Study on thermal characteristics of symmetric serpentine flow channel liquid cooling plate for prismatic battery module

-

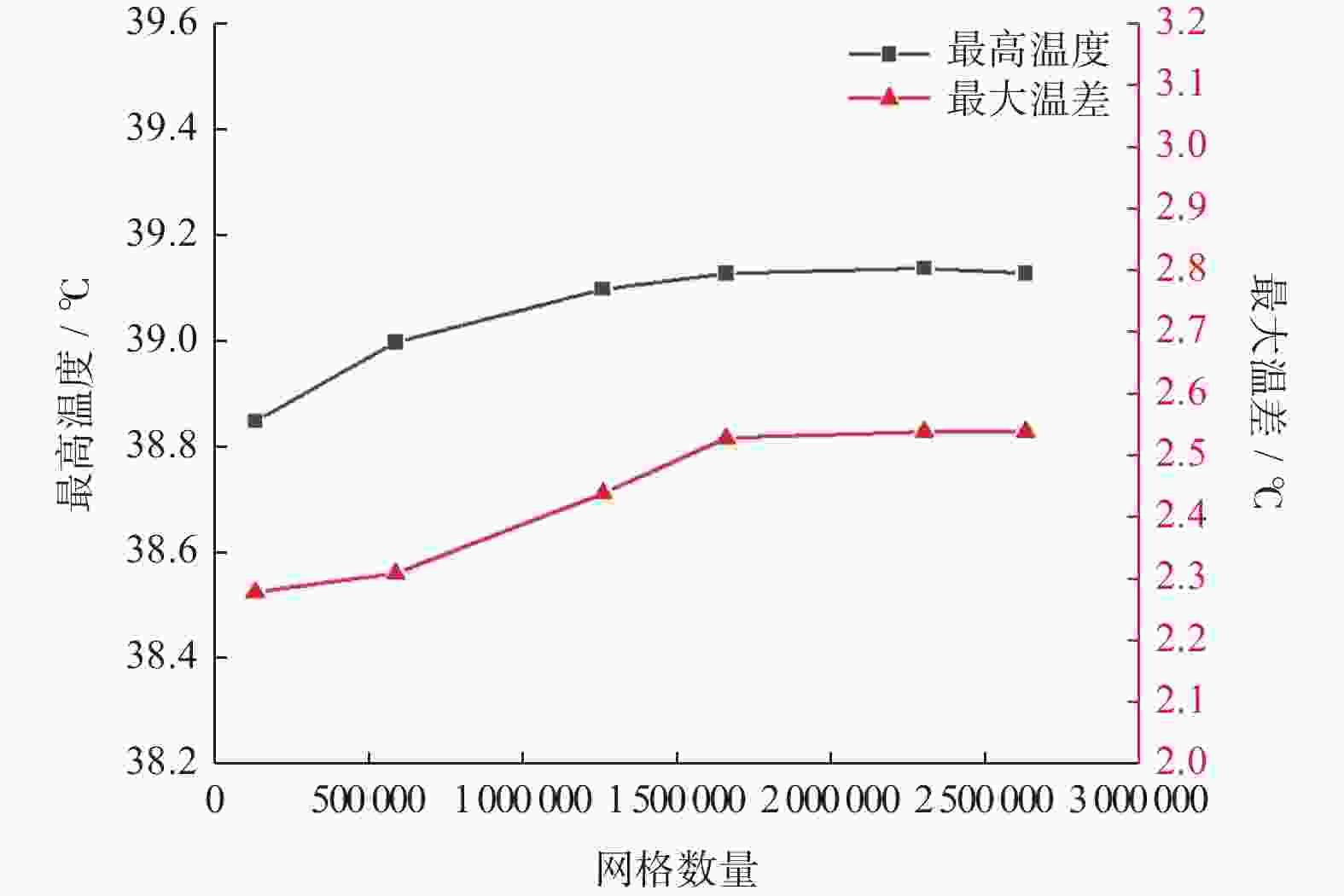

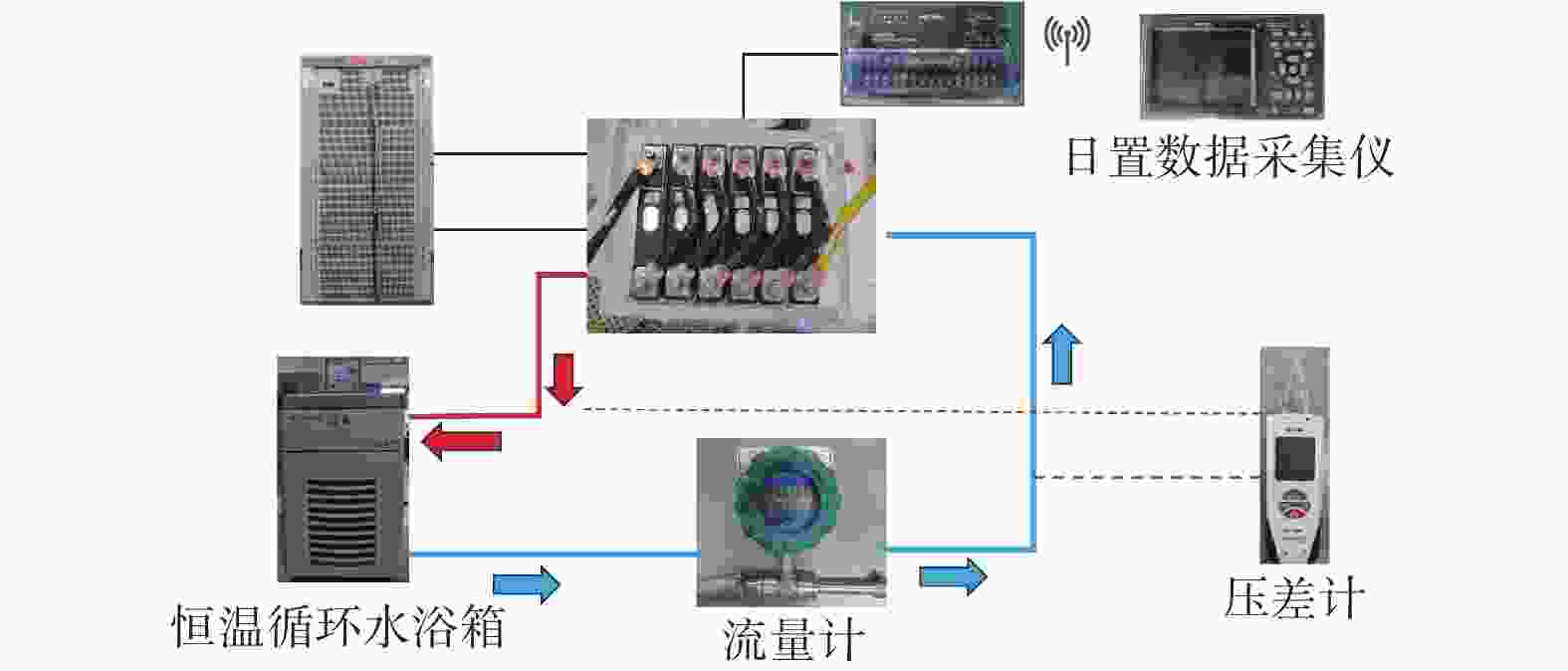

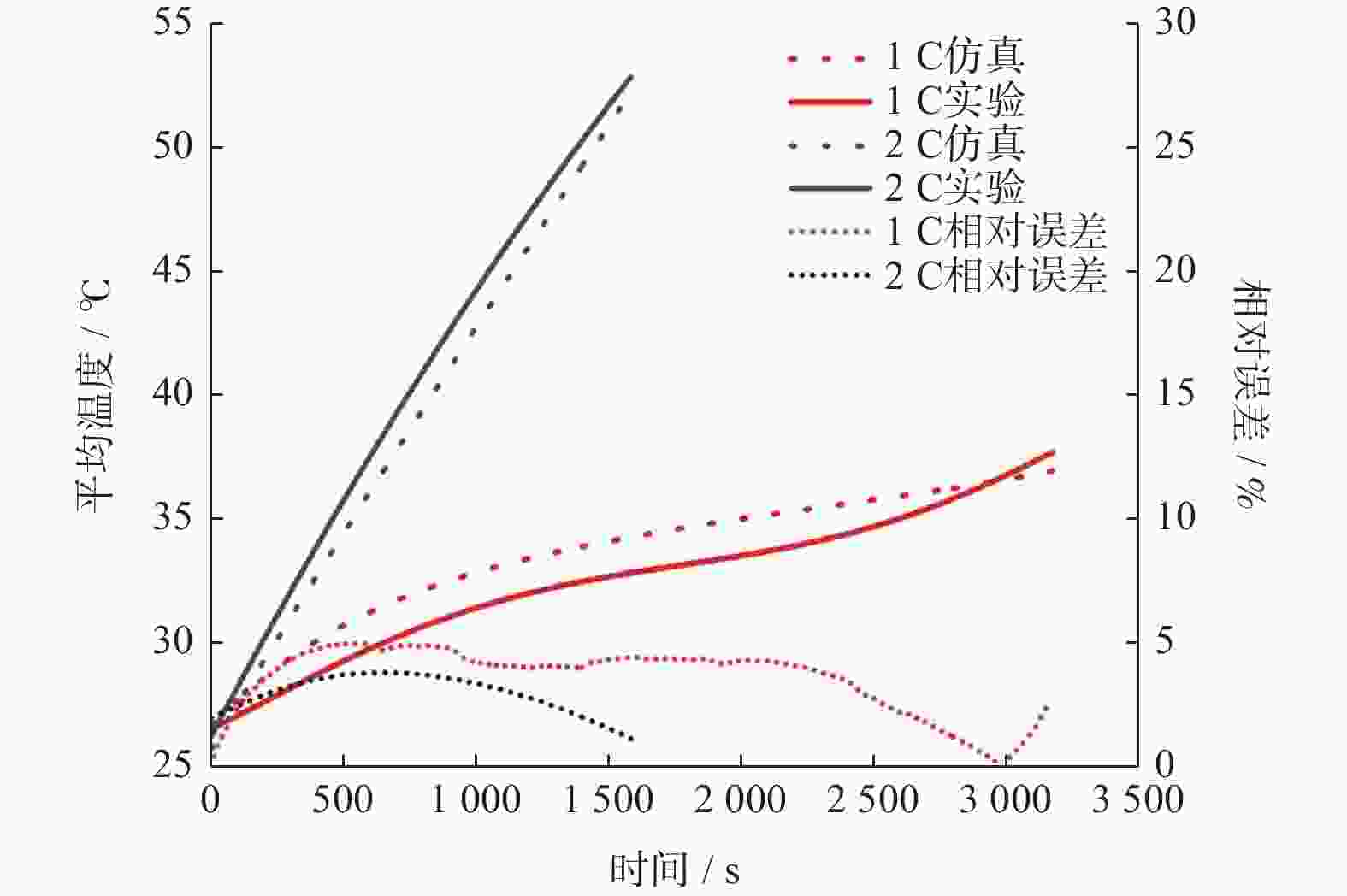

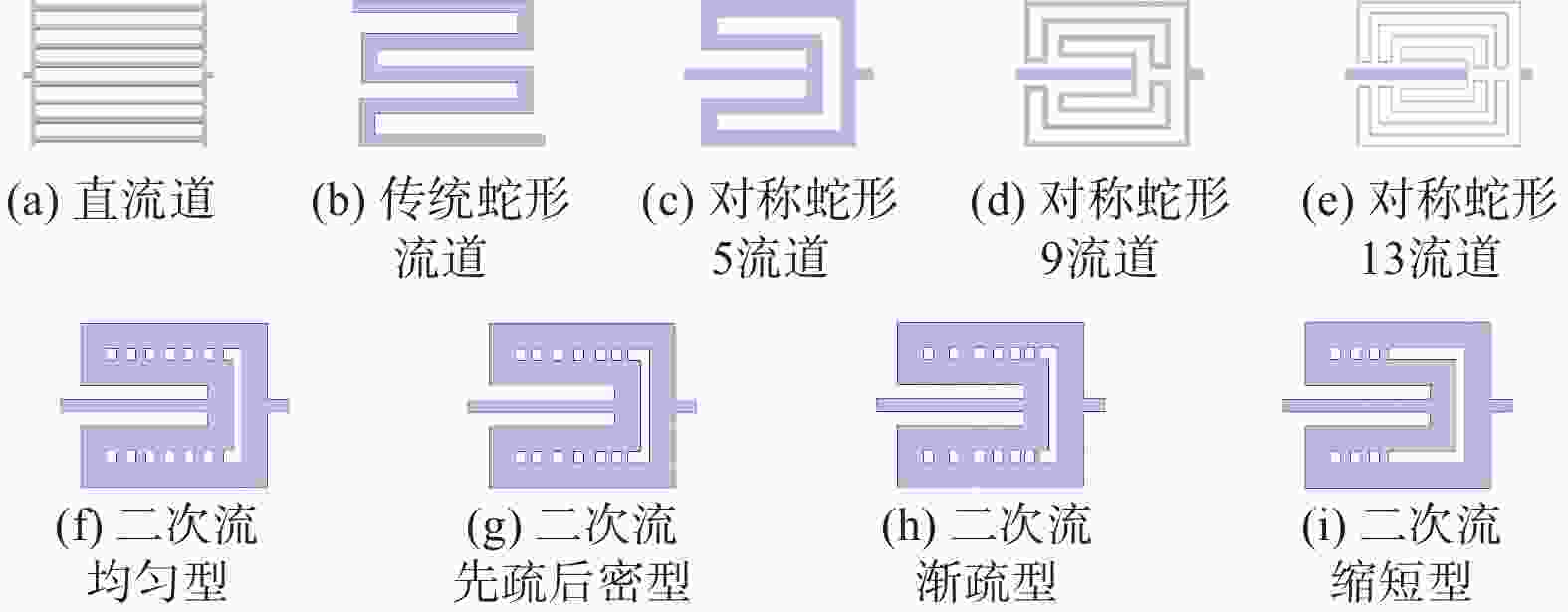

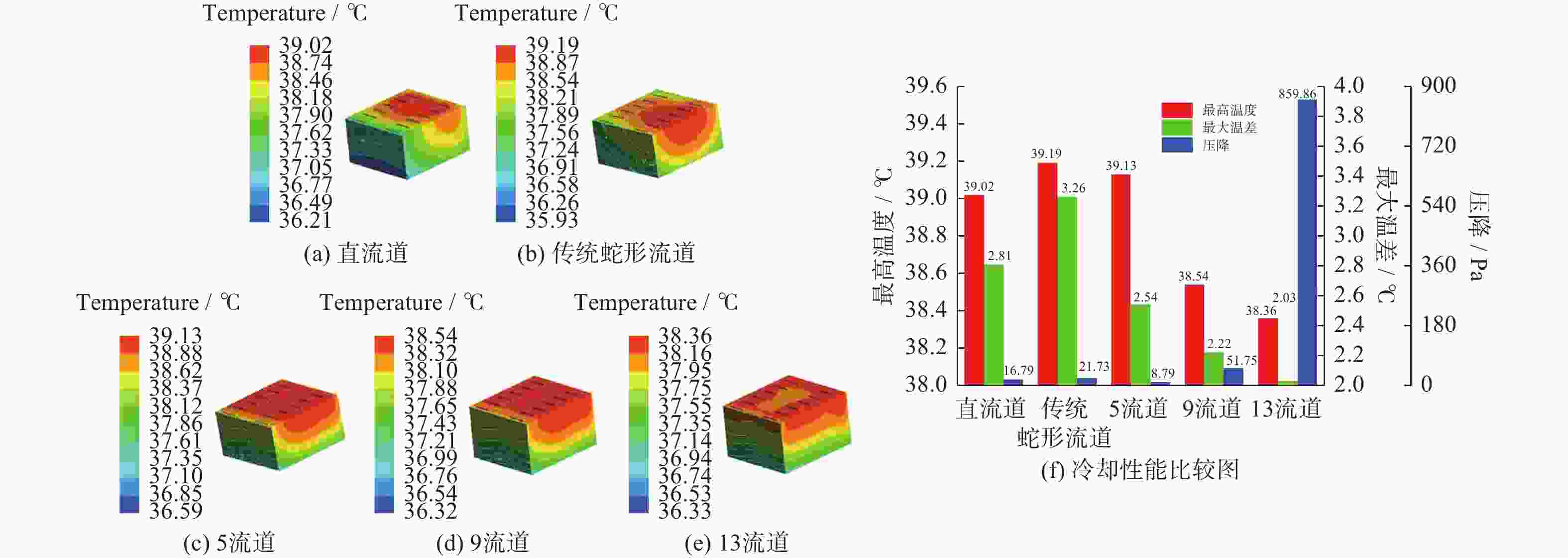

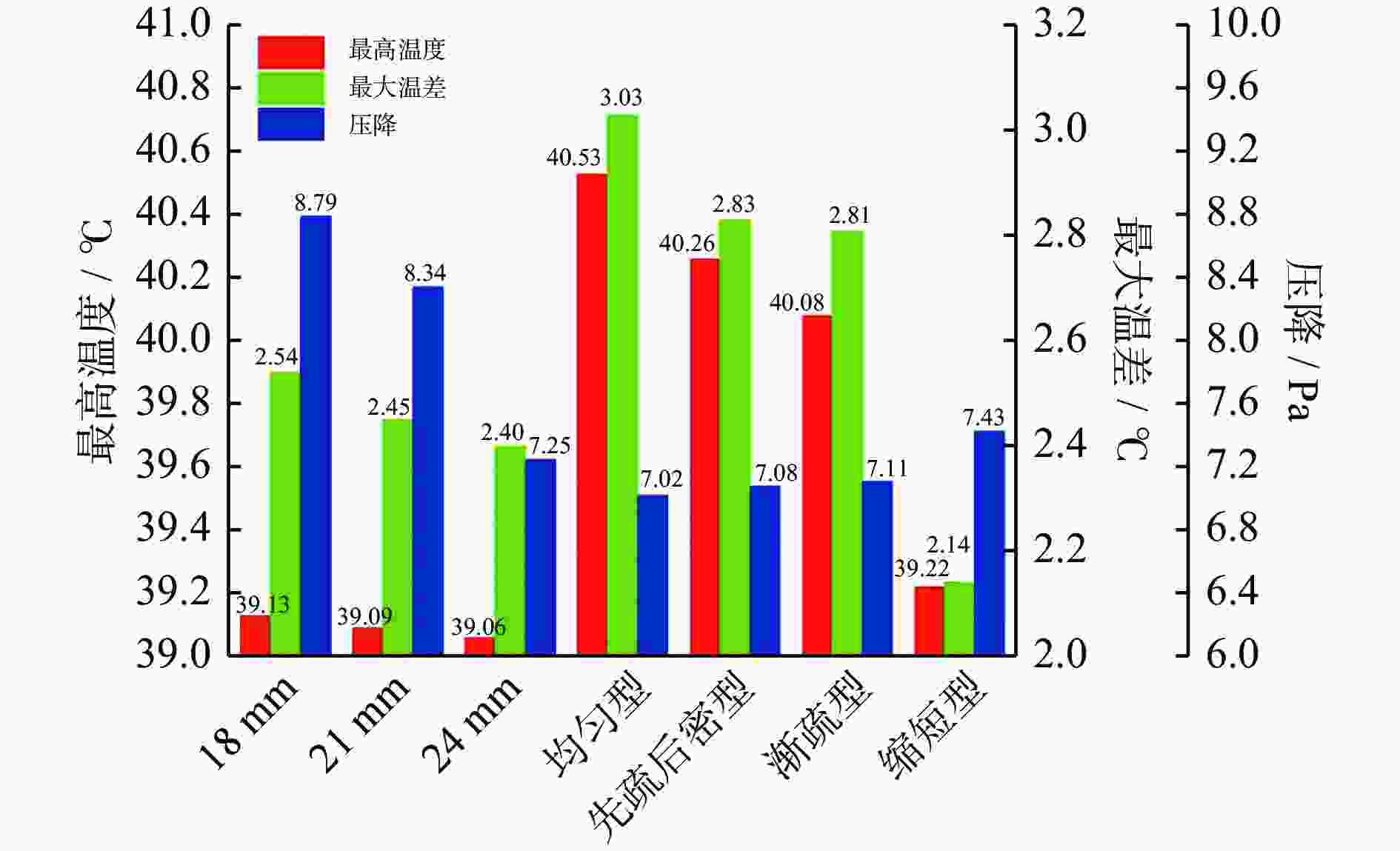

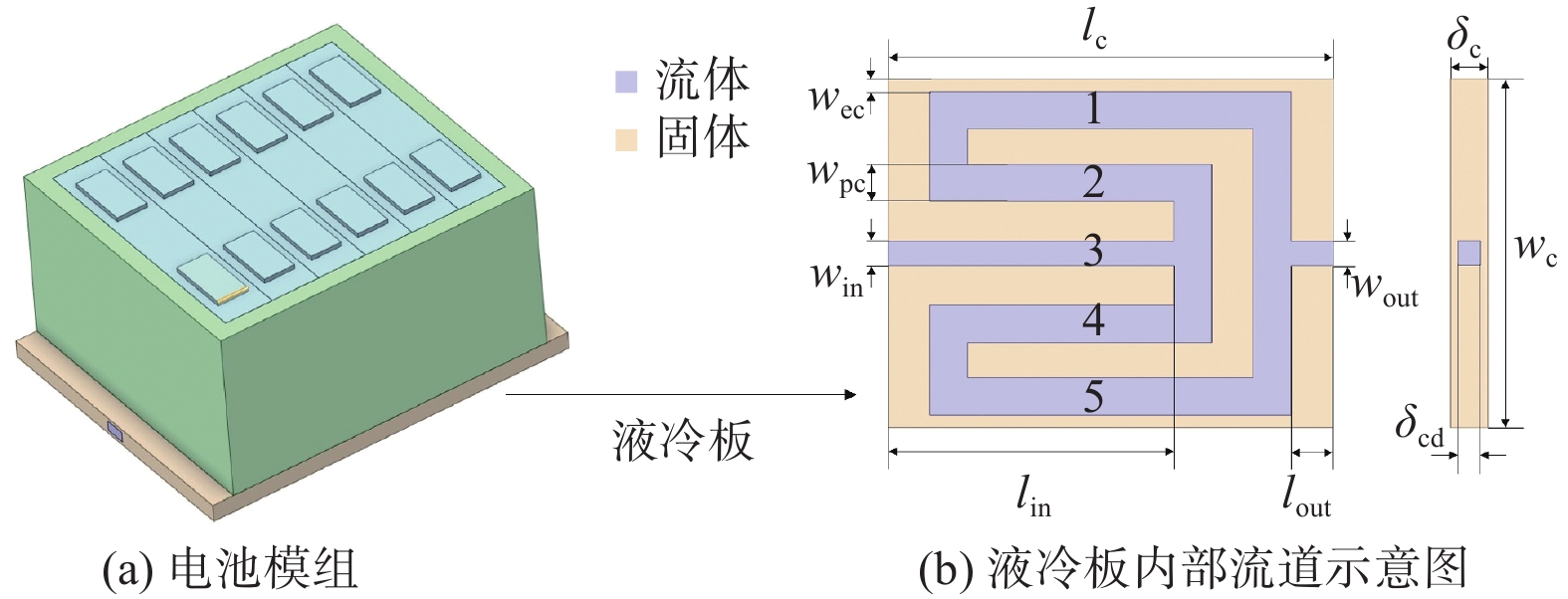

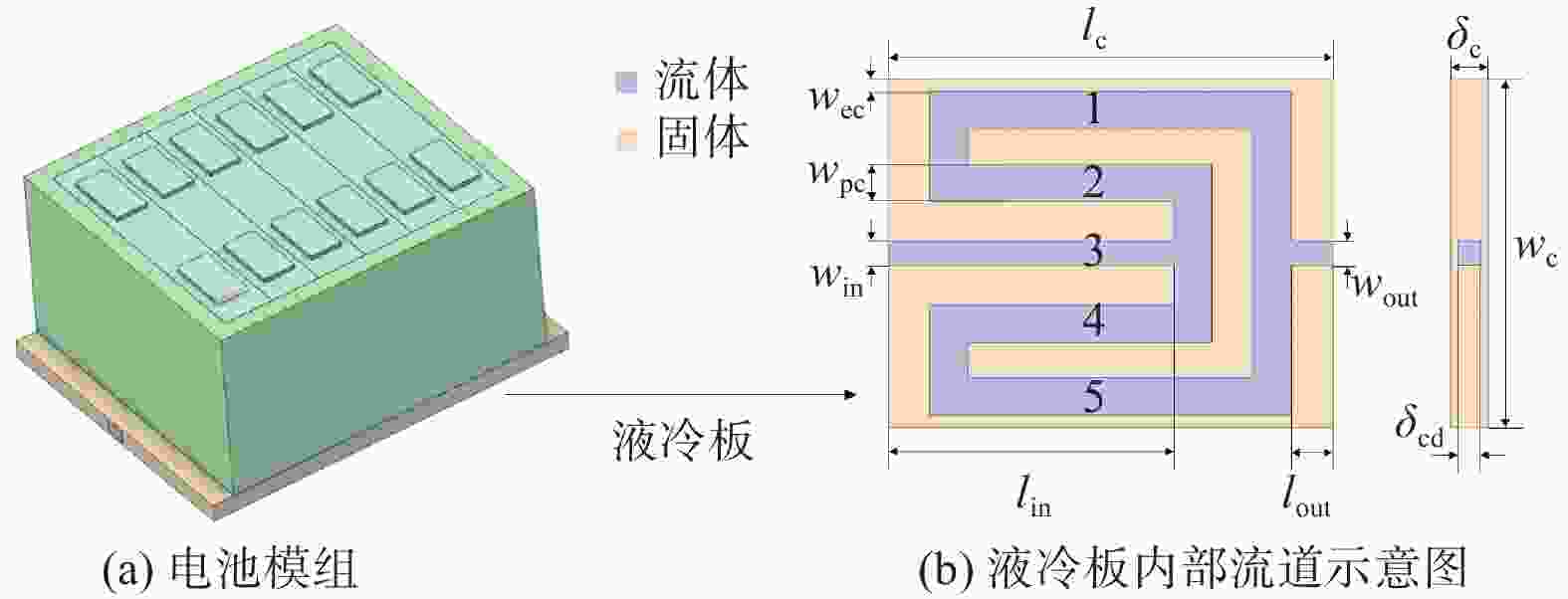

摘要: 提出一种新型对称蛇形流道结构用于电池模组的热管理。采用数值模拟方法研究1 × 6串联方形电池模组底部散热性能,并与直流道液冷板换热性能对比。通过调整对称蛇形流道的结构参数(如流道数量、支流道宽度及二次流结构),研究其换热效果。结果表明,增加流道数量可提升散热性能,但导致进出口压降显著增大;增大支流道宽度能有效改善散热性能。其中,缩短型二次流结构散热性能最佳。当采用5流道、支流道宽度24 mm的缩短型二次流结构时,最大温差和压降分别下降23.84%和59.02%,均温性能和压差均优于直流道液冷板。Abstract: A novel symmetric serpentine channel structure was proposed for battery module thermal management. Numerical simulations were performed to investigate the bottom heat dissipation performance of a 1×6 series-connected prismatic battery module, compared against a straight-channel liquid cooling plate. The effects of the symmetric serpentine flow channel were investigated by adjusting structural parameters such as the number of channels, branch channel width, and secondary flow structure. Results show that increasing the channel numbers can enhance heat dissipation, but significantly increase the pressure drop in the inlet and outlet. Increasing the branch channel width can effectively improve the heat dissipation performance. The shortened secondary flow structure yields superior performance among the tested configurations. Specifically, the design with five channels, 24 mm branch width, and a shortened secondary flow structure reduces the maximum temperature difference and pressure drop by 23.84% and 59.02%, respectively. The proposed design outperforms the straight-channel plate in both temperature uniformity and pressure drop characteristics.

-

Key words:

- liquid-cooling /

- serpentine channel /

- structure design /

- temperature uniformity

-

表 1 液冷板中各结构参数

Table 1. Structural parameters of liquid cooling plate

参数 大小/mm 长度 × 宽度 × 高度(lc × wc × δc) 213 mm× 168 mm× 10 mm 进口段长度(lin) 137 出口段长度(lout) 20 进口段宽度和出口段宽度(win,wout) 12,12 流道高度(δcd) 6 支流道宽度(wpc) 18,21,24 表 2 不同材料热物性参数

Table 2. Thermal properties parameters of different materials

部件材料 密度/

(kg·m−3)比热容/

(J·(kg·K)−1)导热系数/

(W·(m·K)−1)黏度/

(kg·(m·s)−1)水 997 4178 0.6 0.000 902 液冷板 2 719 871 202.4 — 电池 2 300 1 072 kbx= 1.5,

kby=kbz=18.5— 导热垫 3 430 1 500 6.0 — 亚克力板 1 000 1 200 0.2 — 表 3 三元方形锂离子电池物性参数表

Table 3. Physical property parameters of ternary lithium-ion battery

关键指标 参数 额定容量/Ah 50 额定电压/V 3.7 充电截止电压/V 4.2 放电截止电压/V 2.5 最大充电电流/A 50 最大放电电流/A 100 充电工作环境温度/℃ 0 ~ 45 放电工作环境温度/℃ −20 ~ 50 内阻/mΩ ≤0.8 电池质量/ kg 0.85 -

[1] RAMADASS P, HARAN B, WHITE R, et al. Capacity fade of Sony 18650 cells cycled at elevated temperatures: Part II. Capacity fade analysis[J] . Journal of Power Sources, 2002, 112(2): 614 − 620. doi: 10.1016/S0378-7753(02)00473-1 [2] GOZDUR R, GUZOWSKI B, DIMITROVA Z, et al. An energy balance evaluation in lithium-ion battery module under high temperature operation[J] . Energy Conversion and Management, 2021, 227: 113565. doi: 10.1016/j.enconman.2020.113565 [3] PIAO N, GAO X N, YANG H C, et al. Challenges and development of lithium-ion batteries for low temperature environments[J] . eTransportation, 2022, 11: 100145. doi: 10.1016/j.etran.2021.100145 [4] BAO Y H, SHAO S Q. Numerical study on ultrathin wide straight flow channel cold plate for Li-ion battery thermal management[J] . Journal of Energy Storage, 2023, 64: 107263. doi: 10.1016/j.est.2023.107263 [5] JARRETT A, KIM I Y. Influence of operating conditions on the optimum design of electric vehicle battery cooling plates[J] . Journal of Power Sources, 2014, 245: 644 − 655. doi: 10.1016/j.jpowsour.2013.06.114 [6] SHENG L, SU L, ZHANG H, et al. Numerical investigation on a lithium ion battery thermal management utilizing a serpentine-channel liquid cooling plate exchanger[J] . International Journal of Heat and Mass Transfer, 2019, 141: 658 − 668. doi: 10.1016/j.ijheatmasstransfer.2019.07.033 [7] 陈雅, 范立云, 李晶雪, 等. 二次流蛇形通道锂离子电池散热性能[J] . 储能科学与技术, 2023, 12(6): 1880 − 1889. [8] LUO W M, LI H N, CHU T Y, et al. A numerical study of battery thermal management system with square spiral ring-shaped liquid cooling plate[J] . Thermal Science and Engineering Progress, 2023, 45: 102120. doi: 10.1016/j.tsep.2023.102120 [9] 孔为, 金劲涛, 陆西坡, 等. 对称蛇形流道锂离子电池冷却性能[J] . 储能科学与技术, 2022, 11(7): 2258 − 2265. [10] XIN Q Q, YANG T Q, ZHANG H Y, et al. Experimental and numerical study of lithium-ion battery thermal management system using composite phase change material and liquid cooling[J] . Journal of Energy Storage, 2023, 71: 108003. doi: 10.1016/j.est.2023.108003 [11] 吴青余, 张恒运, 李俊伟. 校准量热法测量锂电池比热容和生热率[J] . 汽车工程, 2020, 42(1): 59 − 65. [12] 徐晓斌, 徐叶飞, 张恒运, 等. 风冷电池模组热性能及成组效率的多目标优化[J] . 储能科学与技术, 2022, 11(2): 553 − 562. -

下载:

下载: