Optimization of real-time assembly man-hours scheduling based on digital twin

-

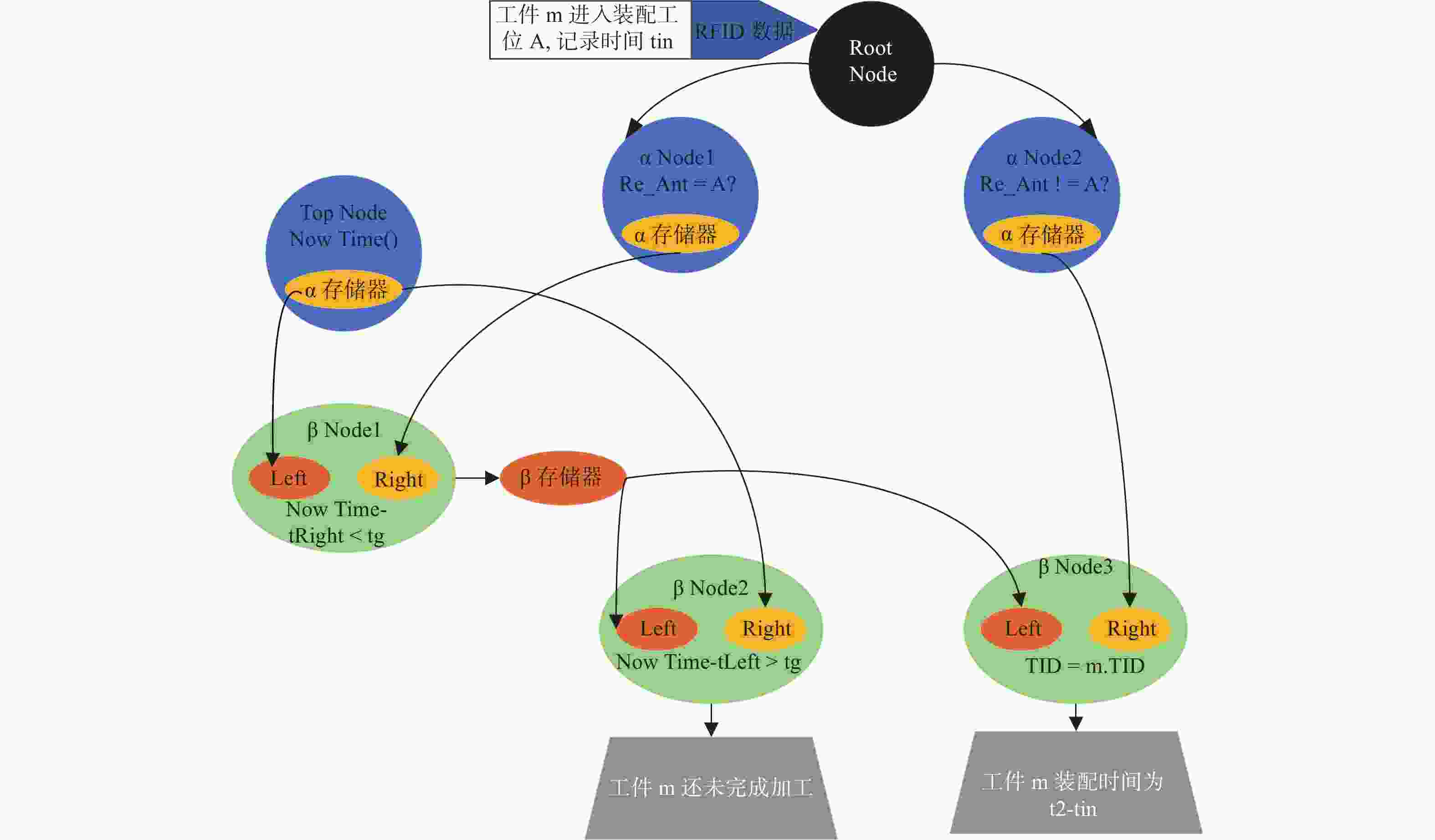

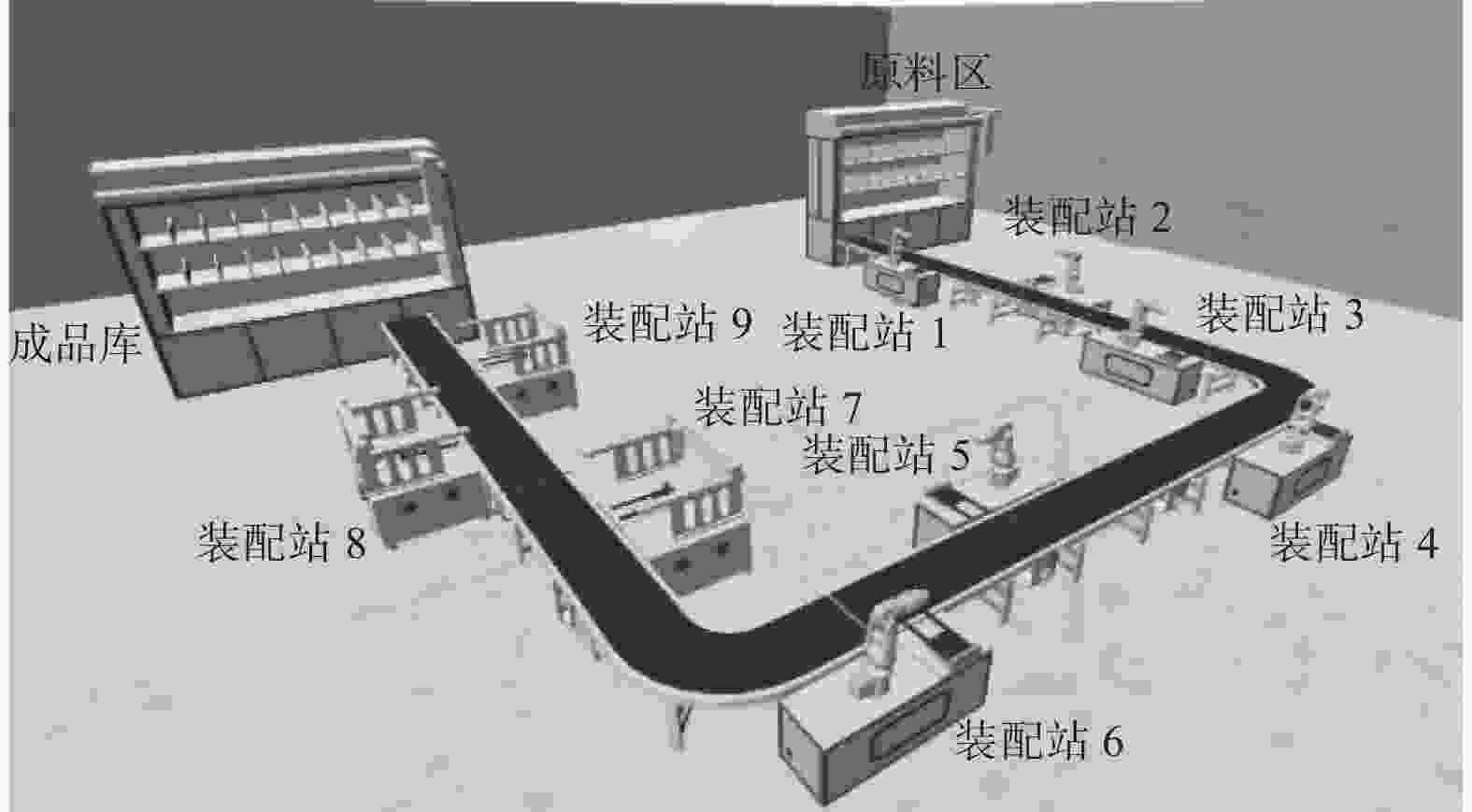

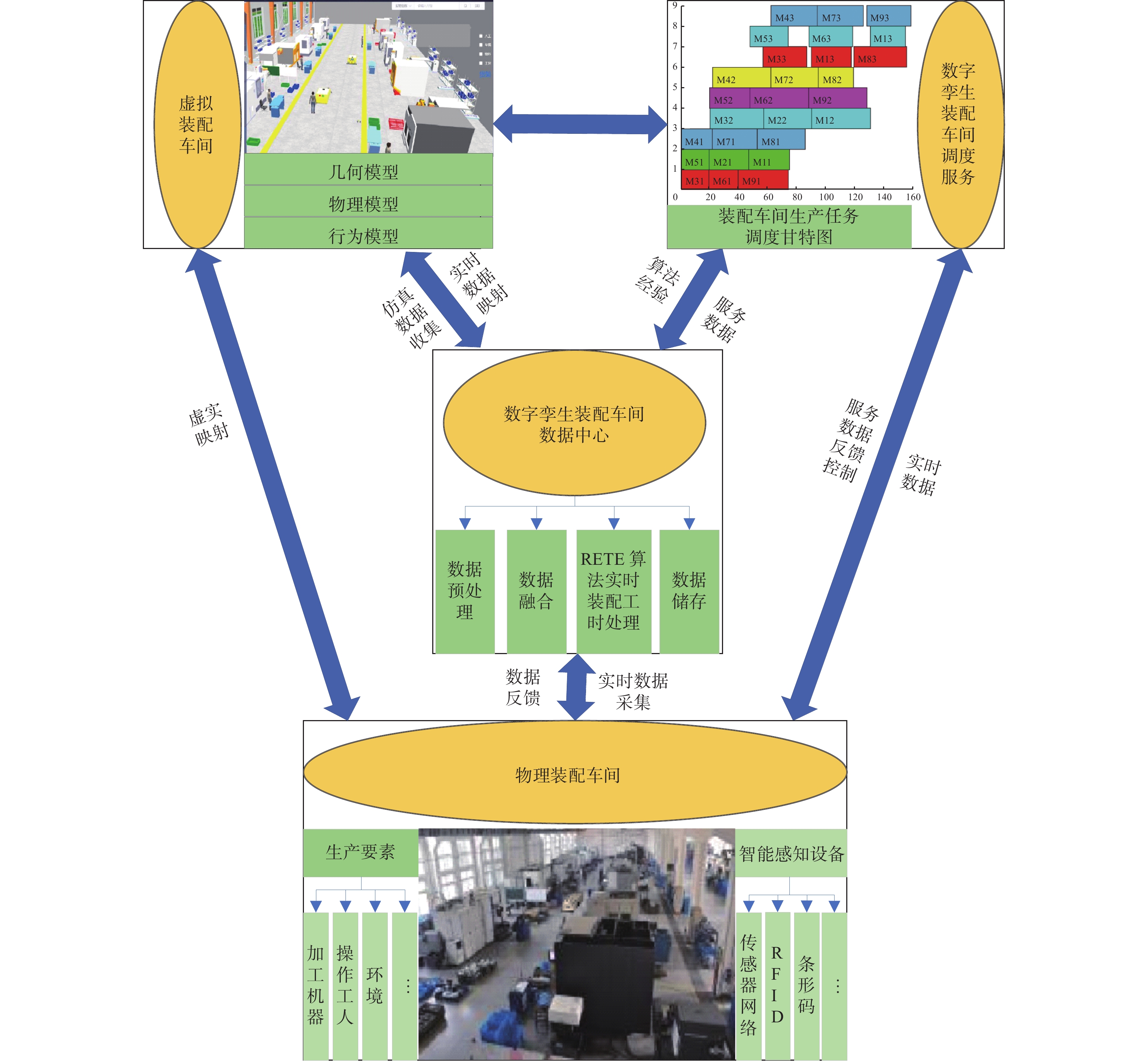

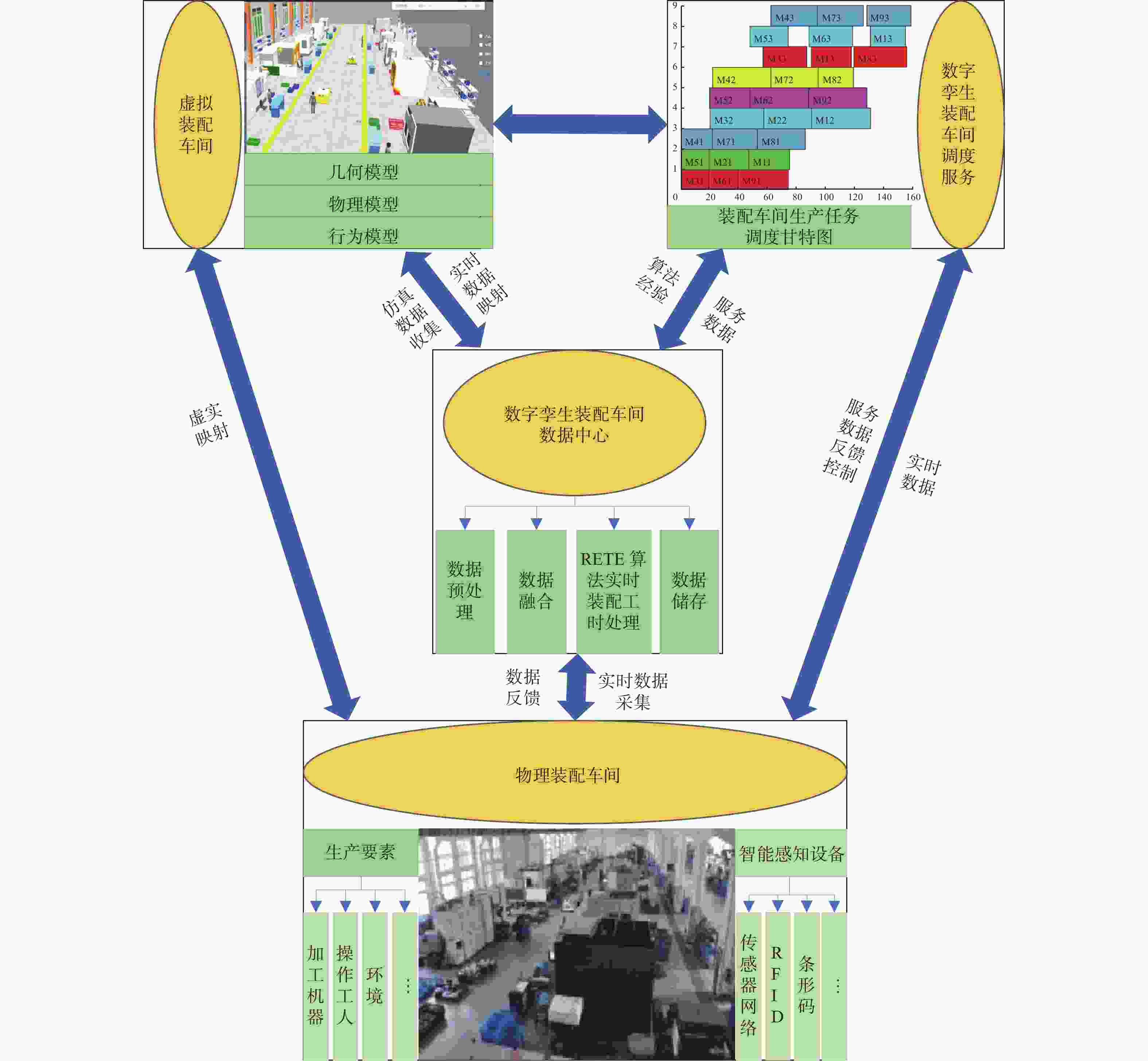

摘要: 针对产品个性化定制过程中装配工时不确定、装配车间动态扰动频发问题,提出基于数字孪生的实时装配工时车间调度模型. 构建基于数字孪生的装配车间调度整体架构,利用射频识别(Radio Frequency Identification, RFID)技术实时采集物理装配车间的工时数据,用改进的Rete算法进行实时装配工时处理. 建立基于实时装配工时的装配车间调度数学模型,采用改进的人工鱼群−禁忌算法对模型求解,以实现实时装配工时车间的调度优化. 实证结果表明,模型算法进行实时装配工时车间调度具有一定的可行性及优越性.Abstract: Based on digital twin, a real-time assembly man-hours workshop scheduling model was proposed, considering the uncertainty of assembly man-hours in the process of product customization and frequent dynamic disturbances in the assembly workshop. The overall architecture of assembly workshop scheduling based on digital twin was constructed. Radio frequency identification (RFID) technology was used to collect real-time working hours data of physical assembly workshops, and the real-time assembly working hours were processed by using the improved Rete algorithm. A mathematical model of assembly workshop scheduling based on real-time assembly man-hours was established, and an improved artificial fish swarm-taboo algorithm was used to solve the model, so as to realize the scheduling optimization of the real-time assembly man-hours workshop. The empirical result shows that the model algorithm has certain feasibility and superiority in real-time assembly man-hours workshop scheduling.

-

表 1 基于实时装配工时的装配车间调度参数表

Table 1. Assembly workshop scheduling parameter table based on real-time assembly man-hours

参数名称 表示 参数名称 表示 $N=\{ {N}_{1},{N}_{2},\dots ,{N}_{i},\dots ,{N}_{I}\}$ 工件 $ {T}_{i,j,l} $ 基于历史数据的第$ i $个工件的第$ j $道工序由$ l $装配班组的装配时间 I 工件总数 ${C}_{{\rm{max}}}$ 最大完工时间 $ {N}_{i} $ 第$ i $个工件 $ {t}_{i,j,w1} $ 基于实时数据的第$ i $个工件的第$ j $道工序装配开始时间 $M=\{ {M}_{i,1},{M}_{i,2},\dots ,{M}_{i,j},\dots ,{M}_{i,J}\}$ 工序 $ {t}_{i,j,y2} $ 基于历史数据的第$ i $个工件的第$ j $道工序装配结束时间 J 每个工件的工序总数 $ {t}_{i,j,w2} $ 基于实时数据的第$ i $个工件的第$ j $道工序装配结束时间 $ {M}_{i,j} $ 第$ i $个工件的第$ j $道工序 $\Delta {t}_{{\rm{lim}}}$ 实时数据与历史数据工时时间差值的阈值 $P=\{ {P}_{j,1},{P}_{j,2},\dots ,{P}_{j,l},\dots ,{P}_{j,L}\}$ 第$ j $道装配工序的装配班组 $ {X}_{i,j,l}=\left\{\mathrm{0,1}\right\} $ 第$ i $个工件的第$ j $道装配工序是否安排在第$ l $道装配班组,是为1,否则为0 L 第$ j $道装配工序的装配班组总数量 $ {Z}_{g,h,j}=\left\{\mathrm{0,1}\right\} $ 表示第$ j $道工序上的$ g $,$ h $两个产品的加工顺序,$ g $先于$ h $则为1,否则为0 $ {P}_{j,l} $ 第$ j $道装配工序的第$ l $个装配班组 U 很大的一个正数 表 2 算例L1原始数据

Table 2. Example L1 raw data

工件

编号工序1工时 工序2工时 工序3工时 M1 M2 M3 M4 M5 M6 M7 M8 M9 1 2 2 3 4 5 2 3 2 3 2 4 5 4 3 4 3 4 5 4 3 6 5 4 4 2 3 4 2 5 4 4 3 4 6 5 3 6 5 8 5 4 5 3 3 1 3 4 6 5 6 6 5 4 2 3 4 3 9 5 7 5 2 4 4 6 3 4 3 5 8 3 5 4 7 5 3 3 6 4 9 2 5 4 1 2 7 8 6 5 10 3 6 4 3 4 4 8 6 7 11 5 2 4 3 5 6 7 6 5 12 6 5 4 5 4 3 4 7 5 表 3 不同智能算法的结果对比

Table 3. Results comparison of different intelligent algorithms

运行

次数GA

最优解GSA

最优解ID-KH

最优解人工鱼群算法

最优解1 22 22 21 21 2 22 22 21 21 3 22 22 21 21 4 22 21 21 21 5 22 22 22 21 6 22 22 21 21 7 22 21 21 21 8 22 22 21 21 9 22 22 21 21 10 22 22 21 21 平均值 22 21.8 21.1 21 表 4 装配时间表

Table 4. Assembly time table

工件

编号工序1工时/s 工序2工时/s 工序3工时/s 小组1 小组2 小组3 小组4 小组5 小组6 小组7 小组8 小组9 1 24 28 32 40 48 44 32 24 28 2 31 27 25 33 35 31 27 28 33 3 20 28 24 37 39 42 30 32 34 4 20 24 22 38 34 40 36 34 32 5 28 20 25 27 28 33 31 26 30 6 20 24 22 37 40 35 32 30 34 7 32 26 30 35 30 32 28 30 32 8 33 27 34 27 31 25 36 40 30 9 34 30 24 45 40 42 32 34 30 -

[1] 陈宇轩. 工时不确定条件下基于改进遗传算法的柔性作业车间调度问题的区间数求解方法[J] . 机械工程师,2018(1):79 − 81. doi: 10.3969/j.issn.1002-2333.2018.01.025 [2] JAMROUS T, CHIEN C F, GEN M, et al. Hybrid particle swarm optimization combined with genetic operators for flexible job-shop scheduling under uncertain processing time for semiconductor manufacturing[J] . IEEE Transactions on Semiconductor Manufacturing,2018,31(1):32 − 41. doi: 10.1109/TSM.2017.2758380 [3] 郭映丹, 王贺, 冯翰信, 等. 成组条件下的研制批产混合调度方法[J] . 浙江大学学报(工学版),2016,50(11):2224 − 2230.GUO Y T, WANG H, FENG H X, et al. Trial production and batch production mixed scheduling method in group manufacturing[J]. Journal of Zhejiang University, 2016, 50(11): 2224-2230. [4] 郭钧, 钟精诚, 杜百岗, 等. 考虑模糊作业时间的再制造加工车间多目标调度方法[J] . 控制与决策,2020(6):1497 − 1504. doi: 10.13195/j.kzyjc.2018.1187 [5] 朱传军, 邱文, 朱孟周, 等. 随机工时下的多目标柔性作业车间鲁棒调度问题[J] . 中国机械工程,2016,27(12):1667 − 1672. doi: 10.3969/j.issn.1004-132X.2016.12.020 [6] 常建娥, 李帅, 莫易敏, 等. 基于装配相似性与灰色模型的汽车装配工时预测[J] . 工业工程,2018,21(3):87 − 92. doi: 10.3969/j.issn.1007-7375.2018.03.011 [7] 刘子文, 刘检华, 程益, 等. 基于文本挖掘与神经网络的复杂产品装配工时估算方法[J] . 机械工程学报,2021,57(15):199 − 210. [8] WU C C, GUPTA J N D, CHENG S R, et al. Robust scheduling for a two-stage assembly shop with scenario-dependent processing times[J] . International Journal of Production Research,2021, 59(17):5372 − 16. [9] FERONE D, HATAMI S, GONEALZE‐NEIRA E M, et al. A biased‐randomized iterated local search for the distributed assembly permutation flow‐shop problem[J] . International Transactions in Operational Research,2020,27(3):1 − 24. [10] SHEIKH S, KOMAKI G M, KAYVANFAR V, et al. Multi-stage assembly flow shop with setup time and release time[J] . Operations Research Perspectives,2019,6:1 − 15. [11] FANG Y L, PENG C, LOU P, et al. Digital-twin based job shop scheduling towards smart manufacturing[J] . IEEE Transactions on Industrial Informatics,2019,15(12):6425 − 6435. doi: 10.1109/TII.2019.2938572 [12] ZHANG J, DENG T M, JIANG H F, et al. Bi-level dynamic scheduling architecture based on service unit digital twin agents[J] . Journal of Manufacturing Systems,2021,60:59 − 79. doi: 10.1016/j.jmsy.2021.05.007 [13] 曹远冲, 熊辉, 庄存波, 等. 基于数字孪生的复杂产品离散装配车间动态调度[J] . 计算机集成制造系统,2021,27(2):557 − 568. [14] VILLALONGA A, NEGRI E, BISCARDO G, et al. A decision-making framework for dynamic scheduling of cyber-physical production systems based on digital twins[J] . Annual Reviews in Control,2021,51:351 − 373. [15] 陶飞, 刘蔚然, 张萌, 等. 数字孪生五维模型及十大领域应用[J] . 计算机集成制造系统,2019,25(1):1 − 18. doi: 10.13196/j.cims.2019.01.001 [16] 曹伟, 江平宇, 江开勇, 等. 基于RFID技术的离散制造车间实时数据采集与可视化监控方法[J] . 计算机集成制造系统,2017,23(2):273 − 284. doi: 10.13196/j.cims.2017.02.006 [17] 宫敬程, 庄存波, 刘检华, 等. 基于磷虾群−禁忌算法的复杂产品装配调度问题[J] . 现代制造工程,2020(9):32 − 39. doi: 10.16731/j.cnki.1671-3133.2020.09.005 [18] KAHRAMAN C, ENGIN O, HSAN K, et al. An application of effective genetic algorithms for solving hybrid flow shop scheduling problems[J] . International Journal of Computational Intelligence Systems,2008,1(2):134 − 147. doi: 10.1080/18756891.2008.9727611 [19] BAHROLOLOUMA A, NEZAMABADI-POUR H, BAHROLOLOUM H, et al. A prototype classifier based on gravitational search algorithm[J] . Applied Soft Computing,2012,12(2):819 − 825. doi: 10.1016/j.asoc.2011.10.008 [20] 庄存波, 熊辉, 刘检华, 等. 一种改进离散磷虾群的复杂产品装配调度算法[J] . 兵工学报,2018,39(8):1590 − 1600. doi: 10.3969/j.issn.1000-1093.2018.08.016 -

下载:

下载: