Study on preparation and cycling performance of anode materials for SiC@CNFs lithium-ion battery

-

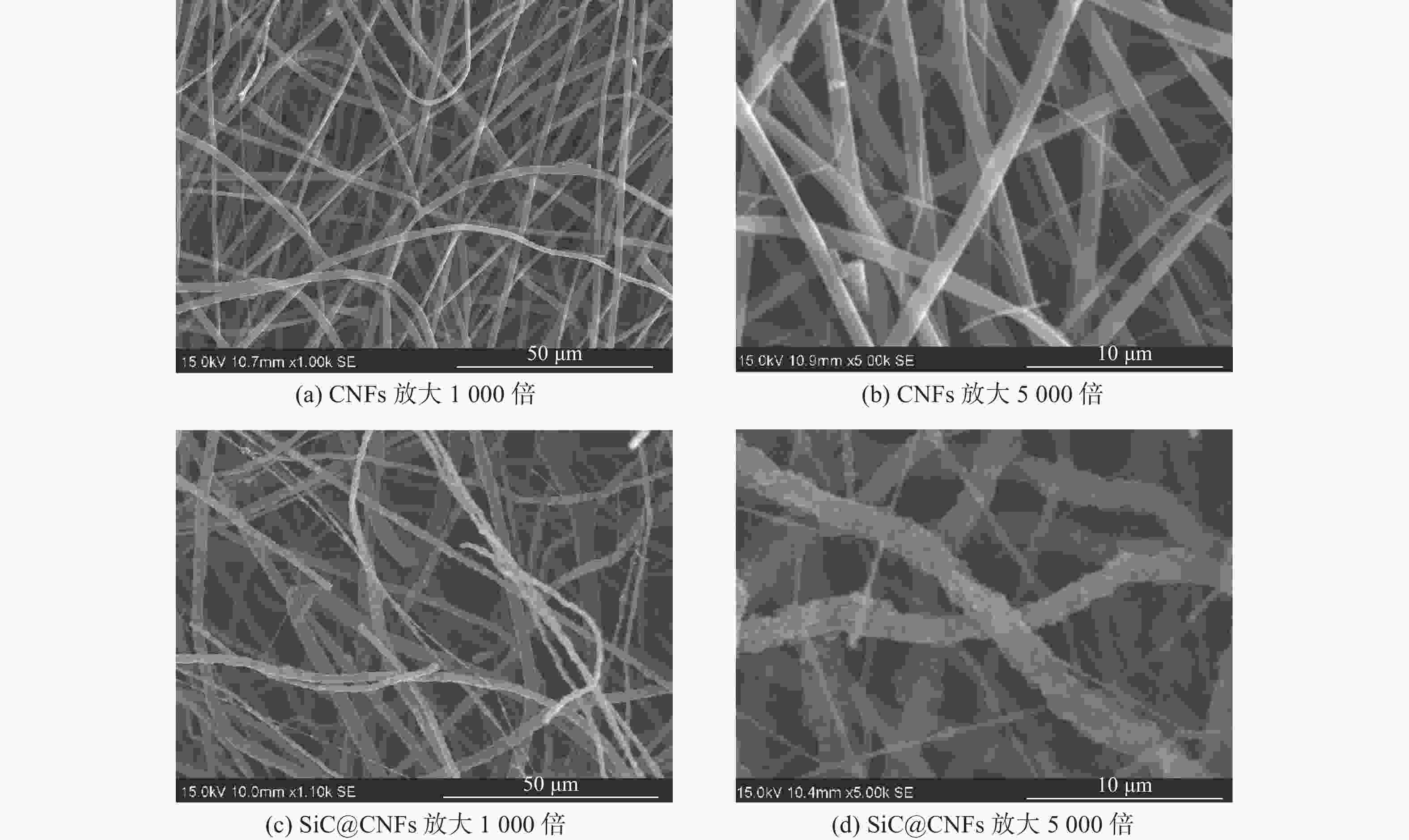

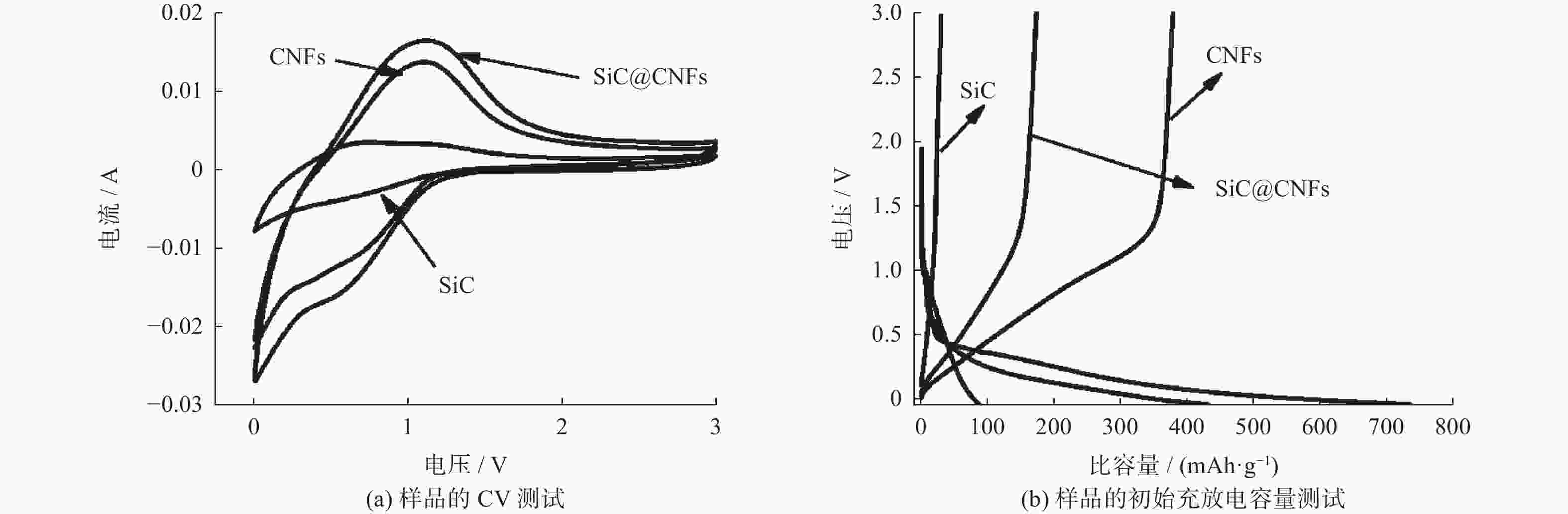

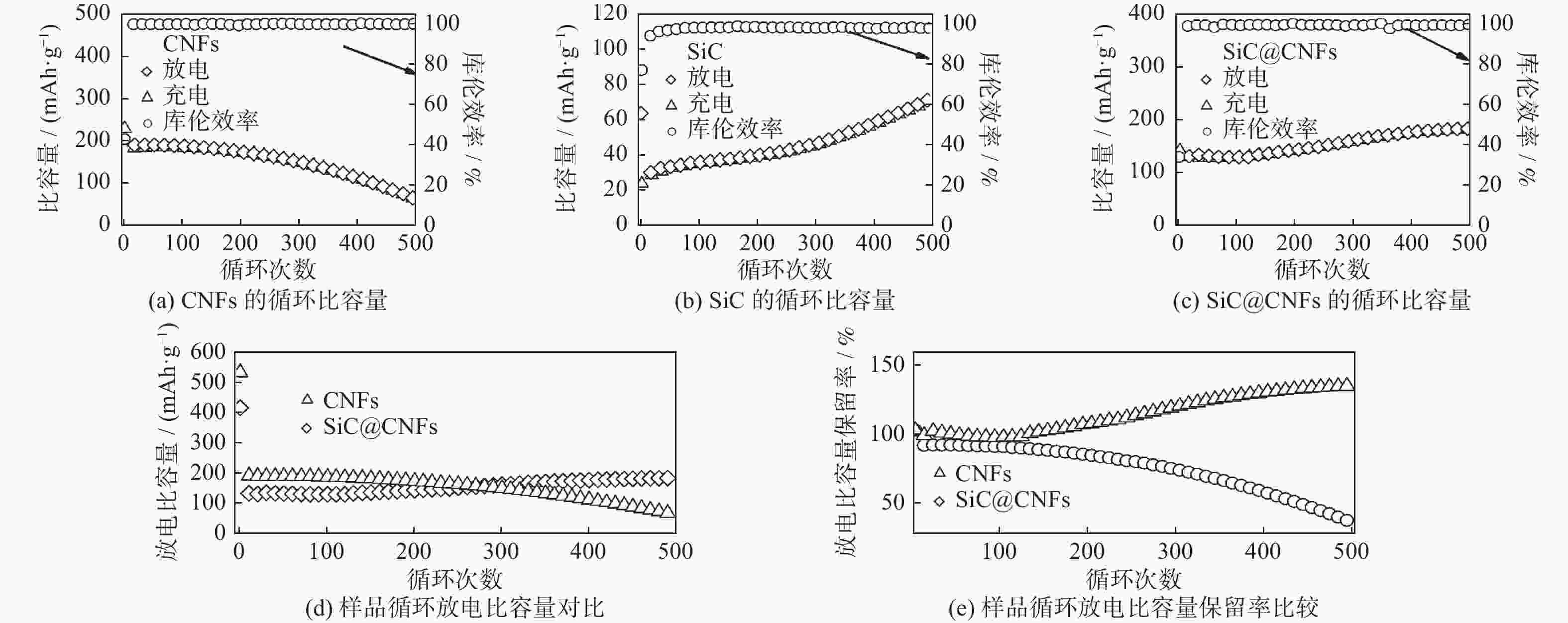

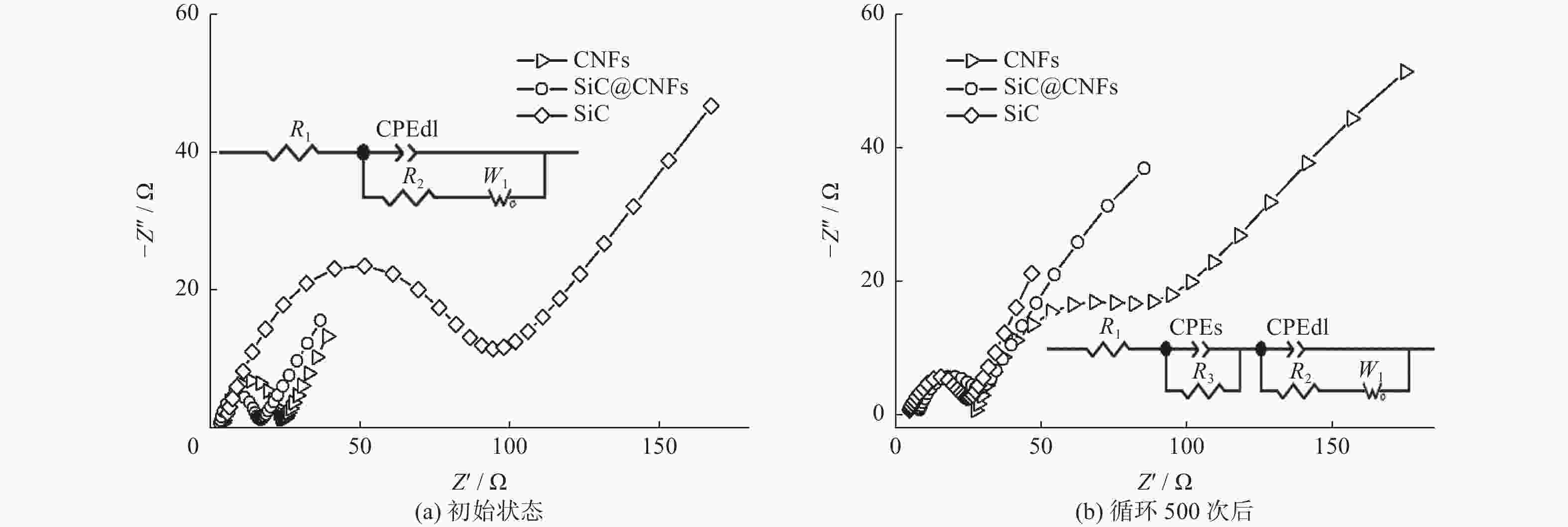

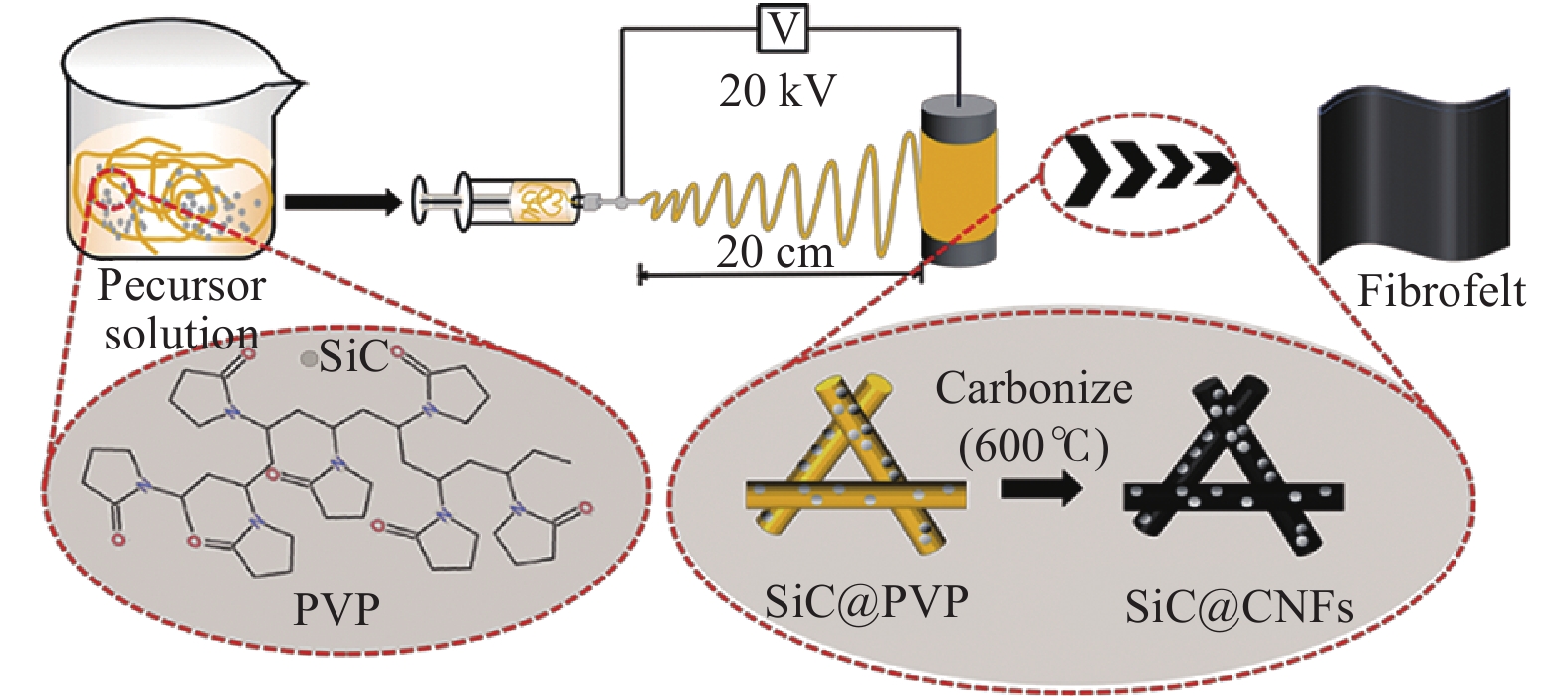

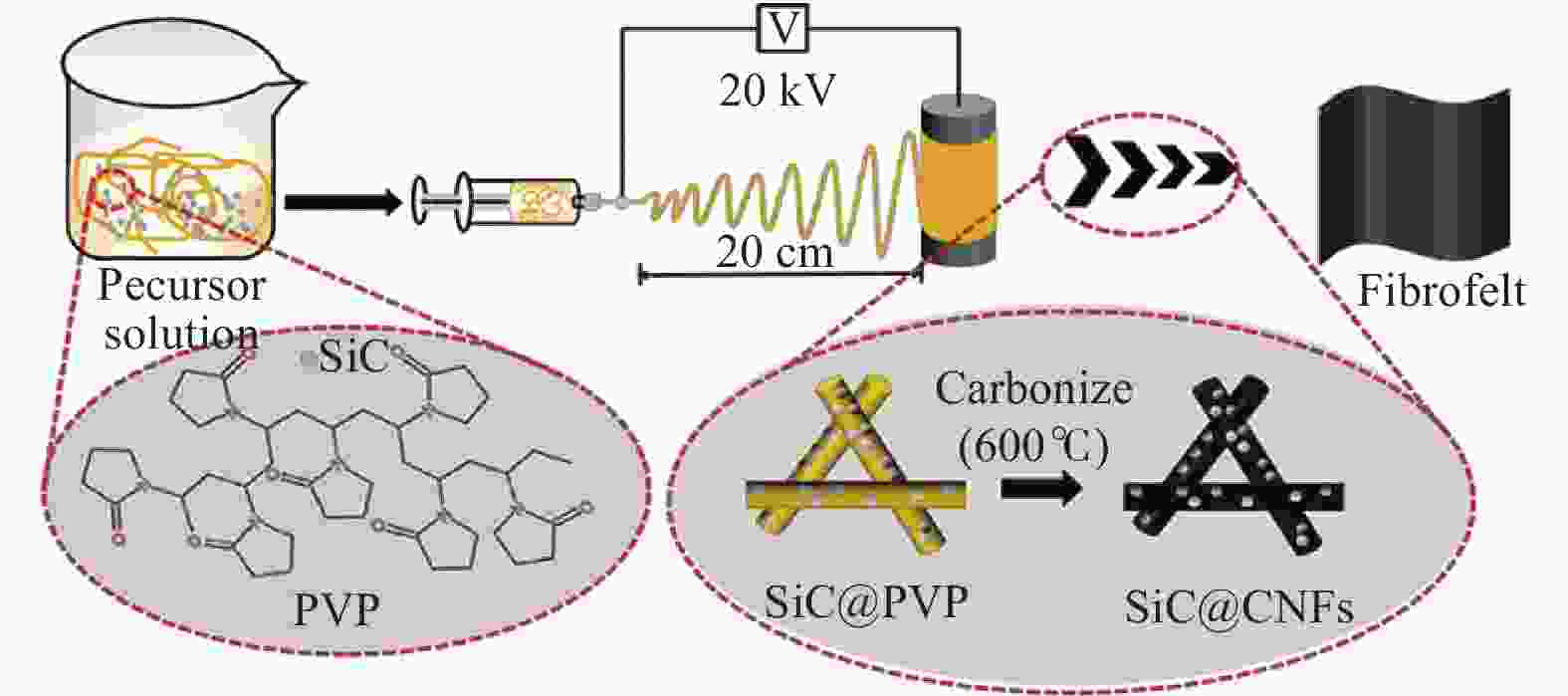

摘要: 通过静电纺丝技术结合碳化工艺制备一种SiC增强碳纳米纤维(SiC@CNFs)复合结构. TGA、XRD、XPS及SEM的样品测试结果显示,SiC颗粒含量(质量分数,全文同)为62%,且均匀分布于CNFs的表面. 该结构制备的锂离子电池负极材料既保留了CNFs的高导电性,又获得了SiC增强的结构韧性. 电化学性能测试结果表明,将其作为锂离子电池负极材料,循环500次后,容量保留率高达134.01%,远高于CNFs. 同时,该结构的电化学阻抗值变化较小,导电性能保持较好. 通过静电纺丝技术制备的SiC@CNFs结构作为锂离子电池负极材料,制作成本低,结构可控且性能稳定,是目前对电池负极材料的有益补充.Abstract: A SiC-enhanced carbon nanofiber composite (SiC@CNFs) structure was prepared by electrospinning technology combined with carbonization process. The results of TGA, XRD, XPS and SEM show that the mass fraction of SiC particles is 62%, and it is evenly distributed on the surface of CNFs. The lithium-ion battery anode material prepared by this structure not only retains the high electrical conductivity of CNFs, but also obtains the enhanced structural toughness of SiC. The electrochemical performance test results show that the capacity retention rate of the lithium-ion battery anode material is as high as 134.01% after 500 cycles, much higher than that of CNFs. Moreover, the electrochemical impedance value of the structure changes less and the conductivity of SiC@CNFs remains good. SiC@CNFs structures prepared by electrospinning technology serve as lithium-ion battery anode, with low production cost, controllable structure and stable performance, which is a beneficial supplement to the current battery cathode materials.

-

Key words:

- lithium-ion battery /

- anode material /

- carbon nanofibers /

- silicon carbide /

- electrospinning

-

表 1 SiC、SiC@CNFs和CNFs样品循环性能对比

Table 1. Comparison of cycle performance of SiC, SiC@CNFs and CNFs samples

样品 碳含量/% 初始放电比容量/

(mAh•g−1)循环5次后放电比容量/

(mAh•g−1)循环500次后放电比容量/

(mAh•g−1)容量保留率/% CNFs 100 534.42 215.21 62.73 29.15 SiC@CNFs 38 417.08 137.42 184.15 134.01 SiC 0 64.02 28.71 72.41 396.49 表 2 样品在初始状态和500次循环后的状态下的电阻值

Table 2. Resistance values for samples at the initial and 500-cycled states

样品 初始状态 循环500次后 R1/Ω Rct /Ω R1/Ω Rct /Ω CNFs 4.14 18.65 24.51 56.88 SiC@CNFs 3.11 11.39 7.89 20.49 SiC 4.42 82.81 4.36 20.89 -

[1] SCROSATI B, GARCHE J. Lithium batteries: Status, prospects and future[J] . Journal of Power Sources,2010,195(9):2419 − 2430. doi: 10.1016/j.jpowsour.2009.11.048 [2] GONZALEZ A F, YANG N H, LIU R S. Silicon anode design for lithium-ion batteries: Progress and perspectives[J] . The Journal of Physical Chemistry C,2017,121(50):27775 − 27787. doi: 10.1021/acs.jpcc.7b07793 [3] 亓美丽. 碳基核壳复合材料制备及其电化学性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2020. [4] 马静波. 锂离子电池用高容量碳基负极材料的研究[D]. 贵阳: 贵州大学, 2020. [5] SOLTANI S, KHANIAN N, CHOONG T S Y, et al. Recent progress in the design and synthesis of nanofibers with diverse synthetic methodologies: Characterization and potential applications[J] . New Journal of Chemistry,2020,44(23):9581 − 9606. doi: 10.1039/D0NJ01071E [6] HE S R, ZOU J P, CHEN L B, et al. A nanostructured Ni/T-Nb2O5@carbon nanofibers as a long-life anode material for lithium-ion batteries[J] . Rare Metals,2021,40(2):374 − 382. doi: 10.1007/s12598-020-01444-y [7] CHEN H, HUA Y R, LUO N J, et al. Lithiation abilities of SiC bulks and surfaces: A first-principles study[J] . The Journal of Physical Chemistry C,2020,124(13):7031 − 7038. doi: 10.1021/acs.jpcc.0c00103 [8] ZHANG H T, XU H. Nanocrystalline silicon carbide thin film electrodes for lithium-ion batteries[J]. Solid State Ionics, 2014, 263(1): 23 − 26. [9] ZHANG Z H, LI H B. Sequential-template synthesis of hollowed carbon polyhedron@SiC@Si for lithium-ion battery with high capacity and electrochemical stability[J]. Applied Surface Science, 2020, 514: 1459201 − 9. [10] SUN X J, SHAO C Z, ZHANG F, et al. SiC nanofibers as long-life lithium-ion battery anode materials[J] . Frontiers in Chemistry,2018,6:166 − 173. doi: 10.3389/fchem.2018.00166 [11] LIU Q, ZHU J H, ZHANG L W, et al. Recent advances in energy materials by electrospinning[J] . Renewable and Sustainable Energy Reviews,2018,81:1825 − 1858. doi: 10.1016/j.rser.2017.05.281 [12] LI X Y, CHEN Y M, HUANG H T, et al. Electrospun carbon-based nanostructured electrodes for advanced energy storage-a review[J] . Energy Storage Materials,2016,5:58 − 92. doi: 10.1016/j.ensm.2016.06.002 [13] PERSANO L, CAMPOSEO A, TEKMEN C, et al. Industrial upscaling of electrospinning and applications of polymer nanofibers: A review[J] . Macromolecular materials and engineering,2013,298(5):504 − 520. doi: 10.1002/mame.201200290 [14] ZHANG Y, HU K, REN J H, et al. A sandwich-like Si/SiC/nanographite sheet as a high performance anode for lithium-ion batteries[J] . Dalton Transactions: An International Journal of Inorganic Chemistry,2019,48(47):17683 − 17690. doi: 10.1039/C9DT04228H [15] 高天一, 龚正良. 碳包覆硅/石墨复合材料的制备及其电化学性能[J] . 电化学,2018,24(3):253 − 261. doi: 10.13208/j.electrochem.170728 [16] WU J, ZHANG X X, LI Z, et al. Toward high-performance capacitive potassium-ion storage: A superior anode material from silicon carbide-derived carbon with a well-developed pore structure[J] . Advanced Functional Materials,2020,30(40):20043481 − 8. doi: 10.1002/adfm.202004348 [17] ZHANG J M, TANG J J, ZHOU X Y, et al. Optimized porous Si/SiC composite spheres as high-performance anode material for lithium-ion batteries[J] . ChemElectroChem,2019,6(2):450 − 455. doi: 10.1002/celc.201801313 [18] 吴静. 锂离子电池硅基复合负极的制备与性能研究[D]. 武汉: 武汉理工大学, 2017. [19] WEI L M, HOU Z Y, WEI H. Porous sandwiched graphene/silicon anodes for lithium storage[J] . Electrochimica Acta,2017,229(17):445 − 451. doi: 10.1016/j.electacta.2017.01.173 [20] POLAT B D, KELES O. Functionally graded Si based thin films as negative electrodes for next generation lithium ion batteries[J] . Electrochimica Acta,2016,187:293 − 299. doi: 10.1016/j.electacta.2015.11.052 [21] WANG D S, GAO M X, PAN H G, et al. High performance amorphousSi@SiOx/C composite anode materials for Li-ion batteries derived from ballmilling and in situ carbonization[J] . Journal of Power Sources,2014,256:190 − 199. doi: 10.1016/j.jpowsour.2013.12.128 [22] LIANG J S, WANG W J, YANG W F, et al. Facile synthesis of ceramic SiC-based nanocomposites and the superior electrochemical lithiation/delithiation performances[J] . Materials Chemistry and Physics,2020,243:122618. doi: 10.1016/j.matchemphys.2019.122618 [23] XIA M, ZHOU Z, SU Y F, et al. Scalable synthesis SiO@C anode by fluidization thermal chemical vapor deposition in fluidized bed reactor for high-energy lithium-ion battery[J] . Applied Surface Science,2019,467:298 − 308. [24] NANGIR M, MASSOUDI A, TAYEBIFARD S A. Investigation of the lithium-ion depletion in the silicon-silicon carbide anode/electrolyte interface in lithium-ion battery via electrochemical impedance spectroscopy[J] . Journal of Electroanalytical Chemistry,2020,873:114385 − 114420. doi: 10.1016/j.jelechem.2020.114385 -

下载:

下载: