Design and simulation analysis of a flux focusing magnetic gear with Z-type pole-pieces

-

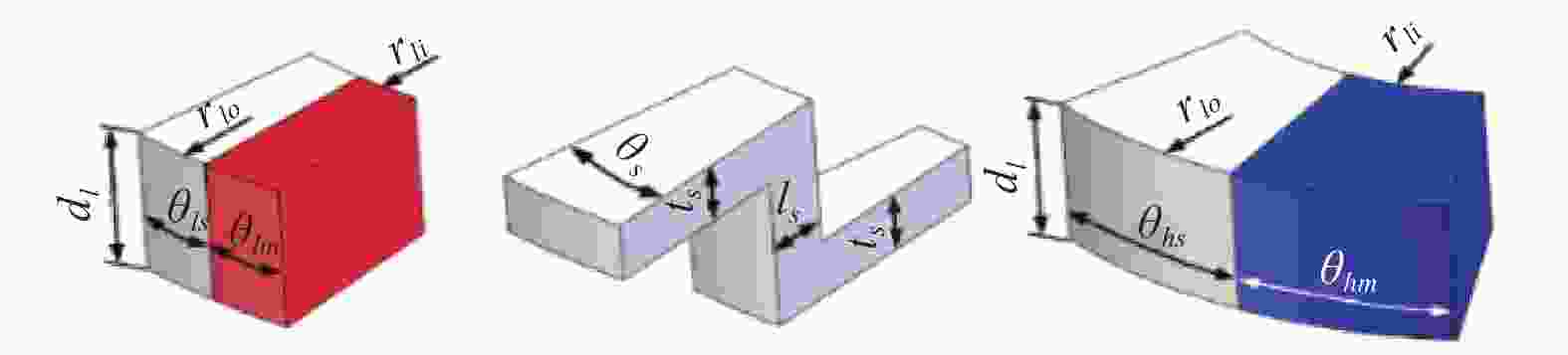

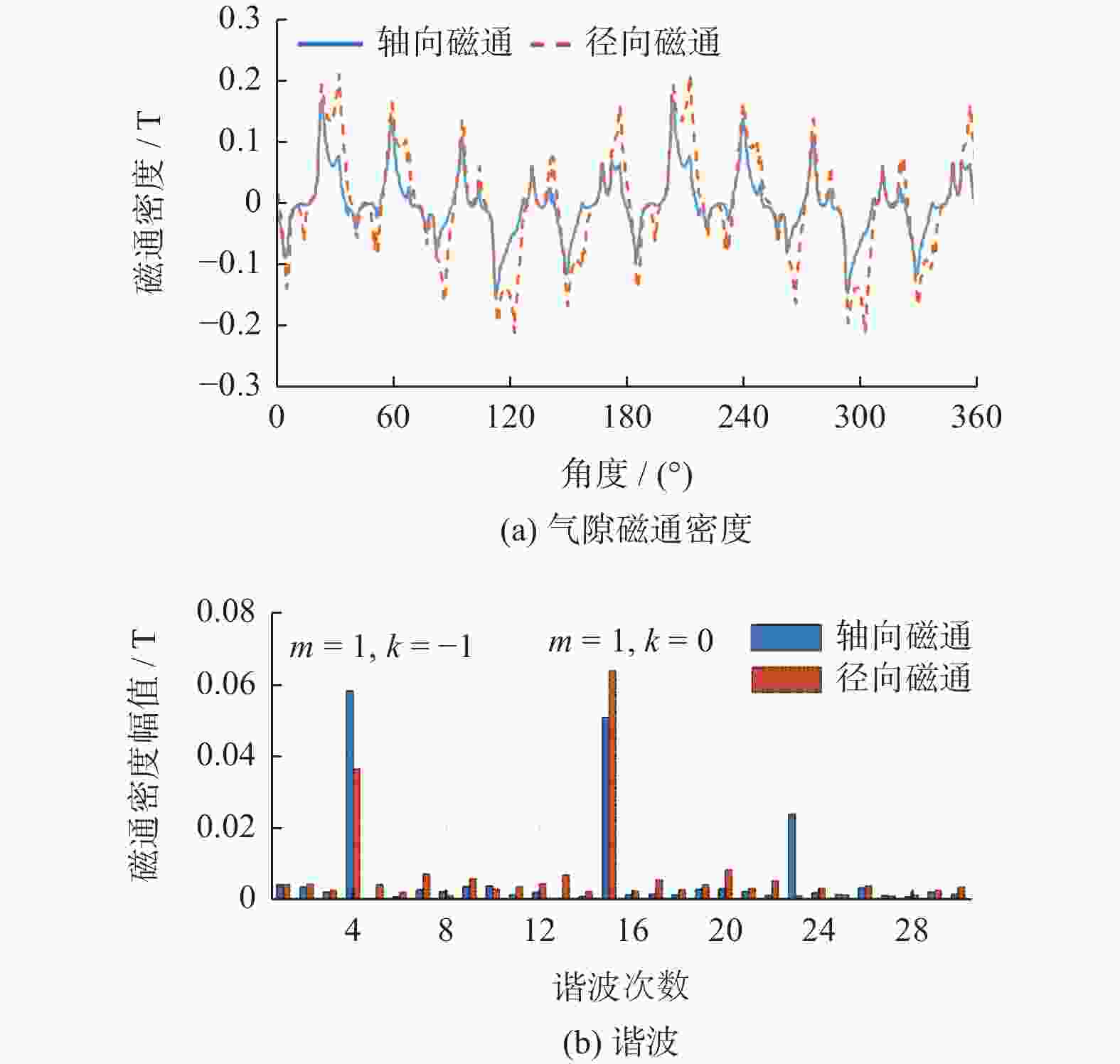

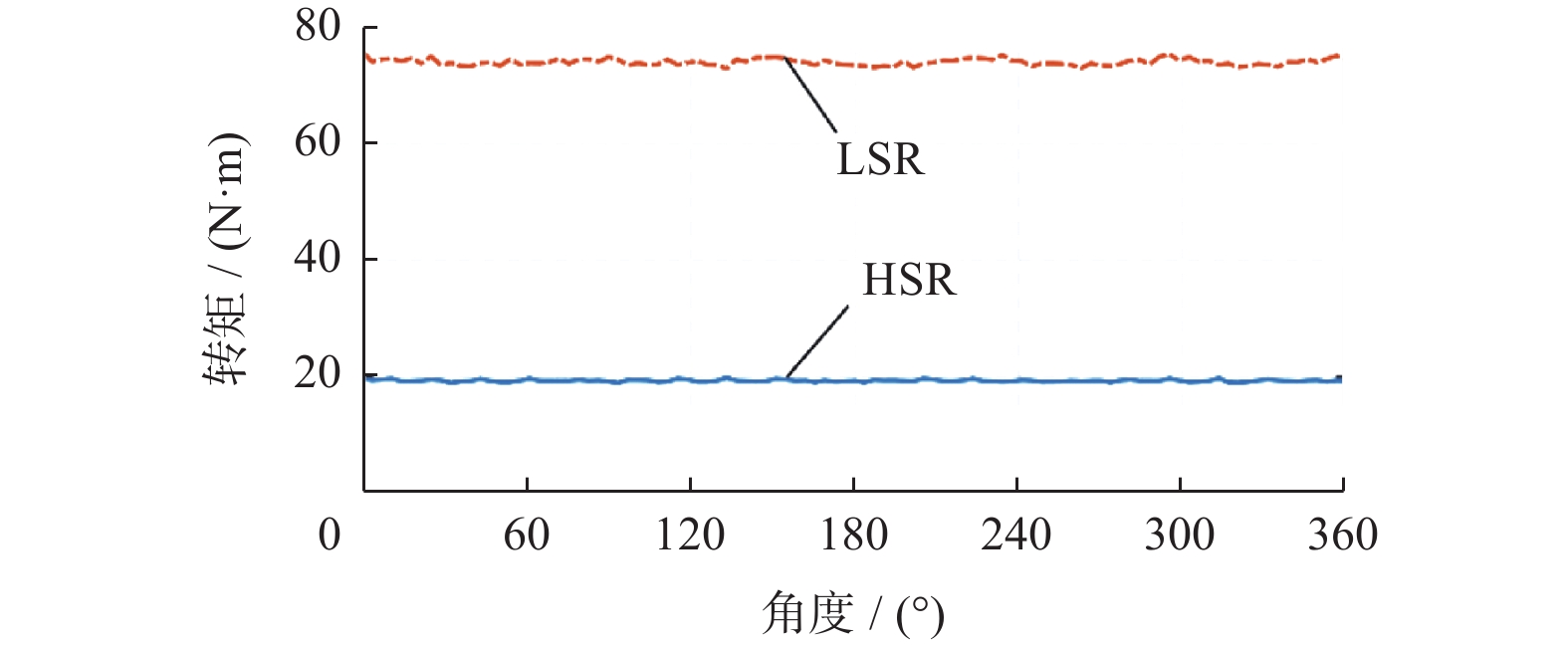

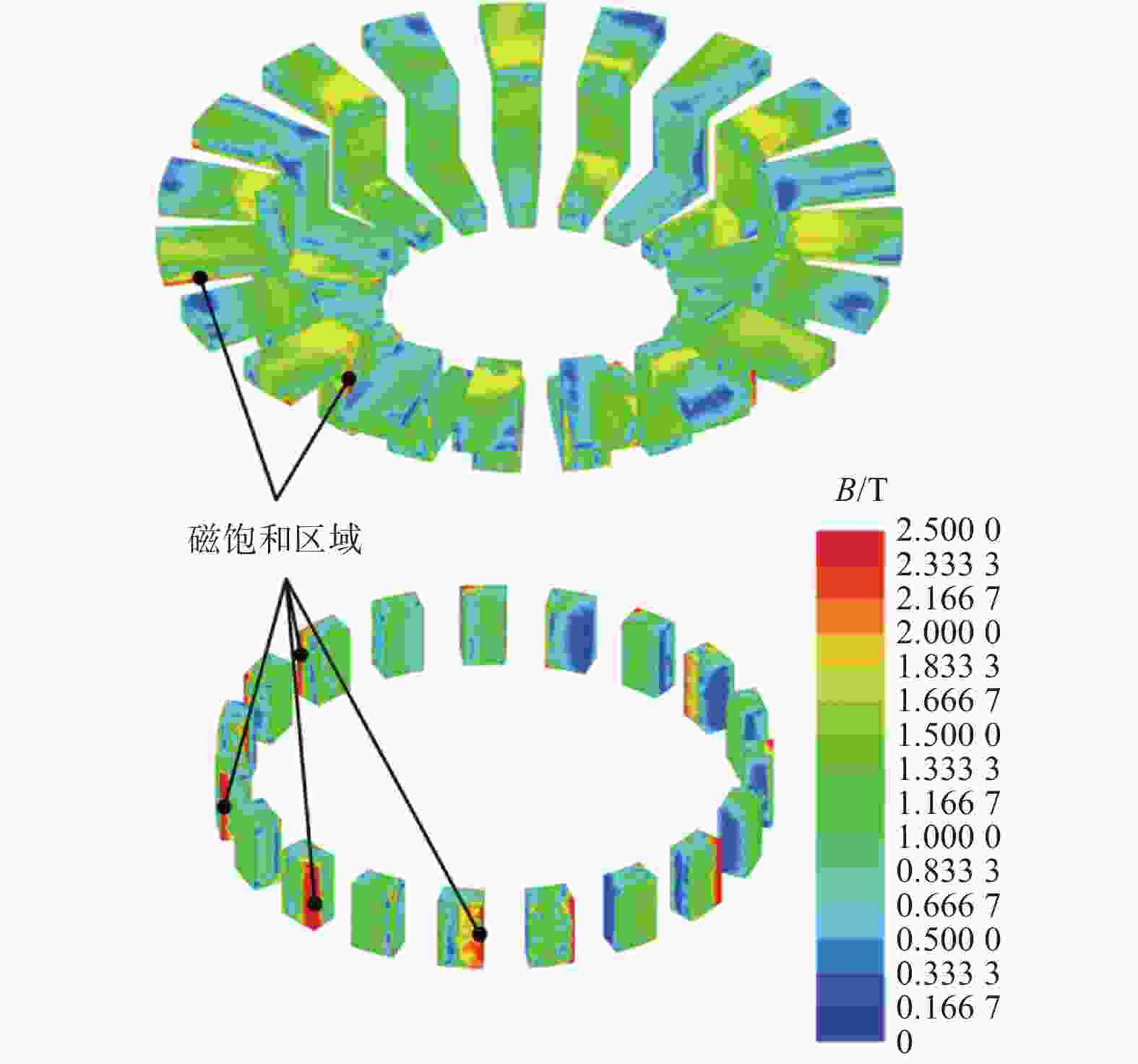

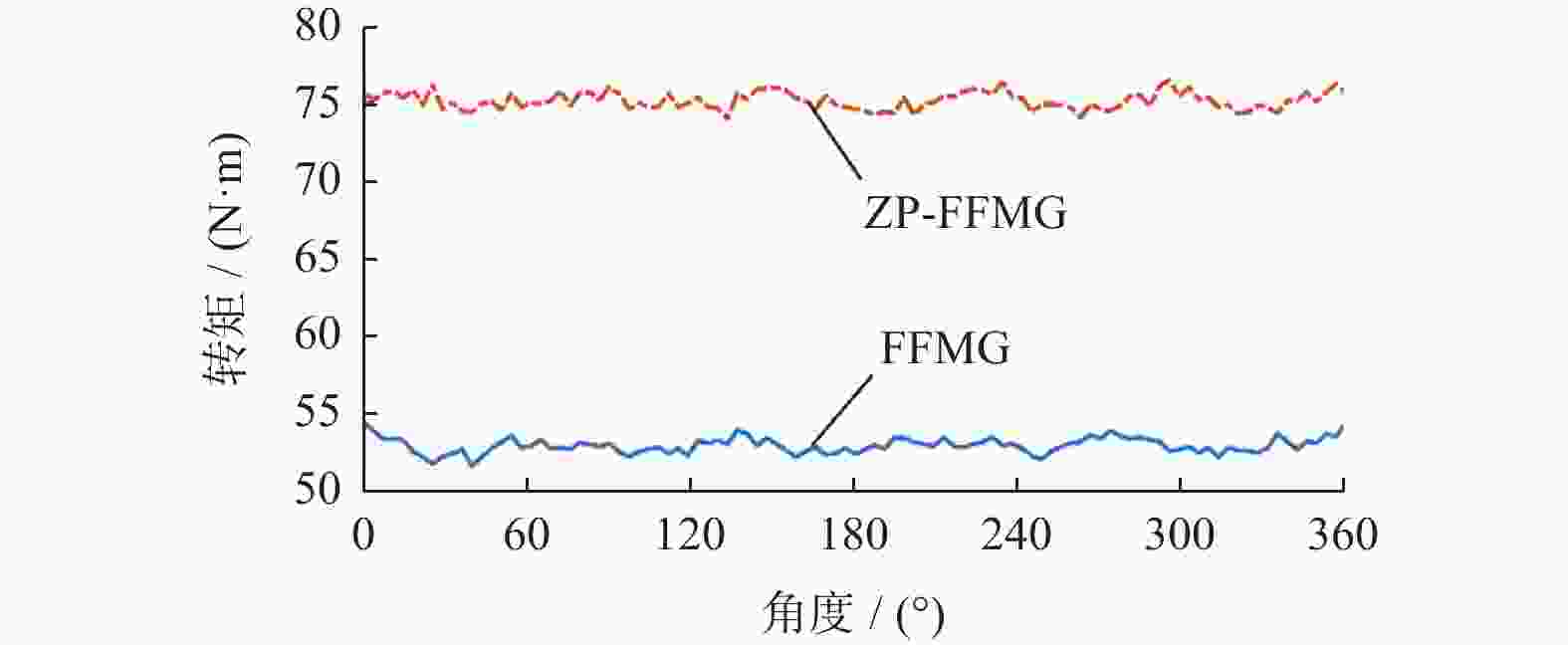

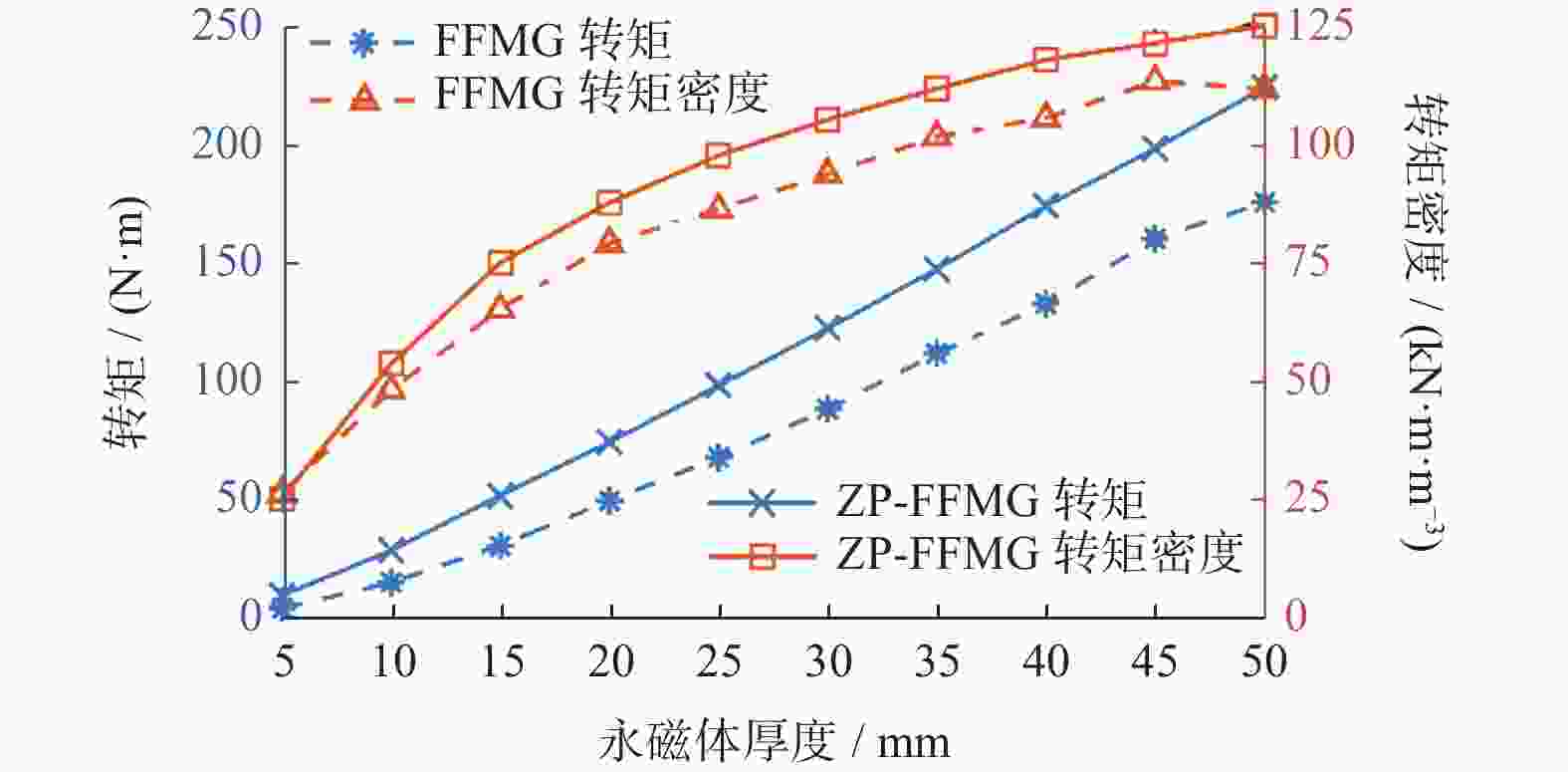

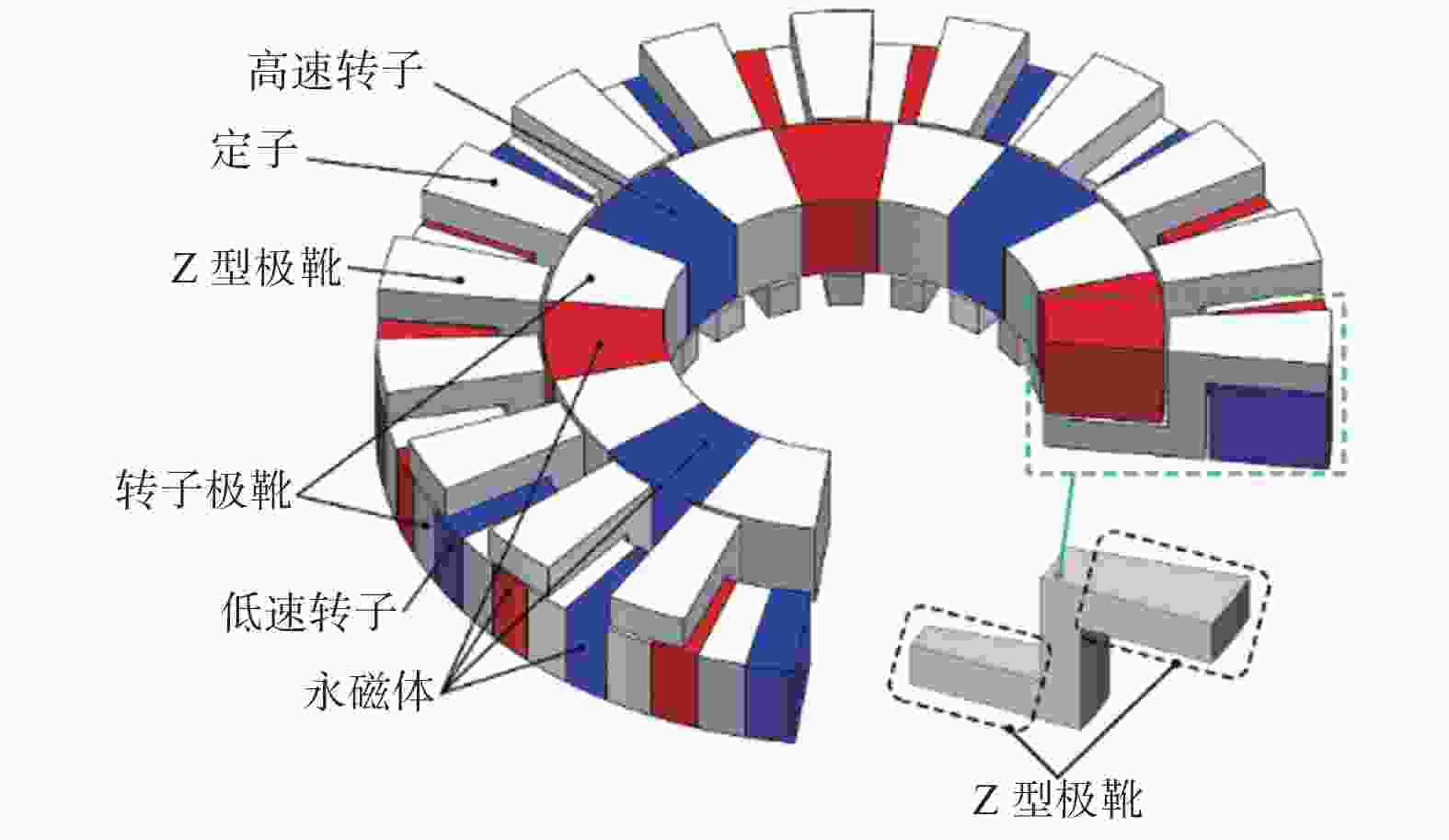

摘要: 提出并研究一种Z型极靴聚磁式磁齿轮(ZP-FFMG). 在该磁齿轮结构中,Z型极靴可以耦合转子端面和圆柱面的磁通. 通过三维仿真可知,Z型极靴聚磁式磁齿轮中存在有助于传递转矩的轴向和径向磁通分量. 对比分析传统聚磁式磁齿轮(FFMG)和Z型极靴聚磁式磁齿轮,结果表明,与传统聚磁式磁齿轮相比,Z型极靴聚磁式磁齿轮的传递转矩提高42%,转矩密度增加15 kN·m/m3,同时磁通密度也有改善.Abstract: A flux focusing magnetic gear with Z-type pole-pieces (ZP-FFMG) was presented and investigated. In this magnetic gear structure, the proposed Z-type pole-pieces can couple the magnetic flux of the end face and cylindrical face of rotors. The 3D simulation shows that there are axial and radial magnetic flux components in the ZP-FFMG, which are helpful to torque transmission. A comparative analysis of traditional flux focusing magnetic gear (FFMG) and ZP-FFMG was given. The results show that compared with the traditional FFMG, the transmission torque of the ZP-FFMG is increased by 42%, the torque density is increased by 15 kN·m/m3, and the magnetic flux density is also improved.

-

Key words:

- magnetic gear /

- Z-type pole-pieces /

- flux focusing magnetic gear /

- structural design

-

表 1 ZP-FFMG参数表

Table 1. Parameter table of ZP-FFMG

部件 参数 值 HSR 外径rho/mm 60 内径rhi/mm 30 极靴角度θhs/(°) 22.5 永磁体角度θhm/(°) 22.5 轴向长度dh/mm 20 极对数ph 4 LSR 外径rlo/mm 100 内径rli/mm 70 极靴角度θls/(°) 6 永磁体角度θlm/(°) 6 轴向长度dl/mm 20 极对数pl 15 定子 径向宽度ls/mm 8 Z型极靴厚度ts/mm 8 (初始)

6 (优化后)角度θs/(°) 11 Z型极靴数量ns 19 气隙/mm 1 永磁体剩磁/T 1.2 表 2 FFMG 与ZP-FFMG聚磁比

Table 2. Magnetic concentration ratio of FFMG and ZP-FFMG

齿轮类型 HSR LSR FFMG 2.26 4.49 ZP-FFMG 1.20 2.90 -

[1] 黄金霖, 张国政, 周克良. 新型永磁调磁式磁齿轮的设计与优化[J] . 电子测量与仪器学报,2020,34(7):187 − 195. [2] 张邦京, 朱姿娜, 吴迪, 等. 混合充磁式磁齿轮复合电机损耗仿真与分析[J] . 机械传动,2021,45(8):118 − 123. [3] 李辉, 戴太阳, 卢敏, 等. 高转矩密度的聚磁Halbach少极差磁齿轮设计与优化[J] . 微特电机,2021,49(7):1 − 5. doi: 10.3969/j.issn.1004-7018.2021.07.001 [4] 周一览. 轴向磁齿轮的优化设计[D]. 长沙: 湖南大学, 2019. [5] 李祥林. 基于磁齿轮原理的场调制永磁风力发电机及其控制系统研究[D]. 南京: 东南大学, 2015. [6] 张进, 张秋菊. 双磁场调制磁齿轮转矩能力增强特性分析[J] . 电机与控制学报,2021,25(1):136 − 142. [7] GERBER S, WANG R J. Design and evaluation of a magnetically geared PM machine[J] . IEEE Transactions on Magnetics,2015,51(8):1 − 10. [8] ATALLAH K, HOWE D. A novel high-performance magnetic gear[J] . IEEE Transactions on Magnetics,2001,37(4):2844 − 2846. doi: 10.1109/20.951324 [9] RENS J, CLARK R, CALVERLEY S, et al. Design, analysis and realization of a novel magnetic harmonic gear[C]//Proceedings of the 18th International Conference on Electrical Machines. Vilamoura: IEEE, 2008. [10] UPPALAPATI K, BIRD J. A flux focusing ferrite magnetic gear[C]//Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012). Bristol: IET, 2012. [11] UPPALAPATI K K, CALVIN M D, WRIGHT J D, et al. A Magnetic Gearbox with an Active Region Torque Density of 239 N·m/L[C]//Proceedings of 2014 IEEE Energy Conversion Congress and Exposition (ECCE). Pittsburgh: IEEE, 2014. [12] ACHARYA V M, BIRD J Z, CALVIN M. A Flux Focusing Axial Magnetic Gear[J] . IEEE Transactions on Magnetics,2013,49(7):4092 − 4095. doi: 10.1109/TMAG.2013.2248703 -

下载:

下载: