Thermal behavior analysis of wheat straw during pyrolysis

-

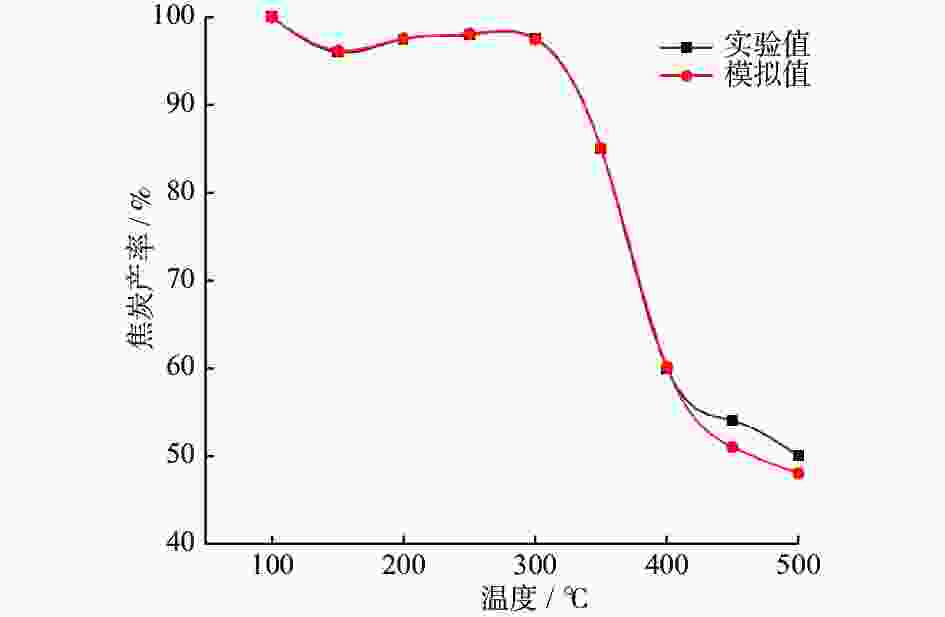

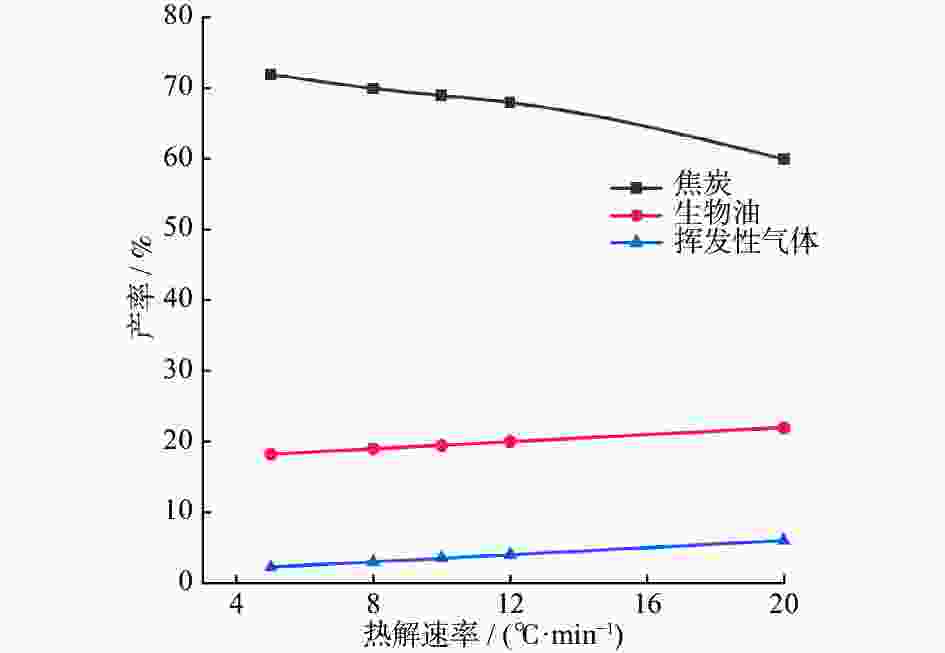

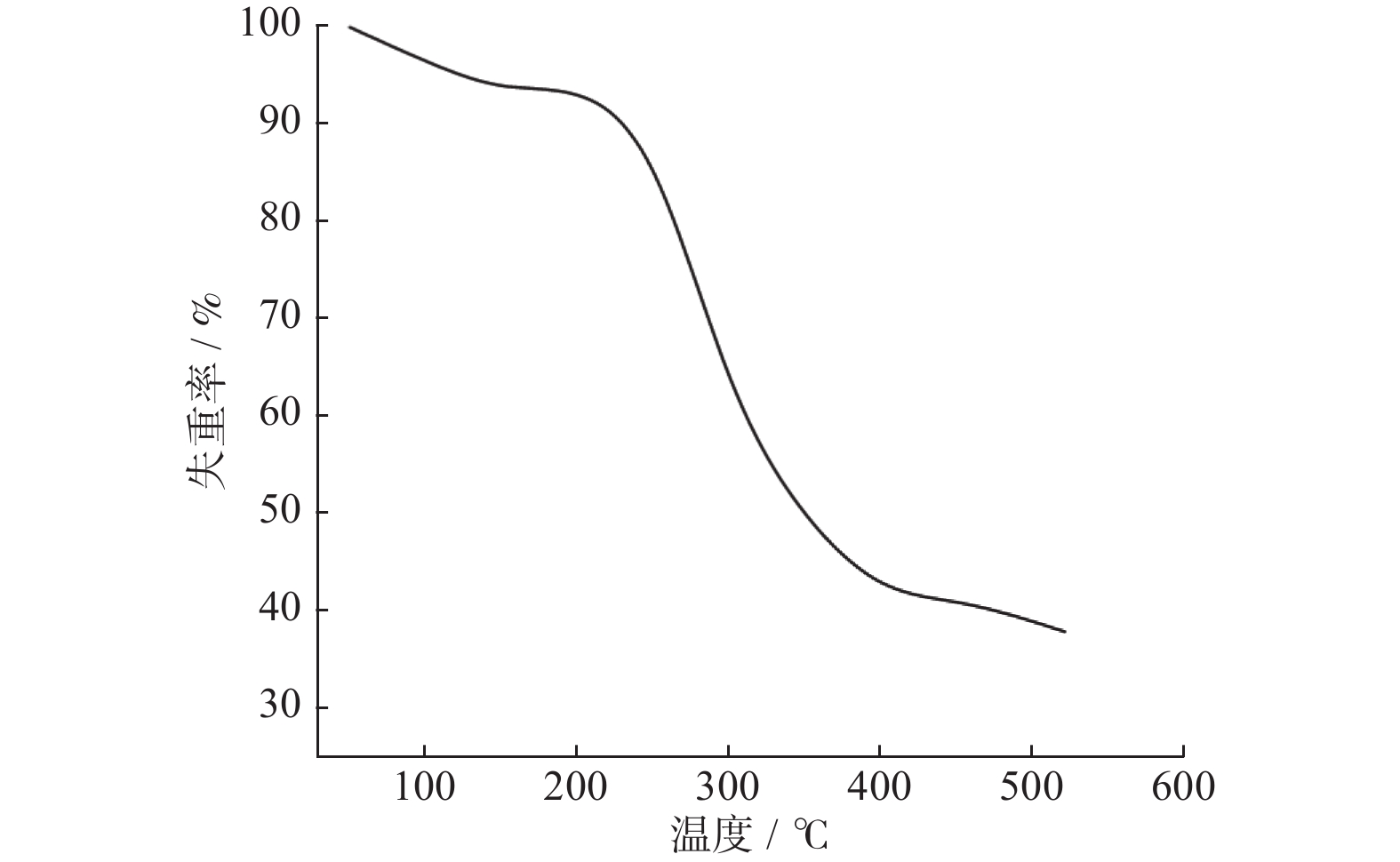

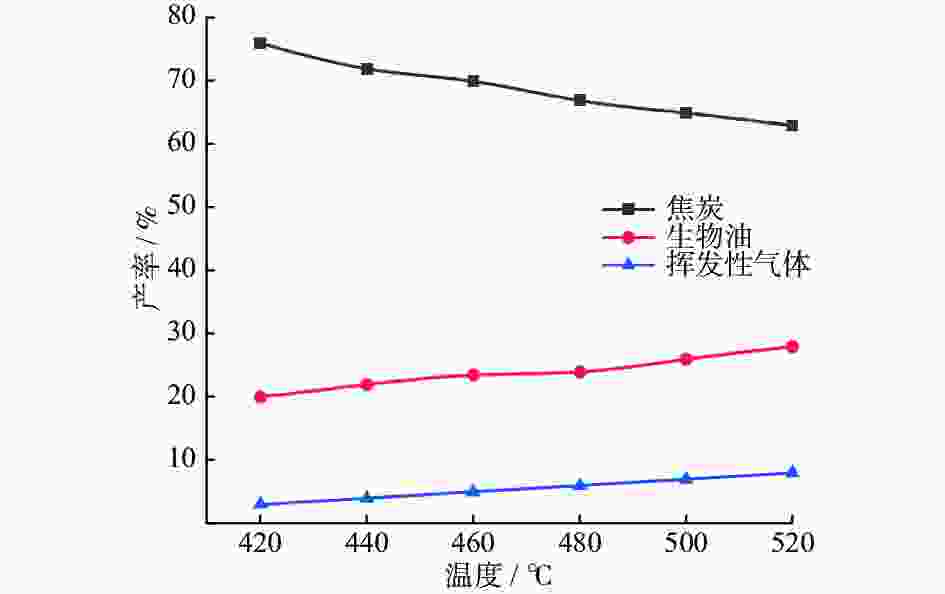

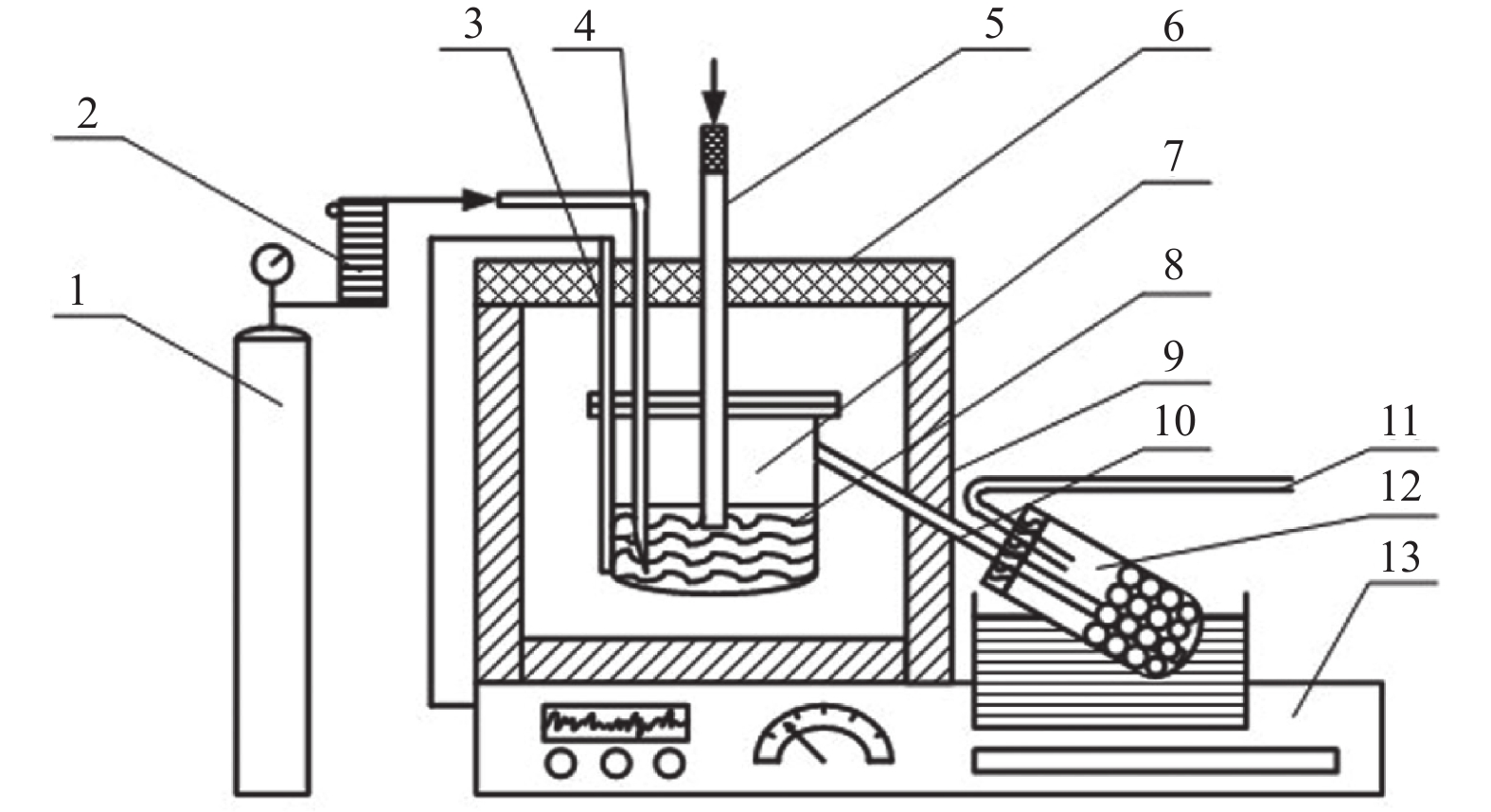

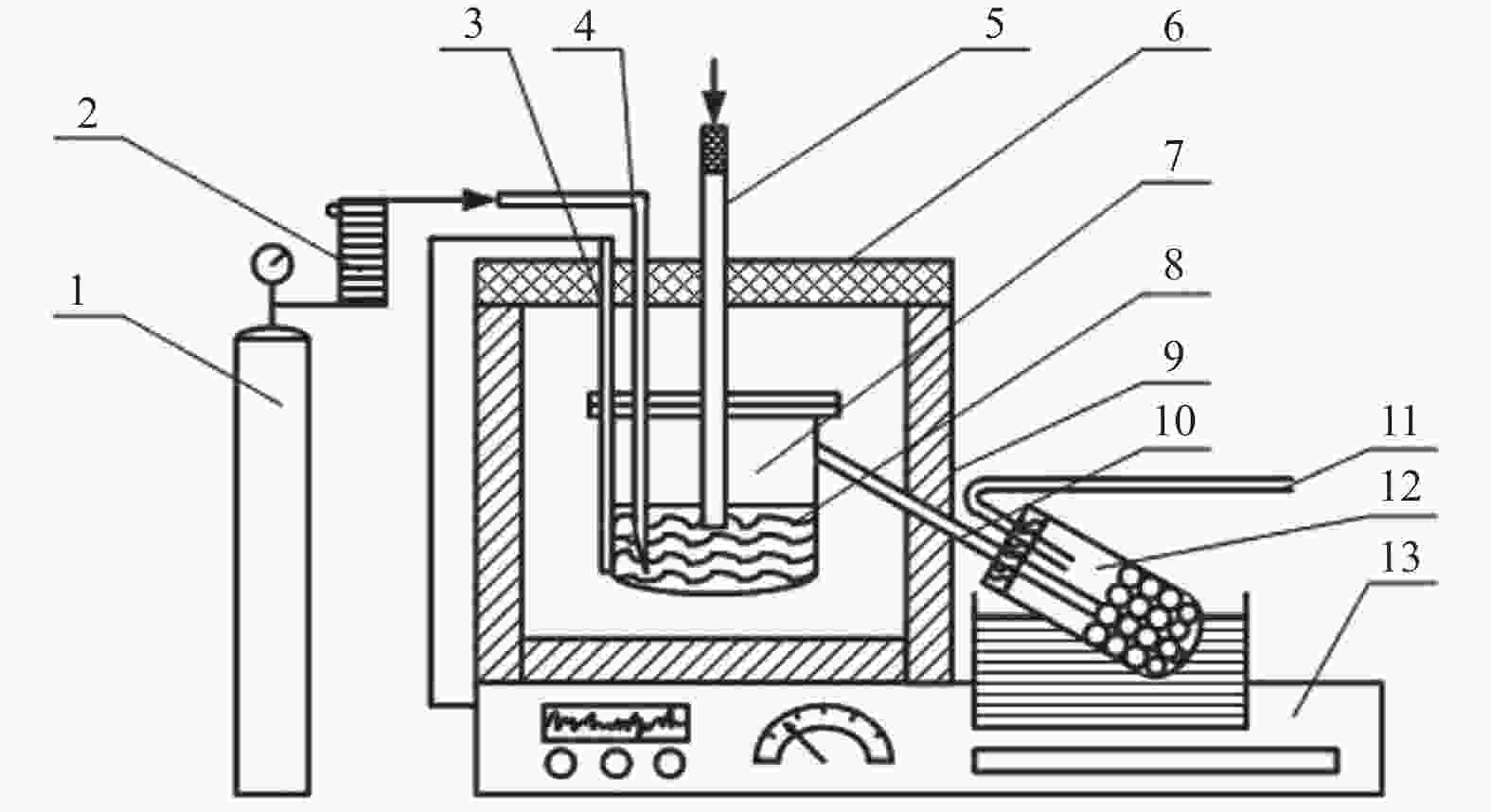

摘要: 热解温度和热解速率是影响小麦秸秆产物的重要因素。为探究温度与速率对小麦秸秆热解过程的影响,在Fluent仿真软件中建立小麦秸秆热解过程的动力学模型和热力学模型,分析其热行为,模拟不同升温速率和热解温度下小麦秸秆的热解过程。模拟结果表明,热解速率和热解温度越高,焦炭等固体产物产率越少,气体产物产率越多。Abstract: The pyrolysis temperature and pyrolysis rate are important factors affecting the products of wheat straw. To investigate the effects of temperature and rate on the pyrolysis process of wheat straw, a kinetic and thermodynamic model of wheat straw during pyrolysis was established in Fluent simulation software, and its thermal behavior was analyzed to simulate the pyrolysis process of wheat straw under different heating rates and pyrolysis temperatures. The simulation results show that the higher the pyrolysis rate and temperature, lower the yield of solid products such as coke, and the higher the yield gas products.

-

Key words:

- wheat straw /

- pyrolysis /

- pyrolysis rate /

- pyrolysis temperature

-

表 1 小麦秸秆的元素分析结果

Table 1. Results of elemental analysis of wheat straw

工业分析 近似值分析 组成分布 比例/% 组成分布 比例/% 纤维素 42.6 水分 7.64 半纤维素 26.4 挥发分物质 71.51 木质素 22.7 灰 16.33 固定碳 4.52 表 2 元素分析结果

Table 2. Elemental analysis result

% C H Od N St H/Ca O/Ca N/Ca S/Ca 余量 41.33 6.17 23.45 0.46 0.1 1.79 0.43 0.01 <0.01 — -

[1] 袁振宏, 雷廷宙, 庄新姝, 等. 我国生物质能研究现状及未来发展趋势分析[J] . 太阳能,2017(2):12 − 19, 28. doi: 10.3969/j.issn.1003-0417.2017.02.002 [2] 牛永红, 蔡尧尧, 李义科, 等. 半焦催化剂对生物质热解产物催化重整的试验研究[J] . 热能动力工程,2020,35(7):207 − 214. [3] 孙振钧, 孙永明. 我国农业废弃物资源化与农村生物质能源利用的现状与发展[J] . 中国农业科技导报,2006(1):6 − 13. doi: 10.3969/j.issn.1008-0864.2006.01.002 [4] 孙宁, 应浩, 徐卫, 等. 松木屑催化气化制取富氢燃气[J] . 化工进展,2017,36(6):2158 − 2163. [5] HOJJAT ANSARI M, JAFARIAN S, TAVASOLI A, et al. Hydrogen rich gas production via nano-catalytic pyrolysis of bagasse in a dual bed reactor[J] . Journal of Natural Gas Science and Engineering,2014,19:279 − 286. doi: 10.1016/j.jngse.2014.05.018 [6] NANDA S, REDDY S N, DALAI A K, et al. Subcritical and supercritical water gasification of lignocellulosic biomass impregnated with nickel nanocatalyst for hydrogen production[J] . International Journal of Hydrogen Energy,2016,41(9):4907 − 4921. doi: 10.1016/j.ijhydene.2015.10.060 [7] SIDDIQUE N, SUZUE M, KATO M, et al. Process optimization for continuous production of sustainable biodiesel from completely non-edible biomass, lignocellulosic hydrous ethanol and waste fatty acids[J] . Fuel,2021,289:119884. [8] JIANG D, LI H, CHENG X, et al. Activation of nitrogen-doped carbon materials on the C–N bond and C–O bond: Modeling study toward enhanced pyrolysis products[J] . ACS Sustainable Chemistry & Engineering,2022,10(23):7473 − 7484. [9] SEDMIHRADSKá A, POHOŘELý M, JEVIČ P, et al. Pyrolysis of wheat and barley straw[J] . Research in Agricultural Engineering,2020,66(1):8 − 17. doi: 10.17221/26/2019-RAE [10] LOU R, WU S B, LV G J. Effect of conditions on fast pyrolysis of bamboo lignin[J] . Journal of Analytical and Applied Pyrolysis,2010,89(2):191 − 196. doi: 10.1016/j.jaap.2010.08.007 [11] ONAY O. Influence of pyrolysis temperature and heating rate on the production of bio-oil and char from safflower seed by pyrolysis, using a well-swept fixed-bed reactor[J] . Fuel Processing Technology,2007,88(5):523 − 531. doi: 10.1016/j.fuproc.2007.01.001 [12] PAN Z, FENG H, SMITH J. Rates of pyrolysis of Colorado oil shale[J] . AIChE Journal,1985,31(5):721 − 728. doi: 10.1002/aic.690310504 [13] HAN X, LIU Q, JIANG X. Heat transfer characteristic of oil shale particle during the retorting[J] . International Journal of Heat and Mass Transfer,2015,84:578 − 583. doi: 10.1016/j.ijheatmasstransfer.2015.01.058 [14] 陈磊, 陈汉平, 陆强, 等. 木质素结构及热解特性[J] . 化工学报,2014,65(9):3626 − 33. doi: 10.3969/j.issn.0438-1157.2014.09.043 [15] BRIDGWATER A V. Renewable fuels and chemicals by thermal processing of biomass[J] . Chemical Engineering Journal,2003,91(2/3):87 − 102. doi: 10.1016/S1385-8947(02)00142-0 -

下载:

下载: