Power loss analysis and cooling design of flat wire motor winding for vehicle electrical motor

-

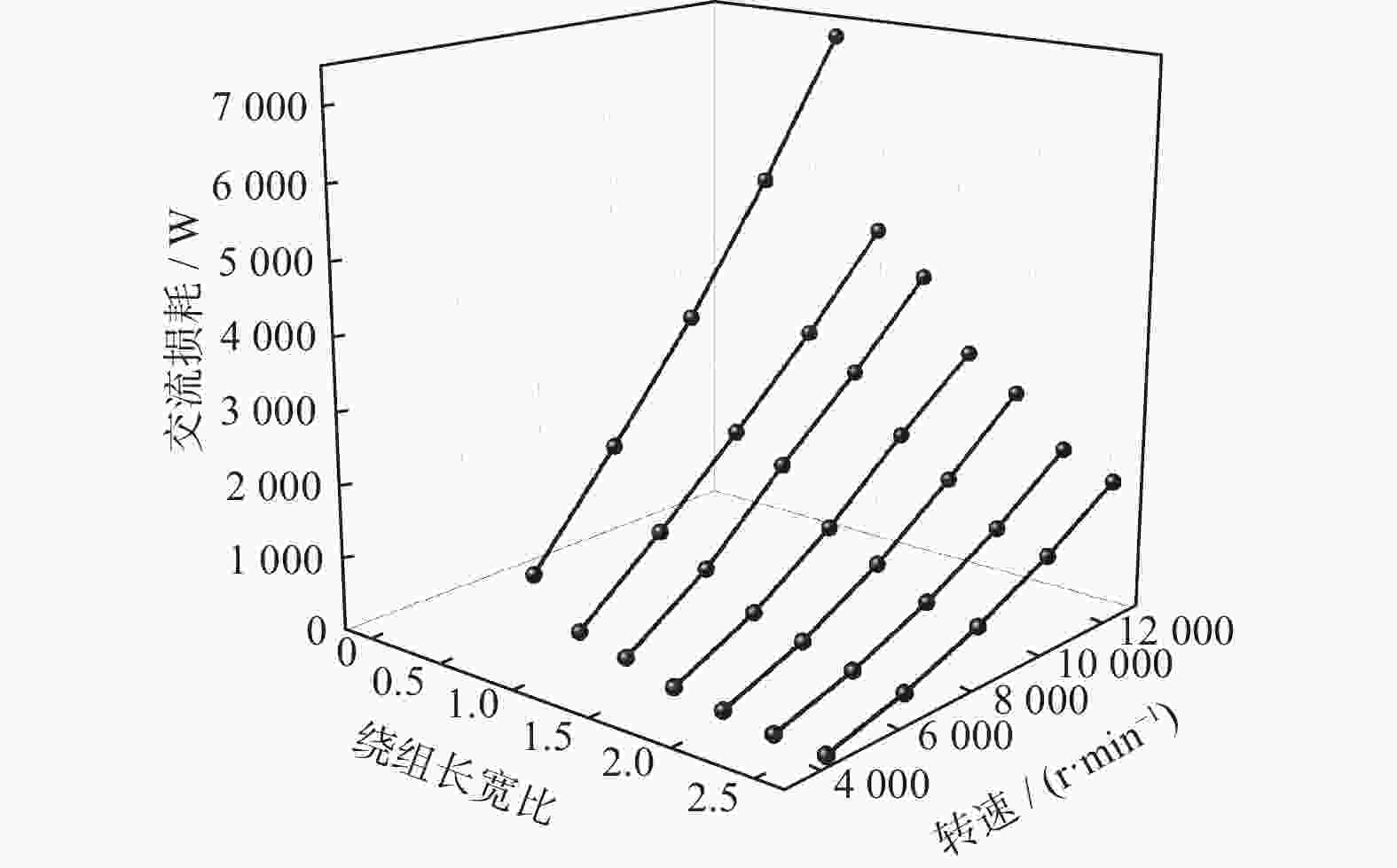

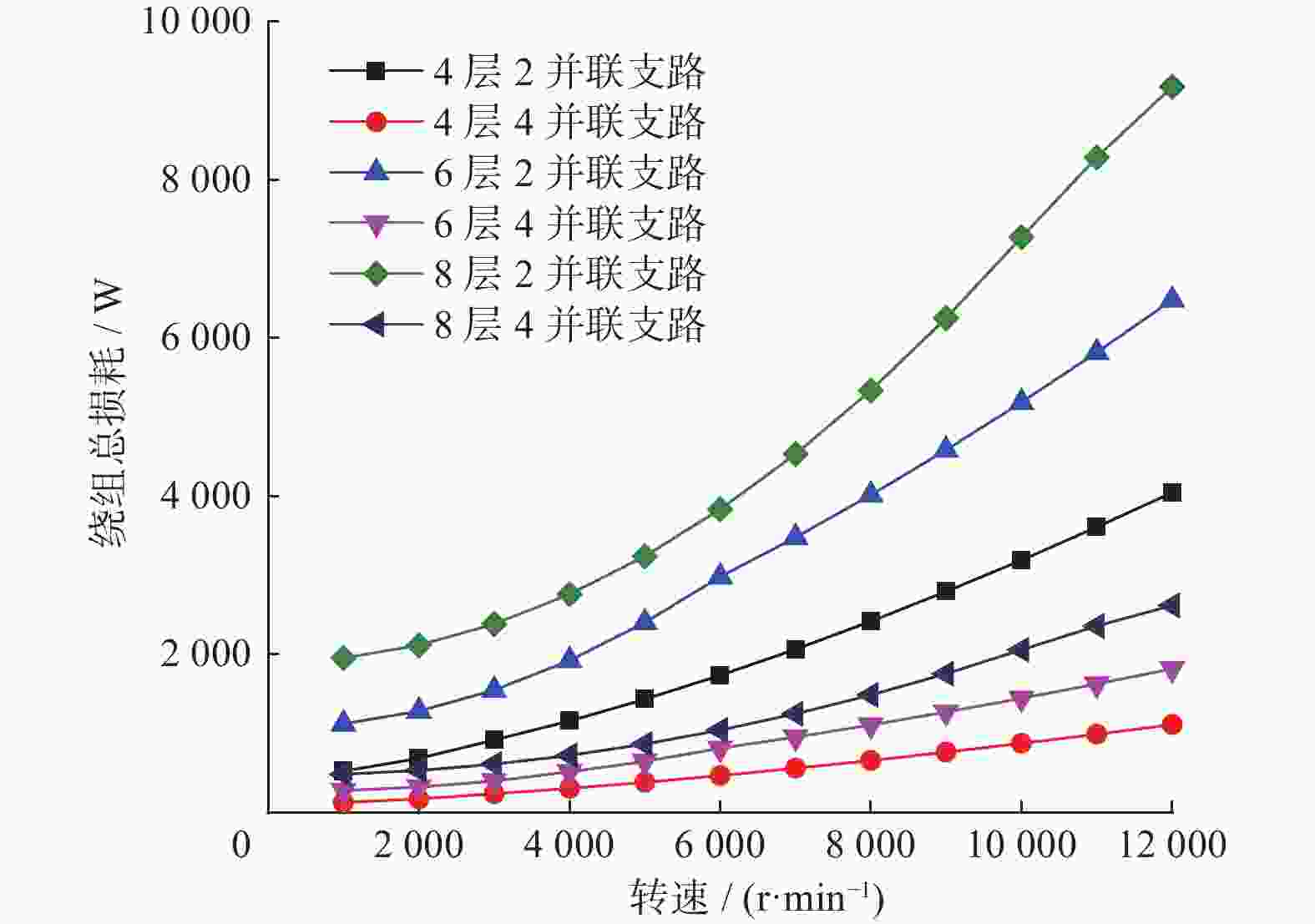

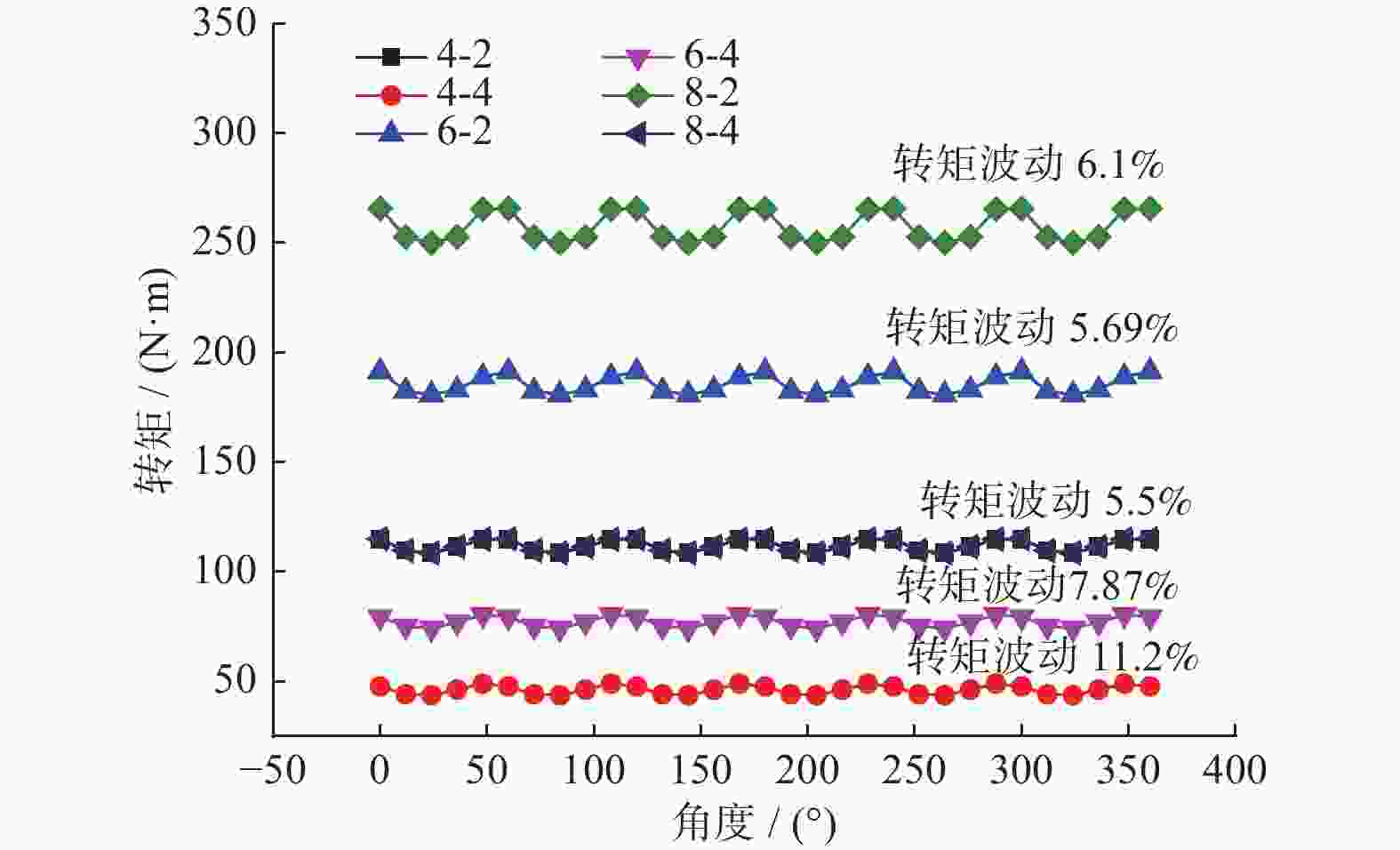

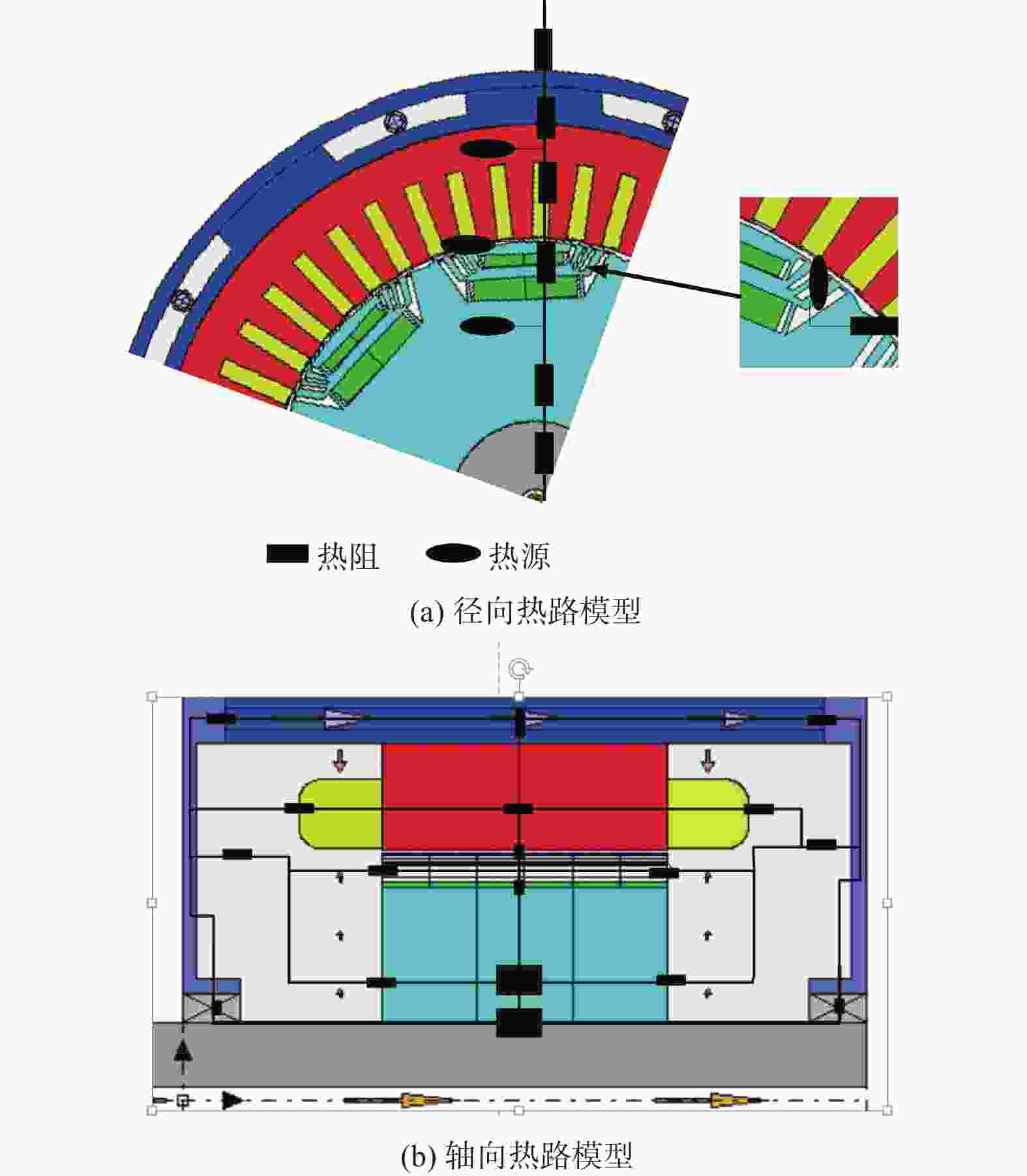

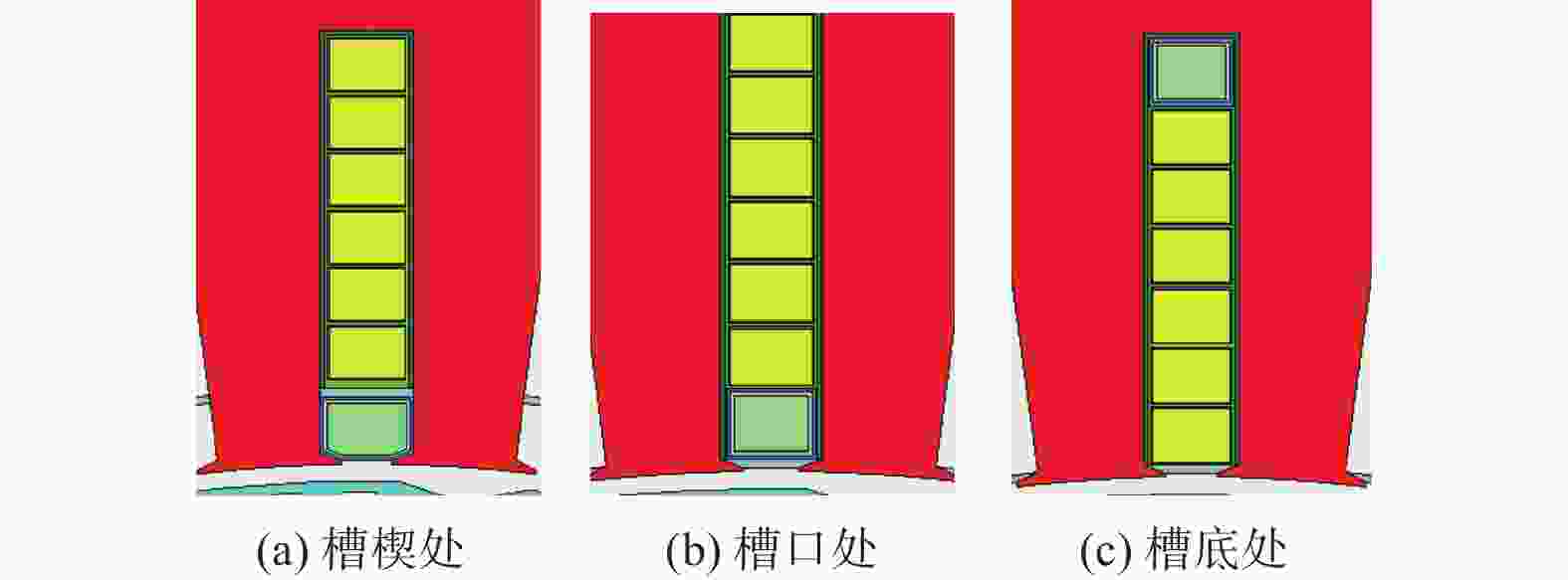

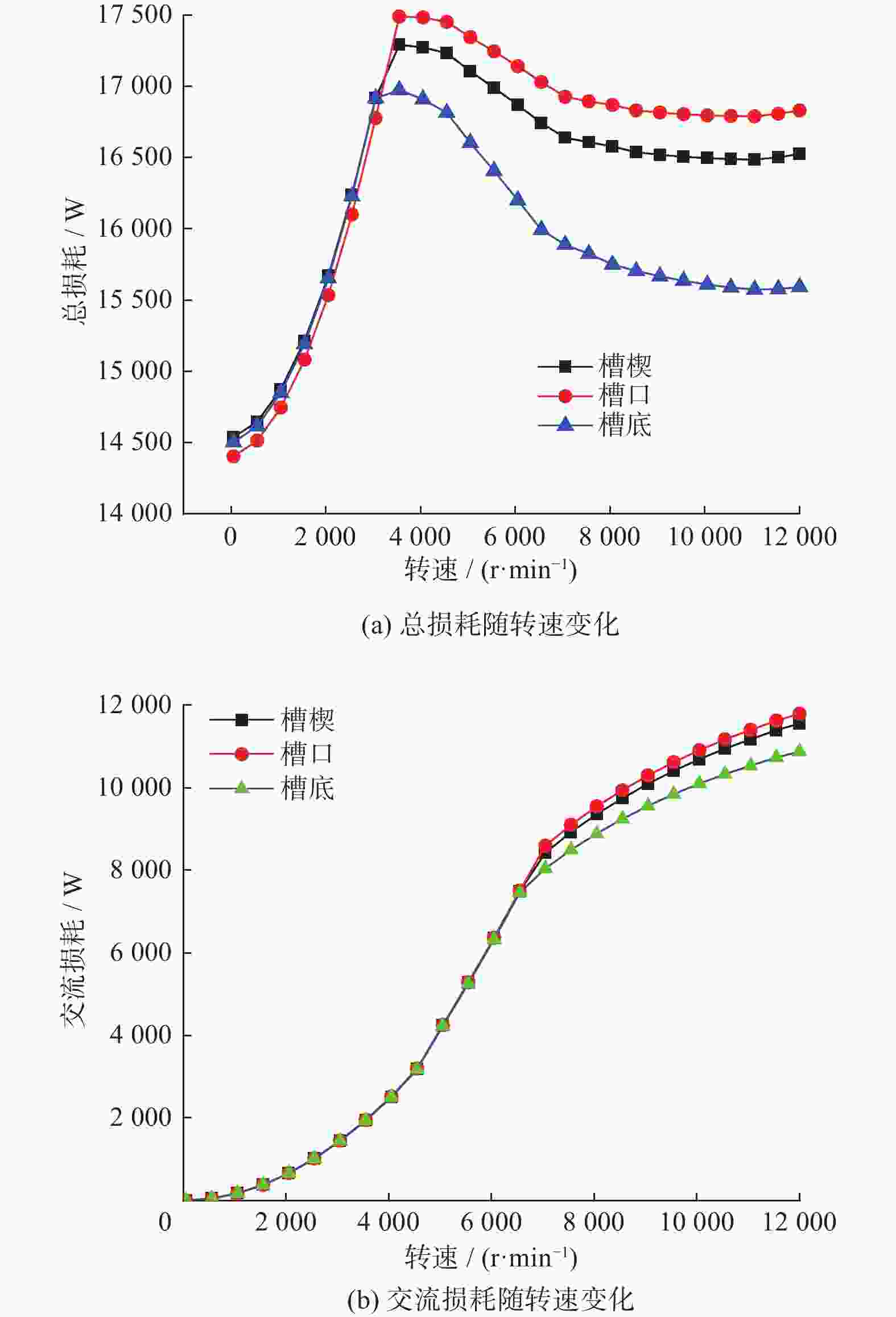

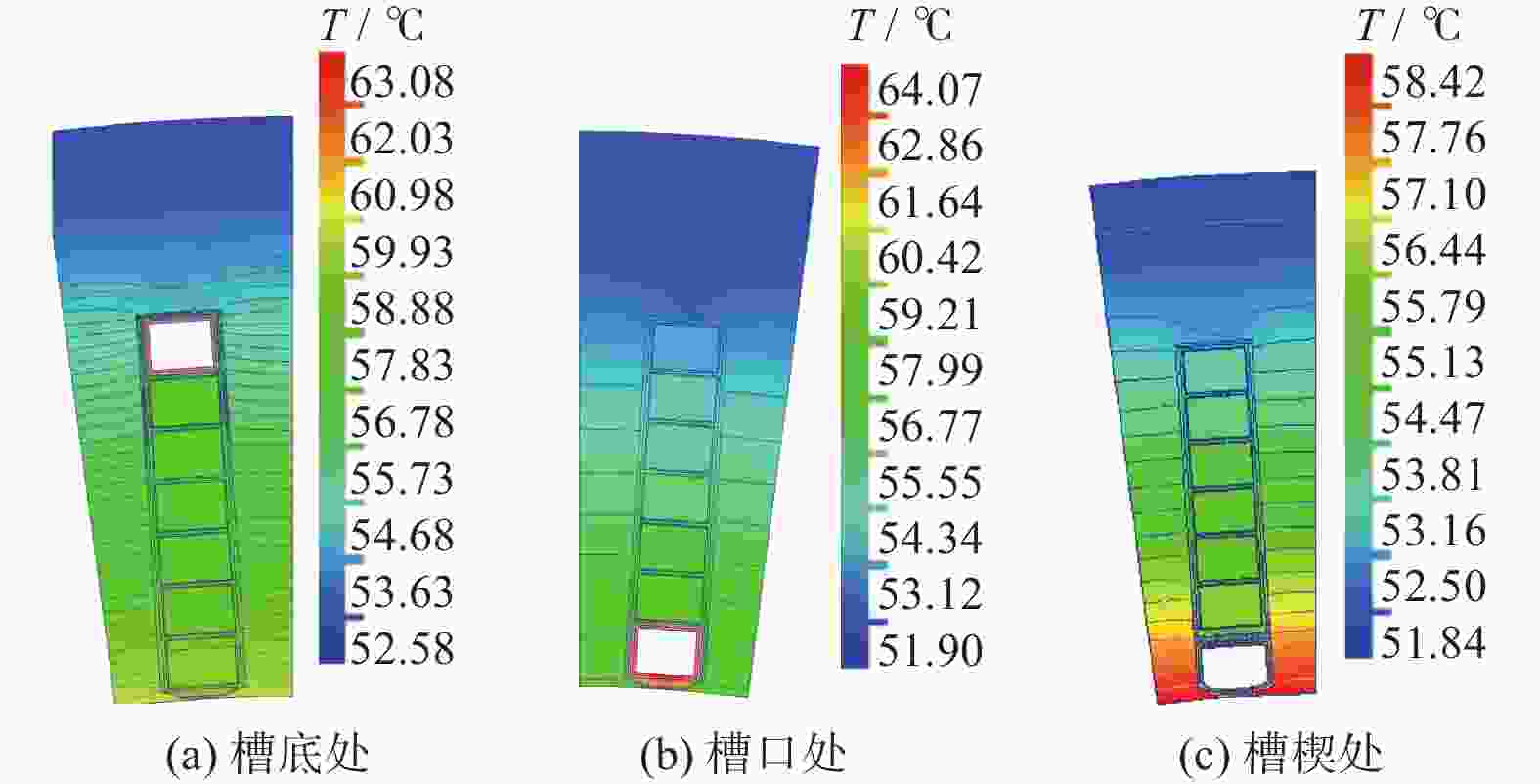

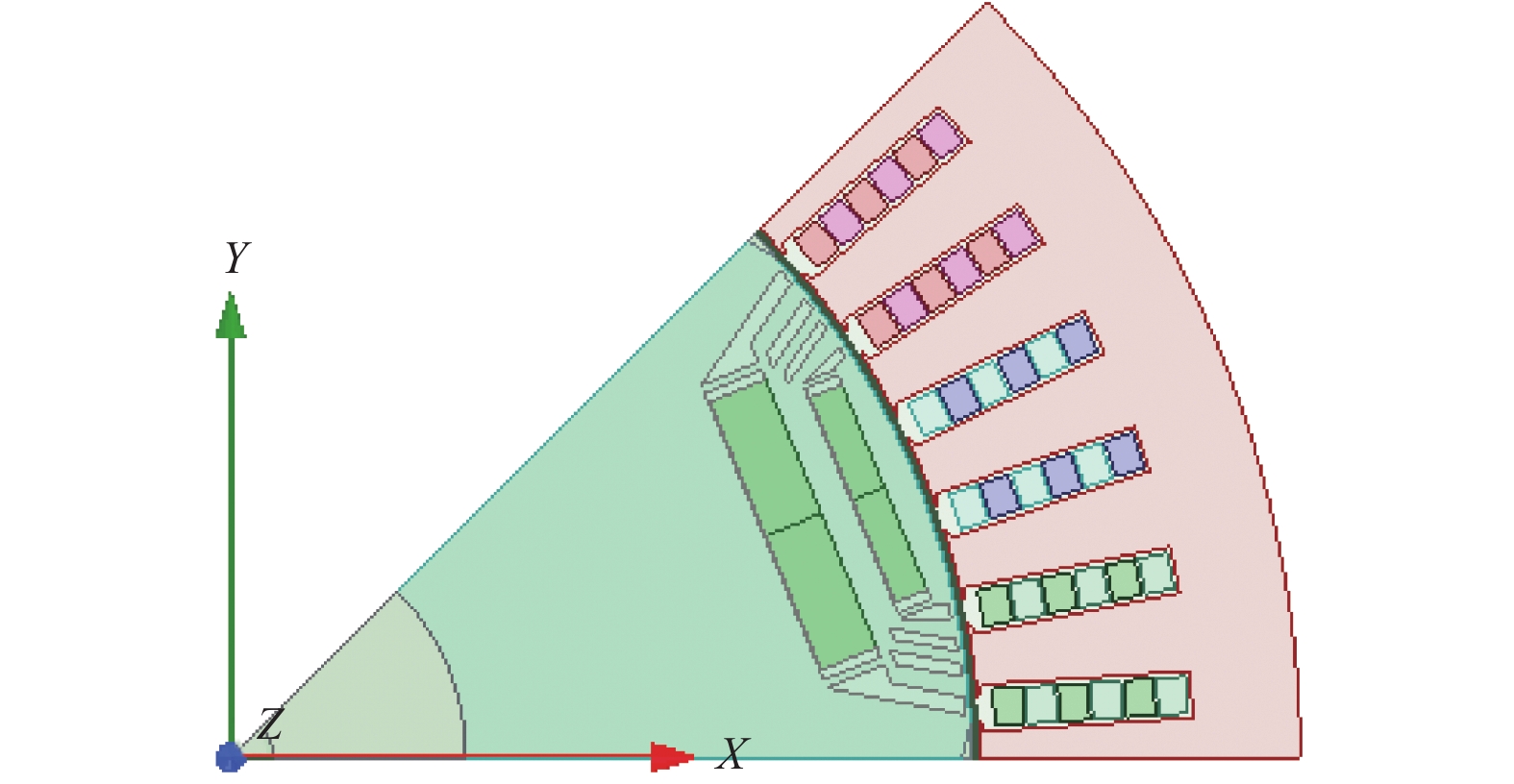

摘要: 车用扁线电机具有体积小、质量轻、功率密度高的特点,但随着车用电机向高速化发展,扁线电机的交流损耗变大,其温升特点不同于传统圆线电机,需要设计与之相适应的冷却方法. 首先建立新能源汽车用高速扁线永磁同步电机的二维有限元模型,分析WLTC-3工况下扁线导体的尺寸、层数以及并联支路数对电机交流损耗的影响规律,获得最优的导体尺寸和绕组连接方式. 然后在损耗分析的基础上,根据电机的温度场分布,设计了电机槽内油冷的最佳冷却方法,降低了温升,提高了电机运行的可靠性.Abstract: The flat wire motor for Electric Vehicles have the characteristics of small size, light weight and high power density. However, with the development of high-speed motor, the AC loss of flat wire motor becomes larger, and its thermal rise performance is different from the traditional circular wire motor, so it is necessary to design a cooling method suitable for it. Firstly, a two-dimensional finite element model of a high speed flat permanent magnet synchronous motor for new energy vehicles was established, the influences of the size, layer number and parallel branches number of the flat conductor on the AC loss of the motor under the driving cycle of WLTC-3 were analyzed, and the optimal conductor size and winding connection mode were obtained. Then on the basis of loss analysis, according to the temperature field distribution of the motor, the optimal cooling method of oil cooling has been designed, which reduces the temperature rise and improves the reliability of the motor operation.

-

Key words:

- flat wire motor /

- AC loss /

- loss analysis /

- cooling method

-

表 1 电机性能指标

Table 1. Motor performance indicators

参数 数值 参数 数值 额定转矩/(N•m) 380 转子内径/mm 135 额定转速/(r•min−1) 6000 峰值功率/kW 200 最高转速/(r•min−1) 12000 效率/% 96 表 2 主要结构参数

Table 2. Main structural parameters

参数 数值 参数 数值 定子外径/mm 250 槽口高/mm 0.2 定子内径/mm 175 槽口宽/mm 3 槽宽/mm 5.5 槽肩角/(°) 20 槽深/mm 25 表 3 绕组层数与并联支路数组合

Table 3. Numbers of winding layers and parallel branches

编号 绕组层数 并联支路数 方式1 4 2 方式2 6 2 方式3 8 2 方式4 4 4 方式5 6 4 方式6 8 4 表 4 电机内部各温度节点

Table 4. Each temperature node inside motor

温度节点 部件 温度节点 部件 T1 机壳 T2 定子铁心轭部 T3 定子铁心齿部 T4 槽内绕组 T5 端部绕组 T6 气隙 T7 转子铁心 T8 转轴 T9 轴承 T10 安装板 T11 电机端部空气 T12 端盖 -

[1] HWANG C C, LYU L Y, LIU C T, et al. Optimal design of an SPM motor using genetic algorithms and Taguchi method[J] . IEEE Transactions on Magnetics,2008,44(11):4325 − 4328. doi: 10.1109/TMAG.2008.2001526 [2] VOLPE G, POPESCU M, MARIGNETTI F, et al. Modelling AC winding losses in a PMSM with high frequency and torque density[C]//Proceedings of 2018 IEEE Energy Conversion Congress and Exposition (ECCE). Portland: IEEE, 2018: 2300 − 2305. [3] 姜华. 扁铜线电机交流损耗的计算方法[J] . 微特电机,2019,47(12):32 − 34. doi: 10.3969/j.issn.1004-7018.2019.12.008 [4] MORISCO D P, IEPURE I L, MOECKEL A. Application of a hybrid modeling approach for eddy current estimation in Hairpin windings[C]//Proceedings of 2019 IEEE International Electric Machines & Drives Conference (IEMDC). San Diego: IEEE, 2019: 2251 − 2258. [5] BIANCHINI C, VOGNI M, TORREGGIANI A, et al. Slot design optimization for copper losses reduction in electric machines for high speed applications[J] . Applied Sciences,2020,10(21):7425. doi: 10.3390/app10217425 [6] ZHANG W J, JAHNS T M. Analytical model for predicting ac losses in form-wound machine windings due to stator current interactions[C]//Proceedings of 2015 IEEE International Electric Machines & Drives Conference (IEMDC). Coeur d'Alene: IEEE, 2015: 1131 − 1137. [7] BIANCHI N, BERARDI G. Analytical approach to design hairpin windings in high performance electric vehicle motors[C]//Proceedings of 2018 IEEE Energy Conversion Congress and Exposition (ECCE). Portland: IEEE, 2018: 4398 − 4405. [8] LIU C, XU Z Y, GERADA D, et al. Experimental investigation on oil spray cooling with Hairpin windings[J] . IEEE Transactions on Industrial Electronics,2020,67(9):7343 − 7353. doi: 10.1109/TIE.2019.2942563 [9] VENTURINI G, VOLPE G, POPESCU M. Slot water jacket cooling system for traction electrical machines with Hairpin windings: Analysis and comparison[C]//Proceedings of 2021 IEEE International Electric Machines & Drives Conference (IEMDC). Hartford: IEEE, 2021. [10] GLAESSEL T, SEEFRIED J, FRANKE J. Challenges in the manufacturing of Hairpin windings and application opportunities of infrared lasers for the contacting process[C]//Proceedings of 2017 the 7th International Electric Drives Production Conference (EDPC). Würzburg: IEEE, 2017: 64 − 70. [11] SCHIEFER M, DOPPELBAUER M. Indirect slot cooling for high-power-density machines with concentrated winding[C]//Proceedings of 2015 IEEE International Electric Machines & Drives Conference (IEMDC). Coeur d'Alene: IEEE, 2015: 1820 − 1825. [12] LA ROCCA A, ZOU T J, MOSLEMIN M, et al. Thermal modelling of a liquid cooled traction machine with 8-layer Hairpin windings[C]//IECON 2021 the 47th Annual Conference of IEEE Industrial Electronics Society. Toronto: IEEE, 2021. [13] HA T, KIM D K. Study of injection method for maximizing oil-cooling performance of electric vehicle motor with Hairpin winding[J] . Energies,2021,14(3):747. doi: 10.3390/en14030747 [14] REINAP A, ANDERSSON M, MARQUEZ-FERNANDEZ F J, et al. Performance estimation of a traction machine with direct cooled Hairpin winding[C]//Proceedings of 2019 IEEE Transportation Electrification Conference and Expo (ITEC). Detroit: IEEE, 2019. [15] 汪文博. 永磁同步电机的热路模型研究[D]. 杭州: 浙江大学, 2014. -

下载:

下载: