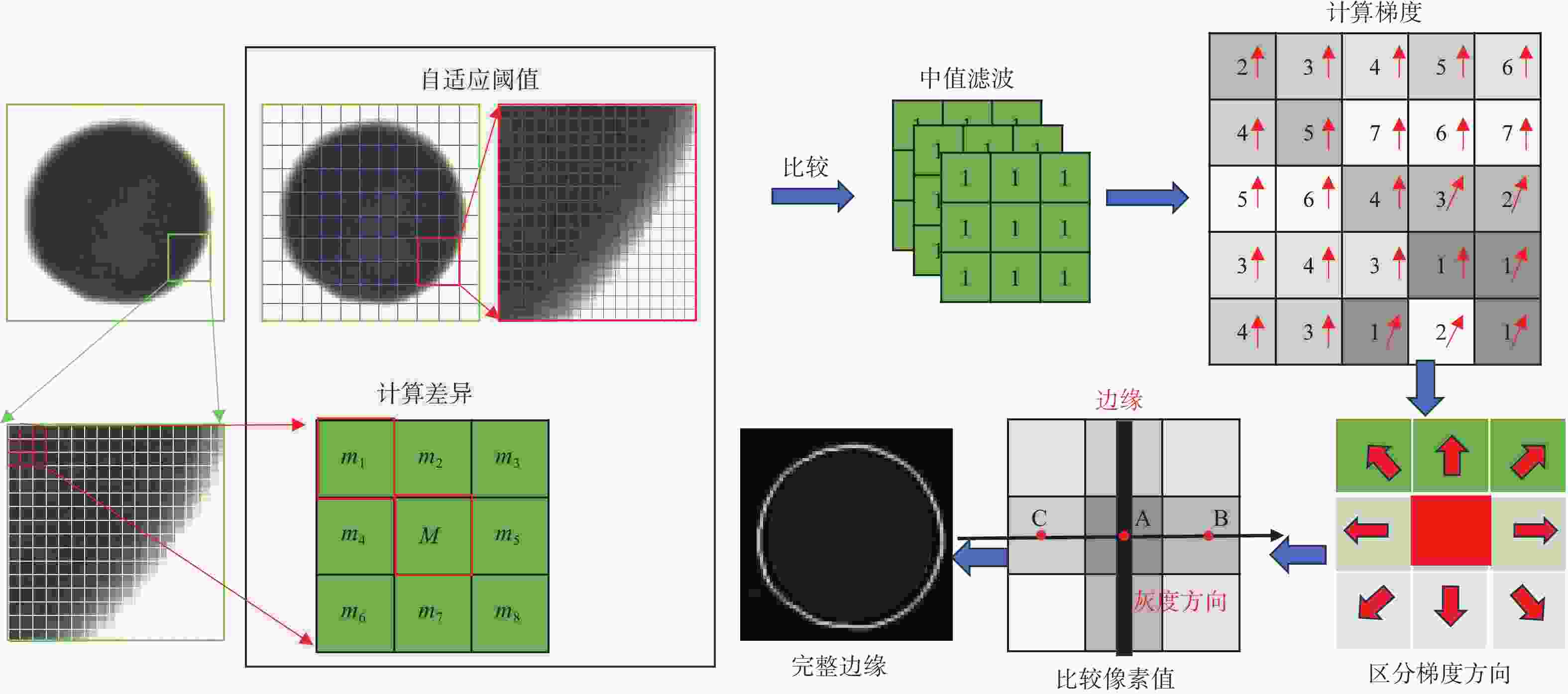

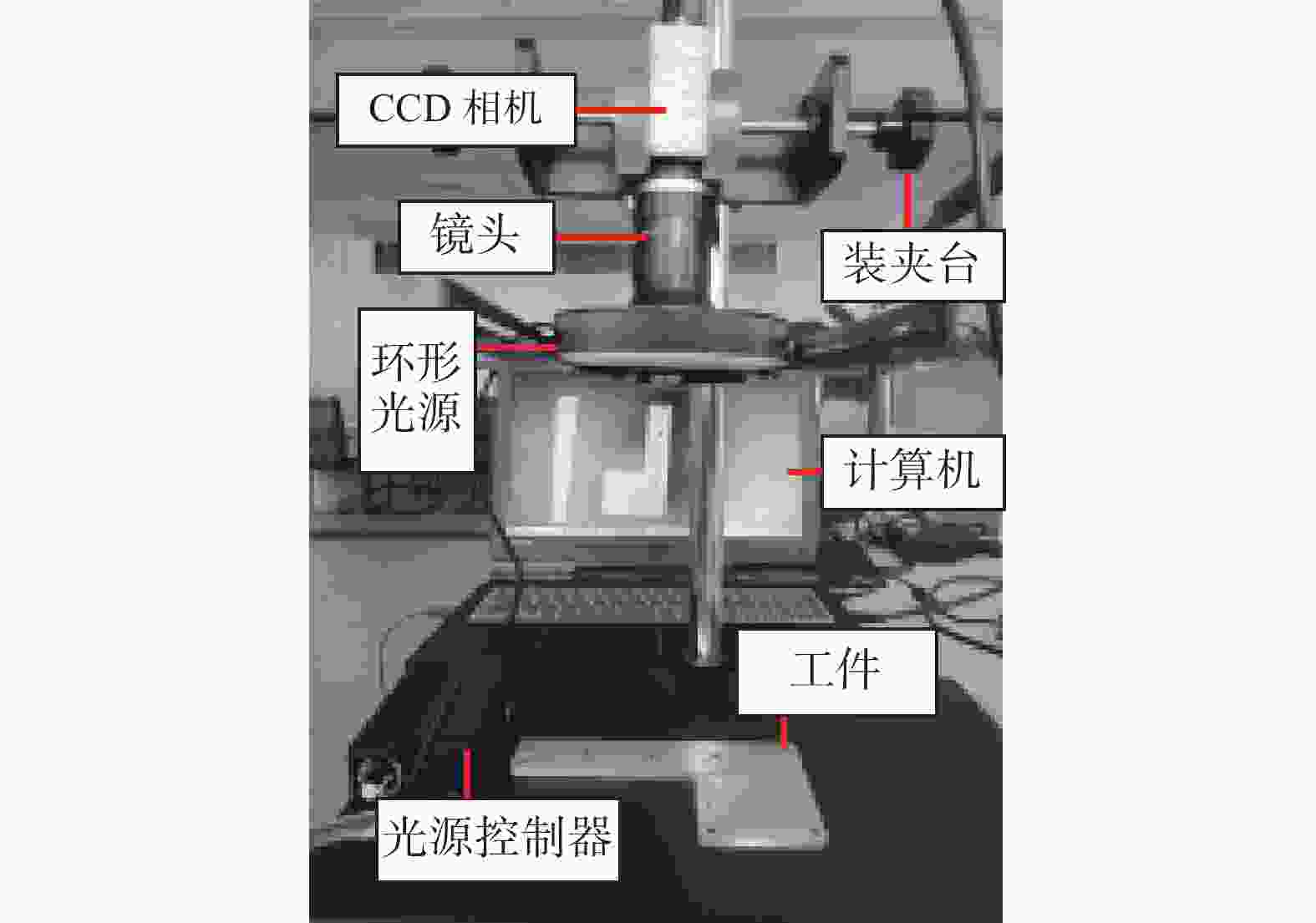

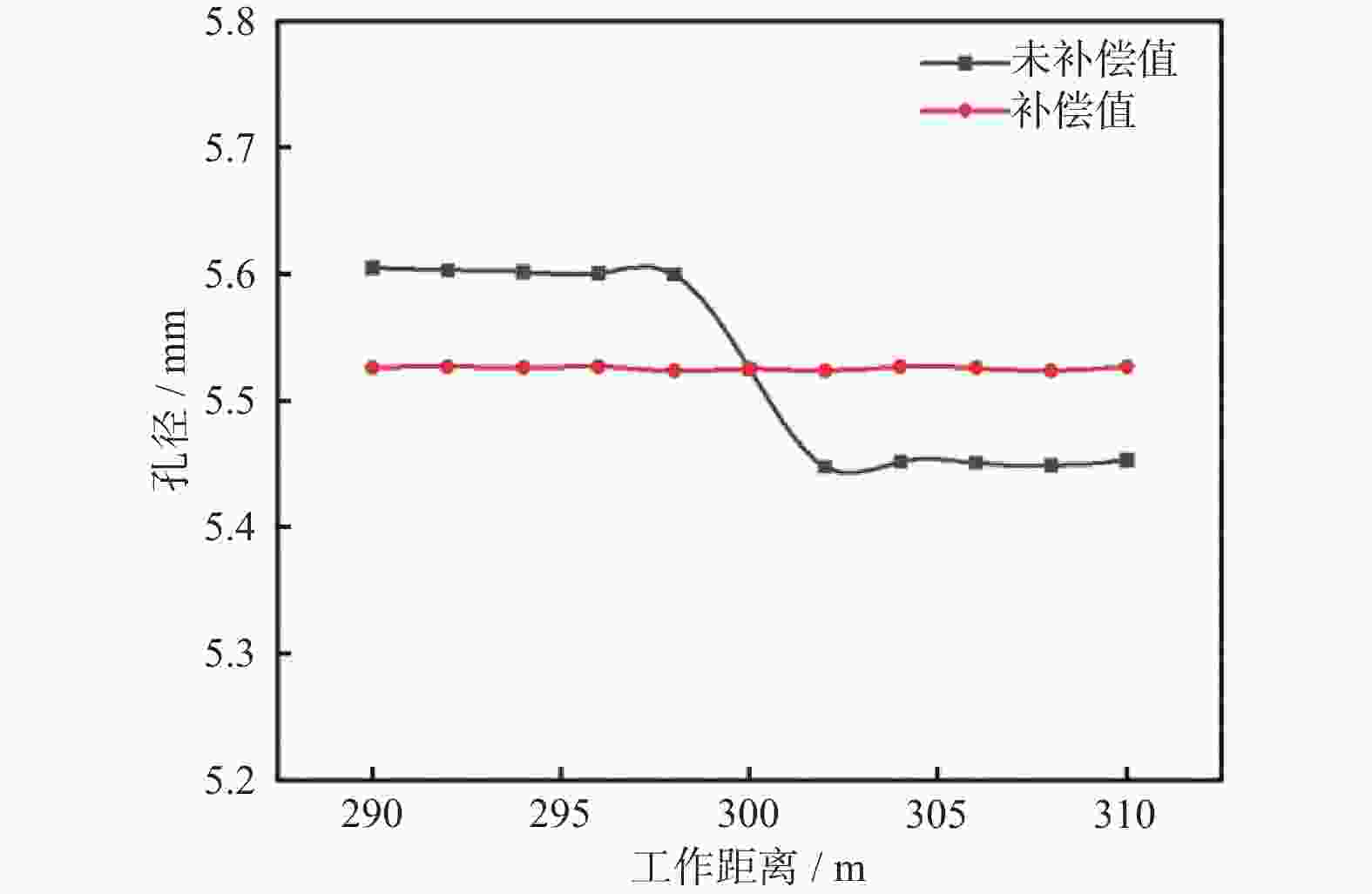

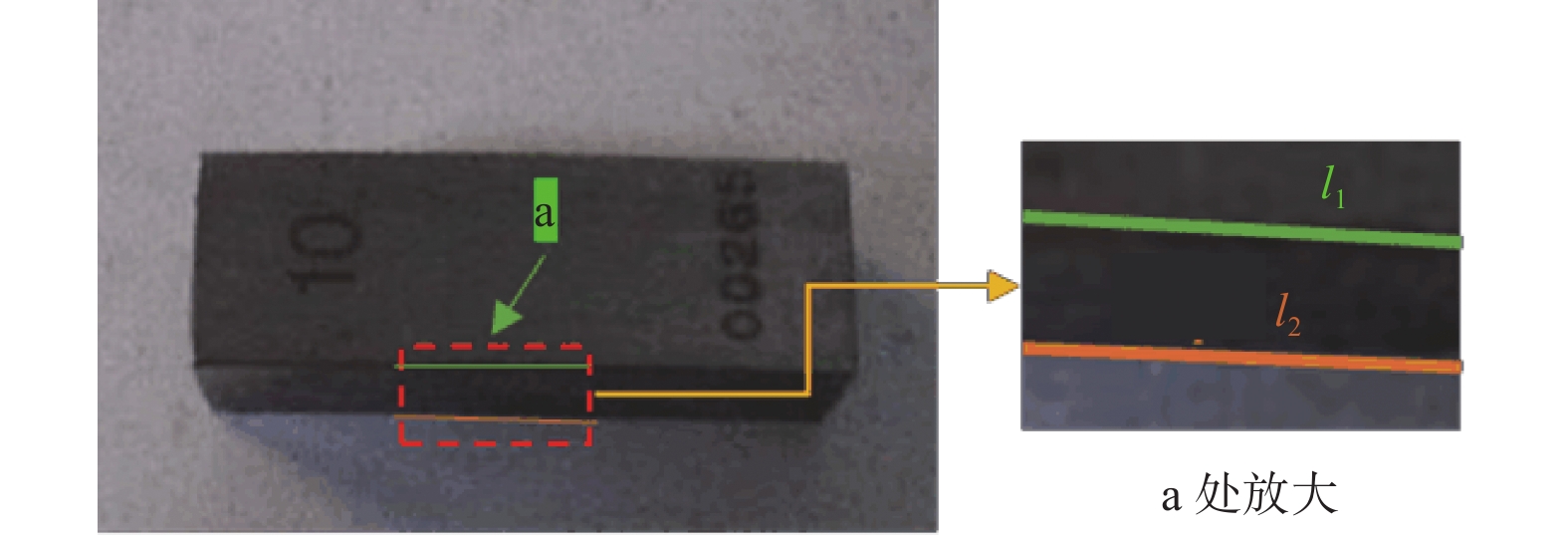

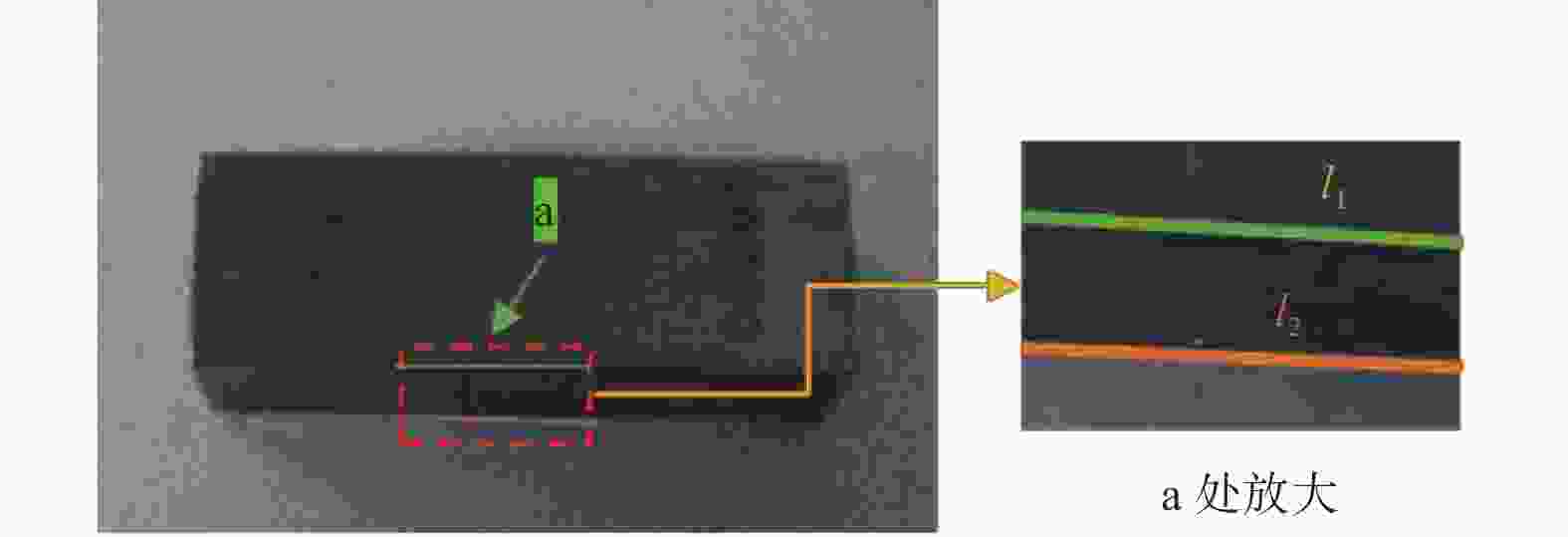

摘要: 针对机器视觉测量孔径时因待测孔表面与标定平面不重合导致的误差和边缘提取时的边缘弱化问题,提出了一种基于透视投影误差的孔径补偿方法。通过自适应中值滤波边缘检测算法进行边缘提取,利用二次曲线不变量求解孔径,引入透视投影误差,得到修正后的孔径。搭建视觉检测平台并进行试验,试验结果表明本研究孔径补偿方法的测量误差范围为 ± 0.002 mm,测量精度为0.001 mm,实现了较好的补偿效果,能够满足企业的精度要求。Abstract: To address the errors caused by the non-coincidence of the hole surface with the calibration plane in machine vision-based aperture measurement, as well as the edge degradation encountered during edge extraction, an aperture diameter compensation method based on perspective projection error was proposed. Edge detection was performed using an adaptive median filtering algorithm, and the aperture diameter was determined by employing quadratic curve invariant. Perspective projection error was then introduced to obtain the corrected hole diameter. A visual inspection experimental platform was constructed, and the test results demonstrate that the proposed compensation method achieves a measurement error within ± 0.002 mm, and a measurement accuracy of 0.001 mm. The method demonstrates a better compensation effect and can meet the enterprise's accuracy requirements.

-

Key words:

- machine vision /

- Gaussian model /

- perspective projection error /

- conic invariant /

- aperture compensation

-

表 1 孔径补偿前后试验数据对比

Table 1. Experimental data for aperture compensation

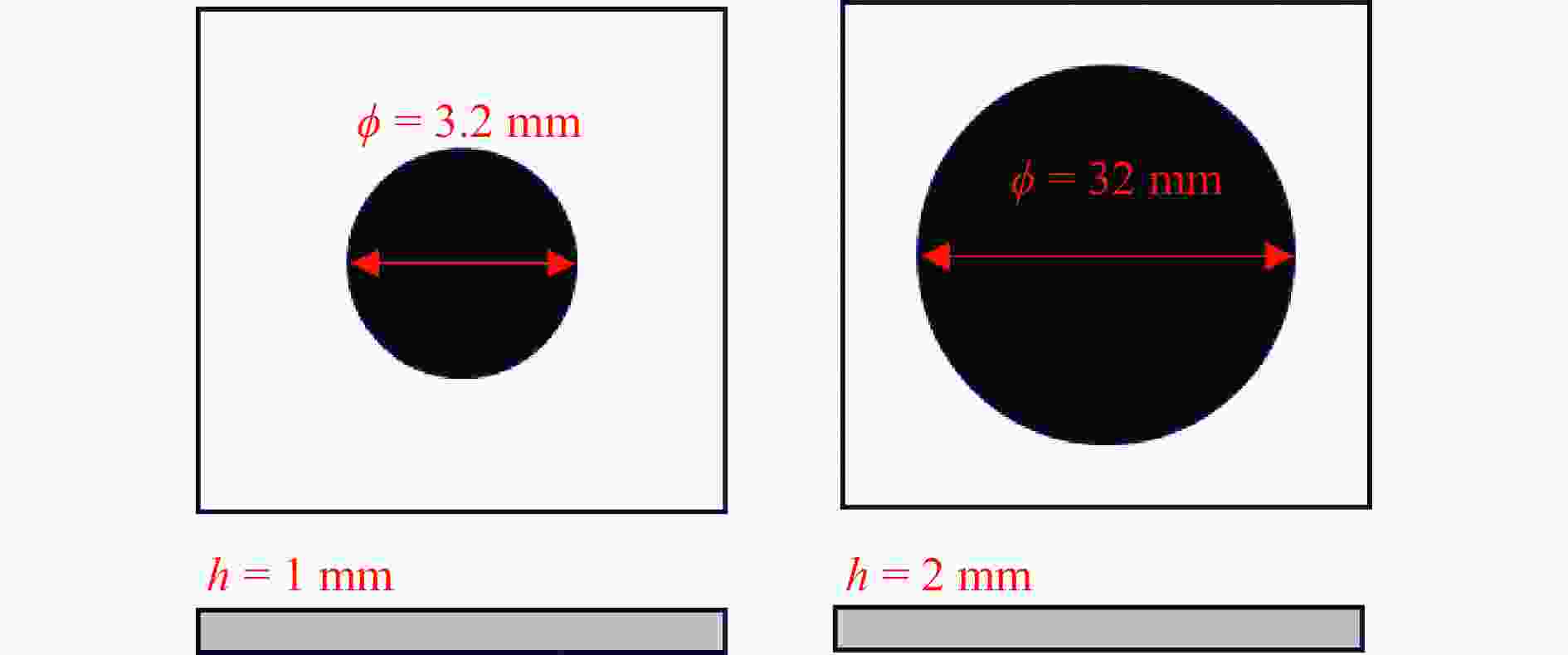

工作距离/mm 未补偿直径/mm 补偿直径/mm 误差/mm 290 5.605 5.526 0.001 292 5.603 5.527 0.002 294 5.602 5.526 0.001 296 5.601 5.527 0.002 298 5.600 5.524 −0.001 300 5.525 5.525 0 302 5.448 5.524 −0.001 304 5.452 5.527 0.002 306 5.451 5.526 0.001 308 5.449 5.524 −0.001 310 5.453 5.527 0.002 表 2 不同规格圆孔测量数据

Table 2. Measured data of different sizes of round holes

理论孔径/mm 工作距离/mm 孔径测量均值/mm 误差/mm 3.2 170 3.202 0.002 230 3.201 0.001 290 3.202 0.002 32 170 32.001 0.001 230 32.002 0.002 290 32.001 0.001 -

[1] LI B. Application of machine vision technology in geometric dimension measurement of small parts[J] . Eurasip Journal on Image and Video Processing, 2018, 2018(1): 127. doi: 10.1186/s13640-018-0364-9 [2] JOSHI K D, CHAUHAN V, SURGENOR B. A flexible machine vision system for small part inspection based on a hybrid SVM/ANN approach[J] . Journal of Intelligent Manufacturing, 2020, 31(1): 103 − 125. doi: 10.1007/s10845-018-1438-3 [3] BENBARRAD T, SALHAOUI M, KENITAR S B, et al. Intelligent machine vision model for defective product inspection based on machine learning[J] . Journal of Sensor and Actuator Networks, 2021, 10(1): 7. doi: 10.3390/jsan10010007 [4] ZHANG W, HAN Z W, LI Y, et al. A method for measurement of workpiece form deviations based on machine vision[J] . Machines, 2022, 10(8): 718. doi: 10.3390/machines10080718 [5] 朱云, 凌志刚, 张雨强. 机器视觉技术研究进展及展望[J] . 图学学报, 2020, 41(6): 871 − 890. [6] 焦博, 刘国宁, 赵孟轩, 等. 基于机器视觉的亚像素精度法兰盘尺寸测量方法[J] . 现代制造工程, 2022(7): 121 − 126. [7] ZHANG X Y, YU C Z, QIU Z S, et al. Noncontact high-precision aperture detection based on distortion compensation and adaptive mean blur algorithm[J] . IEEE Transactions on Instrumentation and Measurement, 2023, 72: 5014410. [8] 张函力, 李海伟, 于国栋, 等. 基于改进Zernike矩的铆接孔径亚像素检测方法研究[J] . 航空制造技术, 2022, 65(18): 98 − 104. [9] 孙钊, 许增朴, 王永强, 等. 机器视觉测量中透视投影误差分析控制与补偿[J] . 计算机工程与应用, 2018, 54(2): 266 − 270. doi: 10.3778/j.issn.1002-8331.1606-0456 [10] ZHANG Z Y. Camera calibration with one-dimensional objects[J] . IEEE Transactions on Pattern Analysis and Machine Intelligence, 2004, 26(7): 892 − 899. doi: 10.1109/TPAMI.2004.21 [11] 张龙飞, 李晶, 寇莹, 等. 一种基于二次曲线不变量的孔径测量方法[J] . 华南理工大学学报(自然科学版), 2021, 49(5): 129 − 134. -

下载:

下载: